TROUBLESHOOTING

If your tumbler fails to operate correctly, check the following:

Barrel does not turn, turns very slowly, or stops after being

placed on tumbler.

No power to unit. Make sure machine is plugged in

correctly.

Make sure electrical circuit is

operational.

Barrel not installed

correctly. Align barrel correctly.

Barrel too heavy. Do not exceed rated capacity.

Belt slipping. Tighten belt.

Drive belt broken. Remove cover and replace belt.

Motor doesn’t run or

runs intermittently. Replace motor.

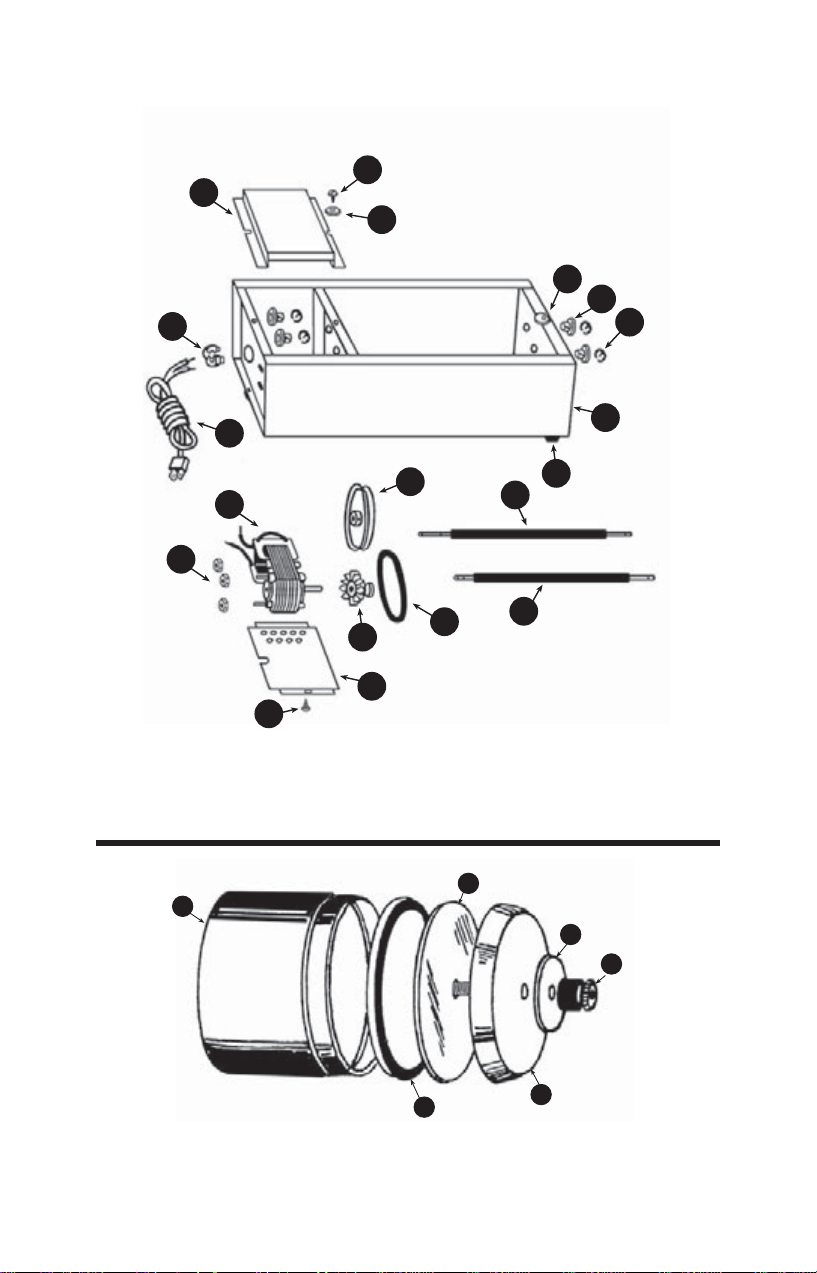

Barrel leaks or barrel lid comes off during operation.

Inner lid not seated

correctly. Make sure inner lid and barrel shoulder

are clean and free of contaminants.

Make sure inner lid is seated on

shoulder inside barrel.

Knurled nut over

tightened. Tighten knurled nut by hand only until

snug. Do not use tools.

Gas build-up in

barrel. Open barrel occasionally to vent gas

that might be formed during tumbling.

Barrel or boot gasket

damaged. Replace damaged barrel or boot gasket.

If you need assistance, please contact:

Lortone Customer Service (425) 493-1600

4