Table of Contents

Introduction ................................................................................................................................................. 1

About this guide ..................................................................................................................................... 2

Organisation ............................................................................................................................................ 2

Document Change Control ................................................................................................................. 3

Document Key ........................................................................................................................................ 3

Copyright and Acknowledgements................................................................................................... 4

Loma Systems.......................................................................................................................................... 5

Safety First .................................................................................................................................................... 7

Safety Awareness ................................................................................................................................... 9

EC Declaration of Conformity.............................................................................................................. 9

Safety Warnings .................................................................................................................................... 10

Safety Labels ......................................................................................................................................... 12

Safety Guards........................................................................................................................................ 13

Responsibilities and Disclaimer .......................................................................................................... 13

Safety Measures.................................................................................................................................... 14

Intended Use of the Machine ............................................................................................................ 14

Noise Levels ........................................................................................................................................... 15

End of Life Treatment........................................................................................................................... 15

Emergency Procedures....................................................................................................................... 15

Quality Assurance ................................................................................................................................ 16

ISO9000 ................................................................................................................................................... 17

End User Licence Agreement ............................................................................................................ 17

Introduction to your X5c X-Ray Inspection System.......................................................................... 19

Getting Started ......................................................................................................................................... 23

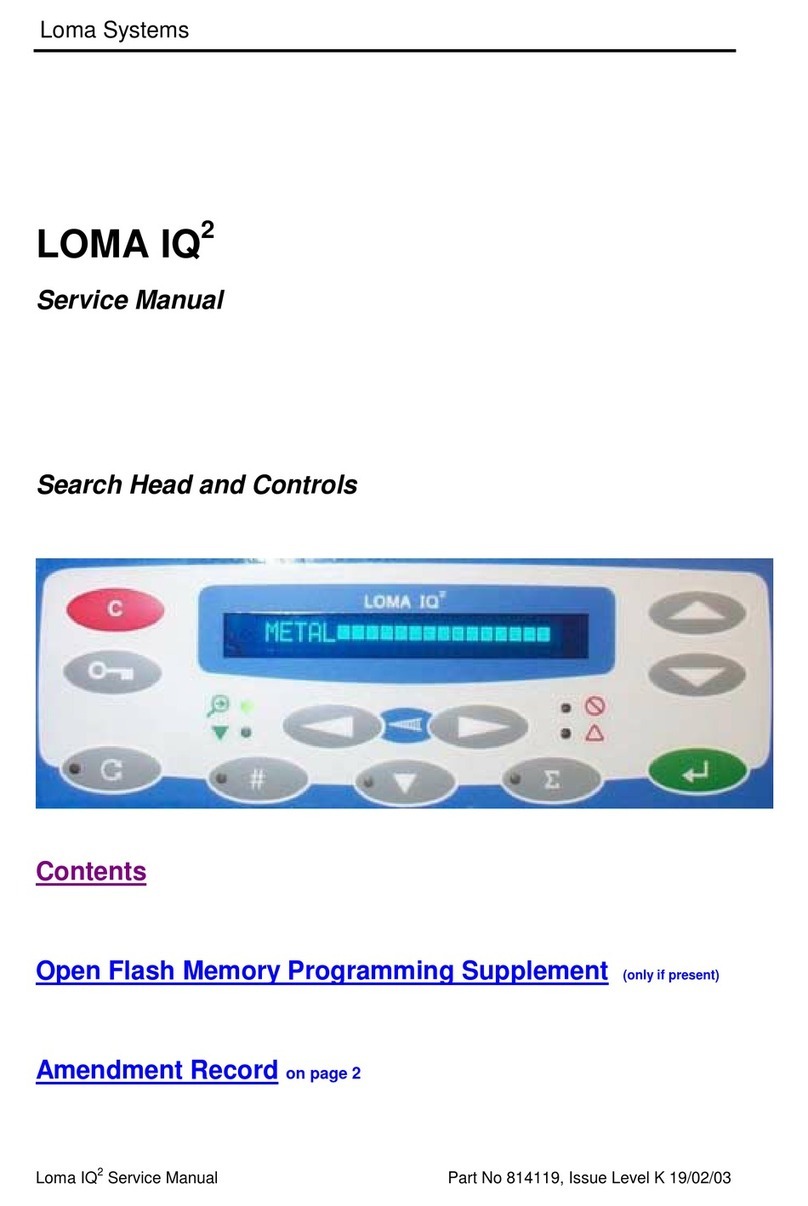

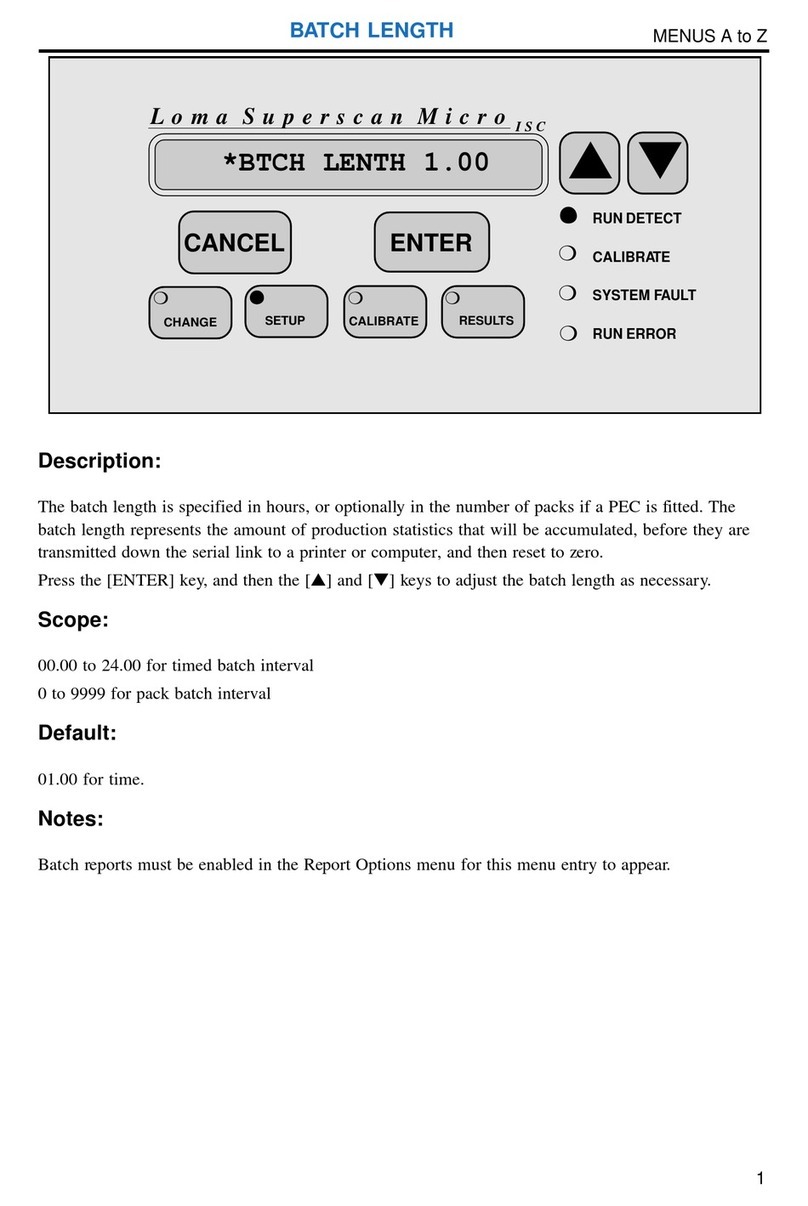

The Front Panel...................................................................................................................................... 23

Control Panel......................................................................................................................................... 24

Isolator Switch........................................................................................................................................ 25

Starting and Stopping.......................................................................................................................... 25

To Log In and Out ................................................................................................................................. 28

User Access............................................................................................................................................ 29

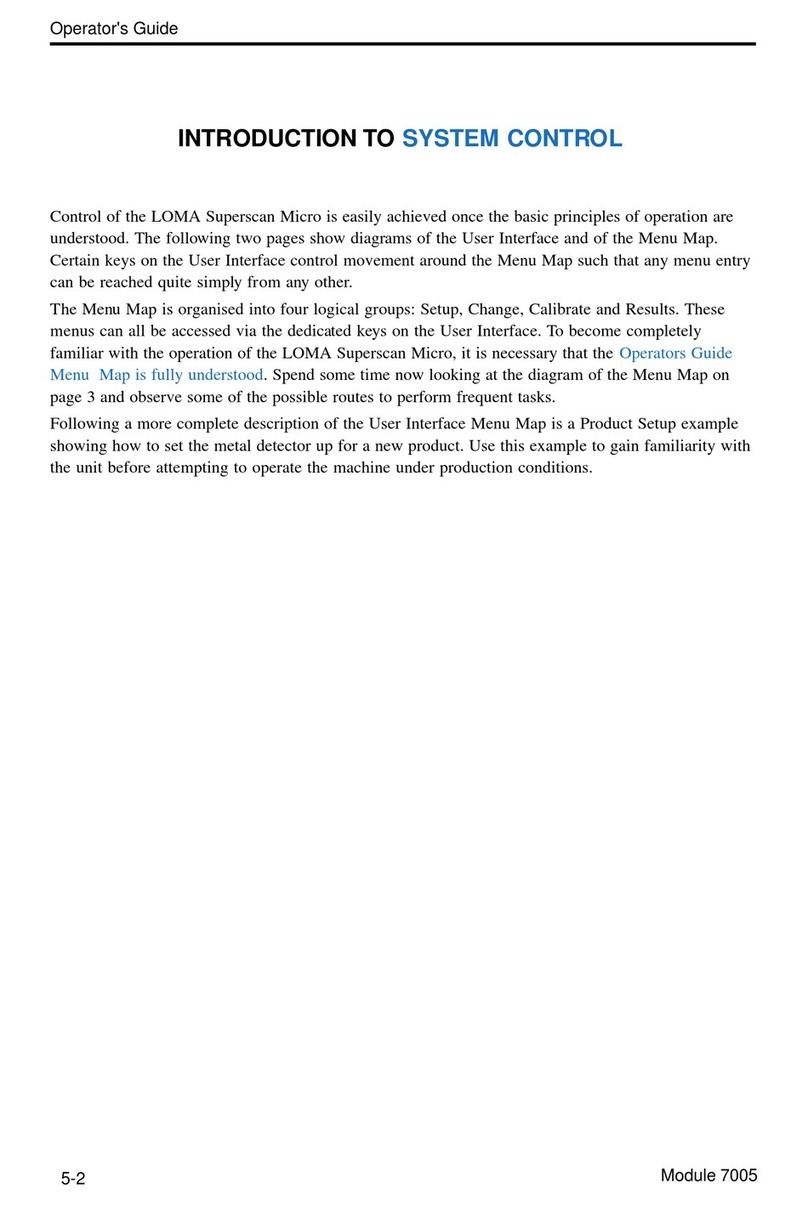

User Interface............................................................................................................................................ 31

General Navigation ............................................................................................................................. 31

Main Run ................................................................................................................................................ 32

Product Menus...................................................................................................................................... 34

GOTO.......................................................................................................................................................... 36

Access Level.......................................................................................................................................... 36

Statistics .................................................................................................................................................. 37

Totals ....................................................................................................................................................... 38

Current Totals......................................................................................................................................... 39

Inspection............................................................................................................................................... 40