- 10 - - 11 -

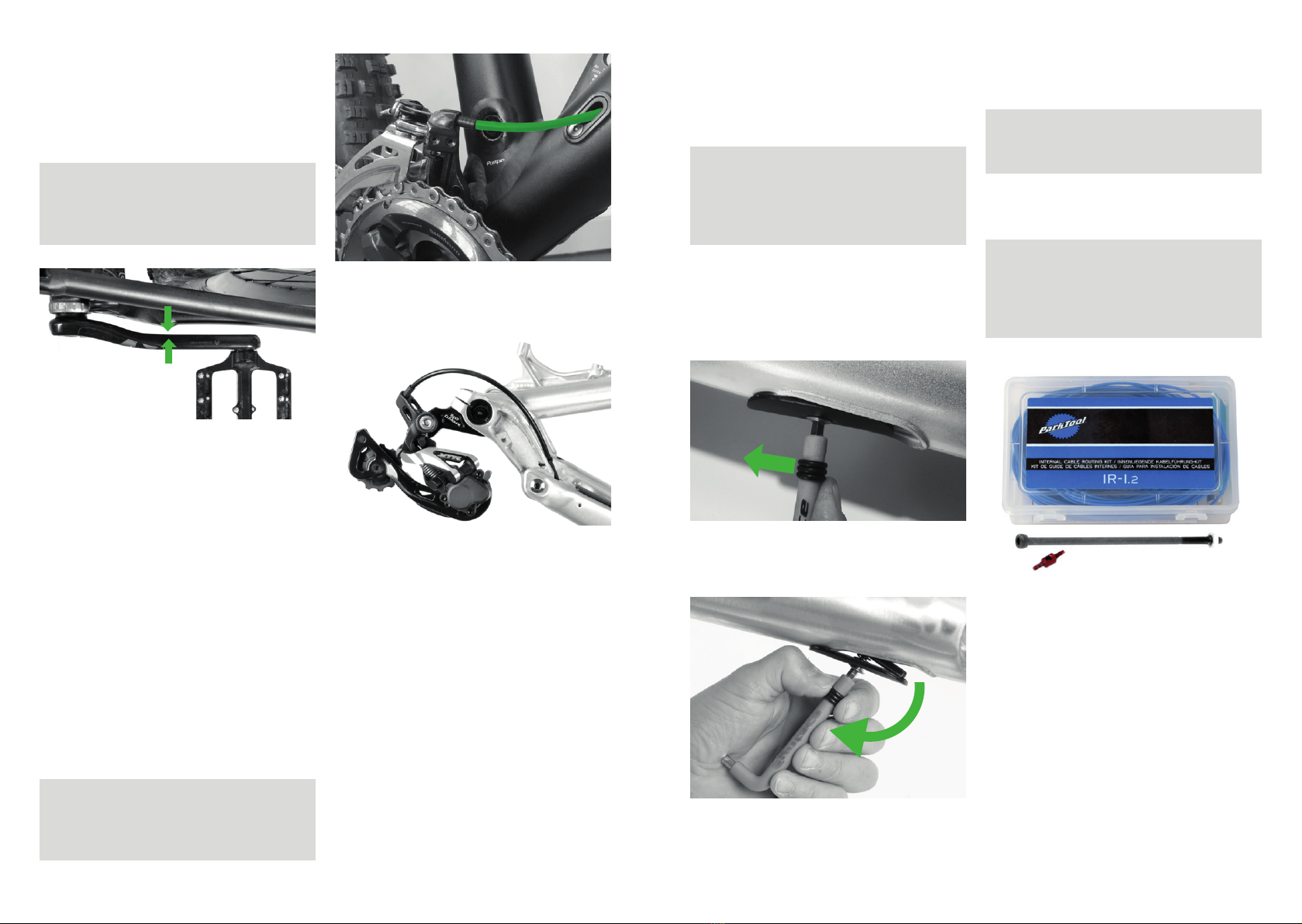

4. Assembly

Frame preparation

The contact surfaces (bottom bracket, disk

brake socket, seat tube) are fully prepared

for the assembly� In case you face problems

during the assembly, please directly contact

Syntace�

Note: The seat tube is manufactured

particularly accurately for the Eight-

pins variable seatpost with very small

tolerances only� This is why it must not

be changed in any way�

Note: In case the frame is painted or

anodized after the purchase, make sure

that the inner diameter of the seat tube

remains the same for the entire 140 mm

insert length�

Seatpost / seat

The 601 Mk4 is designed for variable

seatposts with internal cable routing�

The assembly is simplified thanks to the

ServicePort at the lower end of the down

tube close to the bottom bracket�

VPlease refer to the extra manual of

Eightpins that exemplifies the assembly

process with a Liteville 601 Mk4�

Note: the standard Eightpins variable

seatpost interface at the seat tube is

adapted already and does not need to be

changed�

Using a common seatpost, the frequent

changing of the seat height leads to a

certain wear of the seatpost and the seat

tube� For carbon fiber seatposts, this wear

is considerably higher than for Aluminum

seatposts� In order to minimize the wear,

please clean the seatpost and seat clamp

after every ride in the rain� The diameter of

the seatpost must never become less than

34�7 mm at any point� If this is the case,

please exchange the seatpost as it might

result in damages of the frame�

Headset / fork

The frame comes with nothing but the cone

and the cover cap for tapered fork steer

tubes (see picture)�

Advice: Reduction kit for 1 1/8“-fork

steer tube: Syntace Art�# 14593

Make sure all parts of the headset including

the bearings are greased before the

assembly� Put the bigger (1,5”) cone on the

fork, which is to lay evenly on the fork crown�

The fork can now be inserted into the frame

before the smaller (1 1/8”) cone is put on the

fork steer tube� Installing the cover cap is

the last step of the headset assembly�

Advice: Using a Syntace MegaSpacer, a

silver 0�6 mm washer needs to be added

between the SuperSpin cover cap and

the MegaSpacer� The washer is included

in the MegaSpacer package or can be

ordered separately as a spare part at

Syntace�

Advice: Tighten the adjustment screw of

the Ahead star nut hand-tight� Loosen it

again thereafter with about ¾ revo-

lutions and only in the next, last step

adjust the bearing play of the headset

bearing� Following this procedure, you

make sure that the bearings sit evenly

in the bearing shells� The result should

be that the fork can be turned easily

without any bearing play� It may be

necessary to repeat the process after

the first ride�

Handlebar / stem

Mount and adjust the handlebar and stem

according to the Syntace manual�

Shift and brake levers

Mount and adjust the shift and brake levers

according to the manufacturers’ manuals�

Advice: Tighten the screws of the brake

and shift levers only so much that they

can still turn in case of a crash� This

might avoid a lever to brake apart and

additionally protects the thin walls of

your handlebar�