Chapter 1

____________________________________________________________________

_______________________________________________________________________________________

BI7717-11 1409 Multipoint Sampler LumaSense Technologies A/S

Service Manual Page 7 of 28

1.1 Introduction to the Service manual

This Service Manual is intended for the service and maintenance of the 1409

Multipoint Sampler, hereafter referred to as the 1409.

It will provide the service engineer with information about the operating

principle on a technical level and the use of the Service software BZ7006 for

fault finding and testing.

A Service Note that will be published on our web site, http://innova.lumasenseinc.com,

informs any product change that will impair the safety or performance of the

device.

The operation and maintenance procedures are fully described in the Technical Documentation

BE6037 delivered with the 1409 and the service technician must fully acquainted with the

operation of the instrument prior to any attempt to service it.

Due to the complexity of the 1409 the service and repair is only possible

on module level and only a few individual components are made available for

field service.

Handling of the electronic parts must be done with proper ESD equipment to

avoid any possibility of an electrostatic discharge to the components. Modules

returned to LumaSense Technologies A/S for repair/credit will be discarded if

not properly packed in ESD material.

1.2 Introduction to the 1409

1.2.1 The Sampler System

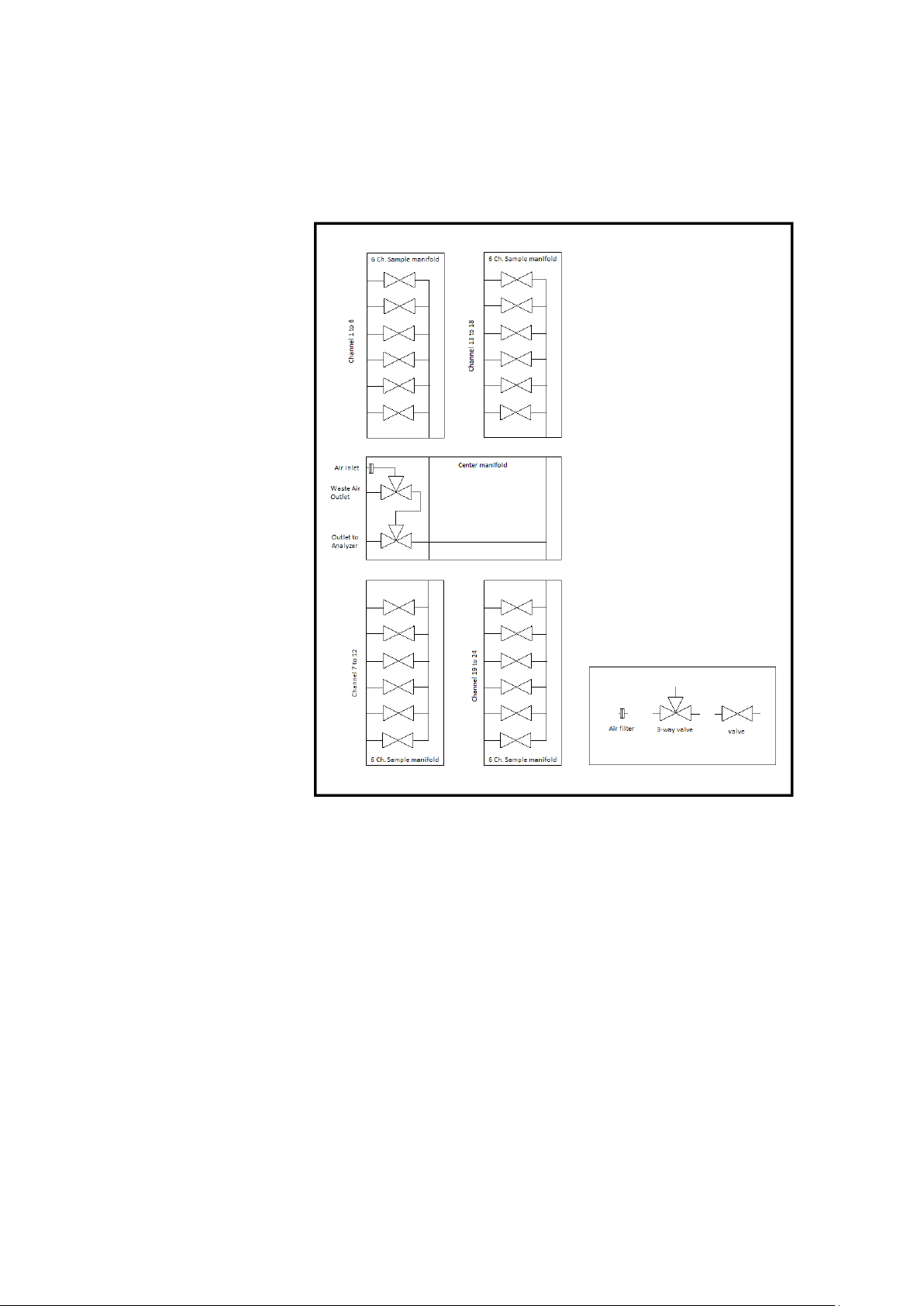

The pneumatic system of the 1409 is shown schematically in Fig.1.1. The sampler system is

constructed of stainless steel (AISI 316) to minimize adsorption of samples.The 1409 is

delivered with 6, 12, or 24 channels. All inlet channels are with a solenoid valve. Each inlet

channel has a tube-mounting stub on the back-plate of the 1409 to connect each channel to

the respective sampling point. The inlet channels converge into one; a three-way valve then

directs the gas sample to the Gas Monitor for analysis, or through the waste-air outlet on the

1409’s back-plate.

An external pump (optional) can be connected in the airway system to the waste air outlet.

The 1409’s sampler system functions efficiently, transporting gas samples from the sampling

point at approximately 4 metres per second. However, this speed depends on the type of

pump, the diameter of the tubing and the length of tubing attached to the 1409. An air-filter is

attached to the end of each sampling tube to keep the samples free of particles.