10DNY

P. 1 / 2 EM-0824 Rev.6

INSTRUCTION MANUAL

MODEL 10DNY

CURRENT LOOP SUPPLY

(with square root extractor)

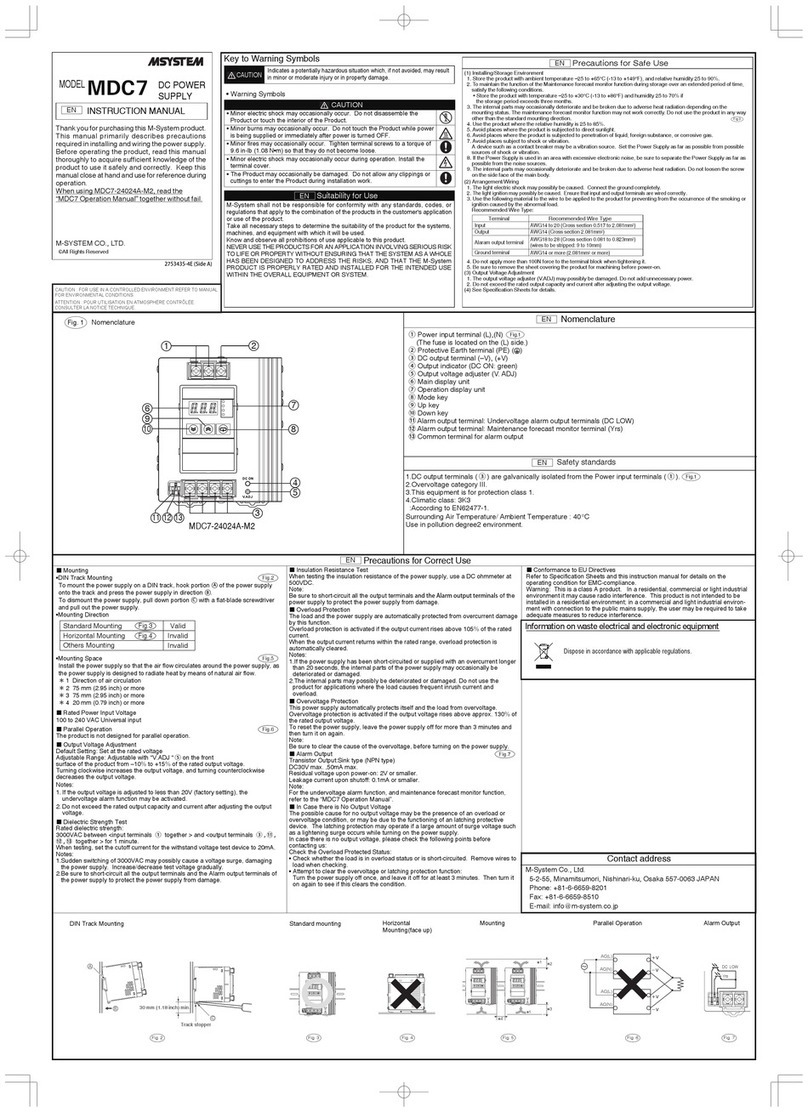

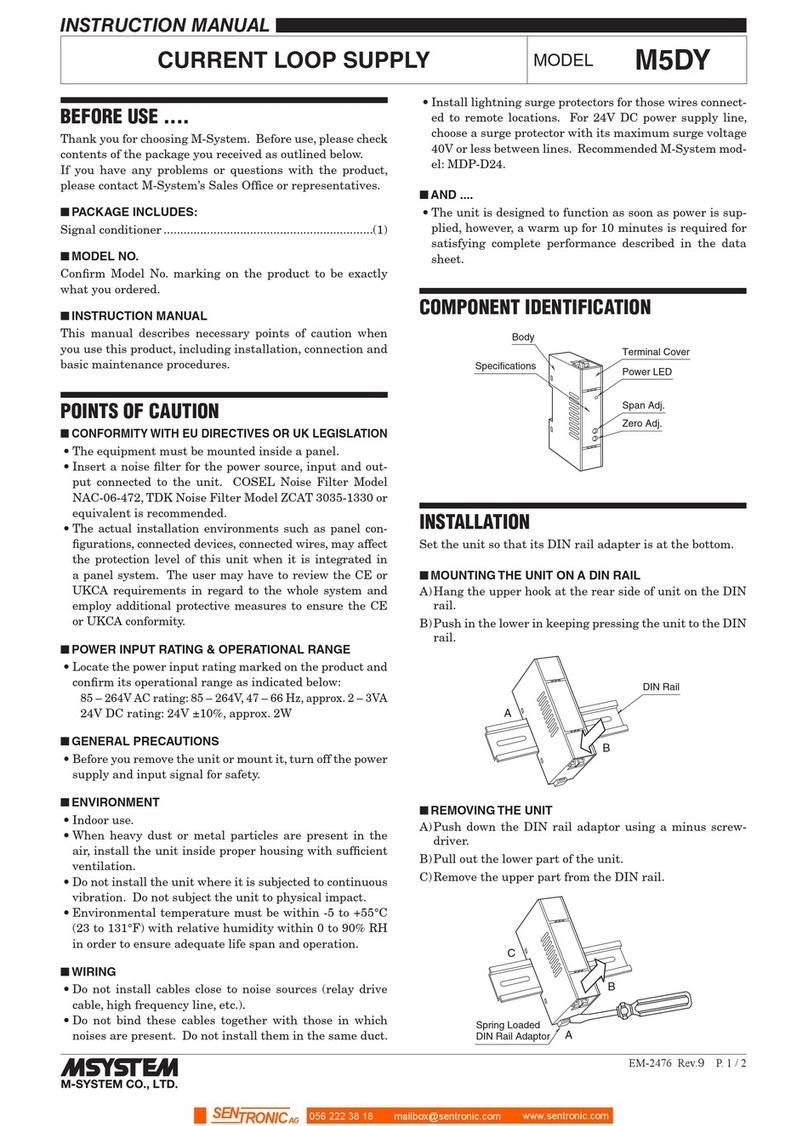

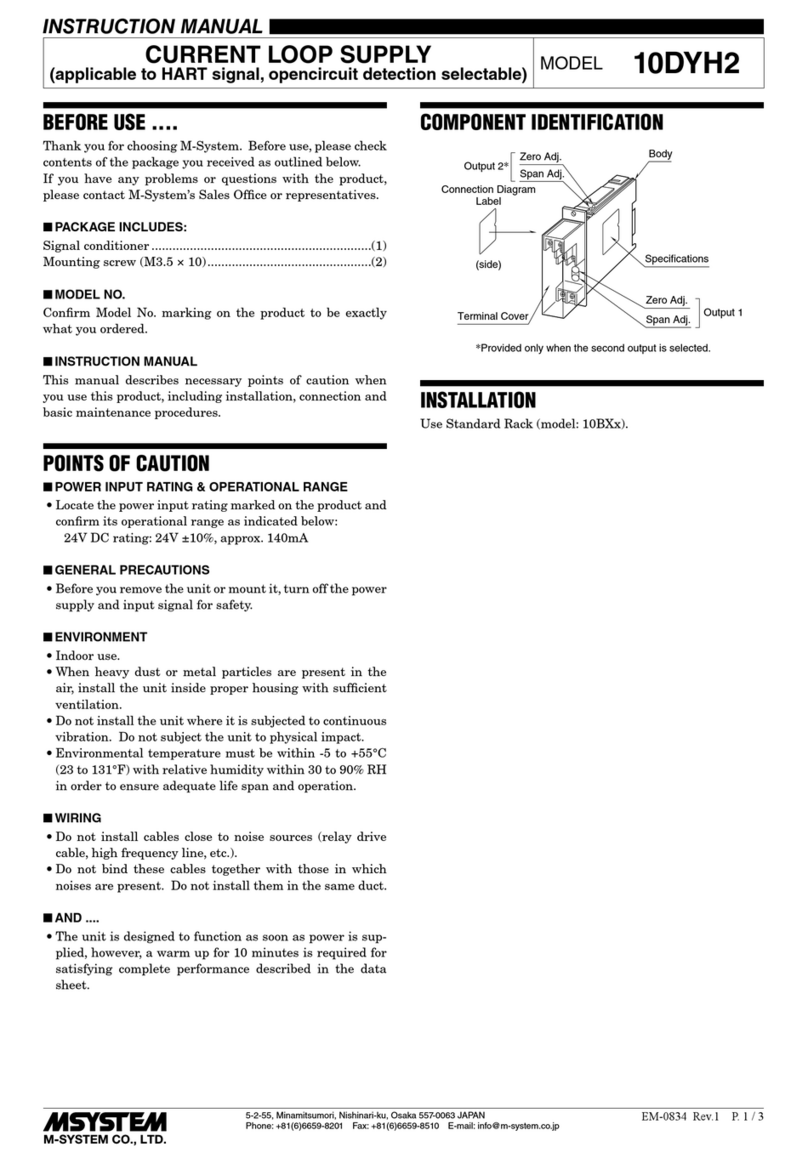

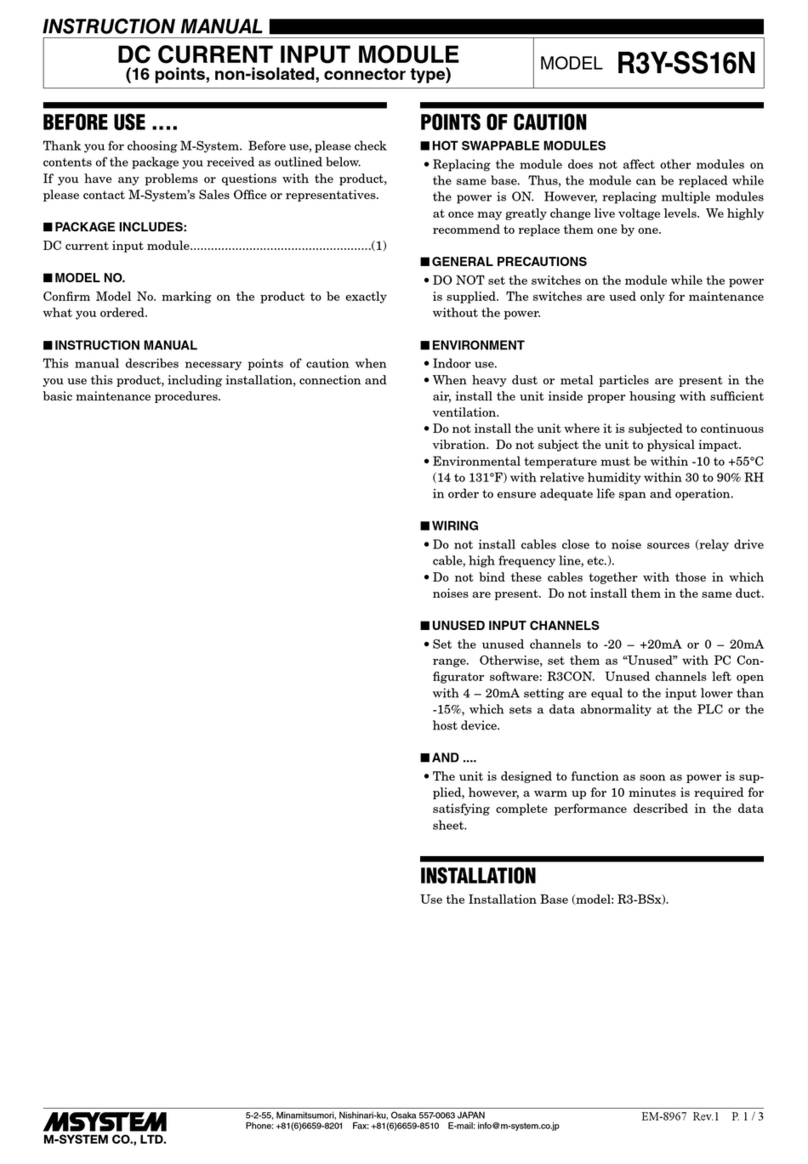

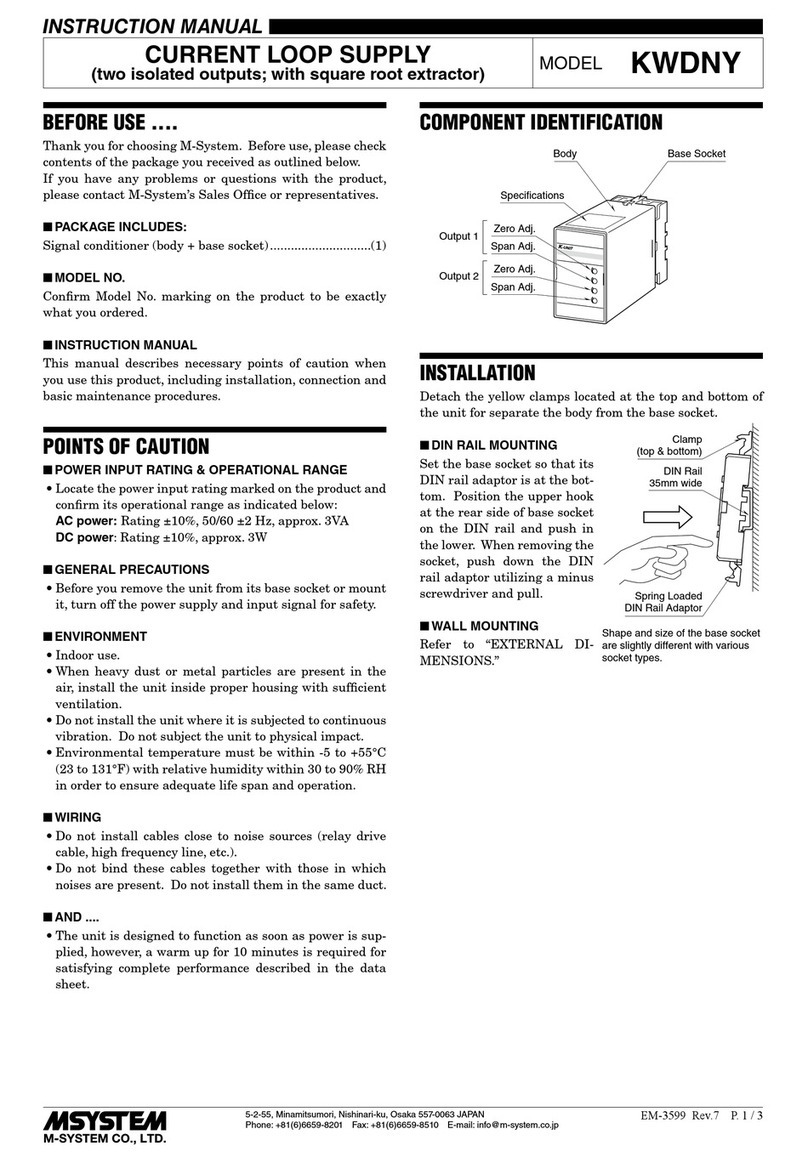

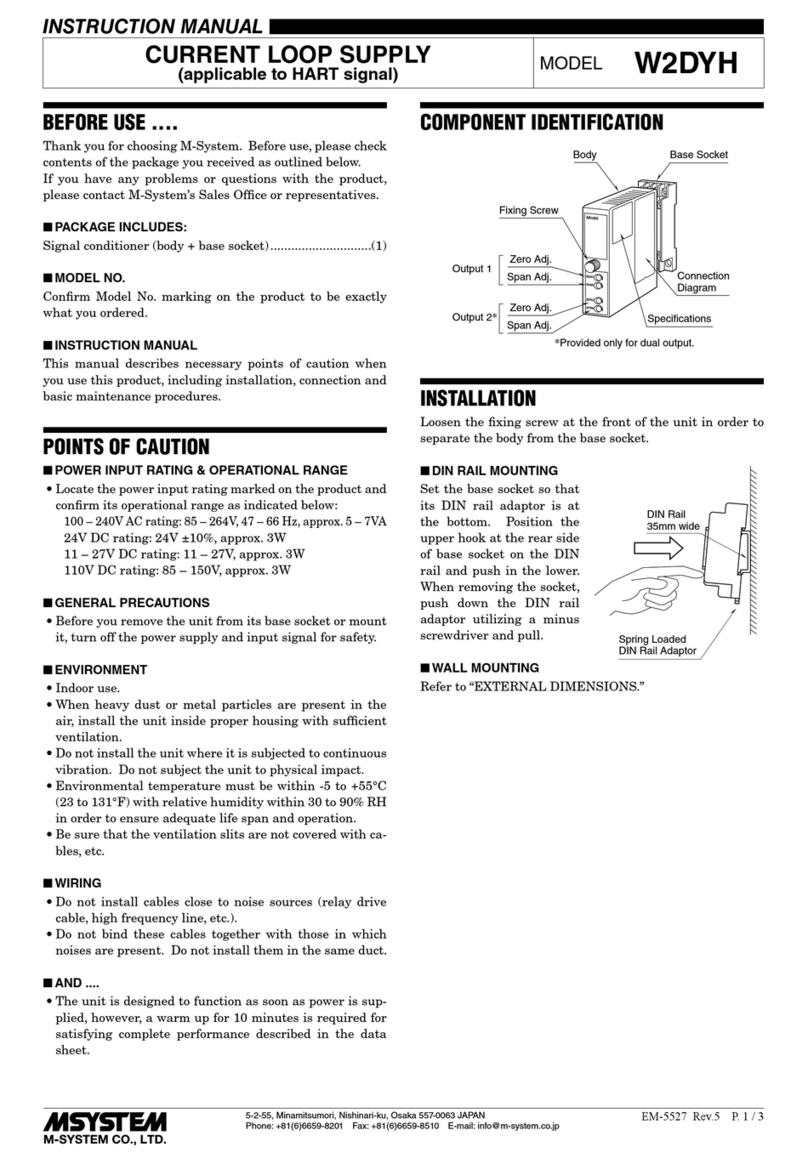

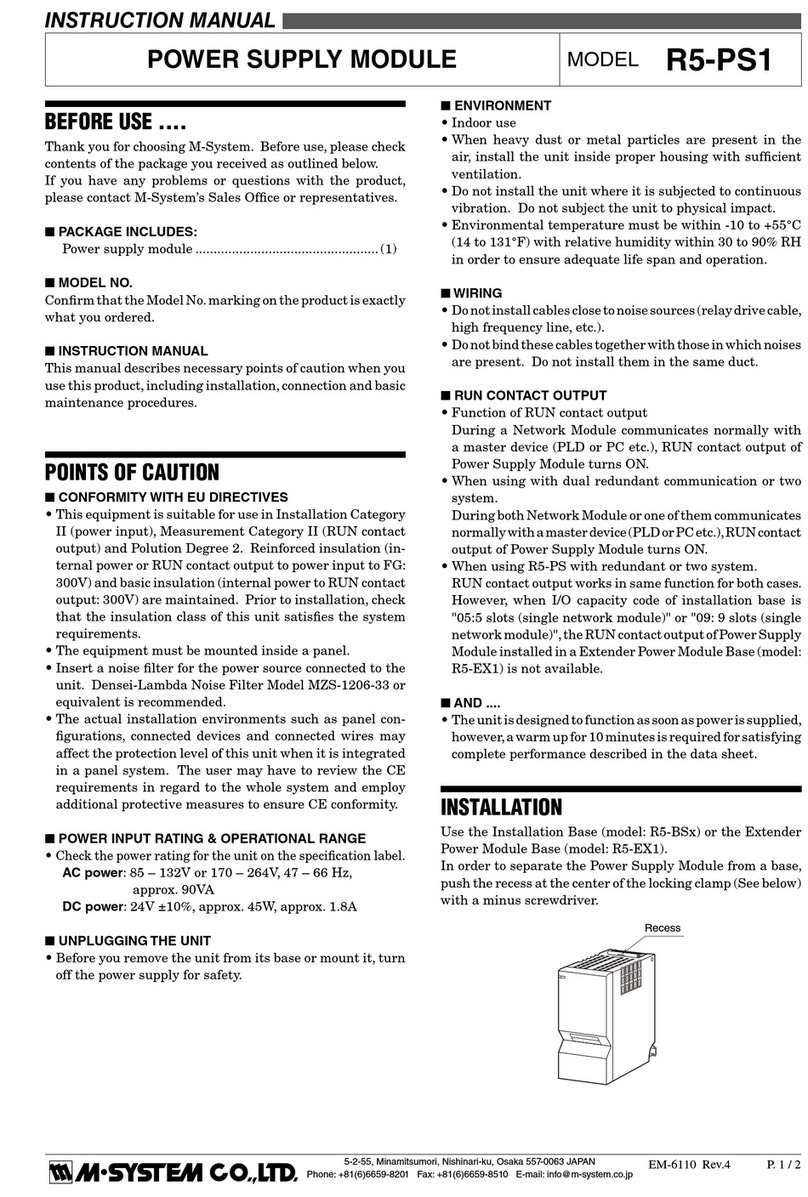

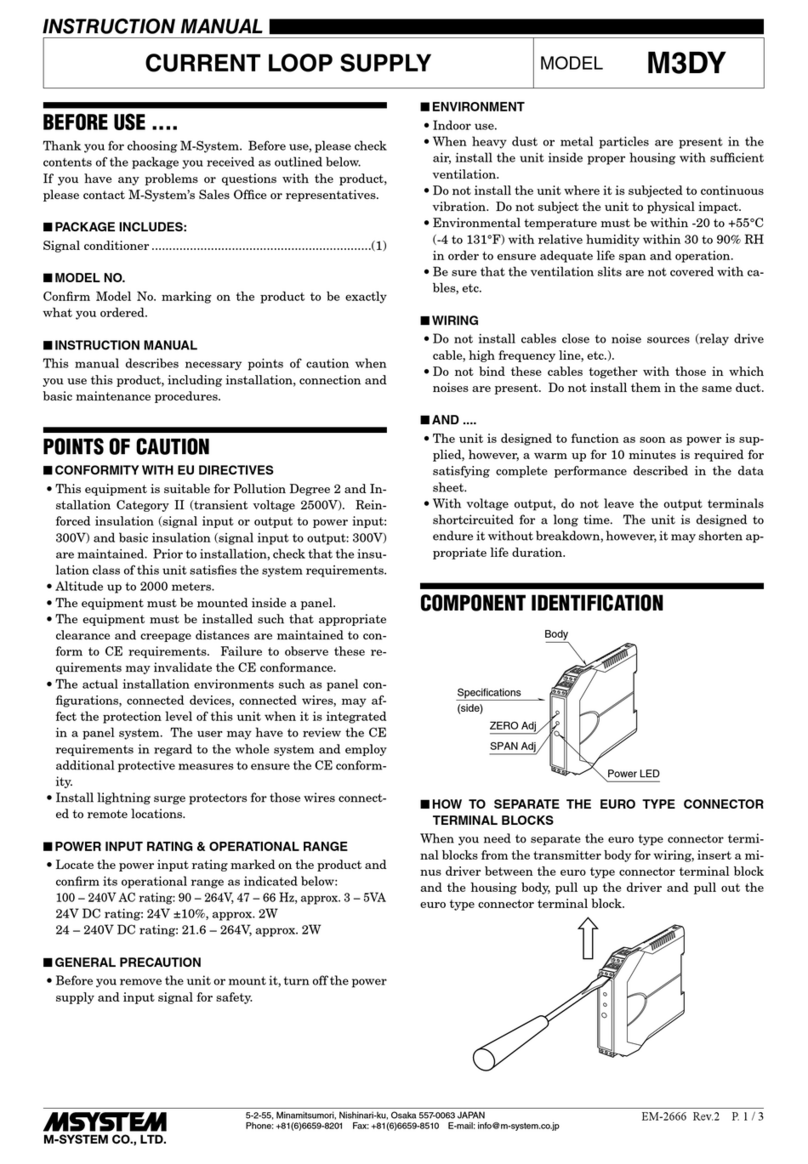

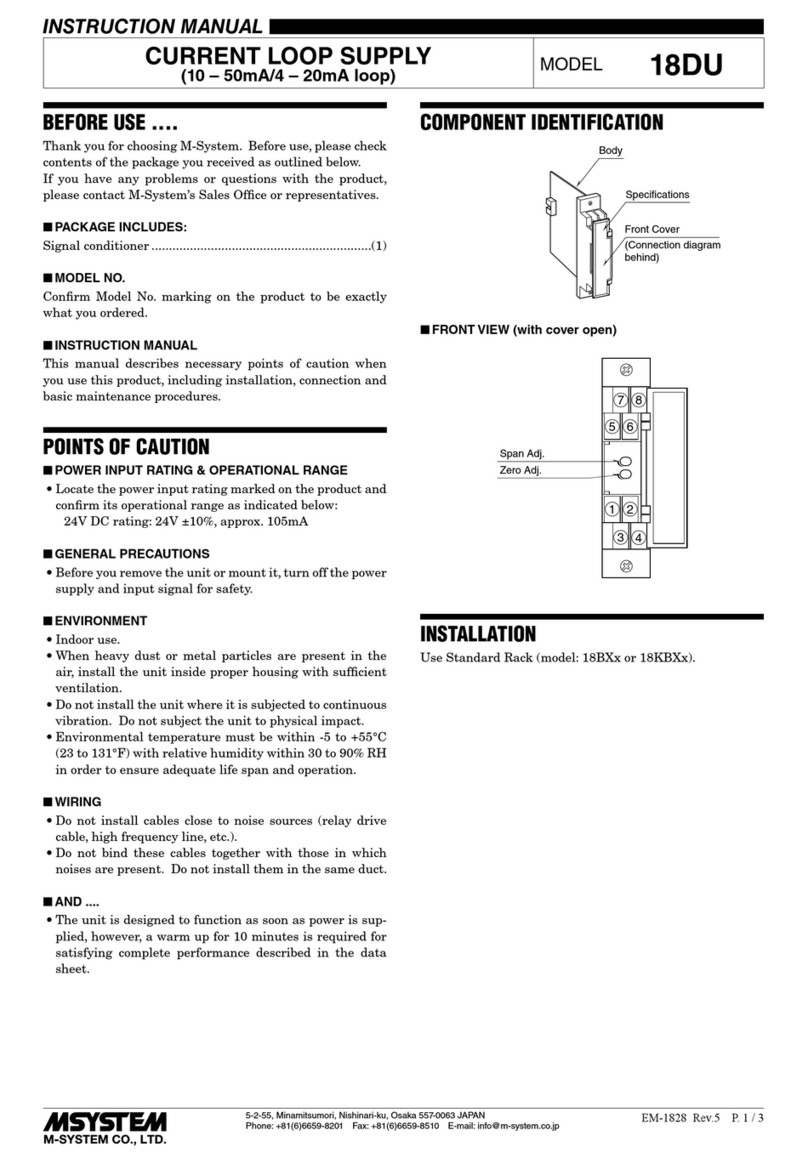

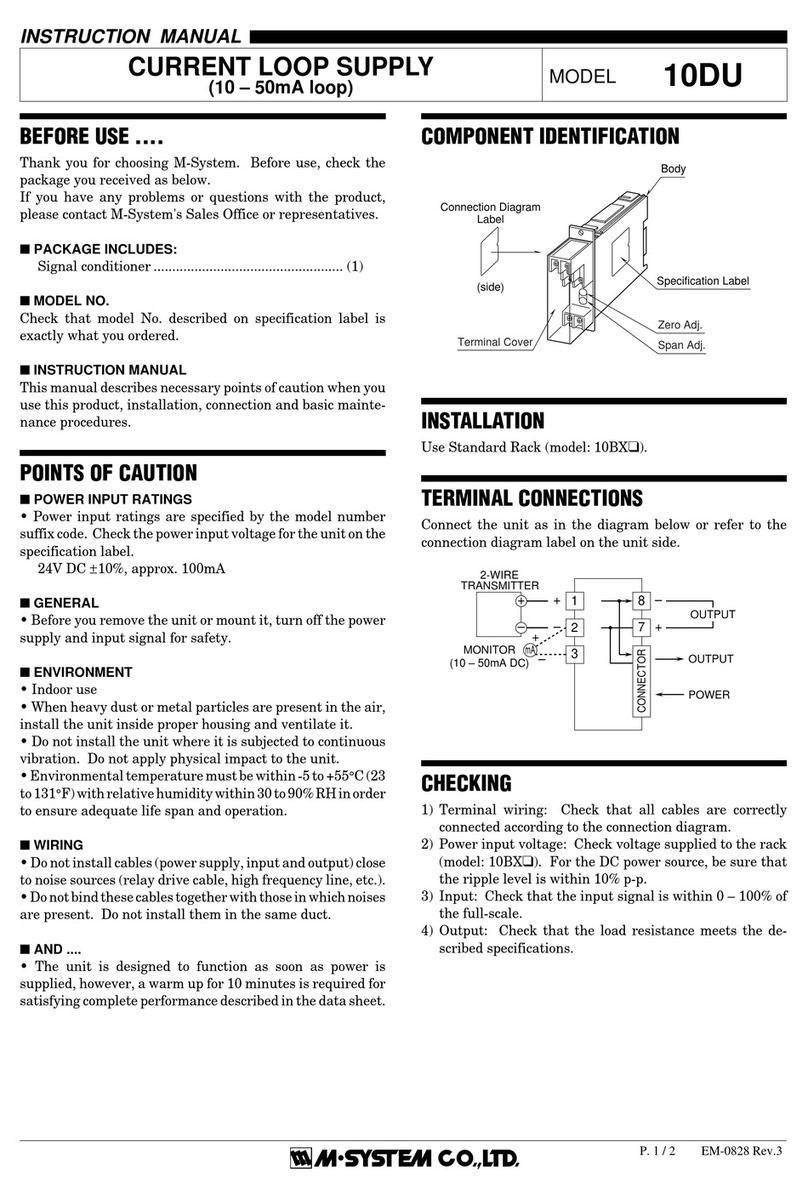

COMPONENT IDENTIFICATION

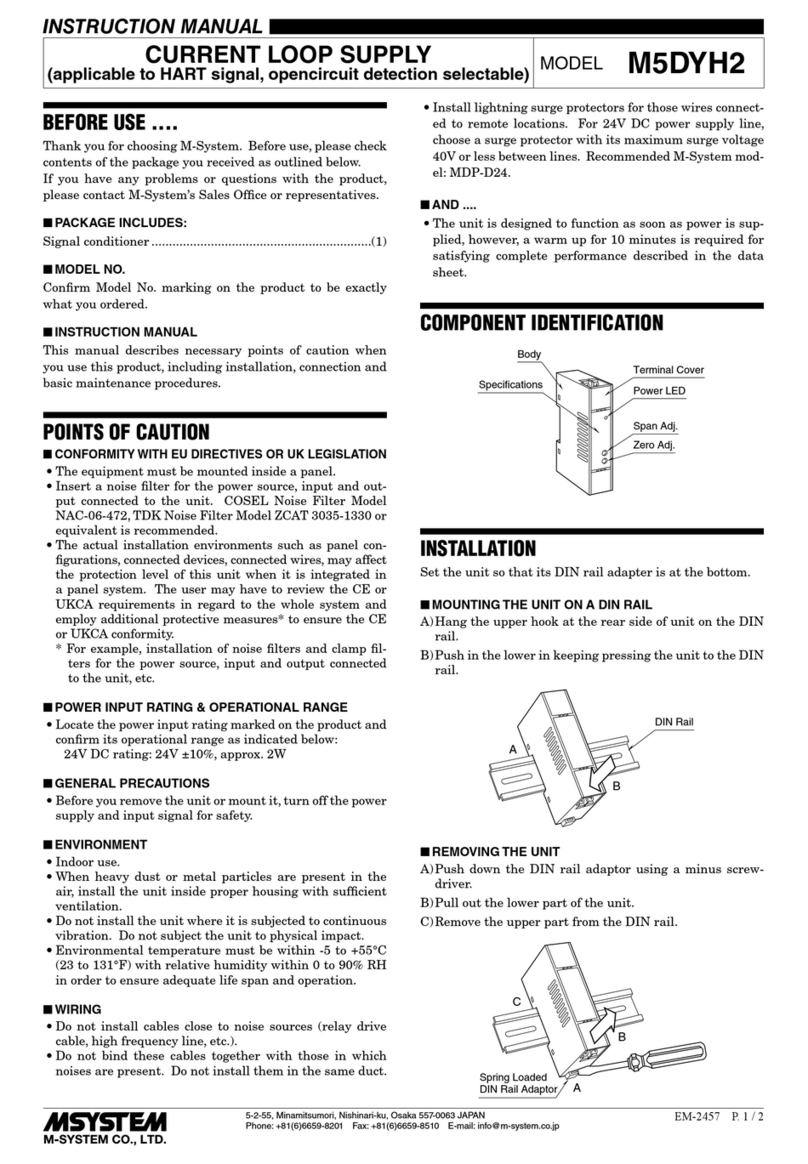

INSTALLATION

Use Standard Rack (model: 10BX❑).

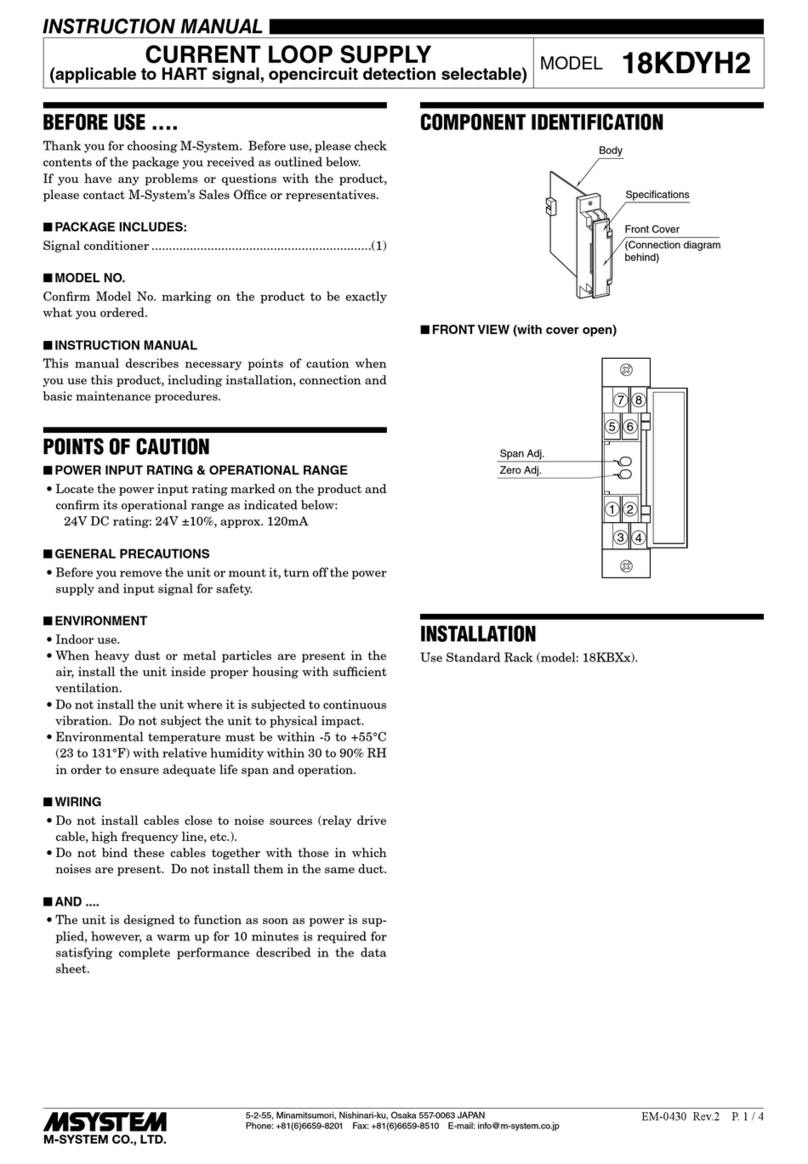

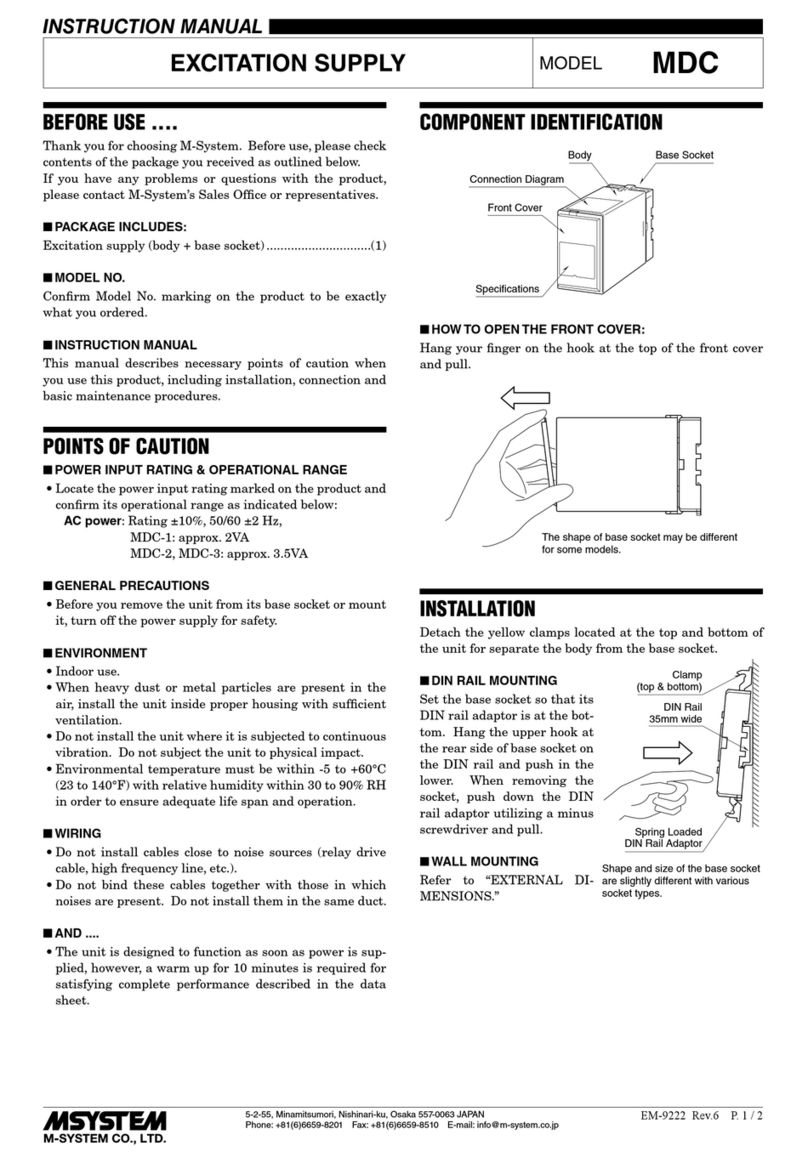

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the

connection diagram label on the unit side.

CHECKING

1) Terminal wiring: Check that all cables are correctly

connected according to the connection diagram.

2) Power input voltage: Check voltage supplied to the rack

(model: 10BX❑). For the DC power source, be sure that

the ripple level is within 10% p-p.

3) Input: Check that the input signal is within 0 – 100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications.

Zero Adj.

Span Adj. Output 1

Body

Specification Label

Connection Diagram

Label

(side)

Zero Adj.

Output 2*Span Adj.

Terminal Cover

*Provided only when the second output is selected.

BEFORE USE ....

Thank you for choosing M-System. Before use, check the

package you received as below.

If you have any problems or questions with the product,

please contact M-System's Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner................................................... (1)

■ MODEL NO.

Check that model No. described on specification label is

exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when you

use this product, installation, connection and basic mainte-

nance procedures.

POINTS OF CAUTION

■ POWER INPUT RATINGS

• Power input ratings are specified by the model number

suffixcode. Checkthepowerinputvoltagefortheunitonthe

specification label.

24V DC ±10%, approx. 60mA with voltage output 1

approx. 90mA with current output 1

■ GENERAL

• Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing and ventilate it.

• Do not install the unit where it is subjected to continuous

vibration. Do not apply physical impact to the unit.

•Environmentaltemperaturemustbewithin-5to+55°C(23

to131°F)withrelativehumiditywithin30to90%RHinorder

to ensure adequate life span and operation.

■ WIRING

•Donotinstallcables(powersupply,inputandoutput)close

to noise sources (relay drive cable, high frequency line, etc.).

•Donotbindthesecablestogetherwiththoseinwhichnoises

are present. Do not install them in the same duct.

■ AND ....

• The unit is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required for

satisfyingcompleteperformancedescribed inthedatasheet.

+

–

1OUTPUT 1

7

8

+

–OUTPUT 2

5

6

CONNECTOR

*1 output type has the output 1 connected to the

card-edge connector in parallel.

OUTPUT 2*

POWER

3

+

–2

2-WIRE

TRANSMITTER

+

–

V

MONITOR

(1 – 5V DC)