Page 2 / 12

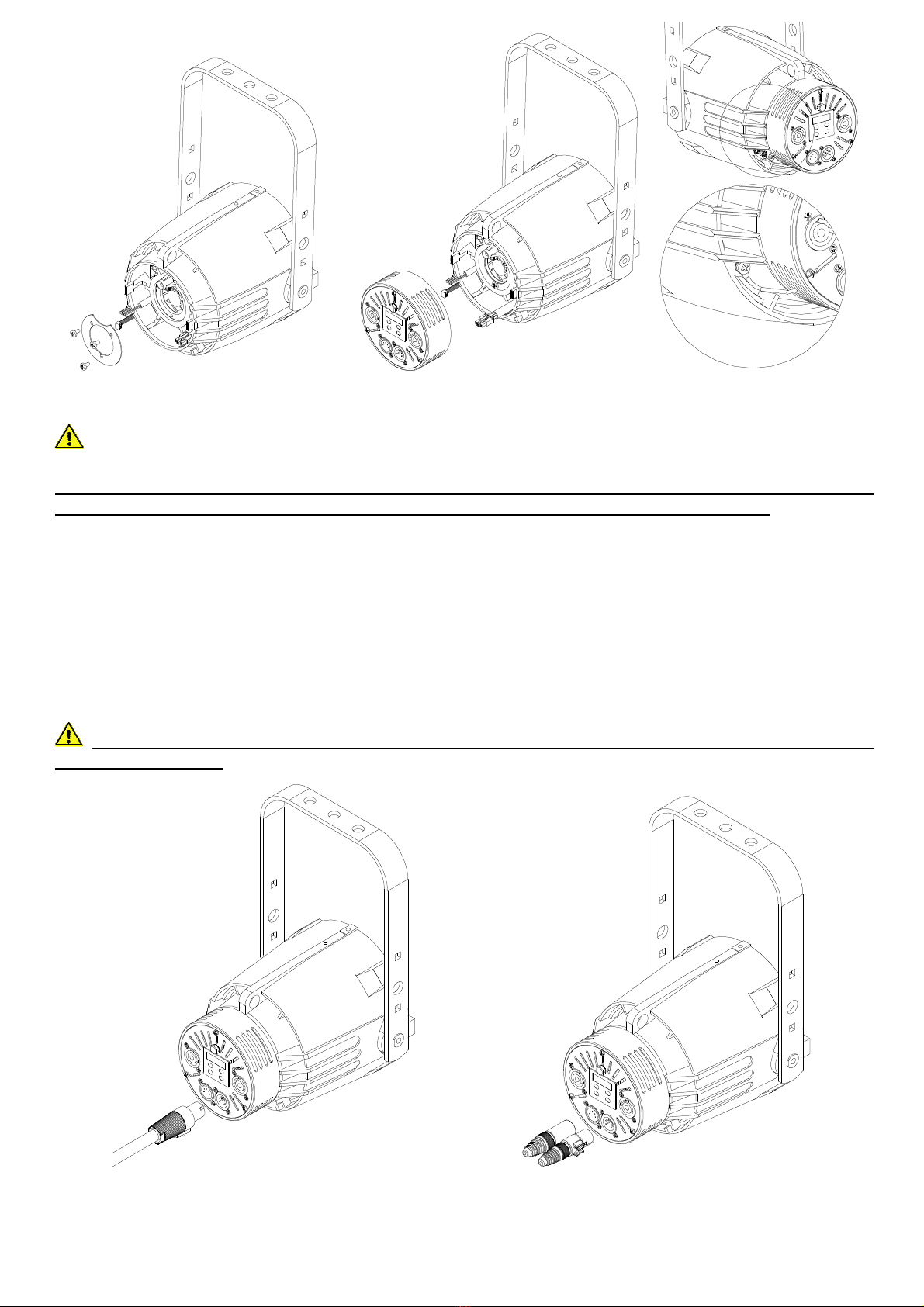

Unpacking

Unpack the carton and gently remove

HPLED II 6

from the box. Ensure

HPLED II 6

is received in all its parts.

In the event the HPLED II 6 shows any damage, do not use it and contact immediately your transporter as

well as your seller

Items in the carton consist of:

HPLED II 6 Module

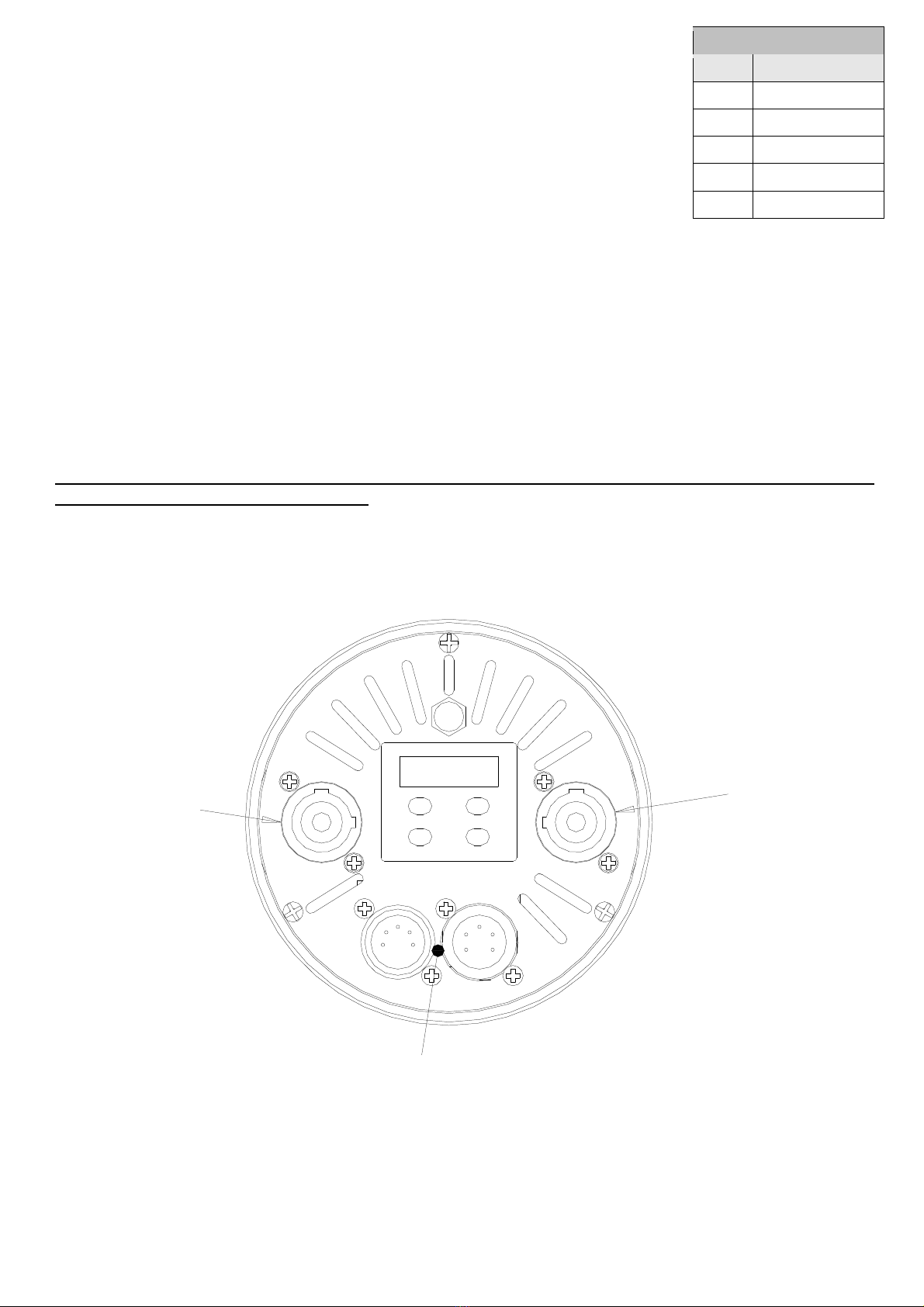

Rear metal cover with input connections

Blue Neutrik Power on connector

This owner's manual

Safet information for the use of the HPLED and periodical maintenance of unit.

Users must scrupulously comply with information/indications that follows

HPLED II 6 must be installed on original “ ETC source 4” fixture only. Any other use will void warranty and

will free the manufacturer of any sort of responsibility and liability.

Never utilise HPLED II 6 assembly alone as it must always be housed in original ET Source 4 barrel.

Minimum distance from any flammable source is of 0.25m.

Minimum throw distance from illuminated surface: 0.5m.

Installation of the unit(s), including external source4 body, must be secured with adequate clamps, safety

cords, nuts and bolts to bear at least 4 times the weight of the whole unit(s)

Always Power HPLED II 6 to safety circuit breakers

Install HPLED II 6 in ventilated ambient which temperature must not exceed 35°

HPLED II 6 is NOT for domestic use. HPLED II 6 can only be used for professional applications

Some outer parts of the ET Source4 can reach temperatures of up to 60 ° when HPLED is operated

HPLED II 6 must be fitted with protection shields (Lenses)

On no account, directly or indirectly, LED must be touched as it may impair its use.

An Essential and Periodically throughout cleaning of the HPLED is recommended. This practice avoids that

layers of dust and other impurity jeopardise and reduce the correct operation of the unit. Lenses must be

cleaned to remove layers of dust that may impede and or reduce the passage of the light through the lenses.

The correct and periodically maintenance keeps also fans and vents clean thus keeping the HPLED II 6 in

its best performance conditions. Never touch, directly or indirectly, the Yellow core of the LED nor use

solvents that can damage the LED irremediably. Protection shields if battered/worn, must be replaced with

new ones (Lenses)

Warning from electric shocks

All operations must be accomplished, handled and carried out by qualified personnel only

Warning High voltage hazard, always disconnect Power before any handling and any servicing of

HPLED II 6

Do not and never handle HPLED II 6 with humid/wet hands or near to any water or any kind of moisture

sources

Always connect HPLED to mains fitted with safety device switch that cuts power off in case of danger

The HPLED does NOT and CAN NOT be operated via Phase control dimmer nor

connected/operated in NON-DiM mode

HPLED II 6 is rated lass I

Earth connection is mandator !

CE Approvals

The HPLED II 6 products to which this manual refers to, complies with European directive pursuant to:

2014/35/EU safety of electrical equipment supplied at low voltage (LVD)

2014/30/EU Electromagnetic compatibility (EM )

2011/65/EU Restriction of the use of certain hazardous substances (RoHS)

WARRANTY!

A 24-month warranty is granted on the HPLED II 6 from purchase’s date. Warranty covers fabrication

defects only. Warranty is immediately voided if the HPLED II 6 has been handled by unqualified personnel.

Any improper and unauthorised use, such modification(s) or misapplication of the HPLED II 6 will also void

the warranty of the product(s). Silver colour label showing technical data and serial number, if removed or if

data are impaired to render details illegible, it will immediately void the warranty