Liquid Controls LectroCount LCR-II E3655 Series User manual

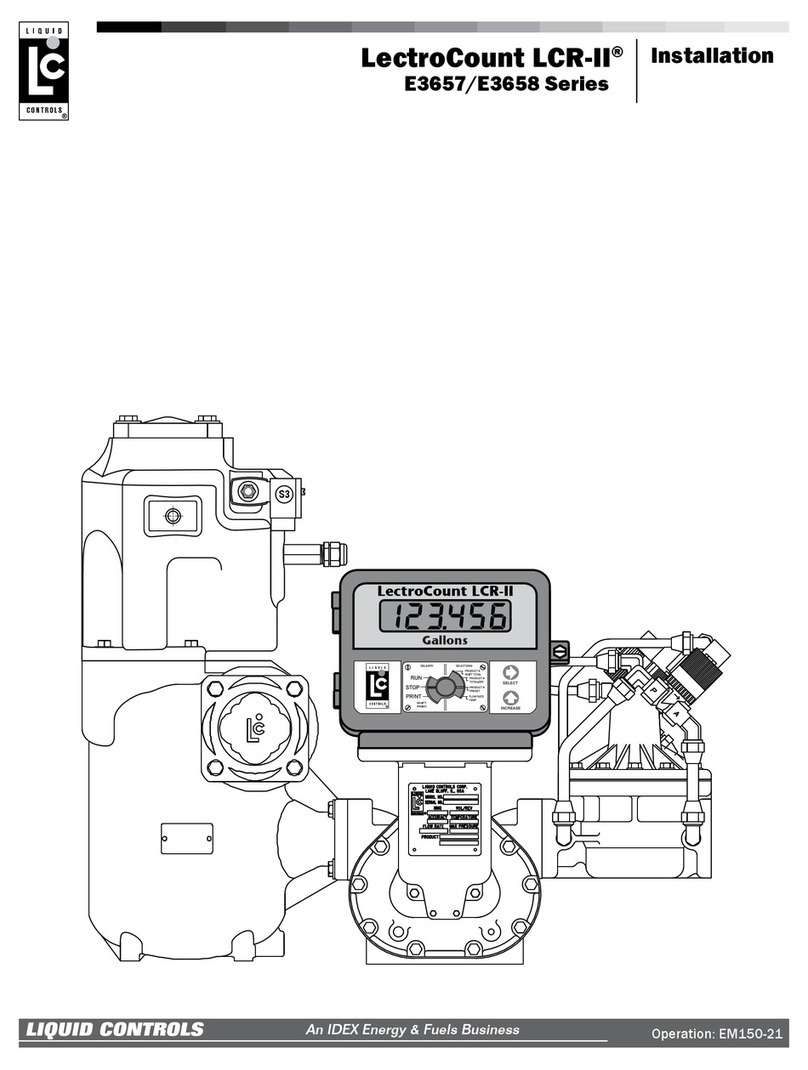

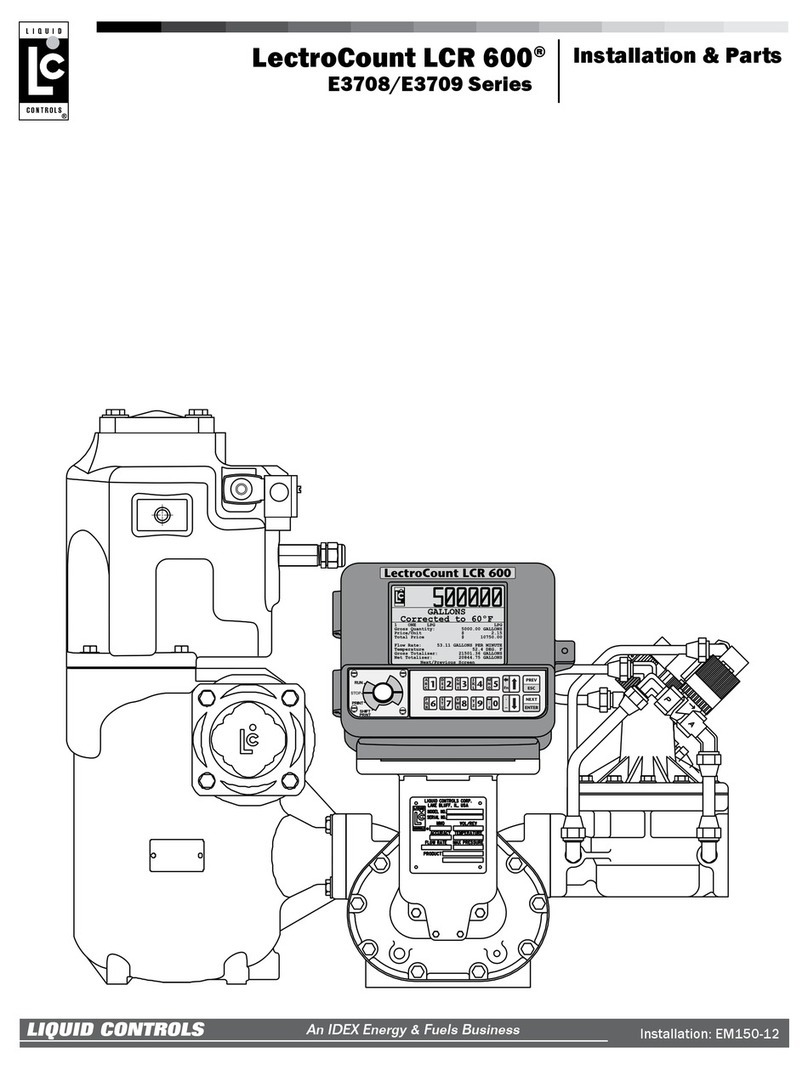

LectroCount LCR-II®Installation

Liquid ControLs Group An IDEX Fluid & Metering Business

Operation: EM150-20

E3655/E3656 Series

2

TABLE OF CONTENTS

The most current English versions of all Liquid Controls publications are available on our web site, www.lcmeter.com. It is the

the required language of the country, or the language of the end user to which the products are shipping. If there are questions

Publication Updates and Translations

INTRODUCTION

Safety Procedures ................................................... 3

ESD Protection......................................................... 4

.......................................................... 5

Dimensions .............................................................. 6

LectroCount LCR-II Overview .................................. 7

Meter System Overview ........................................... 8

INSTALLATION

Installation Overview ............................................... 10

LectroCount Ground Strap Kit................................. 12

LectroCount LCR-II Mounting ................................ 14

Routing LCR-II Data and Power Cables ................ 17

Electronic Temperature Volume Compensation ...... 18

Valves...................................................................... 19

Optical Air and Vapor Eliminators............................ 23

Pulse Output Device (POD) .................................... 24

..................... 25

Remote Display and Auxiliary Outputs.................... 26

Printers.................................................................... 27

Data Communications............................................. 28

Power Installation.................................................... 29

Post Installation....................................................... 32

BILL OF MATERIALS

External Components.............................................. 33

Internal Components............................................... 34

CPU Board .............................................................. 35

3

SAFETY PROCEDURES

!WARNING

maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

and follow the proper procedures

!WARNING

in order to maintain Class I, Division 2 ratings. This may require using connections or other adaptations in accordance

WARNING: Explosion Hazard -

Substitution of components may impair suitability for Class I, Division 2 applications.

WARNING: Explosion Hazard -

WARNING: Explosion Hazard -

Before disassembly of any meter or accessory component:

ALL INTERNAL PRESSURES MUST BE RELIEVED AND ALL LIQUID DRAINED FROM

THE SYSTEM IN ACCORDANCE WITH ALL APPLICABLE PROCEDURES.

-Close all liquid and vapor lines between the meter and liquid source.

Safety Rules Regarding LPG, refer to NFPA Pamphlet 58 and local authorities.

Failure to follow this warning could result in property damage, personal injury, or death from re and/or explosion, or other

hazards that may be associated with this type of equipment.

!WARNING

Be Prepared

Observe National and

Local Codes

Safely Evacuate

Piping System

4

ESD PROTECTION

Potential Damages Caused by Exposure to ESD

To prevent electrostatic discharge (ESD) damage to LectroCount register electronic components, all LectroCount

electrical system).

Epson printer.

Liquid Controls’ Grounding Kits

seats allow static electricity to “bleed off” the driver and the seat before it can build up, discharge, and damage the

The LectroCount Ground Strap Kit will be included with all future LCR-II LectroCount register shipments, and the

ESD Procedural Precautions and LectroCount Register Grounding

Installation Notes

followed to safeguard against ESD damage.

REGISTERS NOT MOUNTED DIRECTLY TO THE METER

In typical LectroCount installations where the LectroCount register is mounted directly to the meter, the LectroCount

LectroCount housing is grounded properly.

Alternate grounding method

1 ohm). Use a 12ga. or larger stranded wire.

FIXED INSTALLATIONS

require metal conduit to the conduit hubs for the wiring. The metal conduit provides the necessary ESD protection.

Divison 2 installations can ground the LectroCount housing by using shielded cables (or wiring) run through liquidtite

installations require and additional grounding method to ensure a proper ground.

1 ohm). Use a 12ga. or larger stranded wire.

Follow this procedure each time you open a LectroCount register or approach a LectroCount register with the door open.

Before opening the LectroCount register and handling the CPU board, it is important to discharge any ESD that may have built up on

your person. To discharge ESD from your person, touch a well-grounded point such as the LectroCount register housing, the meter,

the truck piping, or the bumper. When the maintenance is complete and the LectroCount register door is closed, the CPU board is

protected from ESD by the LectroCount register housing which is grounded to the chassis.

.ESD Precaution .

Opening LectroCount Registers

5

SPECIFICATIONS

Materials of Construction

Weight

Display Elements

Cable Entry

Temperature Rating

Mechanical Input/Output

Communications

RS-485: SAE J1708 standard

Auxiliary 1 Output

Current sinking capability:1 A

Auxiliary 2 Output

Current sinking capability:150 mA

Solenoid 1 Output

Voltage: 10.2 to 27.2 VDC

Current maximum:1 A maximum

Solenoid 2 Output

Voltage: 10.2 to 27.2 VDC

Current maximum:1 A maximum

Solenoid 3 Output

Voltage: 10.2 to 27.2 VDC

Current maximum:1 A maximum

Optical Sensor

Voltage: 10 to 28 VDC

Current maximum:0.5 A maximum

RTD Temperature Probe

Printer (Epson Model 295)

Voltage: 24 VDC

Current

maximum:0.8 A

Operating Temperature:

Remote Electronic Display

sinking capability

Electrical

Input Voltage

Voltage: 9 to 28 VDC

Current maximum:4.5 A maximum

(including solenoid valves)

Pulse Output

Voltage peak to peak:5 to 28 V

Frequency maximum:

Scale Pulse Output

Current sinking capability:150 mA

Electrical Protection

6

DIMENSIONS

Side

Front

top

15"

9.94"

5.19"

LectroCount LCR-II

13"

Ø 7.5"

8.04"

10.5"

70º

rear

7

LectroCount LCR-II Overview

GENERAL INFORMATION

The Liquid Controls LectroCount LCR-II is a

microprocessor-based electronic meter register that

LCR-II can control a meter system as a stand-alone

unit, or it can be used as a slave to a host contoller such

as a process controller or an in-cab data management

system.

INPUTS

displacement meter, the LCR-II receives a pulse input

from an internally mounted quadrature pulser that is

and Smith positive displacement meters). This pulse

output can also come from a Liquid Controls external

POD pulser or another pulse generator. In addition to

the pulse input, the LCR-II is equipped with an input for

a temperature probe, so the register can compensate

volume measurements according to the temperature of

the product.

OUTPUTS

The LCR-II is equipped with a scaled pulse output, two

auxiliary outputs, and two solenoids outputs. These

outputs allow the LCR-II to communicate with meter

system accessories such as solenoid-controlled valves,

optical air and vapor eliminators, remote displays,

printers, and third-party devices.

COMMUNICATIONS

The LCR-II is capable of interfacing in RS-232 and RS-

485 communication protocols.

HOUSING

The LectroCount LCR-II housing and base are aluminum

die cast and powder coated. The hinge door design

provides easy access to the internal connections and

LectroCount LCR-II to provide secure cable connections

for all external devices.

DISPLAY

NAVIGATION KEYS

SELECTOR SWITCH

The selector switch controls basic stop, run, print, and

shift print delivery functions. To perform calibration

functions, the cover plate must be removed and the

FUNCTIONALITY AND OPERATION

The principle functions of the LectroCount registers

include:

(ETVC) (with proper accessories)

LCR-II OVERVIEW

8

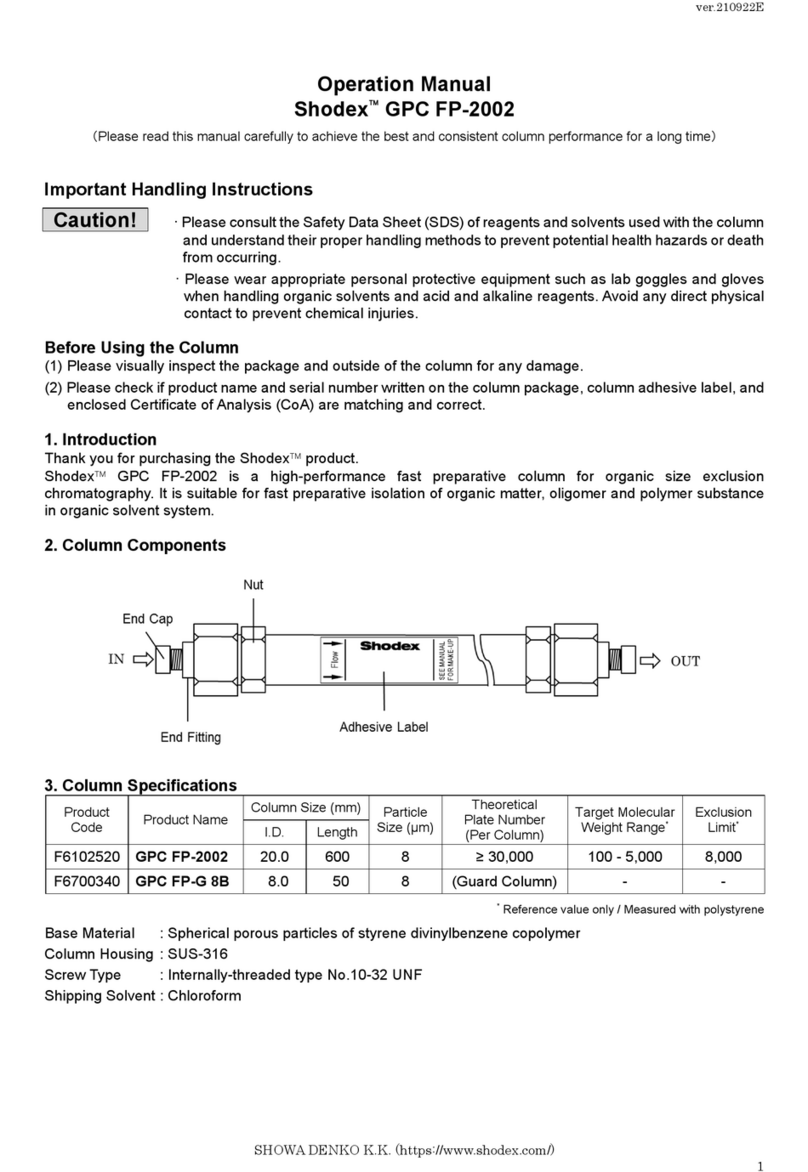

M7 Meter with LectroCount LCR-II Electronic Register, Optical

Optical Air Eliminator

Mechanical Air

Capacity Strainer

Optical Vapor Eliminator

3

Valve

ETVC Kit

E-7 Valve

Meter System Components

METER SYSTEM

A Liquid Controls meter system not only accurately

measurement. Optimal systems typically include an air/

vapor eliminator, strainer, meter, register, and control

valve. The LectroCount LCR-II, a register, serves as the

central controller of the meter system. Most components

in the meter system are hard wired to the LCR-II via data

communication cables. See manual M100-10.

AIR/VAPOR ELIMINATORS

Air and vapor eliminators sense and remove air or

vapor in the piping before it enters the metering system,

ensuring that only liquid will pass through the meter for

measurement. Mechanical air eliminators do not require

a data connection to the LectroCount LCR-II (in LPG

applications, they are often plumbed to a 3-way solenoid

which is wired to the LectroCount LCR-II). Optical air

eliminators use an optical sensor to monitor liquid levels

and a solenoid-actuated valve to turn the vapor vent on

and off. The optical sensor and the solenoid valve are

connected to the LectroCount LCR-II by separate data

cables. See manuals M300-20 and M300-21.

VALVES

open the line to initiate custody transfers and close the

line to stop custody transfers. Some valves can partially

shut off and provide accurate preset deliveries. Many

valves use solenoid-operated valves that require a hard

wired data connection to the LectroCount LCR-II. See

manuals M400-11 and M400-40.

ELECTRONIC TEMPERATURE VOLUME

COMPENSATION (ETVC) KIT

In order to perform temperature compensation

equations, the LectroCount LCR-II relies on a

temperature probe inserted into the strainer housing.

this manual.

METER SYSTEM OVERVIEW

9

METER SYSTEM OVERVIEW

Epson Slip Printer Epson Roll Printer

Remote Display

POD Pulser

DMS i1000

Lap Pad

Meter System Components

PULSE OUTPUT DEVICE

The Liquid Controls Pulse Output Device (POD pulser)

converts the rotary motion of a positive displacement

used in place of an internal pulser. They are ideal for

applications that require explosion proof components in

which the LectroCount LCR-II register is installed at a

distance from the meter. The POD pulser requires hard

wired data communication with the LectroCount LCR-II.

See manual EM300-11.

The differential pressure transducer, common in

aviation applications, monitors the differential pressure

coalescer. The highest differential pressure reached

during the custody transfer will then be printed on the

shut down a custody transfer if the differential pressure

meets a preprogrammed differential pressure shutdown

communication with the LectroCount LCR-II. See

manual EM300-40.

DATA MANAGEMENT SYSTEMS

The DMS i1000 is an in-cab computer with a heavy duty

software. The DMS i1000 must be hard wired to the

LectroCount LCR-II. See manuals EM200-10 and

EM200-11.

LAP PAD

The lap pad programs and displays all operational

functions of the LectroCount LCR registers. It has a

the lap pad, the printer, and the LCR printer cable.

LECTROCOUNT REMOTE DISPLAY

The 2¼" digits on the Liquid Controls LectroCount

Remote Display allow operators to view the register

wire data communication with the LectroCount LCR-II is

required. See manual EM100-13.

PRINTERS

of custody transfers. The Epson slip printer is considered

the industry standard for many applications. Multi-

for both customers and business records. The Epson roll

printer is ideal for recording multiple custody transfers

over an extended time frame.

10

INSTALLATION OVERVIEW

Installation Overview

If the LectroCount LCR-II was ordered as part of a meter system, it will arrive mounted on the meter and prewired to

the ETVC probe, air eliminator, and valve.

Installation overview for LCR-II ordered with meter system:

5. Mount printer and connect printer data cable. Page 27

6. Connect the LCR-II and the printer to power supply. Page 29

7. Setup and calibrate the LCR-II. Refer to manual EM150-11.

to all of the components.

Installation overview for LCR-II ordered without meter system:

2. Mount the LCR-II to the meter. Page 14

5. Mount printer and connect printer data cable. Page 27

6. Connect the LCR-II and the printer to power supply. Page 29

7. Setup and calibrate the LCR-II. Refer to manual EM100-11.

Before installation, check your shipment against the

packing list and ensure that no parts are missing. The

packing list is inside the red information packet along with

the Installation and Operation Manuals.

Check Each Shipment

Specic installation requirements will vary with the model of the truck, the physical layout

of a xed installation, the conguration of any existing metering equipment, the options

selected, and the type of uid being metered

Installation Requirements Vary

This manual explains and details the mechanical installation of the

LectroCount LCR-II and the temperature probe as well as the electrical and

data installation of all components that connect to the LCR-II. For additional

installation information, refer to the manuals of the other components. All

manuals are available at www.lcmeter.com.

This Manual Includes

12

LECTROCOUNT GROUND STRAP KIT

LectroCount Ground Strap Kit

All seat cushions are grounded in a similar manner.

The illustrations on the next page detail the following

seats.

To ground a truck seat:

cab. These seats will typically have pivot points, hinges,

already exist, drill a 9/32” hole in the seat frame.

3. Attach one end of the ground strap to the seat frame

provided.

in the part of the seat frame—above all pivots and

interfere with the ground path between the seat cushion

and the ground strap.

4a. If the seat cushion has a wooden base, use a wood

screw and washer to attach the strap lug to the bottom

of the seat at a point where the seat fabric is attached to

the wood. There must be good contact between the seat

fabric and ground strap lug.

below).

Remove any dirt or oxidation from the ground strap

contact point. Lock washers should penetrate any

paint to ensure a good electrical connection.

Ensure a Good Ground

6

1

2

3

3

5

8

4

9

LectroCount Ground Strap Kit - 82185

Install the LectroCount Ground Strap Kit

before installing the LectroCount register.

.ESD Precaution .

Some truck seats, typically passenger seats, are

not adjustable and do not require grounding.

Grounded Passenger Seats

13

TYPICAL ADJUSTABLE TRUCK SEATS & GROUND CHECK

Checking for a Good Ground

To check for a good ground connection:

contact on both ends of the ground strap. Clean any paint, dirt, or oxidation

attach the ground strap to a different ground point. Repeat the process until

If the multimeter reads “” or “”, typically,

one of the accessories is still on.

Turn Off Accessories

AIR CUSHION SEAT -

AIR CUSHION SEAT -

BENCH SEATS -

(Manufacturer Standard or equivalent)

Typical Adjustable Truck Seats

14

Smith Adapter

LCR-II with LPG

Meter System

LCR-II MOUNTING

Mounting Overview

Typically, the LectroCount LCR-II is mounted directly

require the register be mounted away from the meter.

If the meter is equipped with an external POD pulser,

the LCR-II can be mounted up to 1000 wire feet (304

meters) away from the meter (actual distance depends

Adapters are available for other PD meters such as

includes installation instructions.

Tips for mounting an LCR-II

:

the internal components.

attached to the pulser drive shafts.

and selector switch can be easily operated.

Relieving Internal Pressure

!WARNING

Relieving Internal Pressure Procedure for LPG and NH3Meters

relieve product pressure in the system. Product will drain

from the meter system.

7. As product is bleeding from the differential valve, slowly

Repeat this step until the product stops draining from the

on the system.

2. Close the valve on the vapor return line.

3. Close the manual valve in the supply line on the inlet

side of the meter. If no manual valve exists on the inlet

line.

end of the supply line.

Serious injury or death from fire or explosion could result in performing maintenance on an

improperly depressurized and evacuated system.

15

LCR-II MOUNTING

LC Meter

O-Ring

Lower register

and bolt down

Insert cotter

pin

Place shaft

adapter on

drive shaft

LectroCount LCR-II

Gallons

LCR-II Bolt Pattern

LC Meter Compensated

LC Meter

Mounting Bolt Pattern

The LectroCount LCR-II base casting contains eight bolt

holes in an industry standard bolt pattern. The holes are

If the installation necessitates that you fabricate a

LC Meters

Remove Existing Registration Equipment

See Warning on pg.

14.

2. Remove the four bolts on the bottom that fasten the

register to the meter.

4. If the meter has a Temperature Volume Compensator

(TVC), remove it as well.

Mount the LectroCount LCR-II

1. Place the end of the shaft adapter on the pulser drive

shaft located on the bottom of the register.

2. Place the cotter pin through the hole, and bend open the

ends of the cotter pin.

3. Lower the register onto the meter, and insert the shaft

adapter onto the hex shaft on the meter.

4. Securely bolt down the register.

Apply anti-seize to all bolt threads to ensure

easy removal at a later date.

Apply Anti-seize

16

LCR-II MOUNTING

Neptune Meter Compensated

Insert cotter

pin

Insert cotter

pin

Bolt plate

and flange

to register

Place adapter

on drive

shaft

Bolt flange

to meter

Place fork

and extension

on end of

adapter

LectroCount LCR-II

Gallons

Neptune Meter

Insert cotter

pin

Bolt down

bracket to

meter

Place fork

and extension

on drive shaft

Lower register

and bolt onto

bracket

LectroCount LCR-II

Gallons

with Temperature

Compensation

Extension

Neptune Meters

Remove Existing Registration Equipment

See Warning on pg.

10.

2. Remove the mechanical register from the meter.

3. Leave the star-shaped gear and the two square-head

studs.

4. Remove the bellows from the front of the meter.

5. Remove the compensator.

Mount the LectroCount LCR-II

on the pulser drive shaft located on the bottom of the

LCR-II.

Mount the LectroCount LCR-II onto previously

temperature compensated Neptune meters

1. Place the shaft adapter on the pulser drive shaft under

the LCR-II.

2. Place the cotter pin through the hole, and bend open the

ends of the cotter pin.

3. Pass the other end of the shaft adapter through the

4. Loosely bolt to register.

using two more cotter pins.

Installation kits 82641 (E-26 series) & 82642 (E-36

series) are specically designed for previously temperature

compensated Neptune meters.

Apply anti-seize to all bolt threads to ensure

easy removal at a later date.

Apply Anti-seize

When the register is lowered onto a Neptune meter, make sure

the drive fork is not pressed against the star gear on the meter.

There must be a small gap between these two parts. To lower

the star gear, loosen the set screw on the side of the star gear.

Failure to do so will eventually damage the internal pulser and/

or the meter gear train.

Star Gear and Drive Fork

with Temperature

Compensation

17

ROUTING LCR-II DATA AND POWER CABLES

Data and Power Cable

The LCR-II shipment typically includes a gray 40' power

During

installation, follow these guidelines and ensure the

cables remain undamaged.

Guidelines for routing the data and power cables

on the outside of the truck

automotive plastic corrugated split loom or through

pass through the cab wall, meter box, etc.

re-installing.

proper tool for stripping off the insulation on the cables.

Instructions for hooking up

power to the printer and the

LCR-II begin on pg. 29.

Guidelines for routing the data and power cables

inside the cab

cables before beginning.

vehicle components.

locations where they may be vulnerable to damage.

cables can be easily connected.

the cable.

Routing LCR-II Data and Power Cables

ETVC Kit

Solenoid

Valve

LectroCount

LCR-II Conduit or

Split

Printer

Data Cable

Printer

Printer

Power Cable

LCR-II

Power Cable

Fuse Panel

(Accessory) 7.5A In-Line Fuse

18

ELECTRONIC TEMPERATURE VOLUME COMPENSATION

Thermowell Kit

Screw into the strainer cover

RTD Temperature Probe (71130)

Coat the probe length

with the copper grease

provided in kit.

Thermowell

Foam Washers

Seal Gasket

Slotted Disk Union Fitting

Run probe through

conduit

Connect wires

to J14 connector

ETVC Kit

Weights & Measures

Thermowell Port

Temperature Probe

Fitting

Weatherproof conduit to LCR-II

LectroCount LCR-II

Gallons

ETVC Conduit

TEMPERATURE PROBE J14

White (20)

White (21)

Red (22)

Red (23)

To install the ETVC kit:

See Warning on pg.

14.

2. Remove the old strainer cover.

grease).

6. Bolt the strainer cover in place. Make sure the Weights &

Measures thermowell port is at the top of the cover.

on the left).

8. Coat the entire probe length with the copper grease

provided. Insert and re-coat the probe 2 or 3 times to

provide a uniform coating inside the thermowell and to

ensure proper heat transfer from the liquid to the probe.

middle of the strainer cover. The angled tting at the top

of the cover is for Weights & Measures purposes. See

Step 6.

on connector J14.

Disconnect the power before

working on the CPU board.

Disconnect Power

Electronic Temperature Volume Compensation (ETVC) Installation

to provide protection for the RTD temperature probe wire between the strainer cover and the LCR-II.

19

VALVES

A2847-11 Solenoid-Operated

S1 Solenoid

LectroCount LCR-II

Gallons

Electro-Pnuematic

Preset Valve

Single Stage Electro-Pnuematic

Valve with V-7 Valve

S1 Solenoid

V-7 Valve Electro-Pnuematic

Actuator

LectroCount LCR-II

Gallons

Single Stage

Single Stage Systems

Liquid Controls’ Valves Overview

and wired to the LCR-II at the factory. Electronic control

meter systems already in service. These valves will need

refer to the valve manual. This manual includes wiring

instructions for the valves.

operated valves close off and open the bypass pipes.

in order to open and close the control valve. These

solenoid-operated valves must be wired to the LCR-II

CPU board during installation.

Liquid Controls offers single stage and two stage

electronic valves. Single stage valves have one solenoid

valve (S1) and two positions—an open position and a

closed position. Two stage valves have two solenoid

by the S2 solenoid and initiated shortly before the

register reaches a preset value.

SINGLE STAGE VALVES

The three most common Liquid Controls meter systems

and an electro-pnuematic valve with an S1 solenoid.

A2847-11 Valve

This single stage control valve has a S1 solenoid-

operated valve located at the meeting point of three

external pipes: one pipe from the inlet side of the valve,

outlet side of the valve. This valve is typically used in

A2843 Valve and 3-Way Solenoid

The 3-way solenoid-operated valve—mounted directly

LCR-II—serves as a S1 solenoid-operated valve. The

3-way solenoid-operated valve is located at the meeting

point of two pipes from the vapor eliminator (one for

3.

The LCR-II is also compatible with many other brands

and types of valves.

20

VALVES

S1 Solenoid

E-7 Valve

S2 Solenoid

LectroCount LCR-II

Gallons

Two Stage (S1 and S2) E-7 Valve

S1 Solenoid

S2 Solenoid

LectroCount LCR-II

Gallons

Two Stage (S1 and S2)

Two Stage Systems

2

A2859-11

Solenoid-Operated

E-7 Valve

A2848-11

Solenoid-Operated

TWO STAGE VALVES

The three most common Liquid Controls meter systems

valve (A2859-11) and a 3-way solenoid on the LCR-II,

and an E-7 valve with a S1 and a S2 solenoid-operated

valve.

A2848-11 Valve

This two stage control valve has a S1 and a S2 solenoid-

operated valve. The S1 solenoid-operated valve is

located at the meeting point of three bypass pipes: one

pipe from the inlet side of the valve, one from the top

valve. The S2 solenoid valve is located on a bypass pipe

that connects the inlet and outlet sides of the control

valve. It opens while the control valve is closed to supply

applications.

A2859-11 Valve and 3-Way Solenoid

A two stage valve with a S2 solenoid-operated valve

the LectroCount LCR-II. The 3-way solenoid-operated

valve is located at the meeting point of two pipes from

the vapor eliminator (one for eliminated vapor and

a bypass pipe that connects the inlet and outlet sides

of the control valve. It opens while the control valve is

3.

E-7 Valves

A two stage valve with a S1 and a S2 solenoid-operated

closed valve using channels molded into its housing.

Single Stage Valves (cont.)

A2700 Series Electro-Pnuematic Valve

Electro-pnuematic valves use a S1 solenoid-operated

valve mounted to a pneumatic actuator to open and

close a V-7 valve. These valves are typically used in high

This manual suits for next models

15

Table of contents

Other Liquid Controls Measuring Instrument manuals

Liquid Controls

Liquid Controls LectroCount LCR 600 User manual

Liquid Controls

Liquid Controls M Series User manual

Liquid Controls

Liquid Controls Avery-Hardoll BM Series User manual

Liquid Controls

Liquid Controls LectroCount3 Reference guide

Liquid Controls

Liquid Controls MS Series User manual

Liquid Controls

Liquid Controls CENTRILOGiQ LCR.iQ Manual instruction

Liquid Controls

Liquid Controls M Series User manual

Liquid Controls

Liquid Controls LectroCount LCR-II E3657 Series User manual

Liquid Controls

Liquid Controls LectroCount LCR 600 E3708 Series User manual

Liquid Controls

Liquid Controls A8981 User manual