10DYH2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-0834 Rev.1 P. 3 / 3

WIRING INSTRUCTIONS

■SCREW TERMINAL

Torque: 0.8 N·m

CHECKING

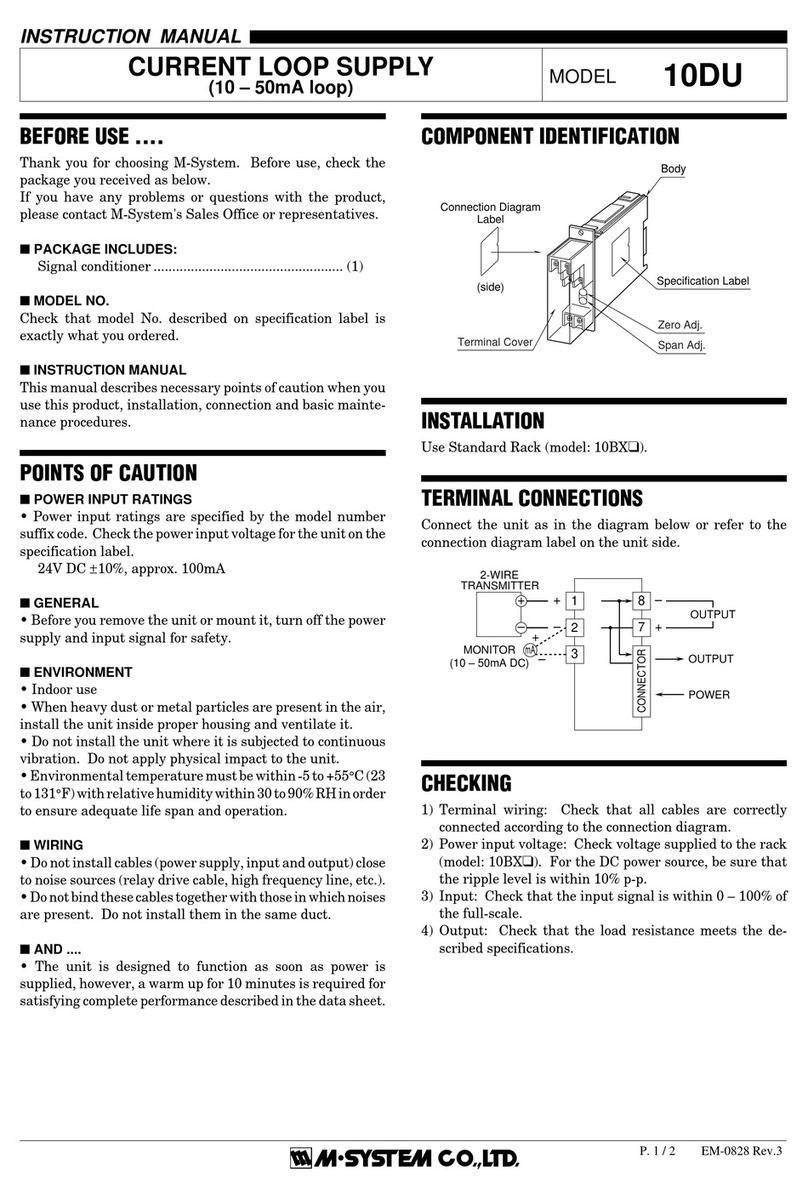

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage supplied to the rack

(model: 10BXx). For the DC power source, be sure that

the ripple level is within 10% p-p.

3) Input: Check that the input signal is within 0 – 100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications. For HART communication, the re-

sistance must be 250 Ω ±10%.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration.

For matching the signal to a receiving instrument or in case

of regular calibration, adjust the output as explained in the

following.

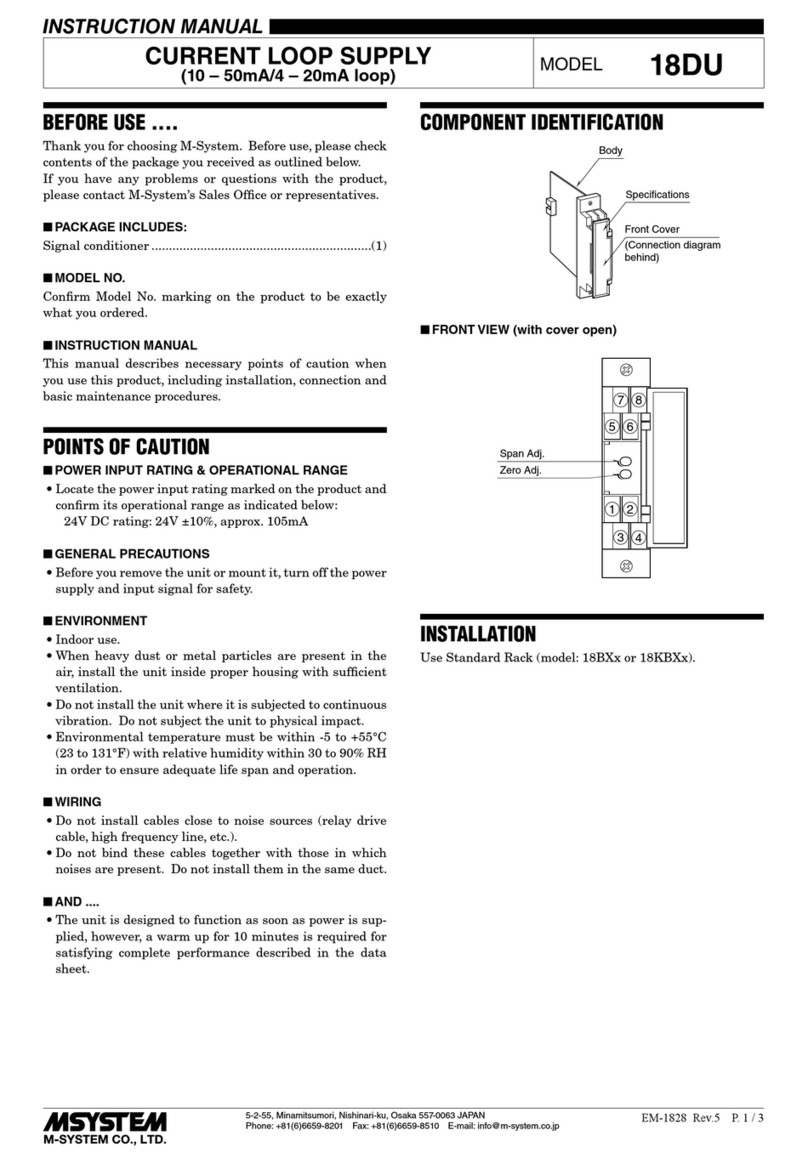

■HOW TO CALIBRATE THE OUTPUT 1

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

1) ZERO: Apply 0% input and adjust output to 0%.

2) SPAN: Apply 100% input and adjust output to 100%.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

5) Go through the same procedure for Output 2. Extender

Card (model: 10EC) is required to access the Output 2

Adjustments on top of the unit maintaining electrical

connection at the rear connector.

MAINTENANCE

Regular calibration procedure is explained below:

■CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the “ADJUST-

MENT PROCEDURE” explained earlier.

LIGHTNING SURGE PROTECTION

M-System offers a series of lightning surge protector for

protection against induced lightning surges. Please contact

M-System to choose appropriate models.