Obere Schloßstr.131

73553 Alfdorf

07172 / 93730-0

Fax 07172 /93730-22

E-Mail: info@lorenz-sensors.com

Technical changes reserved

Internet: www.lorenz-sensors.com

Contents

1Read First.............................................................................................................................................. 4

1.1 Safety and Caution Symbols.......................................................................................................... 4

1.2 Intended Use.................................................................................................................................. 4

1.3 Dangers.......................................................................................................................................... 4

1.3.1 Neglecting of Safety Notes ..................................................................................................... 4

1.3.2 Remaining Dangers ................................................................................................................ 4

1.4 Reconstructions and Modifications ................................................................................................ 4

1.5 Personnel ....................................................................................................................................... 4

1.6 Warning Notes ............................................................................................................................... 4

2Term Definitions .................................................................................................................................... 5

2.1 Terms ............................................................................................................................................. 5

3Product Description ............................................................................................................................... 5

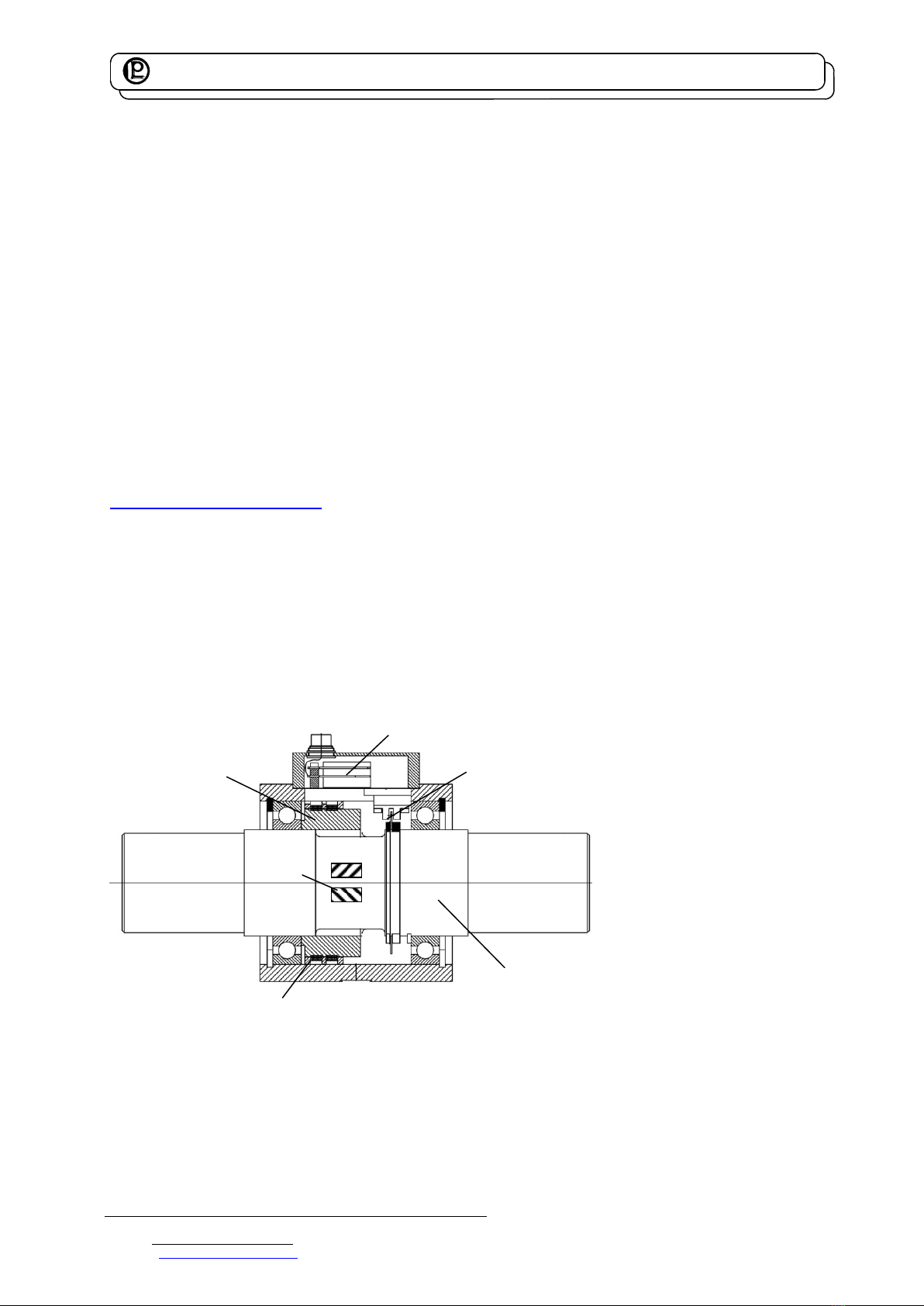

3.1 Mechanical Setup........................................................................................................................... 5

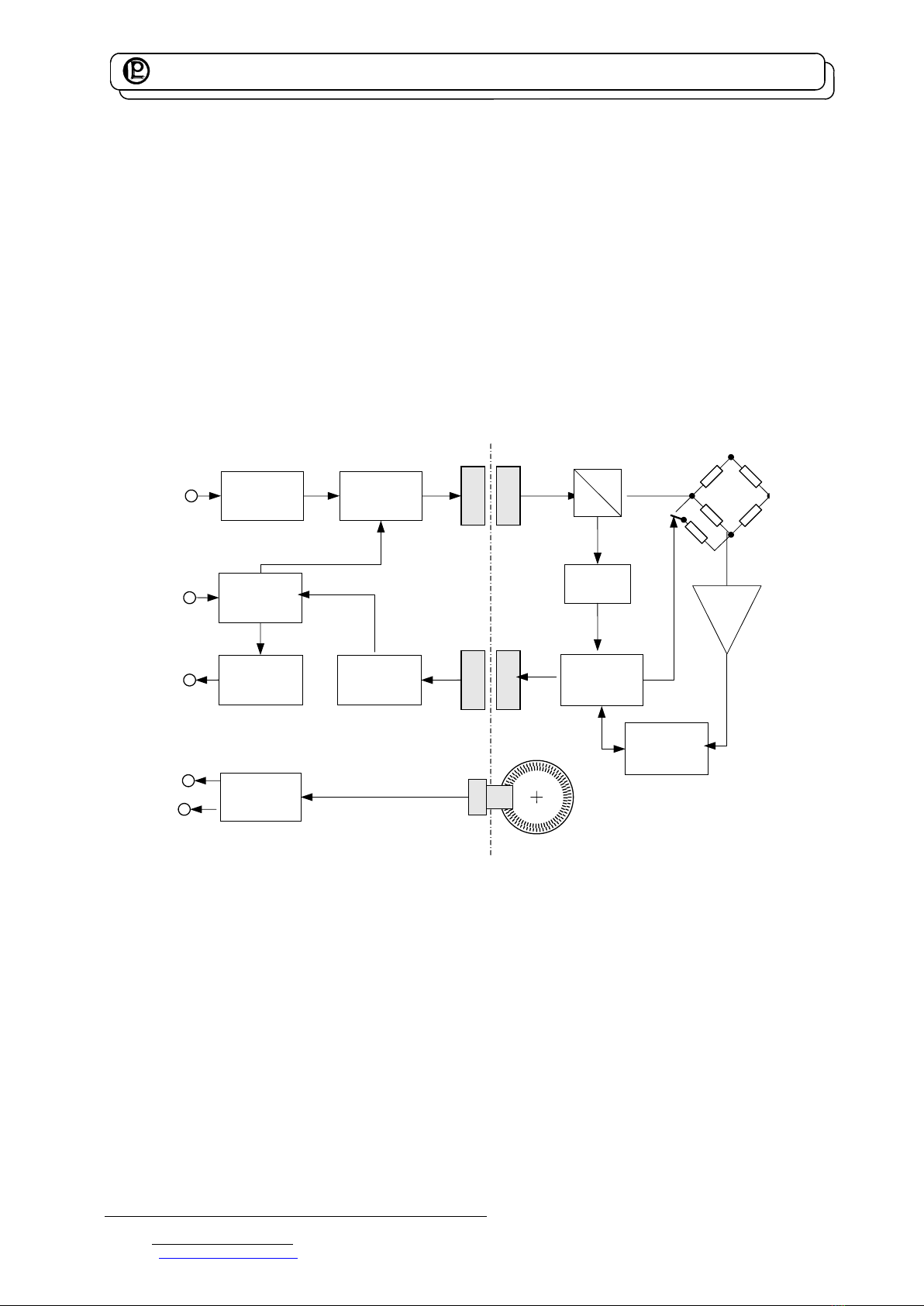

3.2 Electrical Setup .............................................................................................................................. 6

3.2.1 Sensors with Analog Output ................................................................................................... 6

4Mechanical Assembly............................................................................................................................ 7

5Electrical Connection............................................................................................................................. 8

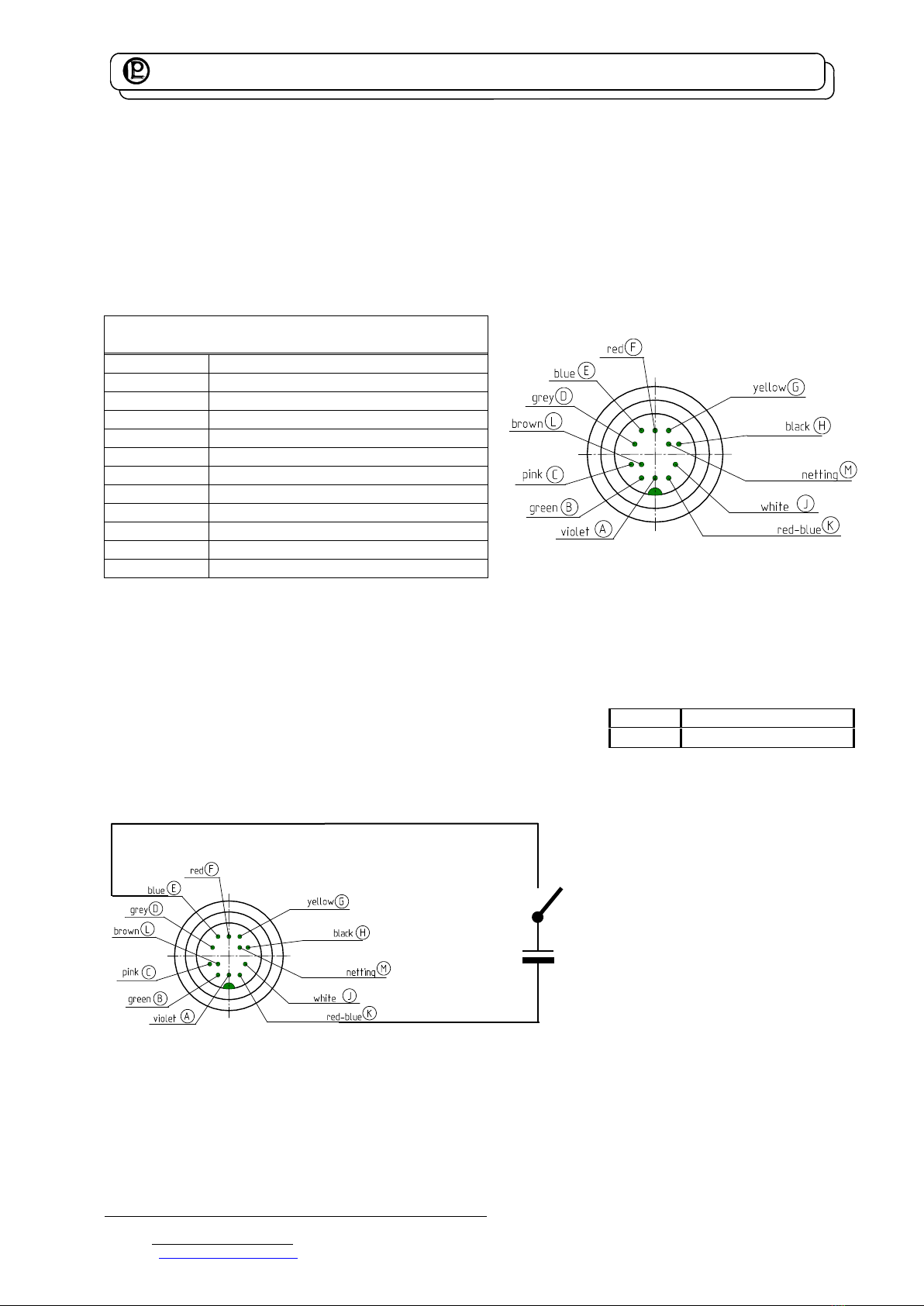

5.1 Pin Connection............................................................................................................................... 8

5.1.1 Standard Version .................................................................................................................... 8

5.2 Calibration Control ......................................................................................................................... 8

5.2.1 Calibration Control at Analog Output ...................................................................................... 8

5.3 Cable.............................................................................................................................................. 8

5.4 Shielding Connection ..................................................................................................................... 9

5.5 Running of Measuring Cables........................................................................................................ 9

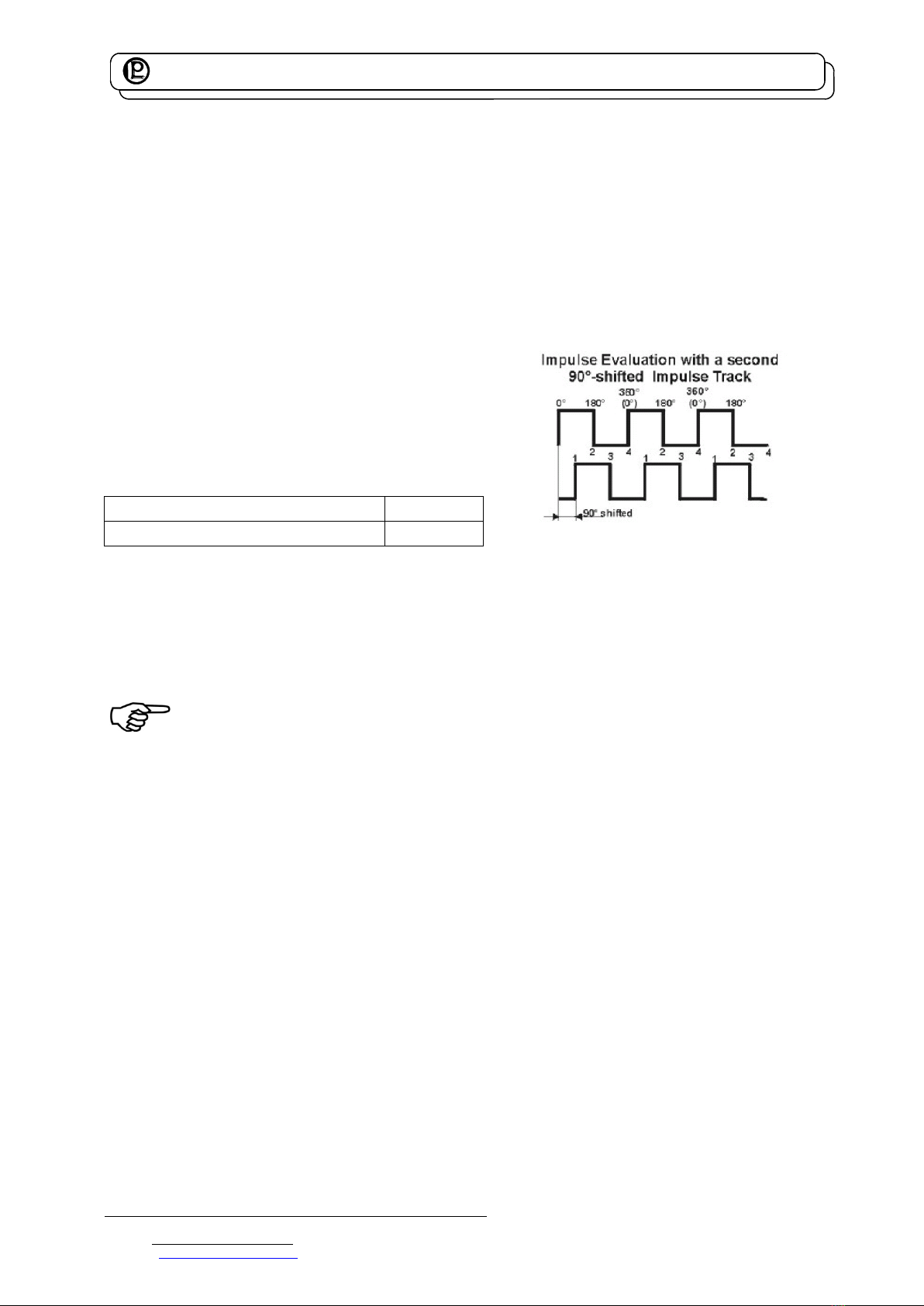

5.6Angle (Option) ................................................................................................................................ 9

6Measuring.............................................................................................................................................. 9

6.1 Engaging ........................................................................................................................................ 9

6.2 Direction of Torque......................................................................................................................... 9

6.3 Static / Quasi-Static Torques ......................................................................................................... 9

6.4 Dynamic Torques ........................................................................................................................... 9

6.4.1 Natural Resonances ............................................................................................................. 10

6.5 Speed Limits ................................................................................................................................ 10

6.6 Disturbance Variables .................................................................................................................. 10

7Maintenance........................................................................................................................................ 10

7.1 Maintenance Schedule ................................................................................................................ 10

7.2 Trouble Shooting.......................................................................................................................... 11

8Decommission..................................................................................................................................... 11

9Transportation and Storage ................................................................................................................ 11

9.1 Transportation .............................................................................................................................. 11

9.2 Storage......................................................................................................................................... 11

10 Disposal ........................................................................................................................................... 12

11 Calibration........................................................................................................................................ 12

11.1 Proprietary Calibration.............................................................................................................. 12

11.2 DKD-Calibration........................................................................................................................ 12

11.3 Re-Calibration........................................................................................................................... 12

12 Data Sheet....................................................................................................................................... 12

13 Literature.......................................................................................................................................... 12