- 18 - - 19 -

16.Damper preload adjustment

In order to guarantee for a perfect setup of the

RockShox Deluxe RT3, the damper is to be ad-

justed with a 30 % negative travel/ Sag of the

entire damper travel of 55 to 65 mm.

For the perfect function of the damping system of

the rear frame, follow precisely the steps below

• Find an even road

• Sit on your bike fully equipped, including back-

pack, bottle, helmet, etc. and start riding.

• Make sure the compression stage of the

damper is open (the black lever is to point

towards the right).

• Look downwards on the “Sag-Indicator

(dynamic level) and check the two indicator

sticks.

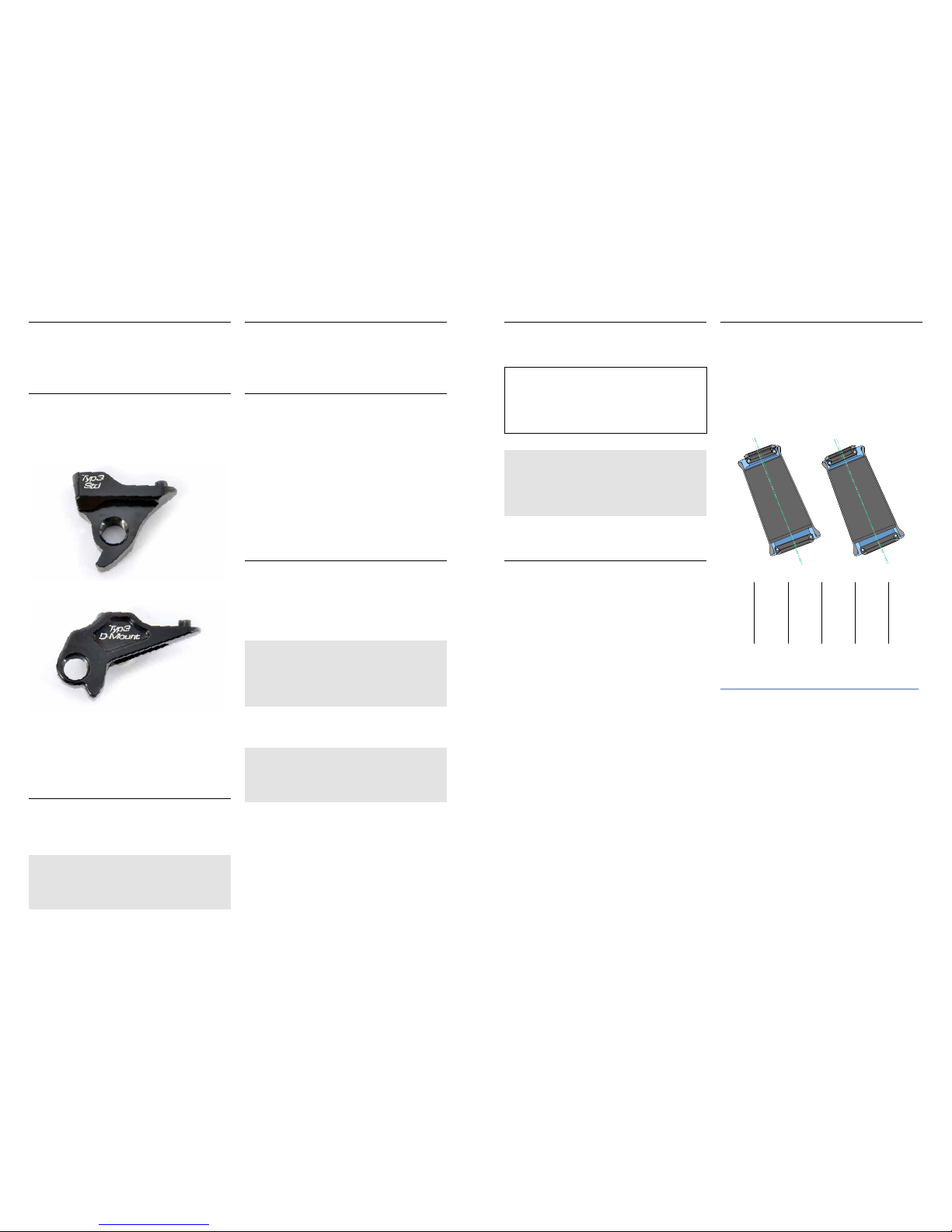

Picture displays dynamic level adjustment

RECOMMENDATION: the sticks should be on the

same height equaling a 30% Sag setting.

NOTE: Even a bigger backpack noticeably

increases the load on the rear wheel. Adjust

the air pressure in the damper respectively.

17.Damper rebound adjustment

Sitting on your bike, ride down a sidewalk. The

rear frame should “bounce” only once. In case

it does so more often, close the rebound of your

damper further. In case the rear frame works too

fast, open the rebound. The rear frame should

not go back into its original position too fast. This

is because it should be “prepared” for further

obstacles to come as soon as possible.

With most dampers, the direction of the adjust-

ment is indicated with a “+” or symbolized with a

“turtle”. The adjustment wheel in the middle, with

most modals, is painted red. Please additionally

refer to the manufacturers’ manuals for further

adjustment advices.

ADVICE for your damper system setup:

if you want your 140mm All Mountain 301

to become even more downhill oriented, we

have some advice for you.

For a more stable and smooth performance

riding downhill, we recommend to mount

the VarioSpin. With this option, the stee-

ring angle becomes less steep (by 1.5°)

which leads to more stability. On top of this,

the damper can be equipped with one or

even more volume spacers. The overall air

volume of the damper is reduced thereby

which alters the characteristic curve. At

the same time, the final progression of the

damper is increased. Please find further

information at the website of the individual

damper manufacturer.

E. MAINTENANCE AND CARE

1. Frame bearings and headset bearing

With conventional usage, the bearings do not

have to be dismounted, greased or cleaned. In

case a bearing gets damaged anyways, you may

order the respective bearing type at your Liteville

Worksstation and have it exchanged there or order

it at Syntace directly.

Picture shows bearings that can be greased in the top tube.

Picture shows bearings that can be greased at the HorstLink.

ADVICE: We recommend the Syntace

GreaseGun (Art. #116931) for most effective

results.

Never point at your bearings with a high-pressure

water jet, as this can easily damage them. After

all, too much “maintenance” may even harm your

bearings.

2. Screws

The screws in your frame are all made from

Titanium or Aluminum and are produced

specifically for Liteville frames. They are all

mounted with screwlock. Nonetheless, you are to

check the correct tightening torque frequently.

ADVICE: in case a screw can actually be

twisted as the tightening torque is che-

cked, the screwlock is broken and as a

consequence needs to be exchanged. The

screw needs to be secured again. Unscrew

it, clean it and reassemble everything with

screwlock.

We have summed up a “Screwlock Basics”

at www.liteville.de > FAQ.