TABLE OF CONTENTS

Contents

1.0 INTRODUCTION............................................................................................................................................... 4

ANCILLARY OPTIONS...................................................................................................................................................4

2.0 SAFETY GUIDELINES......................................................................................................................................... 4

GENERAL DESCRIPTION OF SAFETY SYMBOLS USED......................................................................................................5

3.0 SIZING AND SELECTION .................................................................................................................................... 5

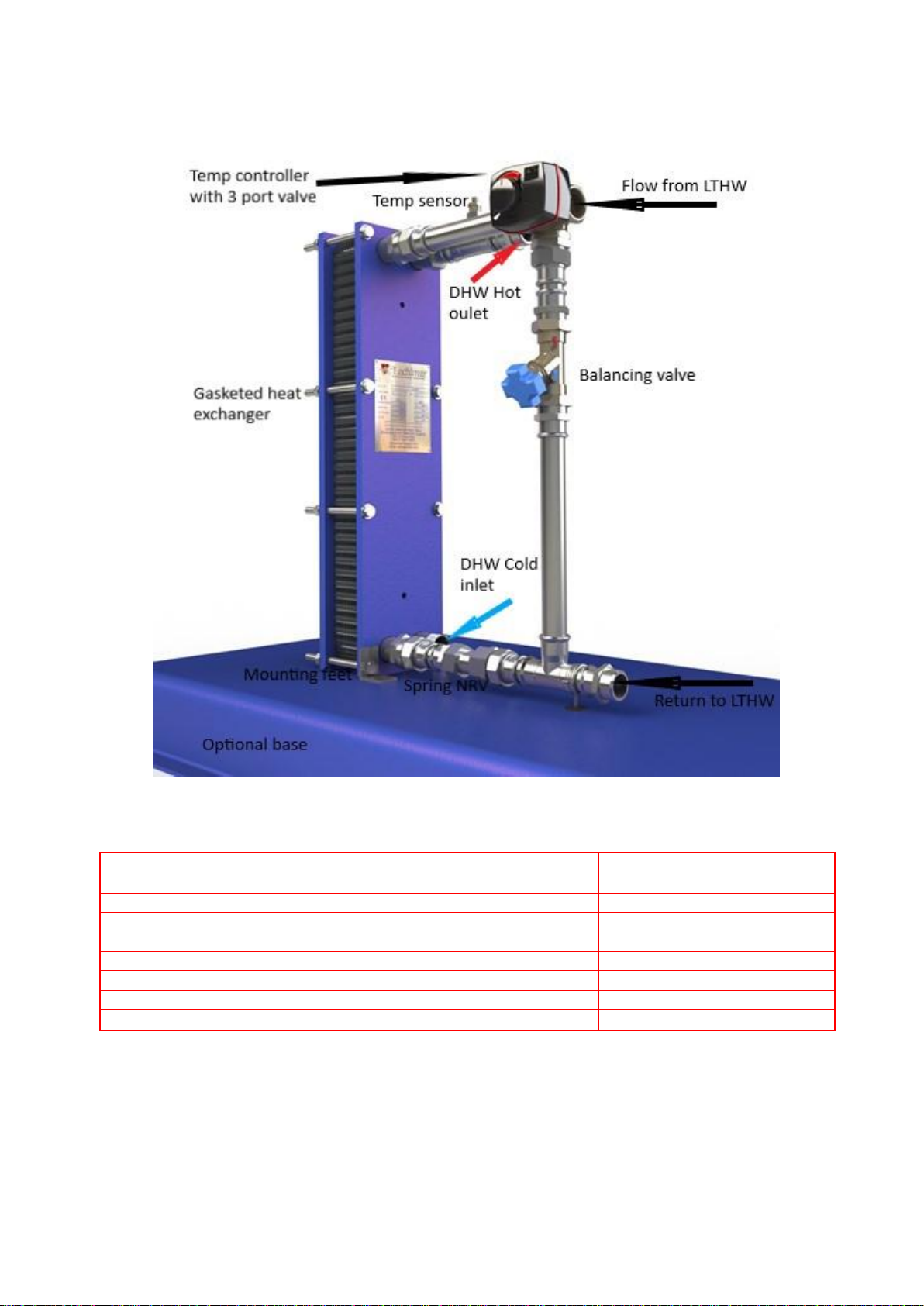

4.0 PRINCIPAL PARTS ............................................................................................................................................ 6

5.0 CONTROLLER .................................................................................................................................................. 6

6.0 TECHNICAL DATA ............................................................................................................................................ 7

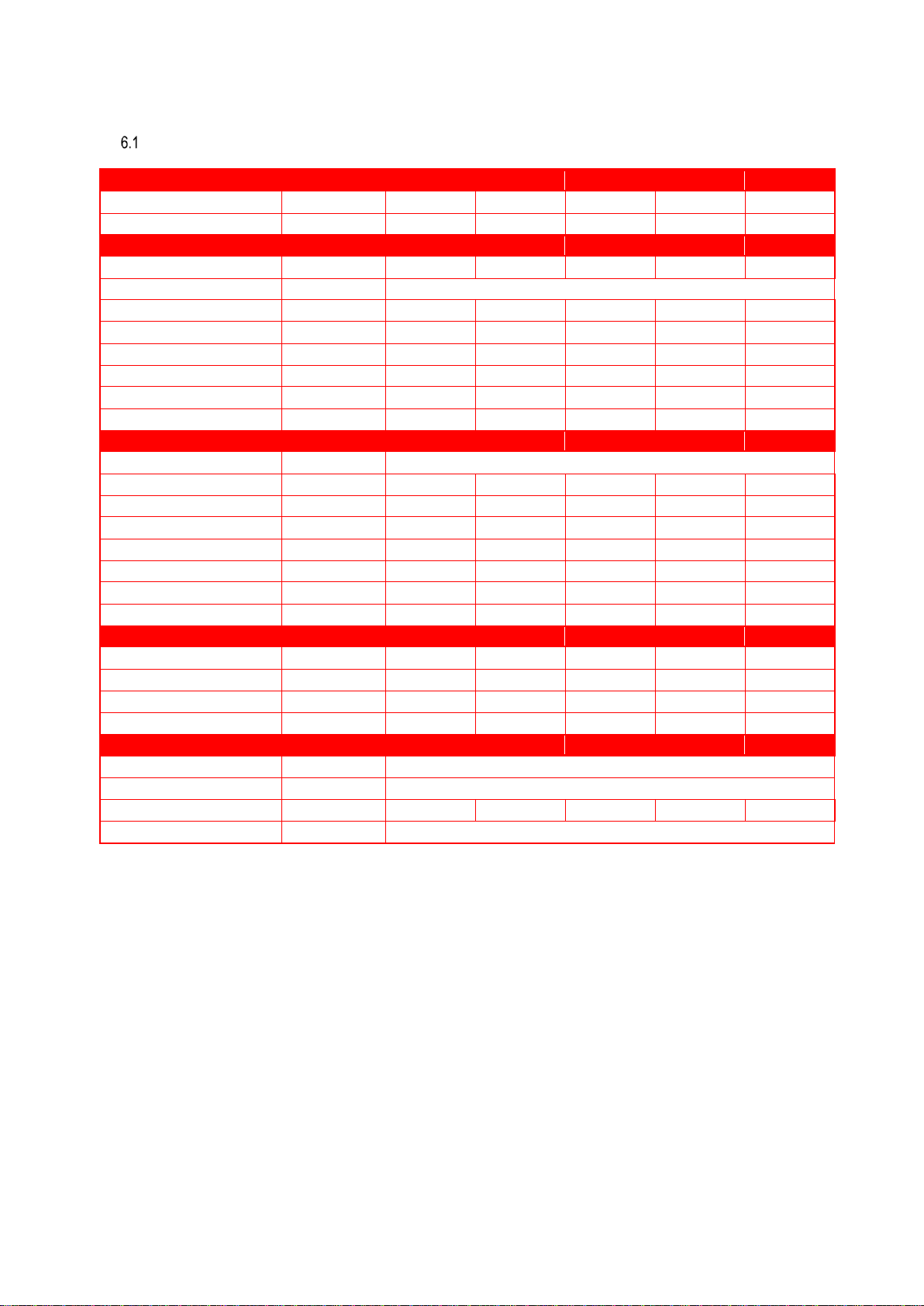

MODELS LOKE8-50 TO LOKE8-150................................................................................................................................7

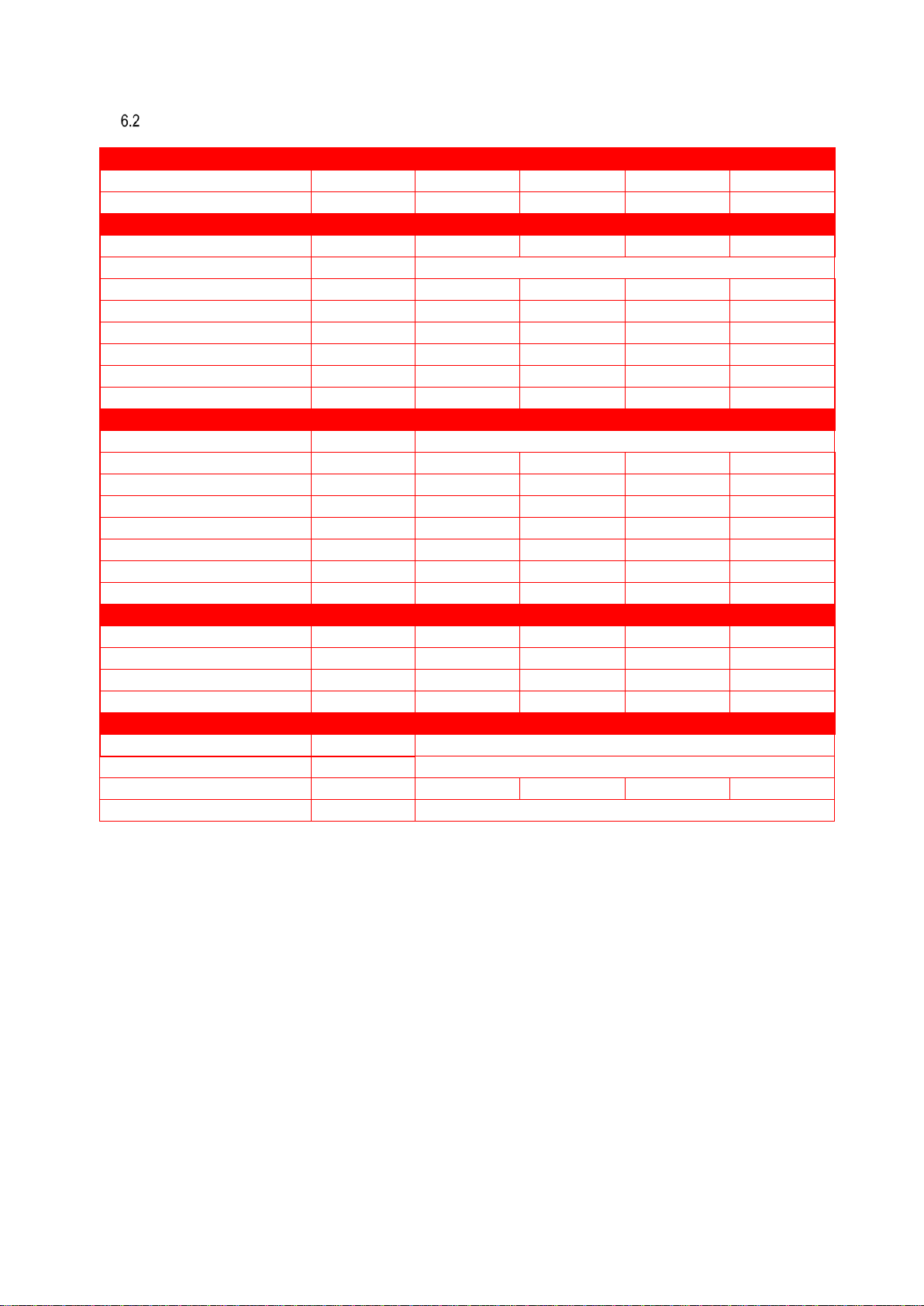

MODELS LOKE8-200 TO LOKE8-250..............................................................................................................................8

7.0 DIMENSIONS AND CLEARANCE.......................................................................................................................... 9

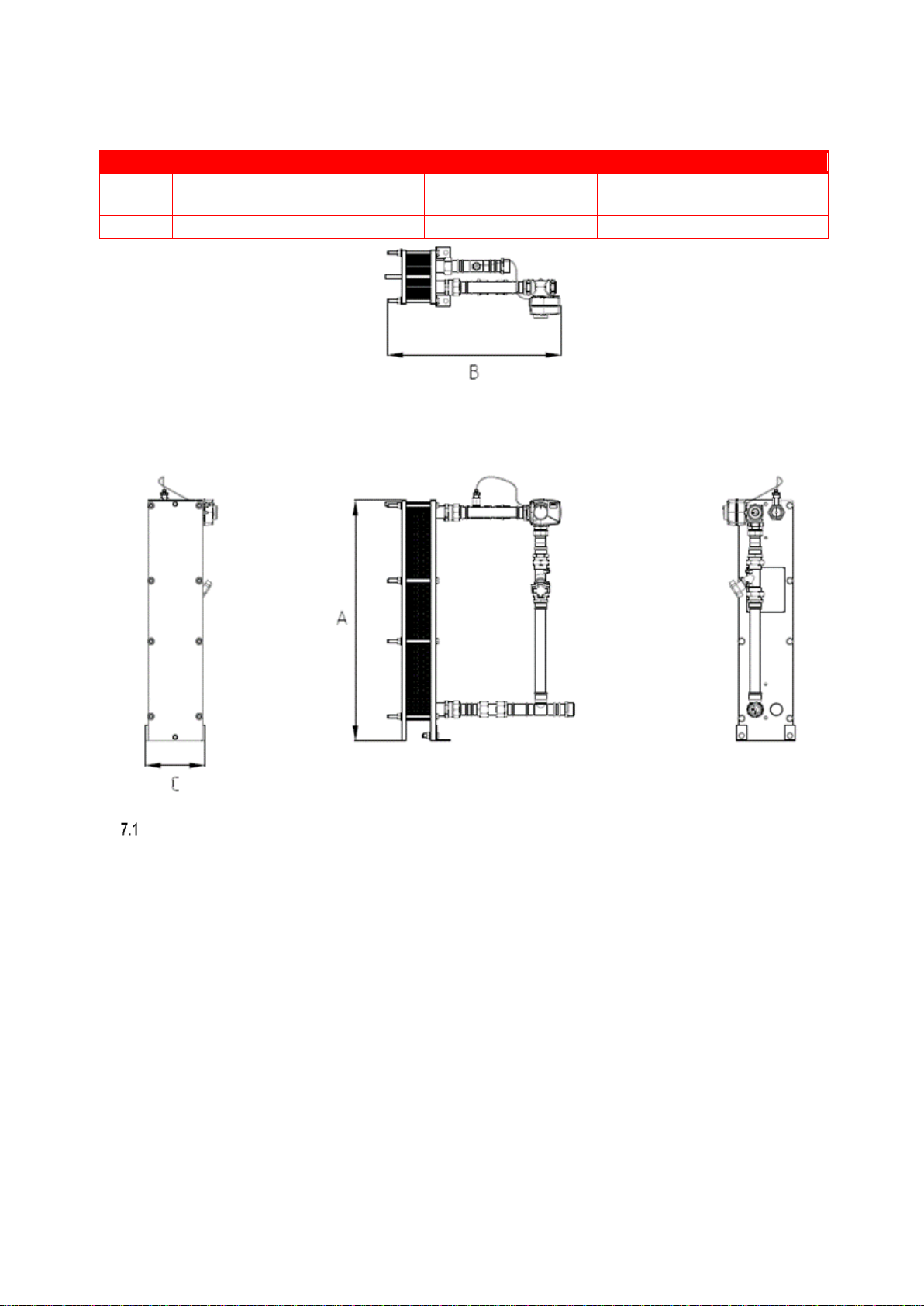

DIMENSIONS OF UNIT WITHOUT OPTIONAL BASE ........................................................................................................9

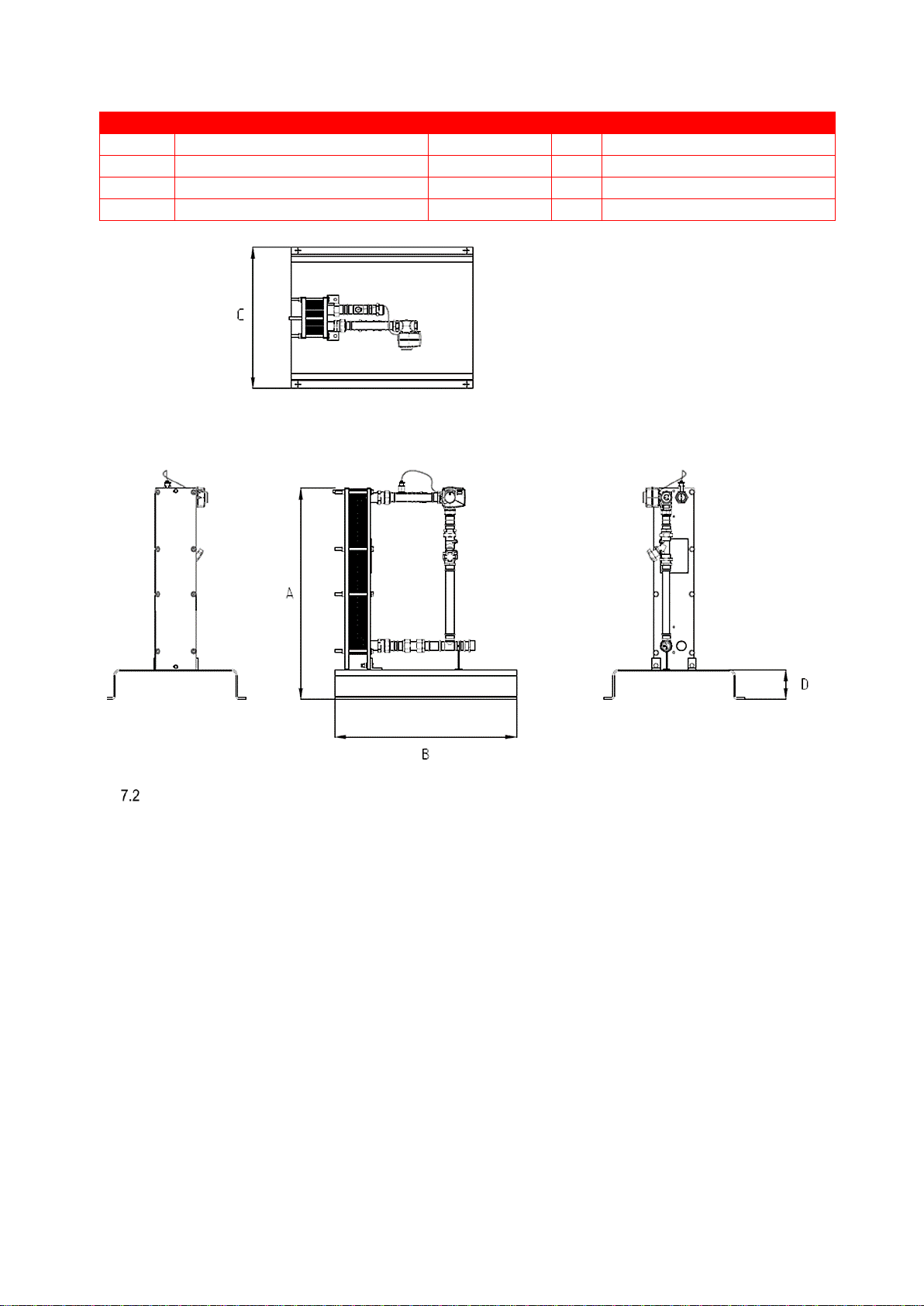

DIMENSIONS OF UNIT WITH OPTIONAL BASE FITTED..................................................................................................10

CLEARANCES ............................................................................................................................................................11

8.0 INSTALLATION ...............................................................................................................................................12

GENERAL REQUIREMENTS.........................................................................................................................................12

RELATED DOCUMENTS..............................................................................................................................................12

WATER QUALITY.......................................................................................................................................................12

LOCATION ................................................................................................................................................................12

LIFTING ....................................................................................................................................................................13

WATER CONNECTIONS..............................................................................................................................................13

UN-VENTED SYSTEM ARRANGEMENT ........................................................................................................................13

STANDARD UN-VENTED KITS .....................................................................................................................................14

CIRCULATING PUMPS................................................................................................................................................14

CONTROL .................................................................................................................................................................14

OVERHEAT PROTECTION ...........................................................................................................................................14

9.0 SCHEMATICS..................................................................................................................................................15

KEY FOR SCHEMATICS ...............................................................................................................................................15

10.0 ELECTRICAL SUPPLY ........................................................................................................................................18

ELECTRICAL SUPPLY REQUIREMENTS.........................................................................................................................18

EXTERNAL CONTROLS ...............................................................................................................................................18

11.0 COMMISSIONING AND TESTING.......................................................................................................................19

WATER CONNECTIONS..............................................................................................................................................19

TEMPERATURE ADJUSTMENT PROCEDURE ................................................................................................................19

12.0 MAINTENANCE ..............................................................................................................................................20

MAINTENANCE SCHEDULE ........................................................................................................................................20

DRAINING DHW WATER SYSTEM ...............................................................................................................................20

REFILLING THE SYSTEM .............................................................................................................................................20

RELIEF VALVE............................................................................................................................................................20

CLEANING PLATE GASKETS ........................................................................................................................................21

ASSEMBLY ................................................................................................................................................................21

PROCEDURE .............................................................................................................................................................22

13.0 FAULT FINDING ..............................................................................................................................................24

HEAT EXCHANGER PLATE PACK ASSEMBLY.................................................................................................................24

EXCESSIVE PRESSURE DROPS.....................................................................................................................................24

LEAKAGE ..................................................................................................................................................................24

DECREASE IN THE PERFORMANCE..............................................................................................................................24

14.0 DECLARATION OF CONFORMITY.......................................................................................................................25