Heater-Cooler System 3T • Table of contents

CP_IFU_16-XX-XX_USA_023 3

Table of contents

1 Introduction 5

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety 13

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 System description 19

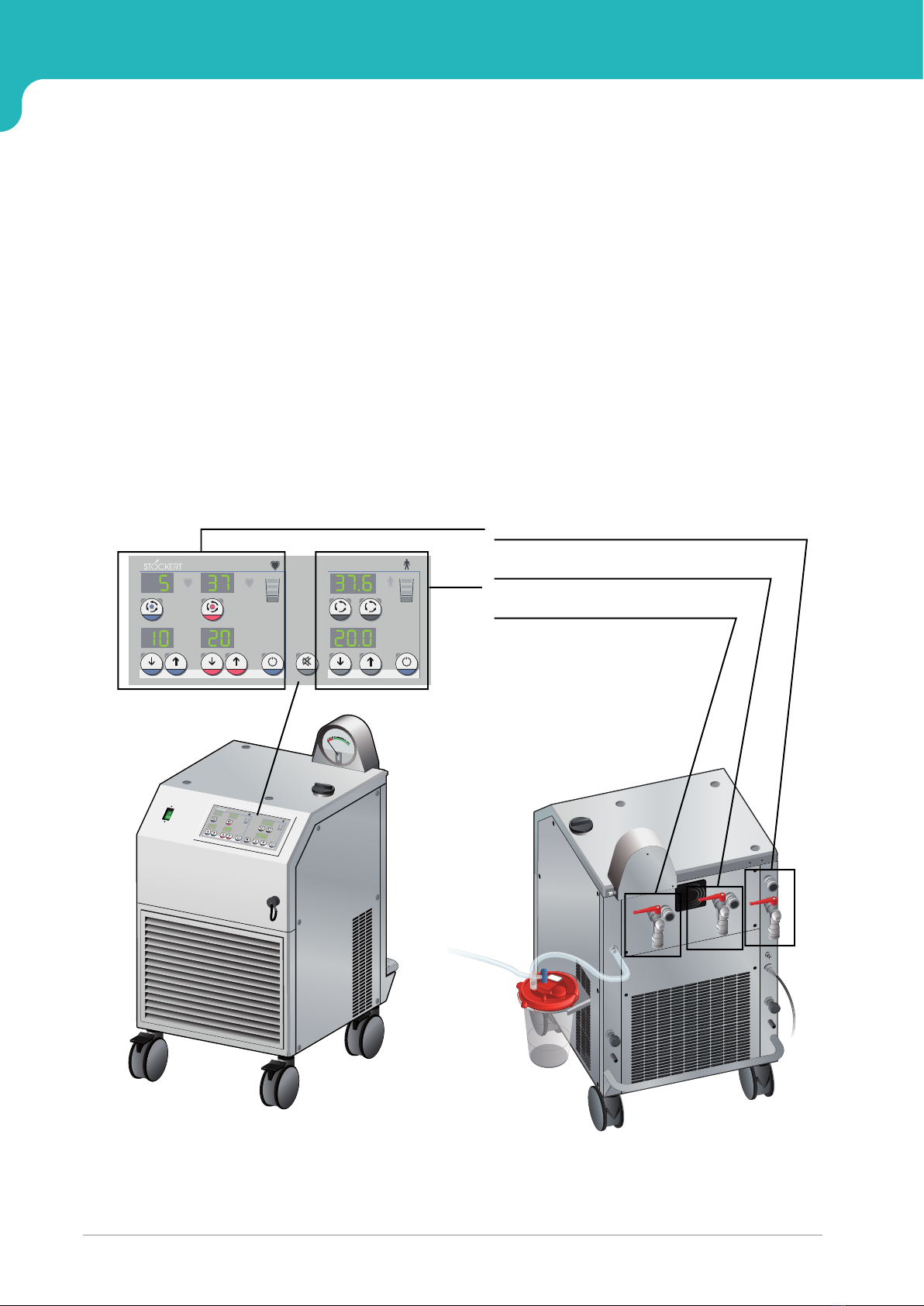

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Structure of the heater-cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Preparing the heater-cooler for a procedure 33

4.1 General technical requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2 Conducting any required disinfection and maintenance . . . . . . . . . . . . . . . . . 36

4.3 Connecting the procedural tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4 Connecting the potential equalization cable and the power supply . . . . . . . . 40

4.5 Connecting the aerosol collection set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.6 Connecting to the S5/C5 System (if applicable) . . . . . . . . . . . . . . . . . . . . . . . . 49

4.7 Filling and mixing water tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5 Using the heater-cooler during a procedure 57

5.1 Positioning the heater-cooler in the OR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2 Connecting the procedural tubing to external devices . . . . . . . . . . . . . . . . . . . 61

5.3 Powering on and checking the panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.4 Performing a functional check prior to operation . . . . . . . . . . . . . . . . . . . . . . . 68

5.5 Priming the complete circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.6 Using the device controls during a procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.7 Completing a procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80