A GUIDE TO COMMISSIONING

4

LOMA Superscan Micro ISC

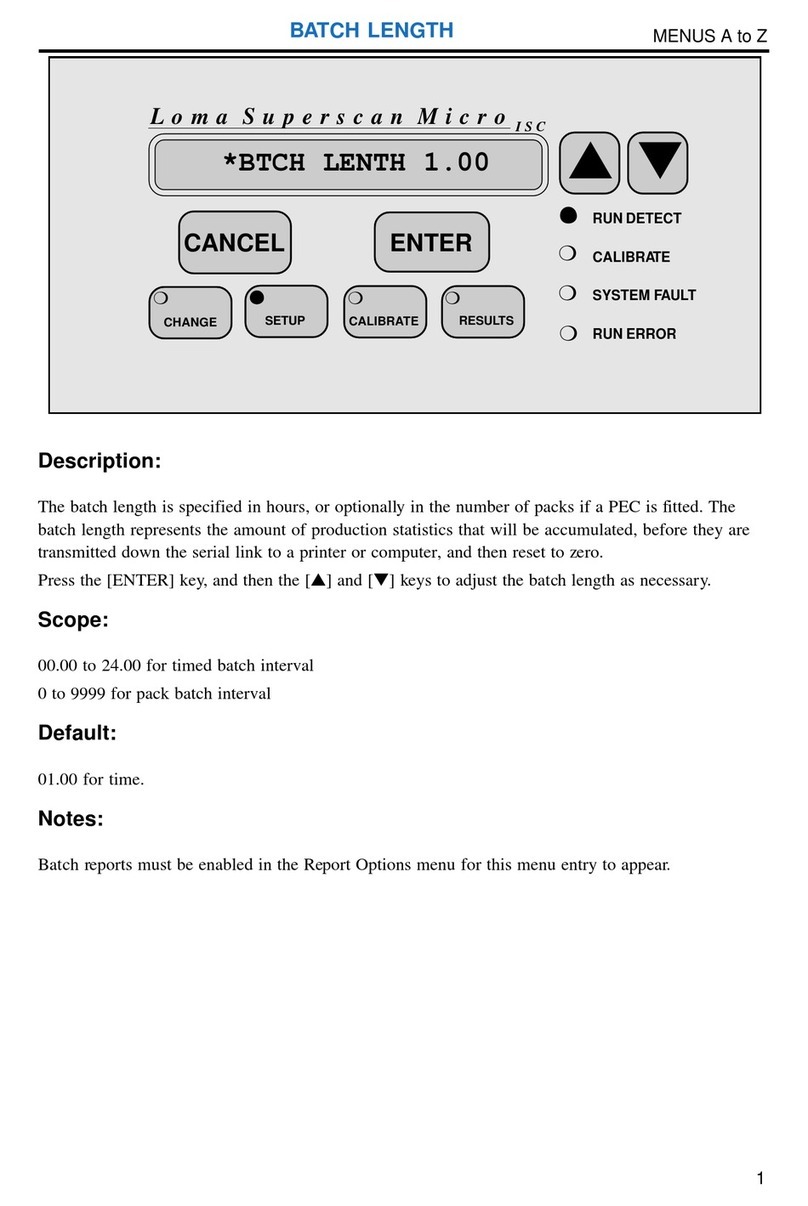

parameters use the [▲] and [▼] keys to move to the parameter (ie. to move up or down the

configuration menu), and then press the [ENTER] key so that the [▲] and [▼] keys will alter the

parameter (notice how the “✱” moves to the right when the display is in parameter edit mode). Once

the correct parameter has been entered, simply press the [ENTER] key again to save the value.

Move down through the Configuration menu now, making adjustments as required by your

application:

TYPE: Select either CONVEYOR, FREEFALL, PIPELINE or PHARM depending

upon your system configuration.

UNITS: Select METRIC or IMPERIAL as preferred.

PHOTO EYE: Select YES if a photo eye has been wired to the control board.

COIL GAP: Enter the Coil Gap as shown on the machine details plate (inside control

box), or by reference to Table 1 below.

PEC LEN: If the entry Photo Eye = Yes has been made, this entry will appear, and a

value must be entered. The PEC Length is the distance from the centre line

of the photo eye to the leading face of the detector plus the Rx distance

(again shown on the machine details plate).

FLTR RES: Enter the filter resistor value as fitted on the main control board. Brown-

plastic plug in module. Remove top to read value.

SPD MODE: Select FIXED, unless your system is vari-speed or free-running. For

variable speed systems select VARI, and for free-running FRUN. If in

doubt about the required selection, refer to the Principles of Operation

section.

BELT SPD: If fixed speed mode has been selected this entry will appear, in which case

enter the belt speed.

CTB CNST: If variable speed mode has been selected this entry will appear, in which

case enter the CTB constant (the CTB constant is the number of pulses per

metre/foot of belt travel from the shaft encoder in vari-speed applications -

see note on vari-speed at the end of this section).

SENSITIVITY: Select the required level of sensitivity to be adopted during auto-

calibration. The higher the setting the more sensitive the detector, but the

more prone it will be to false rejects if the product effect varies (phase

dispersion). We recommend HI for most applications.

AUTOCAL: Select the desired auto-calibration period:

Photo Eye No Photo Eye

Short 8 packs 20 seconds

Long 20 packs 1 minute

Extra Long n/a 2 minutes

Short is recommended for most applications, provided that at least eight

packs can be passed during a calibration cycle.

COMMISSIONING GUIDE