❍

❍

❍

❍

❍❍❍

CALIBRATE

CHANGE RESULTS

RUN DETECT

CALIBRATE

SYSTEM FAULT

RUN ERROR

▼▲

I S C

L o m a S u p e r s c a n M i c r o

❍SETUP

ENTERCANCEL

9

MENUS A to Z

Description:

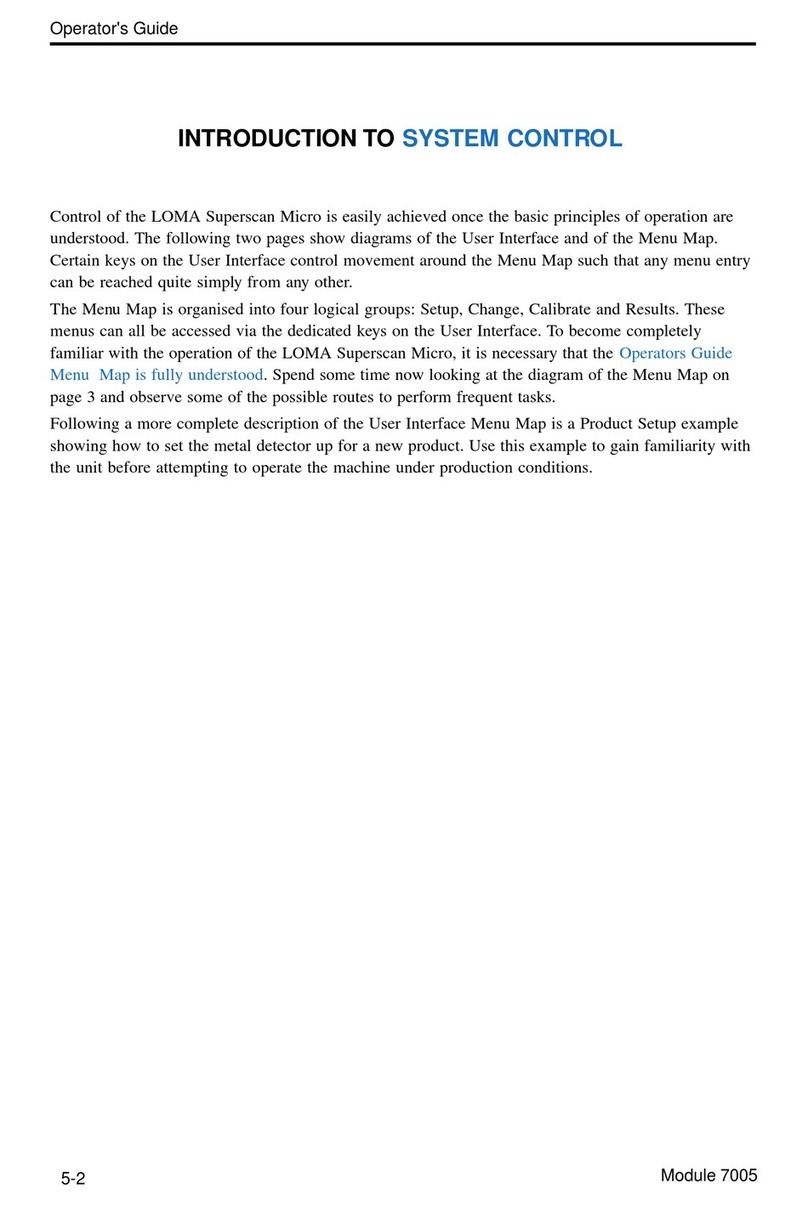

Clearing a system fault will turn the system fault LED and Fault relay off, providing the fault is no

longer occurring. If the fault is active, ie. still happening, then the system fault will immediately come

back putting the fault LED and relay back on.

System faults are usually an indication of a serious malfunction with the equipment, and must

therefore be investigated promptly. Refer to the section on Error/Fault Logging for full details about

system faults, and what to do if you have one on your system.

Press the [ENTER] key to clear any system faults.

Notes:

On failsafe systems, the fault relay is typically wired into the conveyor or reject so that no product

can pass down the line in the event of a system fault.

Clearing the faults as described here will reset the LED fault indicator and the internal fault relay, but

the details in the fault log will not be cleared. These are maintained by the system for Loma Customer

Service Engineer reference.

CLEAR FAULTS?

●

●

●

CLEAR FAULTS