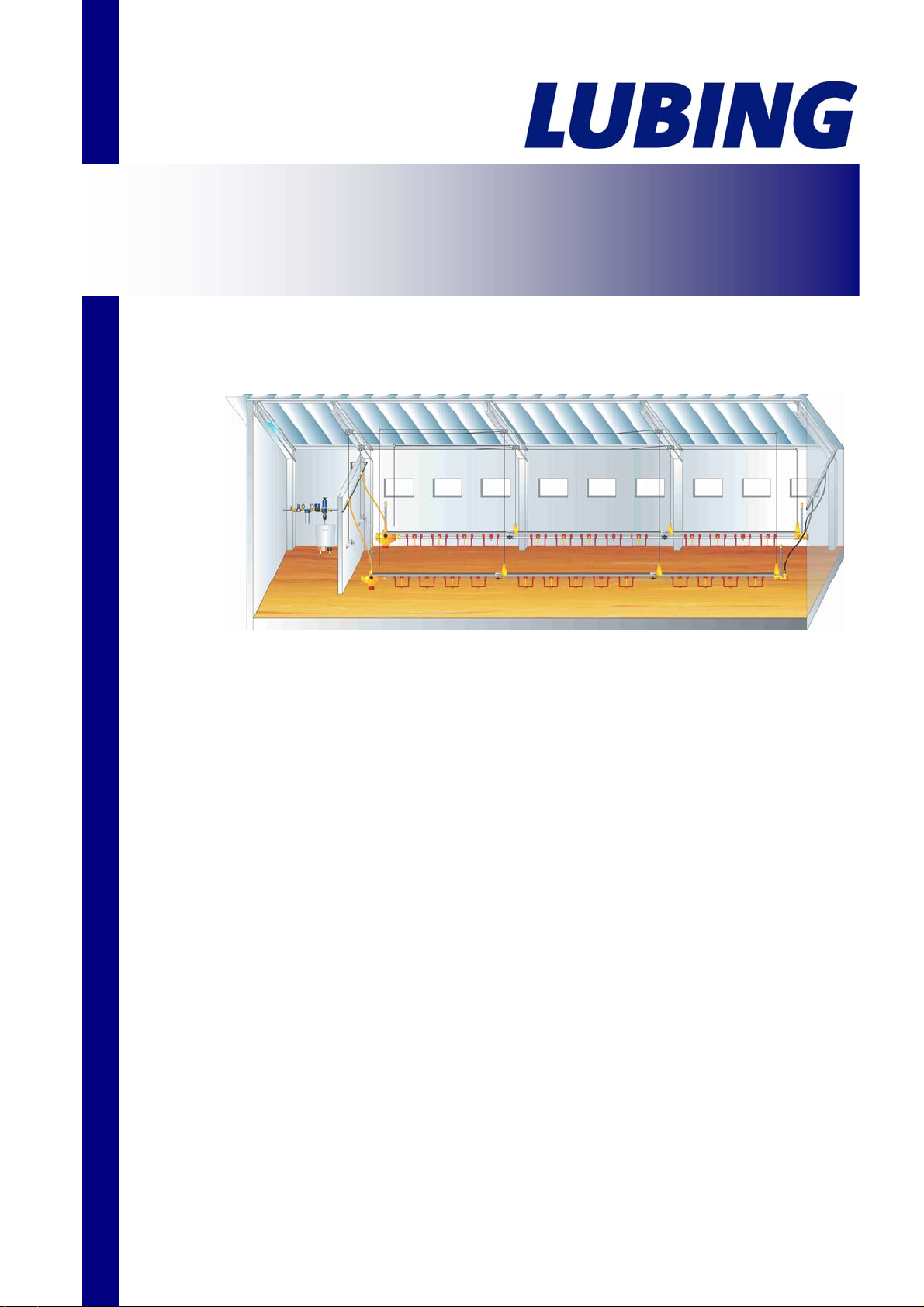

0940-1_M+B-PutentraenkeGB LUBING Floor Watering System

- 3 -

Contents

Manufacturer data ................................................................................................................................... 2

1. Introduction.......................................................................................................................................... 4

1.1 Brief description of LUBING watering systems for floor watering.................................................. 4

1.2 Designated use.............................................................................................................................. 4

2. General information............................................................................................................................. 5

2.1 Warnings and symbols .................................................................................................................. 5

2.2 General safety guidelines.............................................................................................................. 6

2.3 Obligations and liability.................................................................................................................. 6

2.4 Warranty and liability:..................................................................................................................... 7

2.5 Electrical system............................................................................................................................ 7

3. Assembly............................................................................................................................................. 8

3.1 Assembly information..................................................................................................................... 8

3.2 Assembly order.............................................................................................................................. 8

3.3 Spare parts .................................................................................................................................... 8

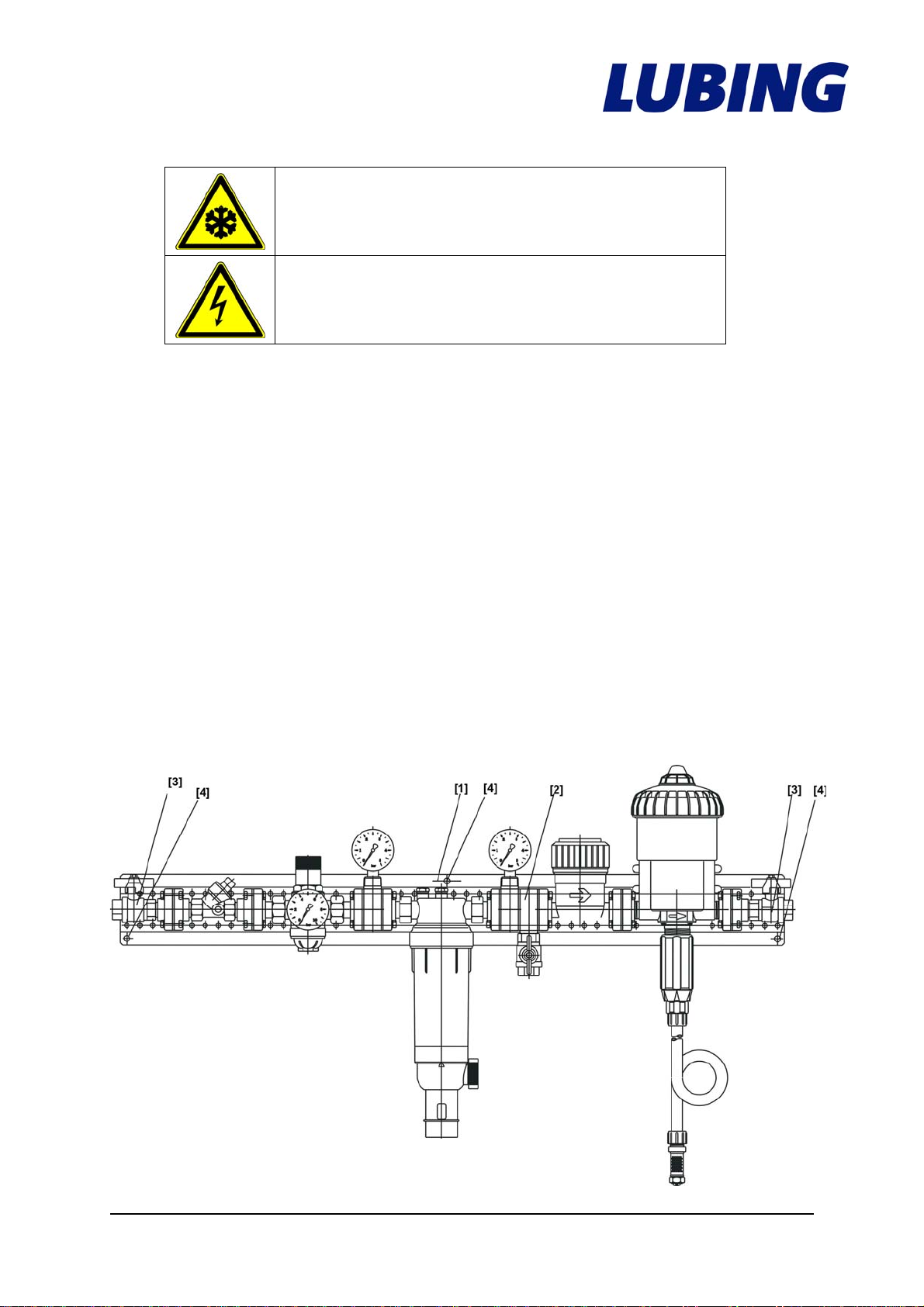

3.4 Assembly overview........................................................................................................................ 9

3.5 Fitting the Main Water Supply...................................................................................................... 10

3.6 Mixer ............................................................................................................................................ 12

3.7 Connection accessories............................................................................................................... 12

3.8 Glued connections....................................................................................................................... 14

3.9 Fitting the drinking line................................................................................................................. 16

3.9.1 Mounting the Hand Winches.................................................................................................17

3.9.2 Mounting the Ceiling Winches............................................................................................... 18

3.10 Pressure Regulator.................................................................................................................... 20

3.12 Breather Unit.............................................................................................................................. 21

4. Operating Instructions ....................................................................................................................... 25

4.1 Adjusting the turkey drinker ......................................................................................................... 26

4.2 Before hutching............................................................................................................................ 28

4.3 Cleaning of the drinking line ........................................................................................................ 28

4.3.1 Cleaning the nipple drinking system of dirt and lime accumulation...................................... 28

4.3.2 Cleaning the nipple drinking system of algaes and accumulations of medicaments............ 30

4.3.3 Cleaning of the dosing system.............................................................................................. 33

4.3.4 Cleaning of the water filter .................................................................................................... 33

4.4 Vaccinating via drinking water..................................................................................................... 35

4.5 Hutching in................................................................................................................................... 36

4.6 While rearing................................................................................................................................ 36

4.7 While fattening............................................................................................................................. 36

4.8 Between the circles...................................................................................................................... 36

4.9 Height table.................................................................................................................................. 37

4.10 Timer for magnetic valve ........................................................................................................... 38

4.11 Attendance and maintenance, fault clearance .......................................................................... 39

Cup is empty.......................................................................................................................................... 39

5. Modification notes.............................................................................................................................. 40