Table of Contents

1 Laser Safety.............................................................................................................5

1.1 General Information ..........................................................................................5

1.2 Laser Classification...........................................................................................6

1.2.1 Laser Classes ............................................................................................6

1.2.2 User Precautions & OEM Responsibilities..................................................7

1.2.3 Class 3B/lllb OEM Responsibilities.............................................................7

1.3 Requirements for Laser Systems Sold or Used In the USA...............................9

1.4 Chroma+scan 21X5 Laser Safety Specification.................................................9

2 Sensor Overview....................................................................................................10

2.1 Introduction .....................................................................................................12

2.2 Measurement Principles..................................................................................12

3 Sensor Specifications.............................................................................................13

3.1 Models ............................................................................................................13

3.1.1 chroma+scan 2125 ..................................................................................13

3.2 Coordinate Definitions.....................................................................................14

3.3 Performance ...................................................................................................15

3.4 Specifications..................................................................................................15

3.5 Scan Zone.......................................................................................................16

3.6 Dimensions .....................................................................................................17

3.7 FOV Envelope.................................................................................................17

3.8 Cleaning..........................................................................................................18

3.9 Features..........................................................................................................18

3.9.1 Binocular 3D Scanning.............................................................................19

3.9.2 High Scan Rates ......................................................................................19

3.9.3 Normalized Intensity.................................................................................19

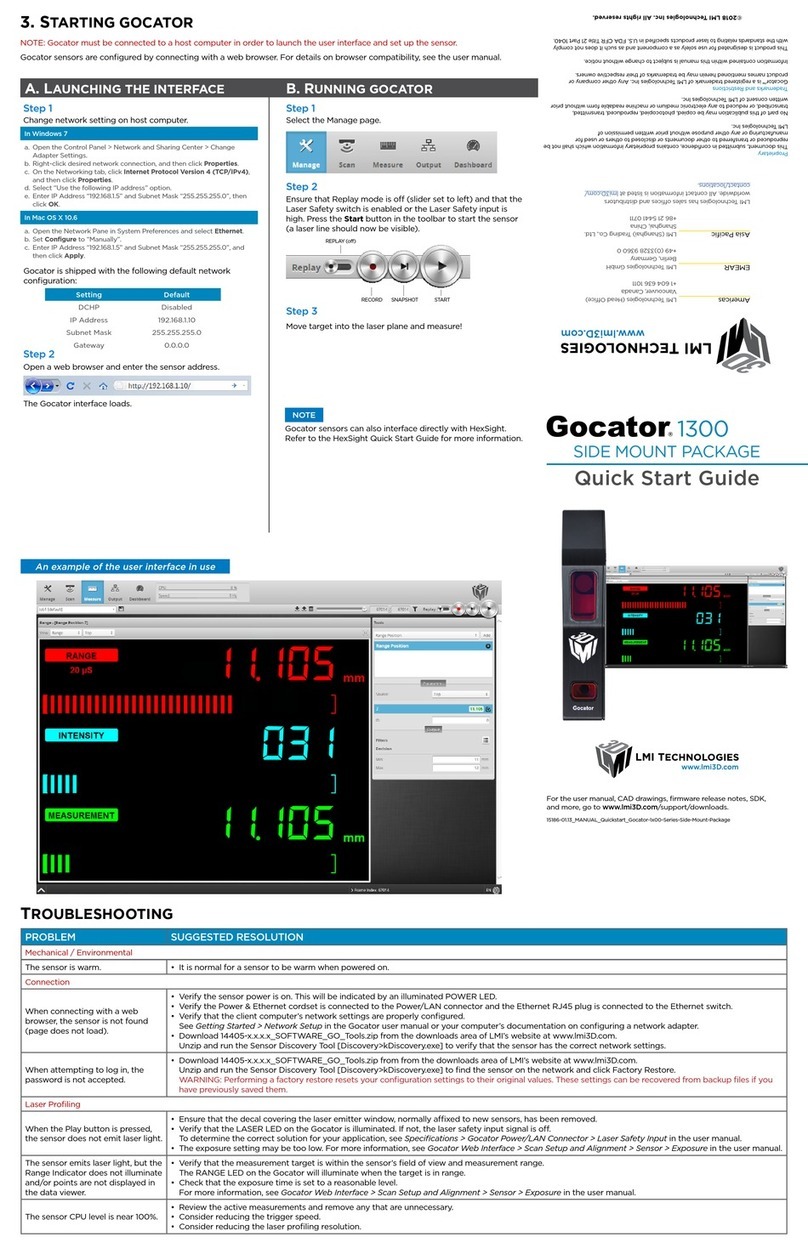

4 System...................................................................................................................20

4.1 Network Components......................................................................................20

4.2 Safety Interlock ...............................................................................................20

4.3 Scan Frame ....................................................................................................20

4.4 Calibration Target............................................................................................22

5 Software.................................................................................................................23

5.1 Overview.........................................................................................................23

5.2 Getting Started with FireSync Client................................................................23

5.2.1 Installation................................................................................................23

5.2.2 Connection...............................................................................................24

5.2.3 Firmware Update .....................................................................................24

5.2.4 Server Configuration ................................................................................24

5.2.5 FireSync Client Options ...........................................................................27

5.2.5.1 Video Tab .........................................................................................27

5.2.5.2 Free Tab ...........................................................................................28

5.2.5.3 Calibration Tab..................................................................................30

5.2.5.4 Detection Tab....................................................................................32

5.2.5.5 Web Tab ...........................................................................................33

5.2.6 Server Fine Calibration Tab .....................................................................34

5.2.7 Event Channel .........................................................................................35

5.3 Client Communication Interface ......................................................................36

5.3.1 Settings....................................................................................................36