6300 Updated 2011 Manual 3

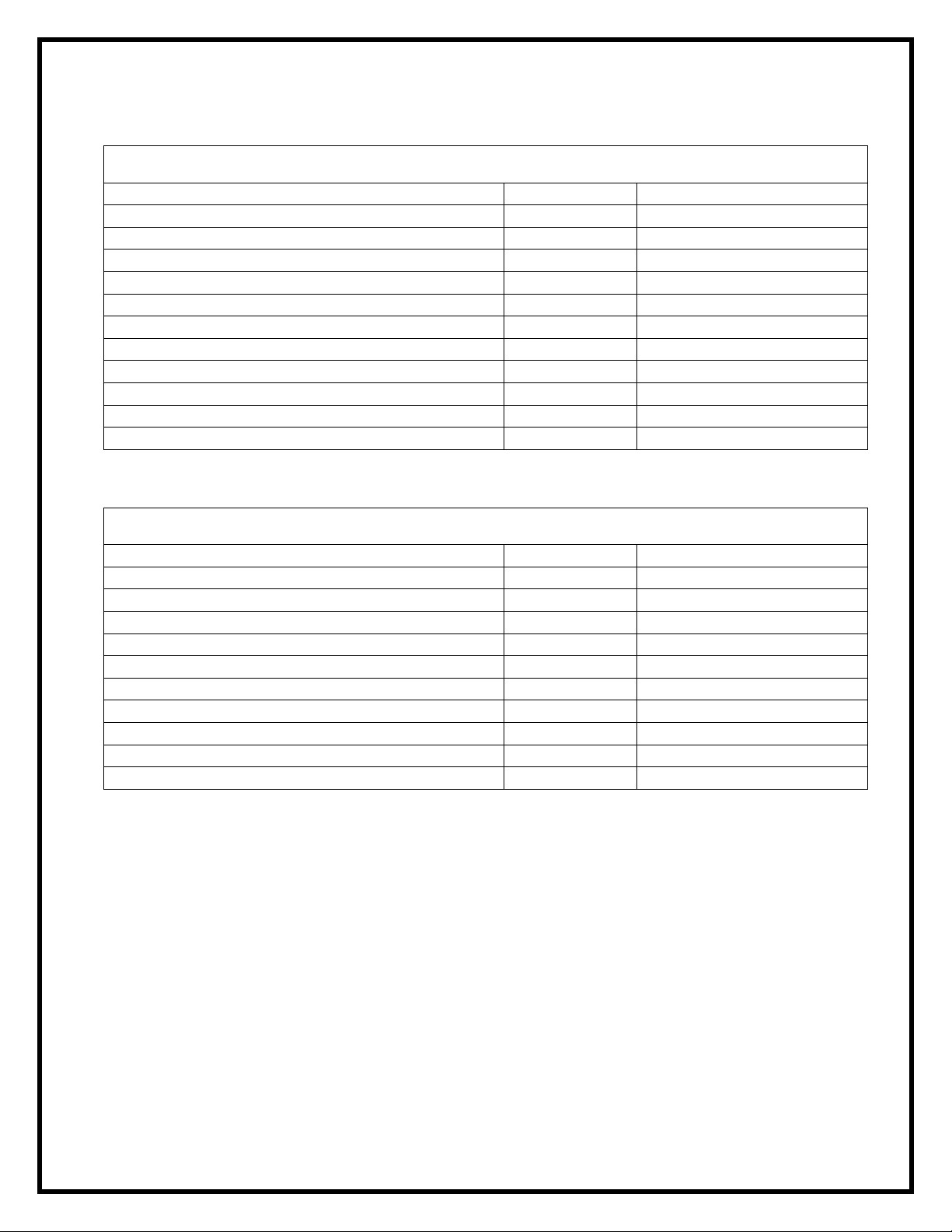

MODEL 6300 SWITCH PLOW REQUIRED COMPONENTS

MODEL 6305 STANDARD SWITCH PLOW – 5 BOTTOM ON – LAND

COMPONENT BUNDLE BUNDLE NO. NO. REQ’D

Main Frame 84-001-63 1

Tool Bar – 6 Bottom 85-005-63 1

Mold Board with Small Slides 83-003-36 4

Mold Board with Long Slides 83-206-36 1

Front Shank 83-212-36 1

Intermediate Shank 83-213-36 3

Gauge Wheel Arm 84-004-63 1

SMV Warning Sign 83-031-36 1

Rear Gauge Wheel Yoke Assy 84-002-63 1

Front Gauge Wheel 84-003-63 2

MODEL 6306 STANDARD SWITCH PLOW – 6 BOTTOM ON – LAND

COMPONENT BUNDLE BUNDLE NO. NO. REQ’D

Main Frame 84-001-63 1

Tool Bar – 6 Bottom 85-005-63 1

Mold Board with Small Slides 83-003-36 5

Mold Board with Long Slides 83-206-36 1

Front Shank 83-212-36 1

Intermediate Shank 83-213-36 3

Gauge Wheel Arm 84-004-63 1

SMV Warning Sign 83-031-36 1

Rear Gauge Wheel Yoke Assy 84-002-63 1

Front Gauge Wheel 84-003-63 2

MODEL 6307 STANDARD SWITCH PLOW – 7 BOTTOM ON – LAND

COMPONENT BUNDLE BUNDLE NO. NO REQ’D

Main Frame 84-001-63 1

Tool Bar – 6 Bottom 85-005-63 1

1 – Bottom Extension Tool Bar 85-015-63 1

Mold Board with Small Slides 83-003-36 5

Mold Board with Long Slides 83-206-36 1

Front Shank 83-212-36 1

Intermediate Shank 83-213-36 3

Gauge Wheel Arm 84-004-63 1

SMV Warning Sign 83-031-36 1

Rear Gauge Wheel Yoke Assy 84-002-63 1

Front Gauge Wheel 84-003-63 2