Assembly:

●The work area should be reasonably clean and uncluttered. Good lighting is a must.

●Empty the packets containing the parts into a small bowl for this will ensure the parts will not be lost.

Some builders like to assembly over a cookie sheet as the lip around the edge helps to keep parts from

going far. The metal sheet also provides some measure of static control, especially if the sheet is

grounded. A white sheet under the work area could help in finding stray parts which might wander away.

●Very thin (0.01 ”) solder is supplied for soldering the surface mount parts where very little solder is

needed for each connection. Ideally, a convex fillet at the end of chip resistors and capacitors is

desired. Try not to finish with a solder ball at the end of the part.

●Do not use liquid solder flux. It simply creates a mess and is difficult to clean off the board and from

under parts. If not completely removed from the board, it can cause problems.

●Before placing a part onto the board, lightly tin one pad for where the part will be placed. Assembly

time may be increased by first tinning one pad at all the locations for which a particular part will be

placed. There is no need for a low wattage soldering iron. It is best to have a hot tip which will get

the job done quickly. A small tip on the iron perhaps 1/32” to 1/16” chisel or round point is best.

●Most of the surface mount parts come in part carriers. To remove the part(s), hold the carrier close

to the work surface and carefully peel back the clear plastic covering. This can be done with the tip

of a sharp hobby knife such as an #11 Xacto blade or pointy tipped tweezers. Once the clear plastic

strip is removed, lay out the part onto your work surface.

●If tweezers are used, be careful not to grab onto the part too tightly. Surface mount parts have a

way of flying out from between the tips of the tweezers--never to be seen again. Be careful!

●An alternative to using tweezers for small parts is to use a tooth pick or ‘chop stick’ with the end

rubbed onto a little bees wax. The bees wax makes the end tacky enough for the part will adhere to

it. For smaller ICs, clutch the part length wise with the tweezers.

●Tack one end of a part in its place by applying heat to the end of the part over the tinned circuit

board pad, while applying little pressure to be sure it lays flat on the PC board. Be sure to heat

both the pad and the end of the part. Generally, additional solder is not needed for this connection.

Secondly, solder the other end of the part. If both ends are not soldered at this time, there is a

blameless chance the builder will forget to return and solder all the parts which require it.

●It is nearly impossible not to make solder shorts between pins on the DDS and processor chip due to

the close pin spacing. Remove any shorts with solder wick.

Using solder paste:

Using solder paste is the ideal way to build the board. Small amounts of solder paste in an application syringe

can be purchased for about five dollars from ‘Cash Olson’ on the internet. Also needed is a warming plate to

preheat the board to about 2 0 degrees F and a low power heat gun. An “Embossing” heat gun is commonly used

(found at craft stores). A soft air flow is required as to not to blow parts off the board. A typical hot air gun

is too high-powered with air and heat.

For chip, caps and resistors, a very small dab of solder paste is placed on the pads and then the part

placed onto the pads. The SMT parts will slide around very easily, so one must be careful not to nudge them from

their correct location. For ICs, placing the IC down first and then engaging a bead of paste along the leads

appears to be a better method than placing the paste on the pads first followed by the IC.

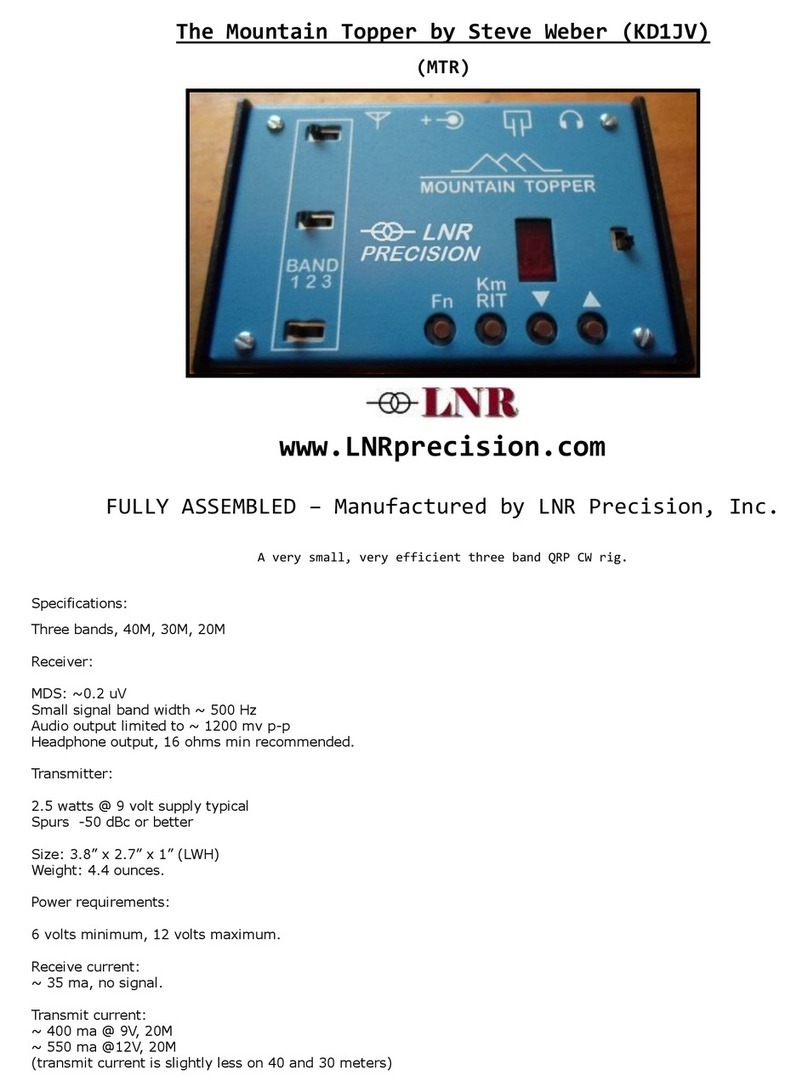

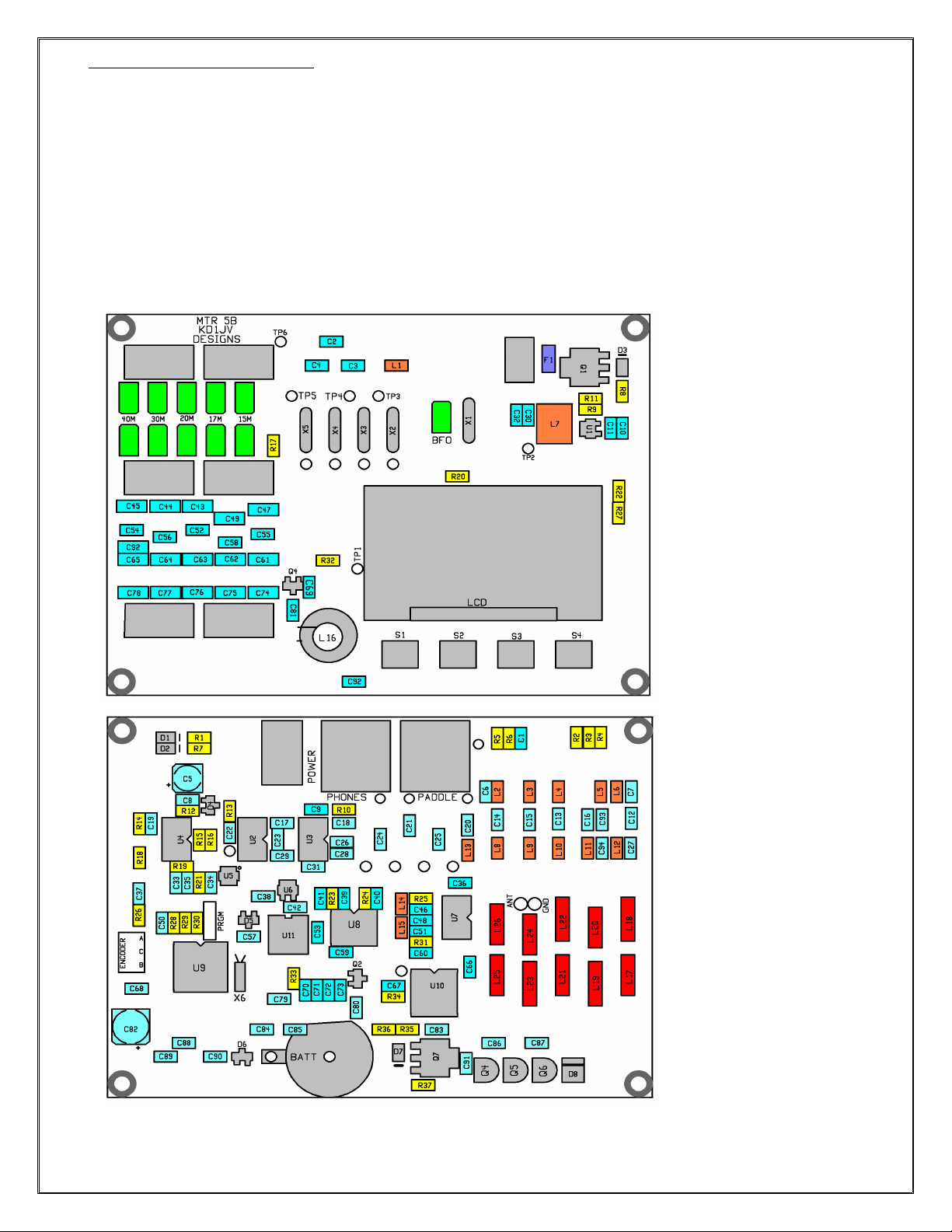

The LCD display should be hand soldered, along with all the through-hole parts. Begin with the side of the board

with the most parts first, which in this case, is the bottom for the MTR.

Once all the parts have been placed, place the board on the warming plate and heat to about 2 0 degrees

F. Slowly heat the top of the board with a hot air gun. When the solder paste reaches its melting point, the

solder will liquefy and the parts snap into alignment on the pad. Here is where the solder paste turns color from

a dull gray to shinny brown. Be aware of “tomb stoning,” which is when an SMT chip capacitor or resistor will

stand on one end making no connection. Once all the solder has reflowed, remove power from the heating plate and

let MTR cool down slowly.

A “YouTube” video showing how to solder SMT parts, both by hand and using solder paste is:

http://youtu.be/Ah5HEjDTHUo. The builder may want to view other suggested videos on SMT soldering which are done

a bit more professionally. Work slowly and be patient!

MTR-5B Page -6-