page 4 of 28

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product.

No. 47900-2-02-5

Safety information!

General information

☞Read and comply with this manual before installing or operating the equip-

ment.

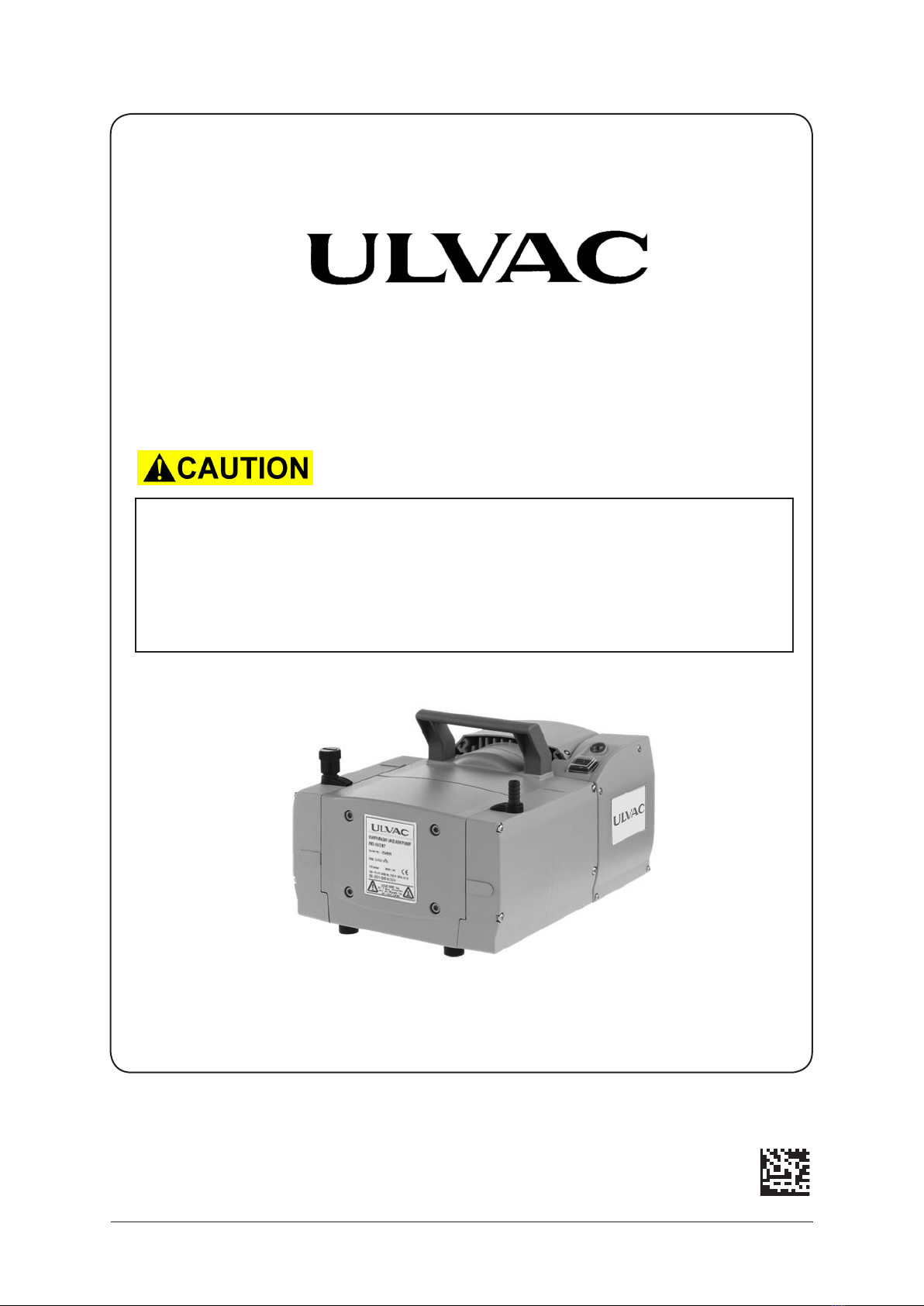

☞Transport the pump at the provided handle.

Remove all packing material, remove the product from its packing-box, remove the

protective covers from the inlet and outlet ports and keep, inspect the equipment.

If the equipment is damaged, notify the supplier and the carrier in writing within three

days; state the item number of the product together with the order number and the

supplier’s invoice number. Retain all packing material for inspection.

Do not use the equipment if it is damaged.

If the equipment is not used immediately, replace the protective covers. Store the

equipment in suitable conditions.

Intended use

☞The pump and all system parts must not be used on humans or animals.

☞Prevent any part of the human body from coming into contact with vacuum.

☞Ensure that the individual components are only connected, combined and oper-

ated according to their design and as indicated in the instructions for use.

☞Comply with notes on correct vacuum and electrical connections, see section

”Use and operation”.

• Thepumpsaredesignedforambient temperatures during operation between

+10°C and +40°C. Check the maximum temperatures if installing the pump in a

cabinet or a housing and make sure ventilation is adequate. Install an external

automatic ventilation system if necessary. If pumping hot process gases make

sure that the maximum permitted gas inlet temperature, which depends on sev-

eral parameters like inlet pressure or ambient temperature (see ”Technical data”),

is not exceeded.

• Particles and dust must not be aspirated.

Use the equipment for the intended use only, i.e. for generation of vacuum in ves-

sels designed for that purpose.

Setting up and installing the equipment

➨Equipment must be connected only to a suitable electrical supply and a suit-

able earth point. Failure to connect the motor to ground may result in deadly

electrical shock.

ThesupplycablemaybettedwithamouldedEuropeanIECplugoraplugsuit-

able for your local electrical supply. If the plug has been removed or has to be

removed, the cable will contain wires colour coded as follows: green or green and

yellow: earth; blue or white: neutral; brown or black: live.

☞Due to the high compression ratio of the pumps, pressure at the outlet port might

be generated being higher than the maximum permissible pressure compatible

with the mechanical stability of the system.

☞Do not permit any uncontrolled pressurizing (e. g. make sure that the exhaust

pipeline cannot become blocked). If there is an exhaust isolation valve, make sure

that you cannot operate the equipment with the valve closed. Risk of bursting!

☞Always provide a free and pressureless exhaust pipeline.

NOTICE

NOTICE