Foes Shaver 29 User manual

1

Foes will repair or replace any part that is determined by Foes to be covered

by this warranty. This limited warranty is made ONLY to the original owner

and is not transferable. All claims must be made through an Authorized Foes

Dealer, and must be accompanied by the original bill of sale or proof of

purchase that identifies the bicycle frame by serial number. The original

owner is responsible for this and any and all labor and transportation charges

associated with the warrantied repair or replacement of parts, even if Foes

determines that it is under warranty.

If the warranty claim on your Foes frame is determined to be invalid, Foes

Racing will offer a replacement frame/swingarm/part of at least equal value at

a reduced price. This transaction will be offered only through an Authorized

Foes Dealer, and under the following conditions: the frame has been regis-

tered with Foes Racing; the Frame is the property of the original purchaser;

the owner provides a valid sales receipt. This crash replacement is only

available to the original owner, and, for a time period of three years from the

original purchase date. The replacement frame must be assembled by an

Authorized Foes Dealer to maintain the Foes warranty. All freight charges

associated with the crash replacement are the responsibility of the original

owner.

We cannot stress enough that building-up a pro-level frame is not an

endeavor recommended for home mechanics. Special tools and skills accu-

mulated over time are needed to accomplish this successfully, and your

dealer can answer 99% of all the questions related to the complete build of a

high-end frameset. Due to this fact, this manual covers only the most

elemental information.

Every Foes Frameset has a useful product life. The length of this product life

will vary with the construction and materials of the frame or fork, the mainte-

nance and care the frame and fork receives over its useful product life, and

the type and amount of use the frame or fork is subject to. Users in competi-

tive events, trick riding, jumping, ramp jumping, aggressive riding, riding on

severe terrain, riding in severe climate or weather, ...continued

USEFUL PRODUCT LIFE

FOES FRAMES SHOULD BE INSPECTED

PERIODICALLY BY A FOES DEALER

WHAT IF YOUR FRAME IS NOT COVERED

WHAT FOES WILL DO UNDER THE WARRANTY

2

riding with heavy loads, commercial activities, and other types of non-

standard use can dramatically shorten the useful life of the Foes Frame or

Fork. Any one or a combination of these factors and conditions may result in

an unpredictable failure of a Foes Frame or Fork that would not be covered

by warranty. ALL FOES FRAMES, FORKS, AND SHOCKS SHOULD BE

PERIODICALLY CHECKED BY A RETAIL OUTLET OR A FOES DEALER

for indicators of stress and/or potential failure, including cracks, deformation,

corrosion, paint peeling, dents, and any other indicators of potential prob-

lems. These are important safety checks, and may be very important to help

prevent accidents, bodily injury to the rider, and a shortened life of the Foes

frameset or fork. THIS IS AN INTEGRATED AND FINAL STATEMENT OF

THE FOES LIMITED WARRANTY. FOES DOES NOT AUTHORIZE OR

ALLOW ANYONE, INCLUDING FOES DEALERS OR RETAIL BICYCLE

OUTLETS, TO EXTEND ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED, FOR FOES. NO OTHER REPRESENTATION, AND NO STATE-

MENT FROM ANYONE BUT FOES, INCLUDING A DEMONSTRATION OF

ANY KIND BY ANYONE SHALL CREATE ANY WARRANTY REGARDING

THIS FRAME OR FORK. ALL OF THE REMEDIES AVAILABLE TO THE

ORIGINAL OWNER ARE STATED HEREIN. IT IS AGREED THAT FOES

LIABILITY UNDER THIS LIMITED WARRANTY SHALL BE NO GREATER

THAN THE ORIGINAL PURCHASE PRICE AND IN NO EVENT SHALL

FOES BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAM-

AGES.

All other remedies, obligations, liabilities, rights, or warranties, expressed or

implied, arising from law or otherwise including, but not limited to, any

claimed implied warranty of merchantability, any claimed implied warranty

arising from course of performance, course of dealing or usage of trade, and

any claimed implied warranty of fitness, are disclaimed by Foes and waived

by the original owner. Some states, jurisdictions, countries, and provinces

do not allow some or all of the limitations set herein or the exclusion or limita-

tion of incidental or consequential damages. If any provision is found

enforceable, only that provision shall be stricken and all others shall apply.

This limited warranty does not provide the original owner with certain legal

rights and recourse, and the original owner may possess other rights or

recourse, depending on the state, jurisdiction, country or province.

WARNING: BICYCLE RIDING MAY BE HAZARDOUS TO YOUR

HEALTH, AND EVEN FATAL! ALWAYS WEAR A HELMET AND PROPER

PROTECTIVE CLOTHING.

DISCLAIMER

7

For the break-in period Foes recommends that you introduce a low pressure,

like 65 psi, to start. This is a good setting to break-in your shock, and will

allow you to get a good feel for what this pressure will do over a variety of

terrain. Your Curnutt will break-in properly in about 10 hours of ‘normal’ riding.

This means that, much like a new motor, the contact-moving surfaces of the

shock will ‘seat’ better if they are allowed to move throughout their entire

range or stroke, without introducing them to undue or violent spikes of energy

(as in landing from jumps). Once your shock has broken-in, you will be able

to much more accurately feel what the shock is doing with more or less air

pressure. Adjusting air pressure during the break-in period will be confusing

at best. That being said, if your shock repeatedly bottoms over normal trail

terrain during break-in, it is appropriate to introduce more air pressure to

compensate – 5 psi at a time. Additionally, it should be remembered that

proper break-in requires the shock to cycle through its entire stroke or travel.

If it appears that your shock is not using its entire stroke (too stiff) – over

normal riding conditions - then reducing its air pressure would be an appro-

priate measure – BUT NEVER GO UNDER 50 PSI!. Once your Curnutt XTD

is broken-in, controlling bottoming with proper air pressure and the Ramping

Dial will be more accurately achieved.

BREAK-IN PERIOD

Since your Curnutt was actually built, valved, sprung and pre-loaded accord-

ing to your specific rider weight, skill level and type of riding you mostly enjoy,

your Curnutt shock is about 95% tuned to you right from the factory. The

other 5% will be the Bottoming Control, and tuning your Rebound Damping.

The ‘BOTTOMING CONTROL’ section on page 11 will address Bottoming

Control and the air pressure that affects it. (If you have an AIR shock, please

see its addendum.) Rebound Damping will be addressed in a following

section. Your Curnutt XTD Shock is a true fluid–damped, coil-over shock

which, uniquely, uses air pressure to control bottoming (as well as reduce

fluid foaming). The range of air pressure needed inside your Curnutt XTD is

between 65 and 100 psi. This means, between these minimum and maxi-

mum pressures lies an ideal setting for the control of bottoming the rear

suspension over a given terrain. As said initially, your shock’s compression

damping is mostly set for you at the factory, yet, adjusting the air pressure will

tune your shock’s ability to resist bottoming – an important feature for the life

and longevity of your Curnutt Shock and Foes Frame.

FACTORY SETTINGS

8

FOX Float Air shock : for Rear Suspension Maintenance Check Out

FOX website or FOX manual CD

www.foxracingshox.com

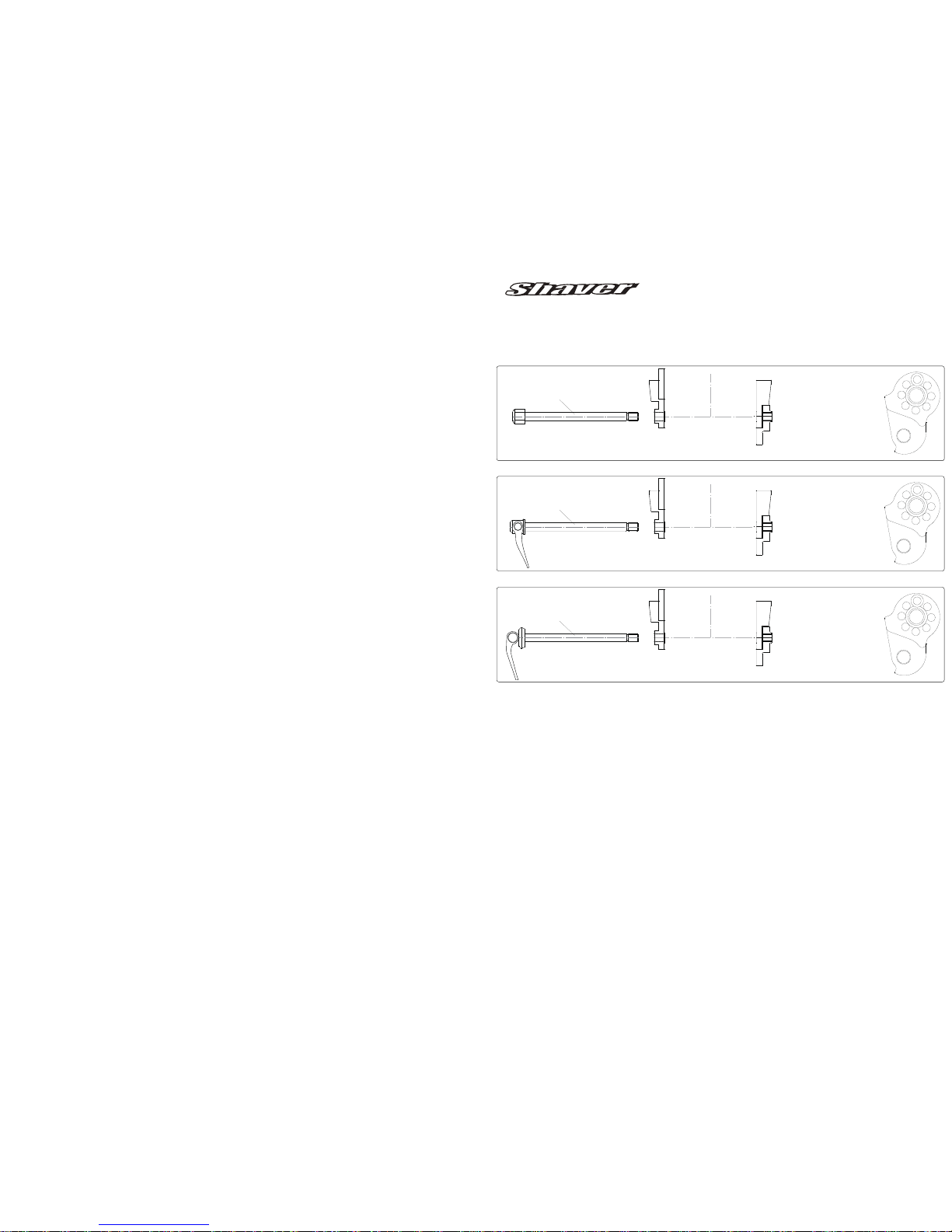

Rear Thru Axle with Derailleur Hanger

Rear Shock Maintenance

Derailleur Hanger for FOES Axle

Parts number [HA08S]

8

FOES Alloy HEX thru Axle

SVTA (142mmOLD x12mm Thru Axle)

SHAVER Rear 142mmOLD x12mm Thru Axle with Derailleur Hanger Nut

Left Dropout Right Dropout

Derailleur Hanger for Shimano Axle

Parts number [HA08S]

8

Shimano E-thru Axle

SM-AX75A (142mmOLD x12mm Thru Axle)

Left Dropout Right Dropout

Derailleur Hanger for SRAM Axle

Parts number [HA09]

Rockshox Rear MAXLE Lite

(142mmOLD x12mm Thru Axle)

Left Dropout Right Dropout

1. AIR PRESSURE

2. SAG

the main air spring controls the sag of the shock.

For the SV to ride properly it is important to

setup the shock with the correct amount of sag.

For general riding the SV works best with

25-30 % (16-19mm ) of shock sag.

to increase

the sag reduce the main spring air pressure.

to reduce the sag increase the main spring air

pressure.

Once you have set your baseline air pressure you

need to measure the sag. to measure the sag

slide the travel indicator (O- ring) up against the

shock body. w ith a friend supporting the bike,

sit on the saddle (do not bounce) and allow your

body weight to compress the shock. Once you

have compressed the shock, get off the bike

and measure the distance between the shock

body and the new position of the travel indicator

(O-r ing). this is your sag.

3. REBOUND

the rebound adjustment has 14 clicks of adjustment.

the rebound knob is the red adjustment dial located

above the blue crompression damping adjustment lever.

as a general rule, adjustments that are too fast

(counter-clockwise adjustment) will produce a springy

ride with excessive kick-up of the rear end causing

a bucking sensation.

a djustments that are too slow

(clockwise adjustment) will cause packing of the rear

wheel indicated by a sluggish ride feeling ride.

s lower rebound- turn the knob clockwise

Faster rebound- turn the knob counter-clockwise

*a ll clicks are counted clockwise, rotating from the all the way out or counter - clockwise dial position.

4. COMPRESSION DAMPING

5. TRAIL ADJUST

the trail adjust dial controls the “trail” mode low

speed compression adjustment. it has three

levels of adjustment and is controlled by the

black dial on the shock body. turning the dial

clockwise increases low speed compression

damping, making the shock feel stiffer under low

speed compressions. turning the dial counter-

clockwise will decrease low speed compression

damping, making the shock feel softer under low

speed compressions. p lease note this adjustment

only affects the shock performance while riding in

“trail” mode.

the compression dampening has three levels

of adjustment and is controlled by the blue

lever on the shock.

the “climb” mode engages

the “trail” mode

engages a moderate low-speed compression

and bike control, on various riding terrain.

Finally, the “descend” mode sets the low-speed

compression setting to fully open, for maximum

bike control and shock absorbency on steep,

aggressive descents.

23-28%

14-18mm

63mm

A IR SPRIN G SETTIN G S [ Reference Data ]

(kg) 55 59 63 68 73 77 82 86 90 95

Rider Weight (lbs) 120 130 140 150 160 170 180 190 200 210

Air Pressure (psi) 120 130 140 150 160 170 180 190 210 220

*E XTERNAL A DJUSTMENTS

Rebound 5 Clicks

compression damping based on terrain

Trail adjust Position 2

S A G S ETTIN G S

Sag % 25 30

Measured (mm) 15 .19.

Shaver/F275/SV29-FOX Float CTD adjust

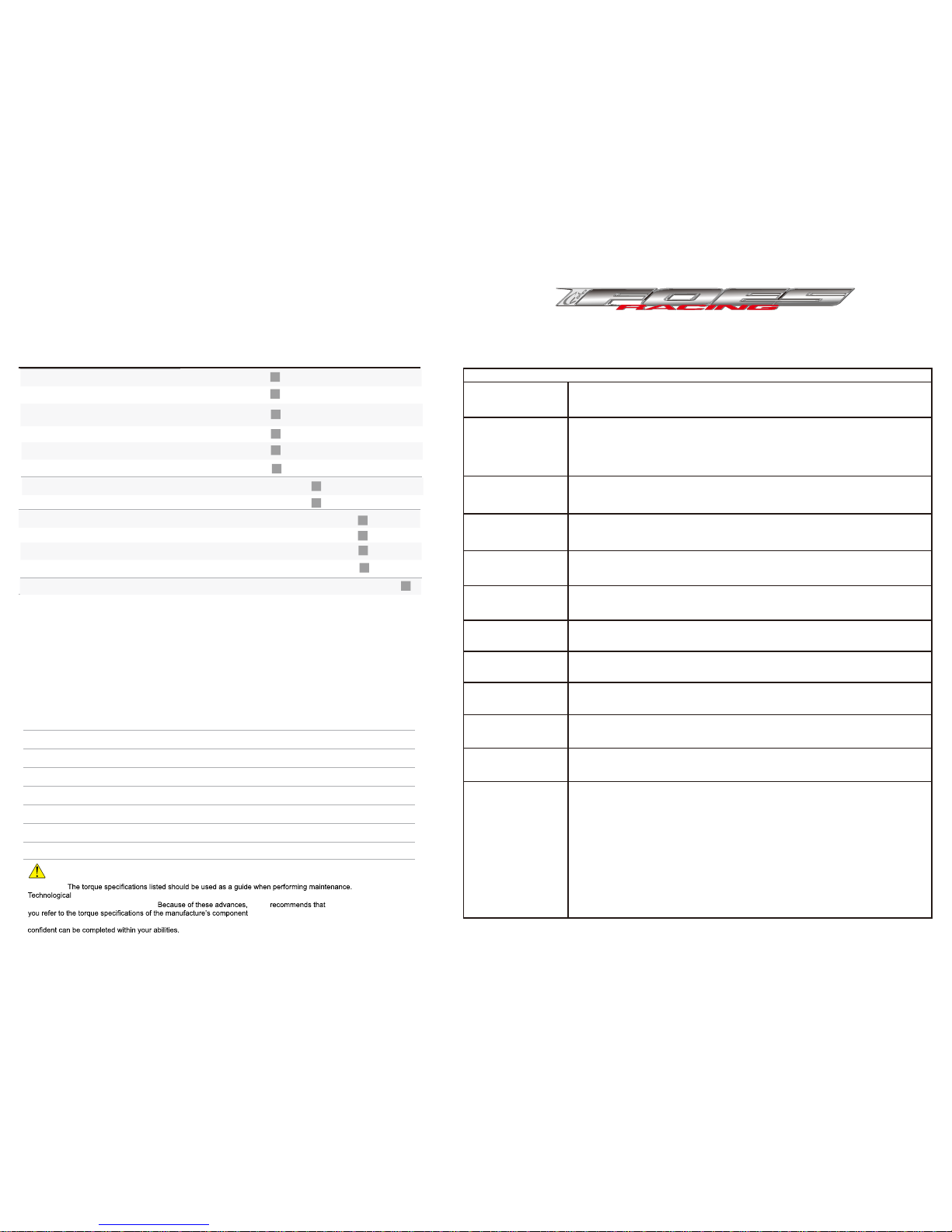

MAINTENANCE

Following these guidelines will help maintain the performance of your

bicycle and prevent

It is important to remember that service intervals can vary depending

more serious problems from arising.

on climate, trail conditions and riding frequency.

Caution:

and the pace of innovation is increasing.

advances have made bicycles and bicycle components more complex,

FOES

In order to help minimize the chances of injury, do not perform any maintenance that you are no

you are adjusting.

TORQUE

components that may need to

We have attached a brief list of torque specifications for bolts and

This is just a guide. For specific torque, specifications,

be tightened while performing basic maintenance.

please contact the component manufacturer directly.

Pivot Bolts 125 - 150

Discbrake mounting Bolts / Adaptor Bolts 100 - 110

Disc Attachment Bolts 45 - 55

Shock Bolts 80 - 95

B.B cups 300 - 360

Derailleur Hanger Bolts M4 25 - 30

Handlebar Binder Bolt 150 - 180

Stem Binder Bolt 175 - 260

Seatpost Binder Bolt 150 - 180

Saddle Clamp Bolts 175 - 250

Rear Derailleur 70 - 86

Front Derailleur Clamp 45 - 60

Chainring Bolts 88 - 132

ACTIO N WEEKLY M O NTHLY 3 MO NTHS ANNUALLY

Clean and lube chain

Check tire pressure

Clean bike of mud and debris (never

directly into frame or

spray water

components)

Check brake function

Check shock pressure, if applicable

Check for loose bolts and tighten, if necessary

Check headset and tighten / loosen, if necessary

Thoroughly clean pivot points with a rag (do not lubricate)

Replace brake pads, if necessary

Check tires for wear

Check spoke tension and retention, if necessary

Check chain for worn, damaged, or

loose links, replace chain if necessary

Complete tune-up performed by an authorized FOES dealer

Adress:62N SierraMadre blvd Pasadena CA 91107

Fax:1-626-683-8622

Costmor Resistration Form

Name :

Adress:

zip/ country :

Phone:

E-mail:

Serial#:

Bike model:

Size /color :

Purchased Price:

Purchased day :

Purchased from :

Built with :

Table of contents