M-system PV User manual

Other M-system Transducer manuals

M-system

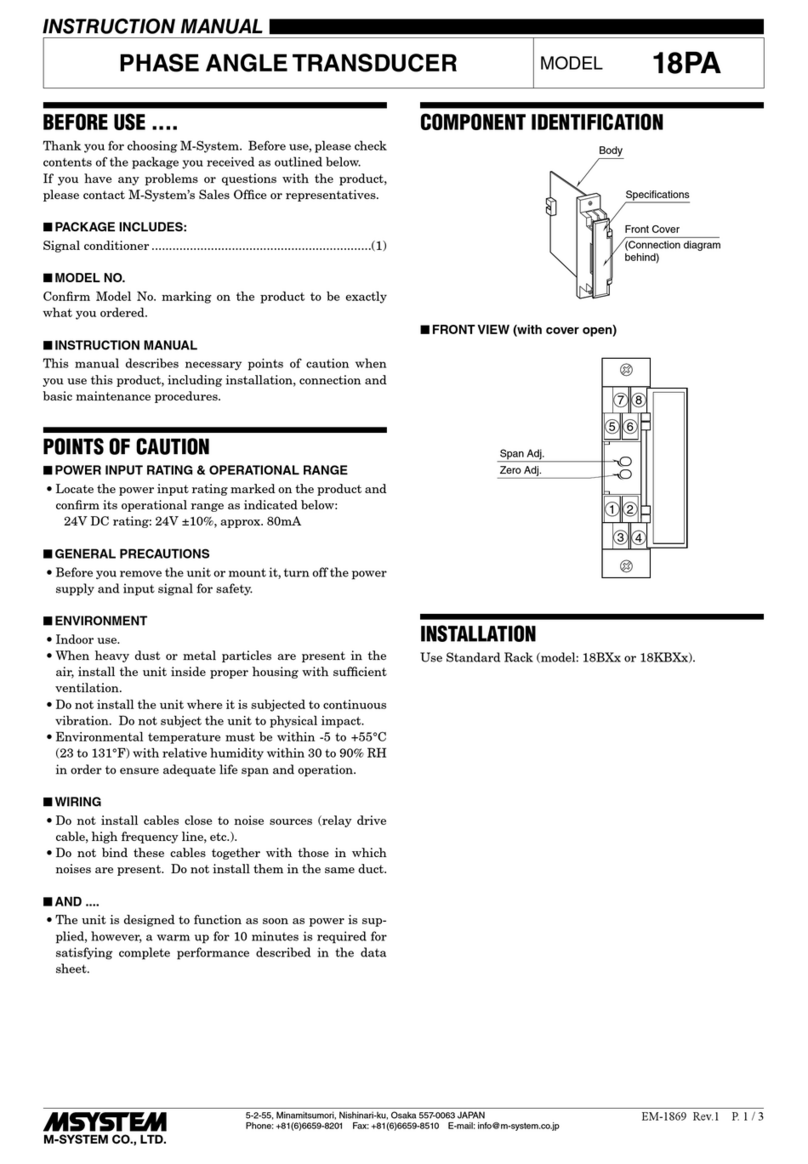

M-system 18PA User manual

M-system

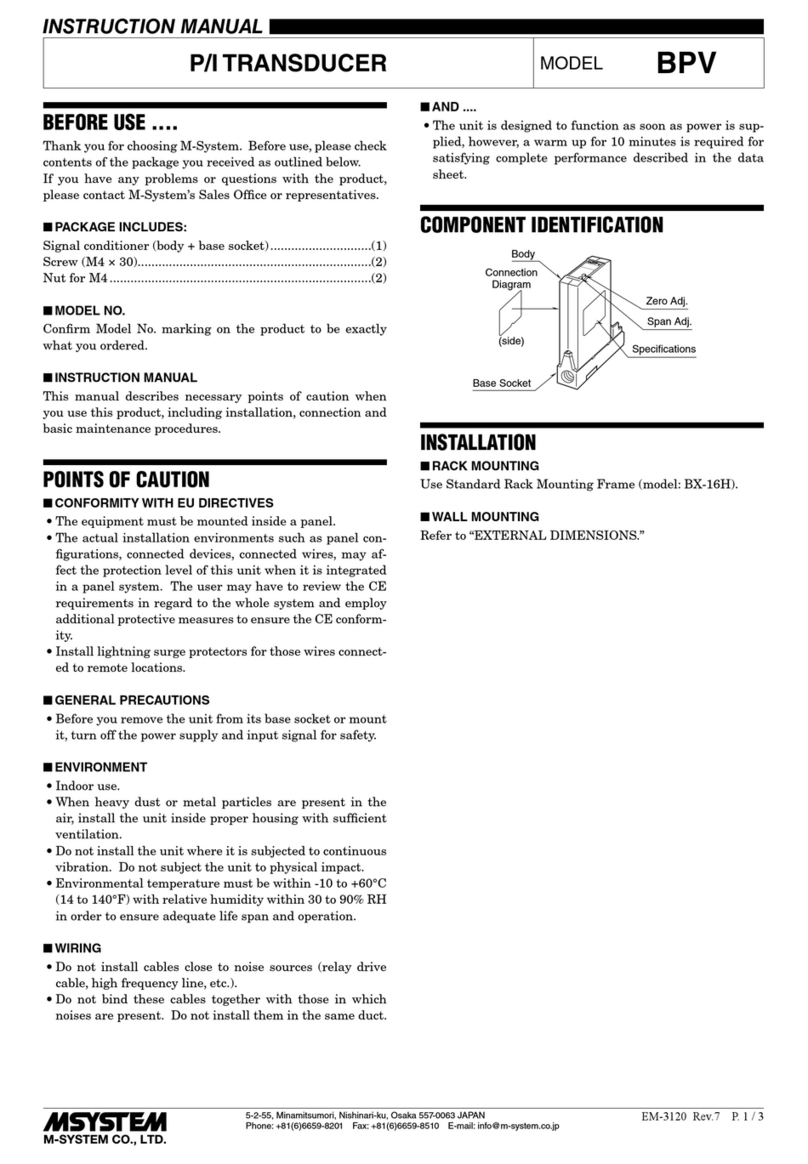

M-system BPV User manual

M-system

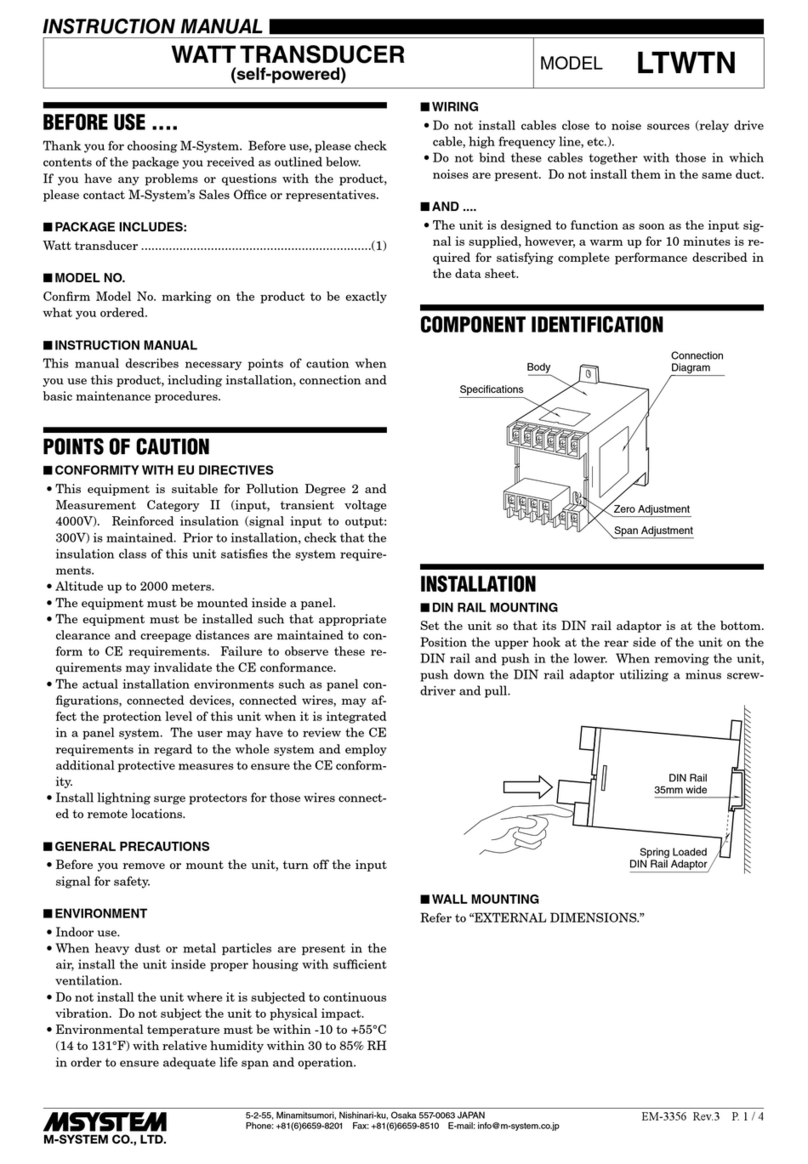

M-system LTWTN User manual

M-system

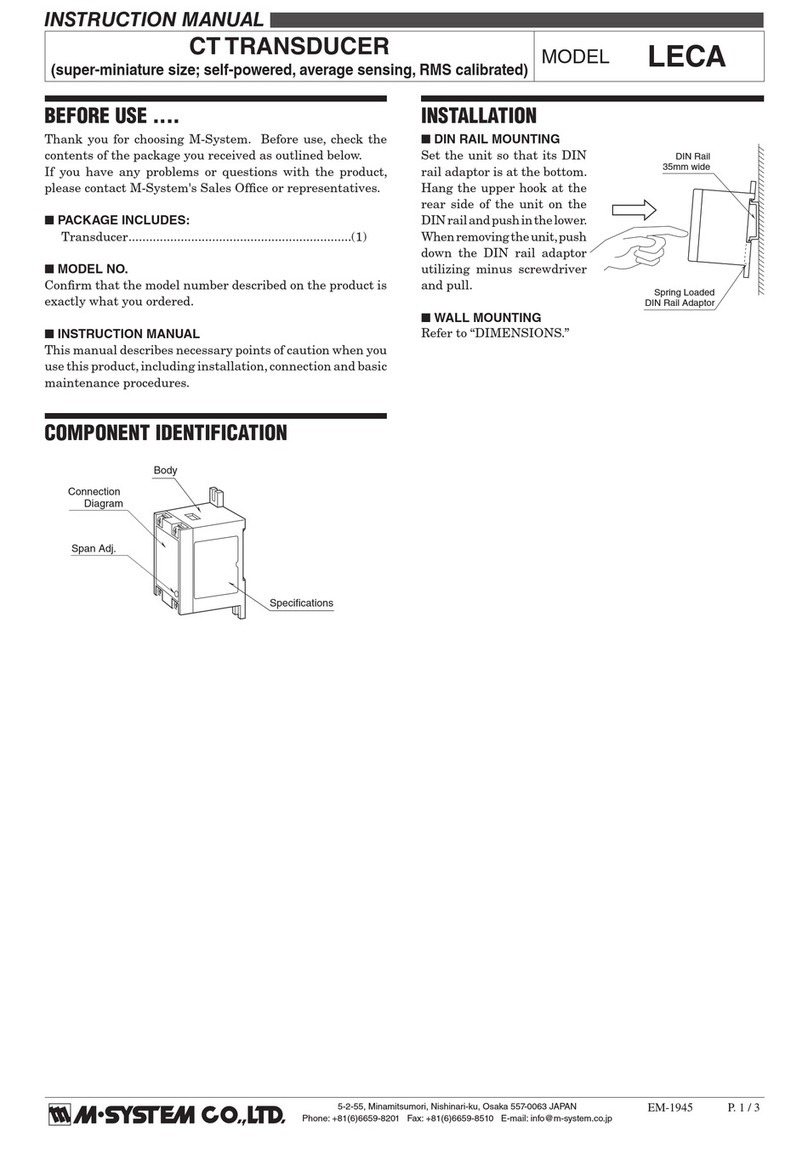

M-system LECA User manual

M-system

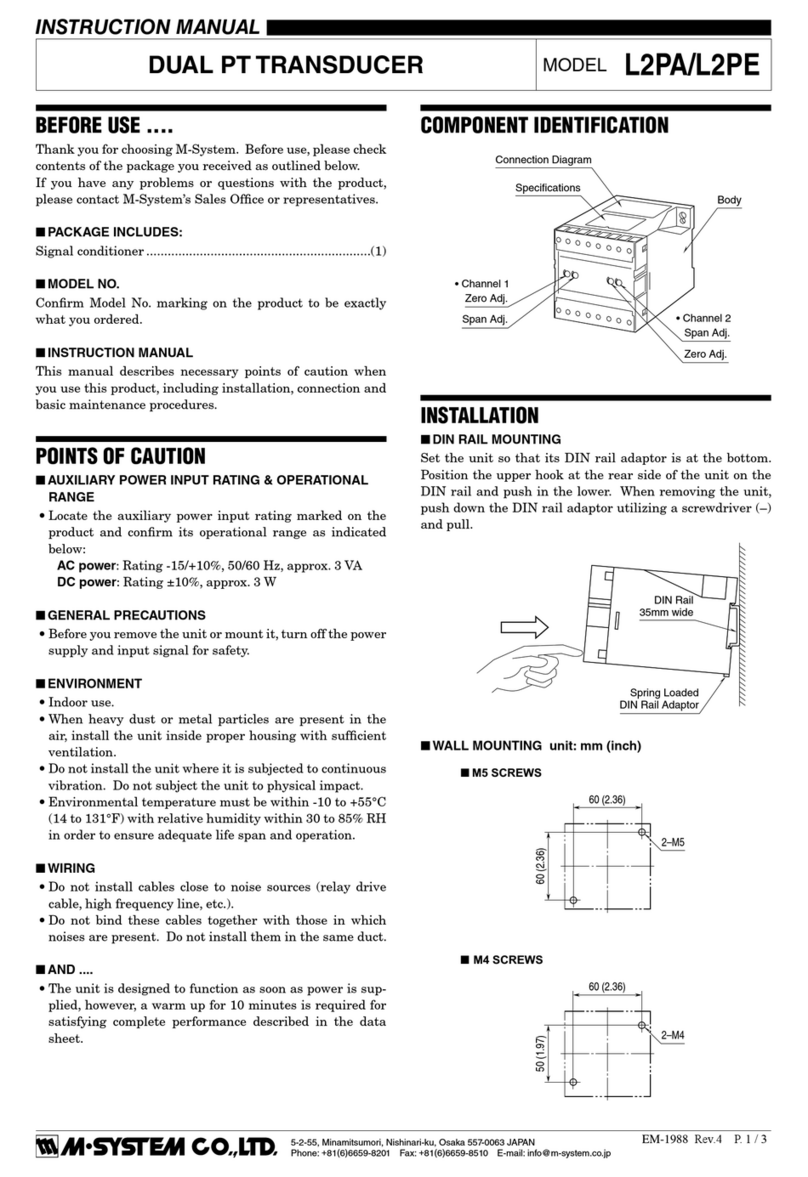

M-system L2PA User manual

M-system

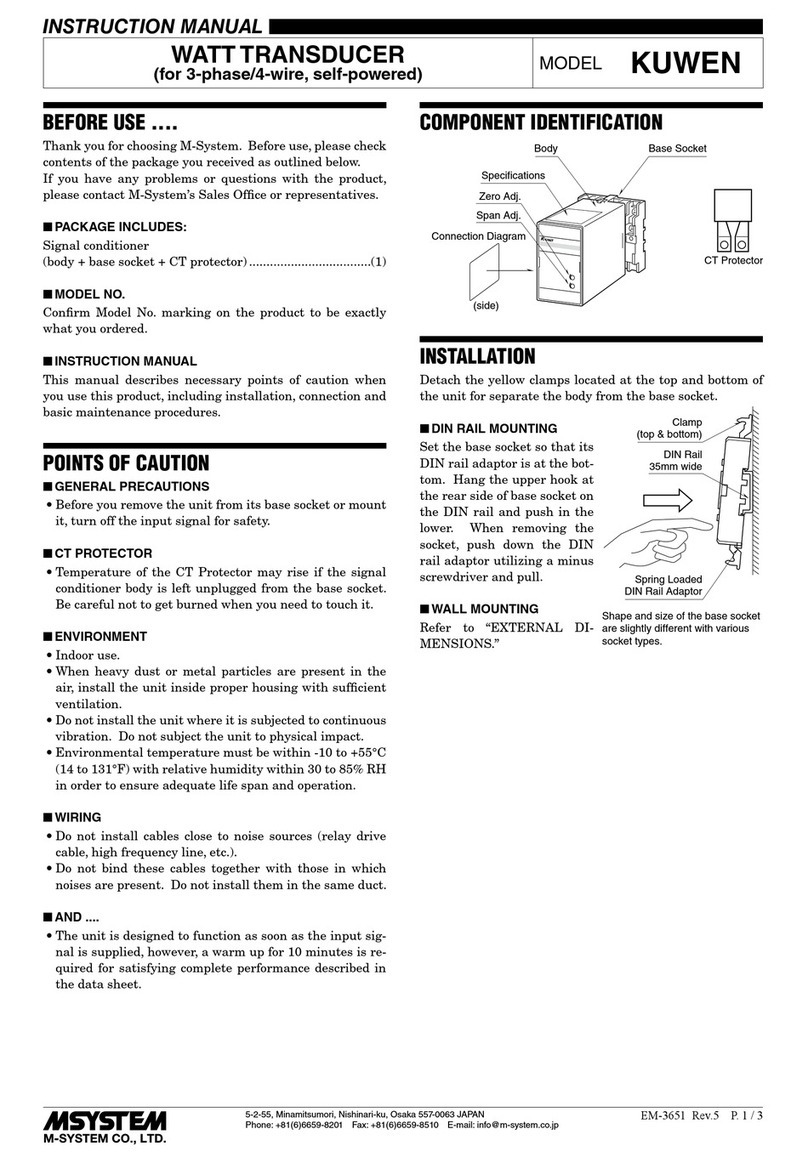

M-system KUWEN User manual

M-system

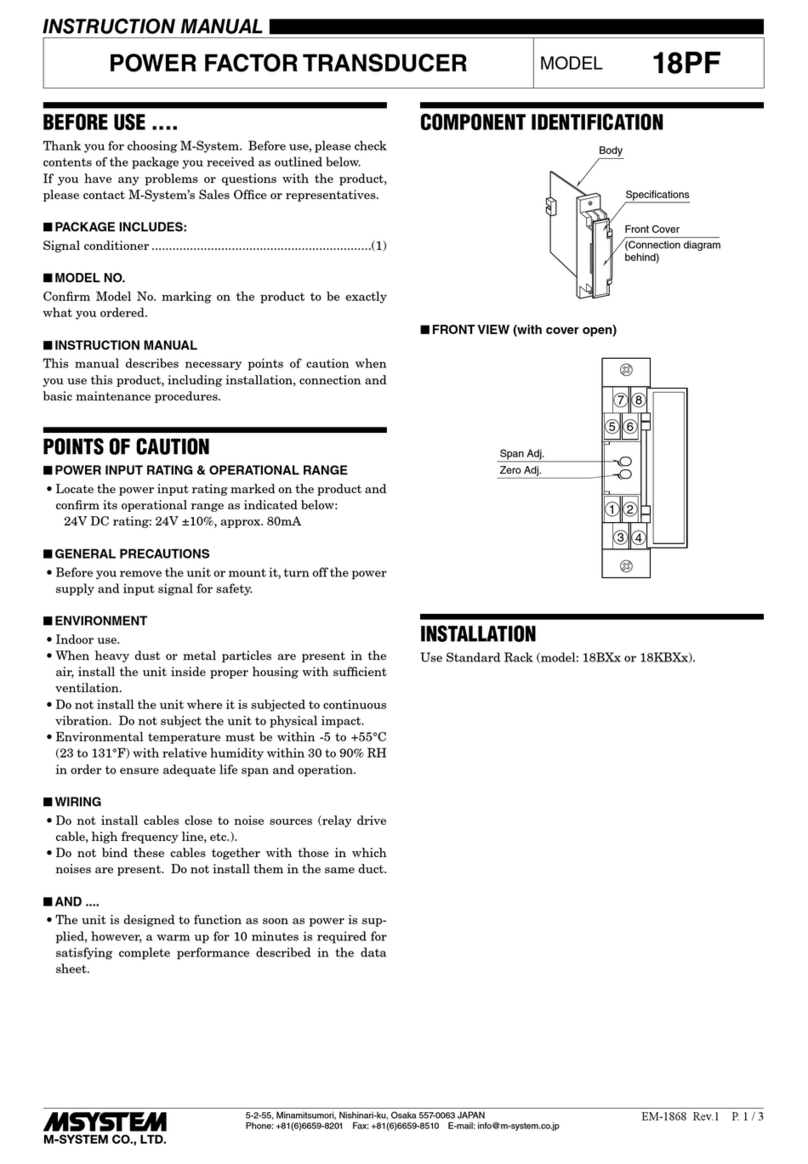

M-system 18PF User manual

M-system

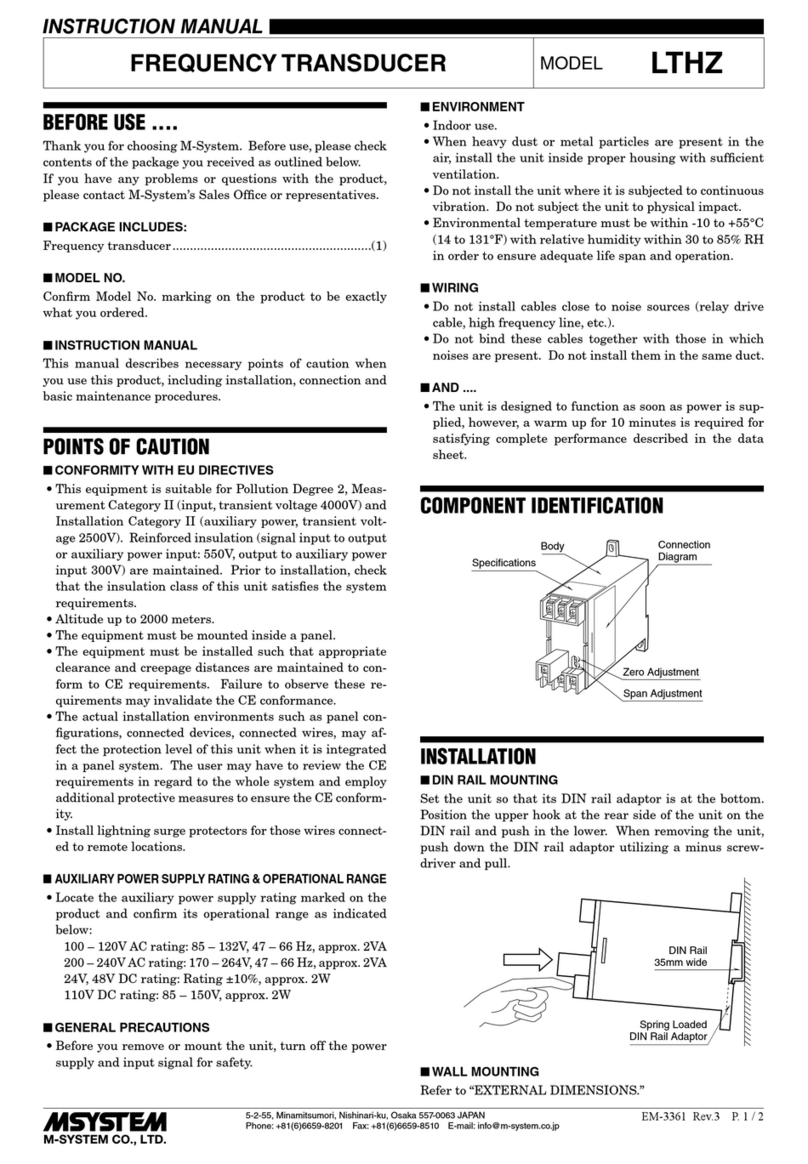

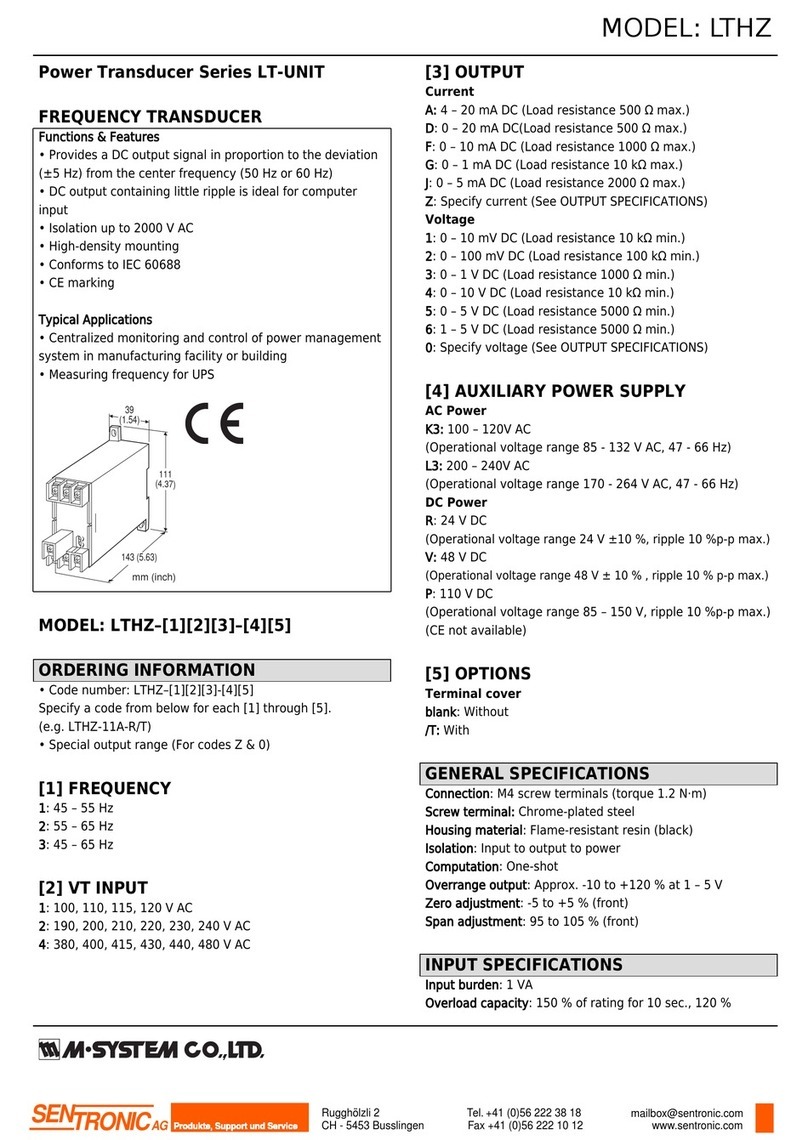

M-system LTHZ User manual

M-system

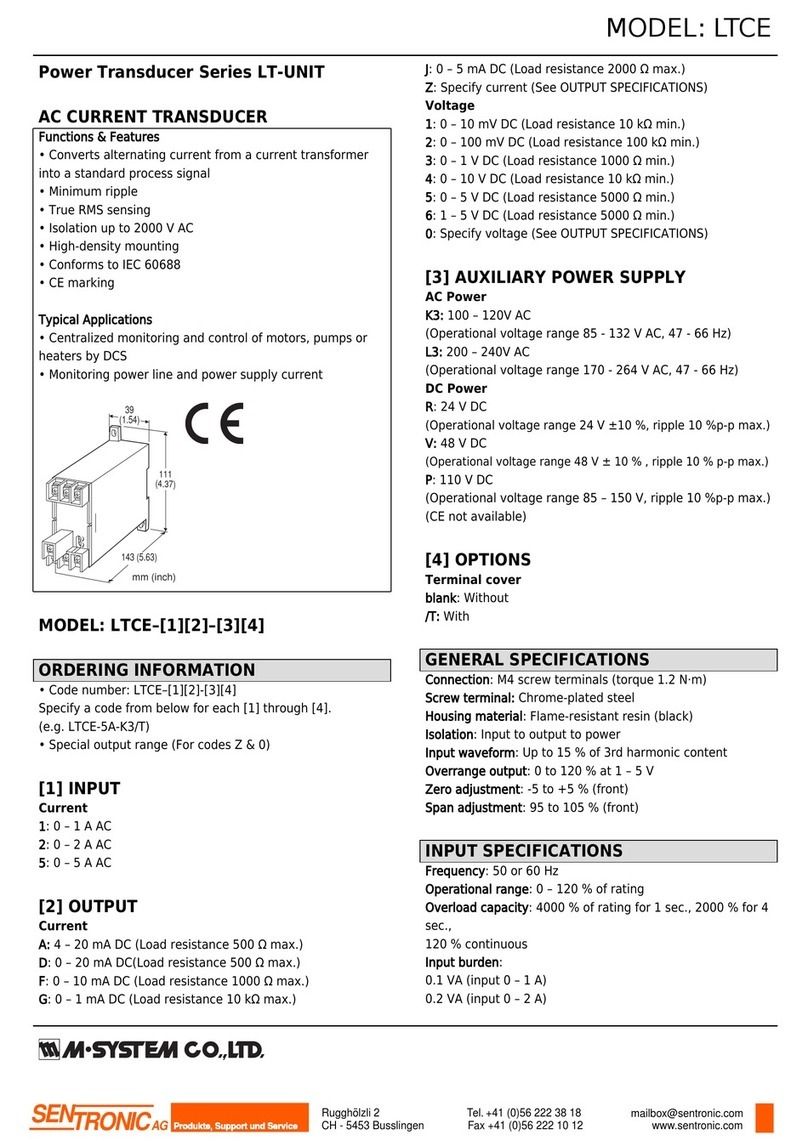

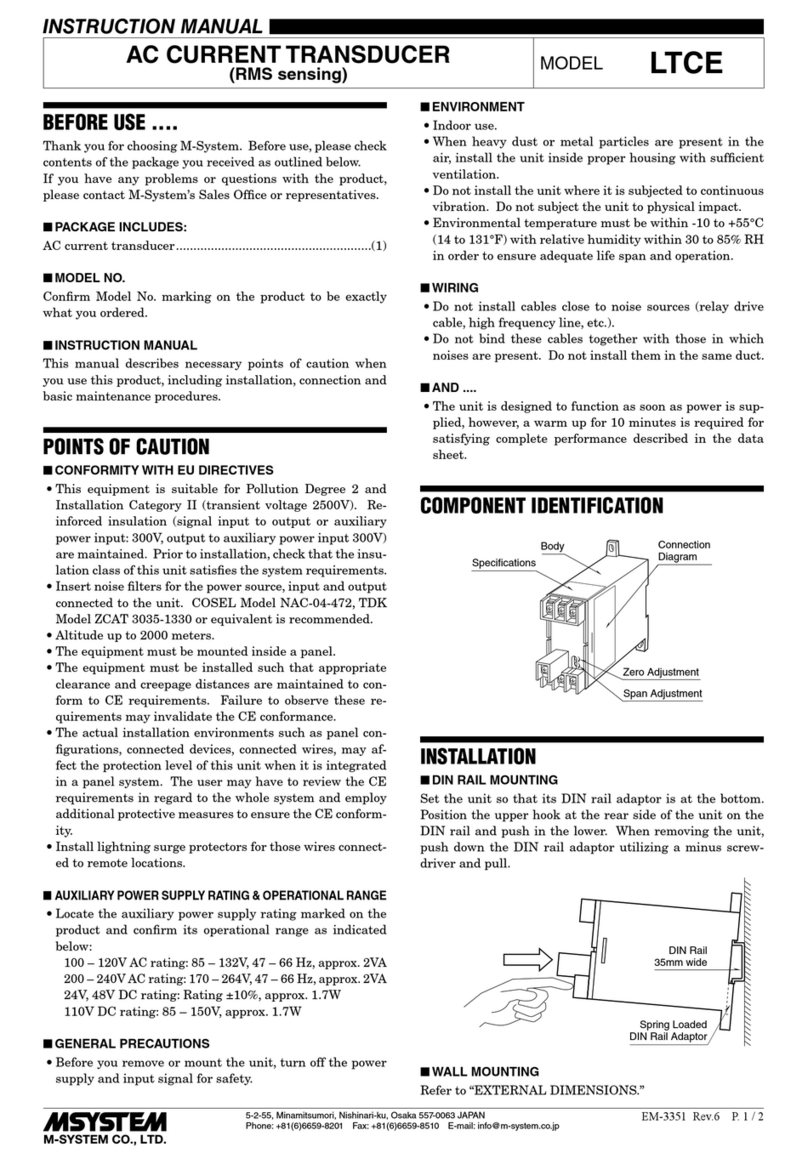

M-system LTCE User manual

M-system

M-system LT-UNIT Series User manual

M-system

M-system Mini-M M2PV User manual

M-system

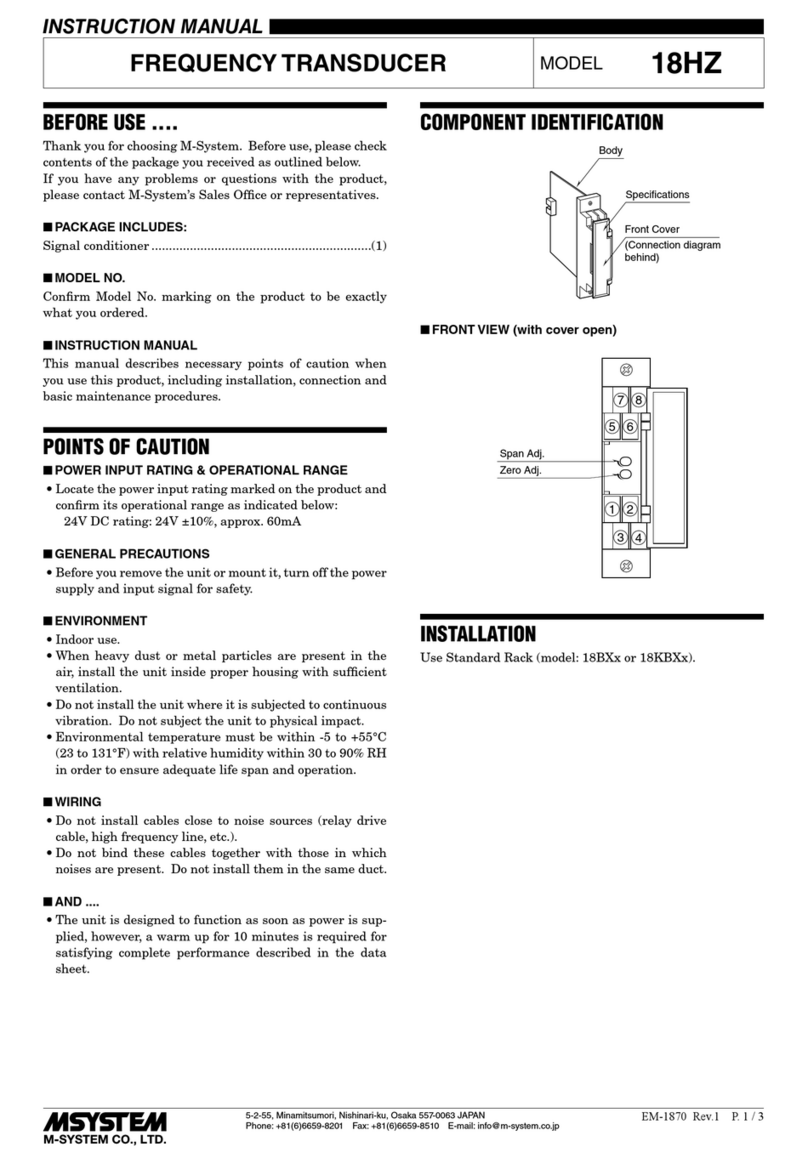

M-system 18HZ User manual

M-system

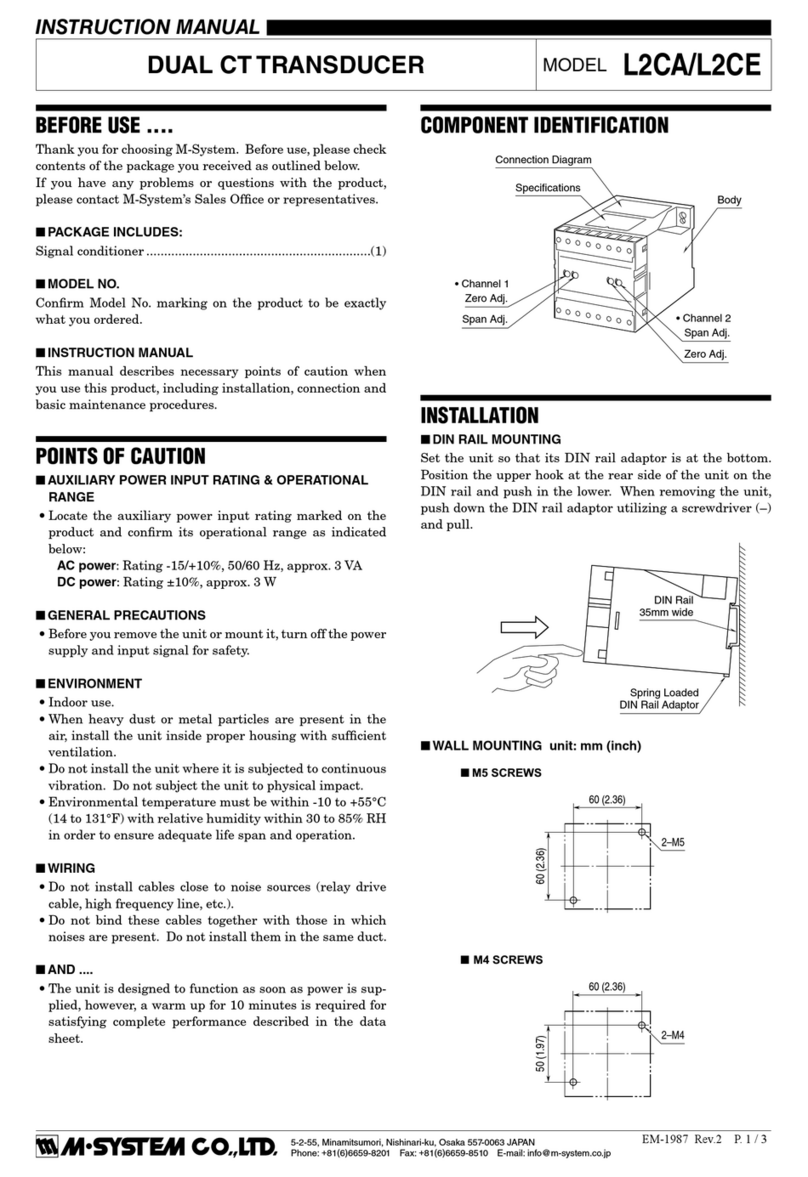

M-system L2CA User manual

M-system

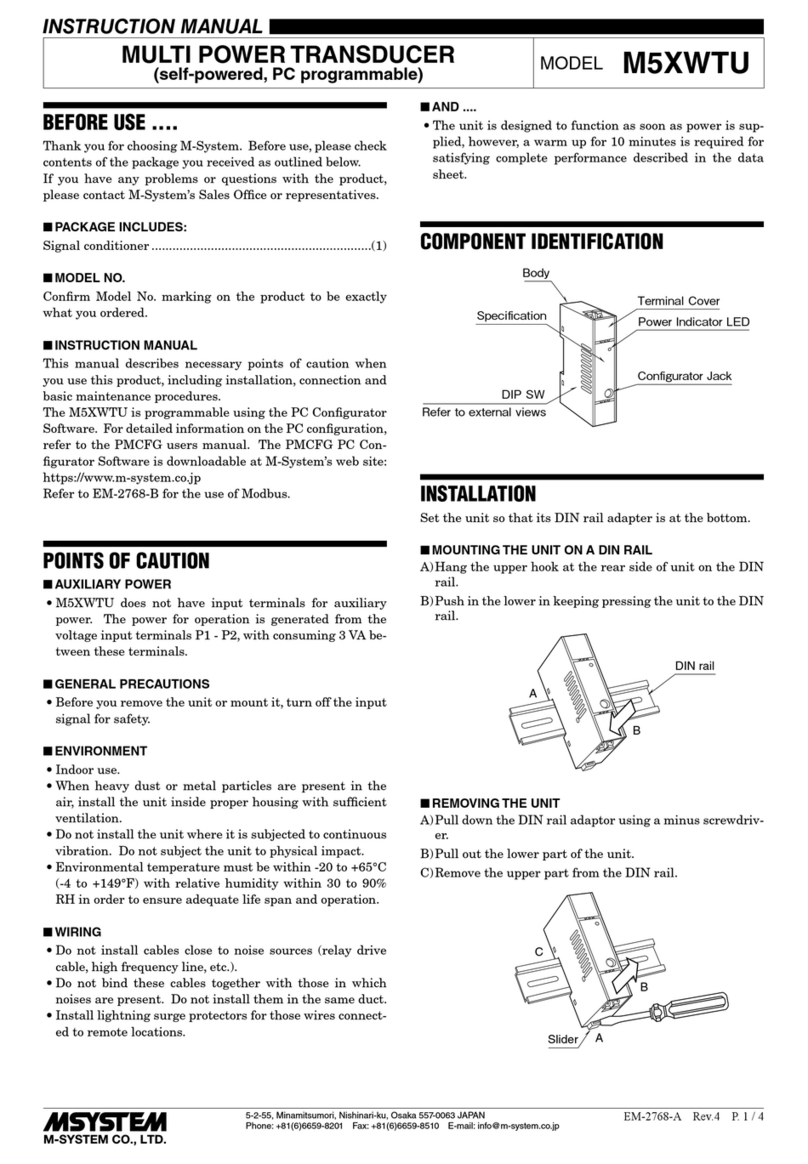

M-system M5XWTU User manual

M-system

M-system L3PK User manual

M-system

M-system LT-UNIT Series User manual

M-system

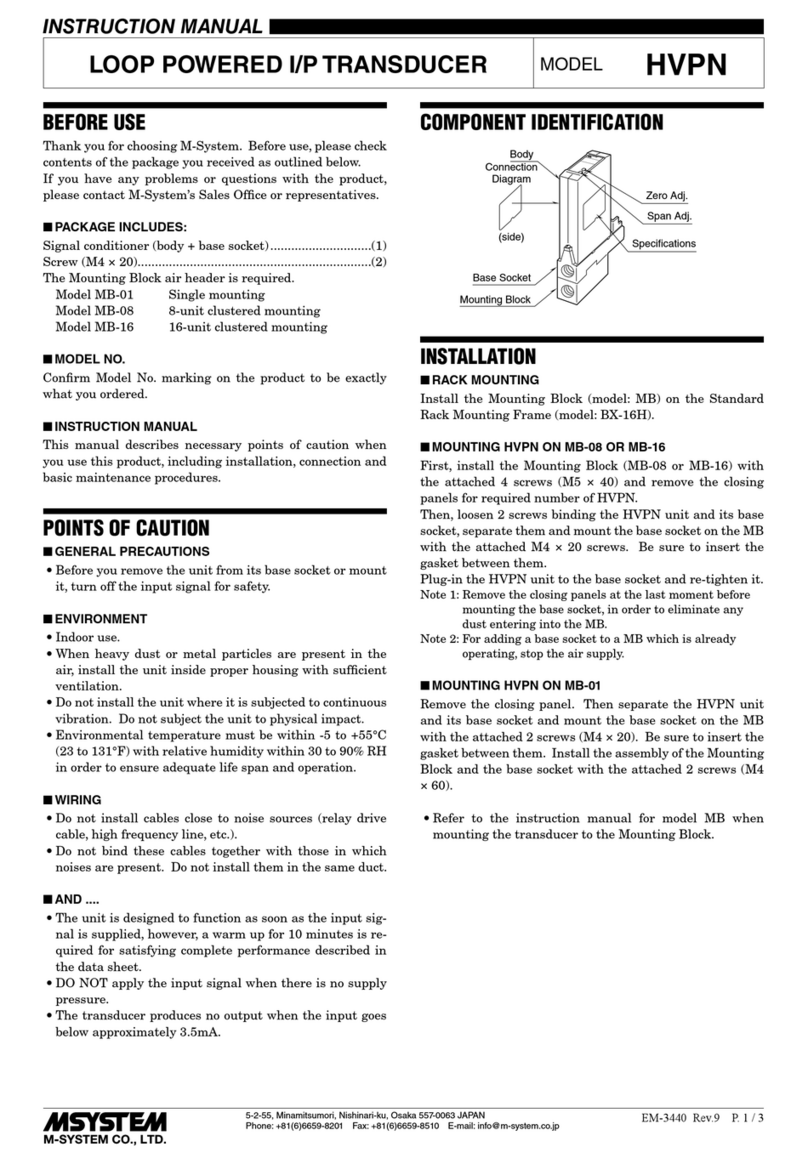

M-system HVPN User manual

M-system

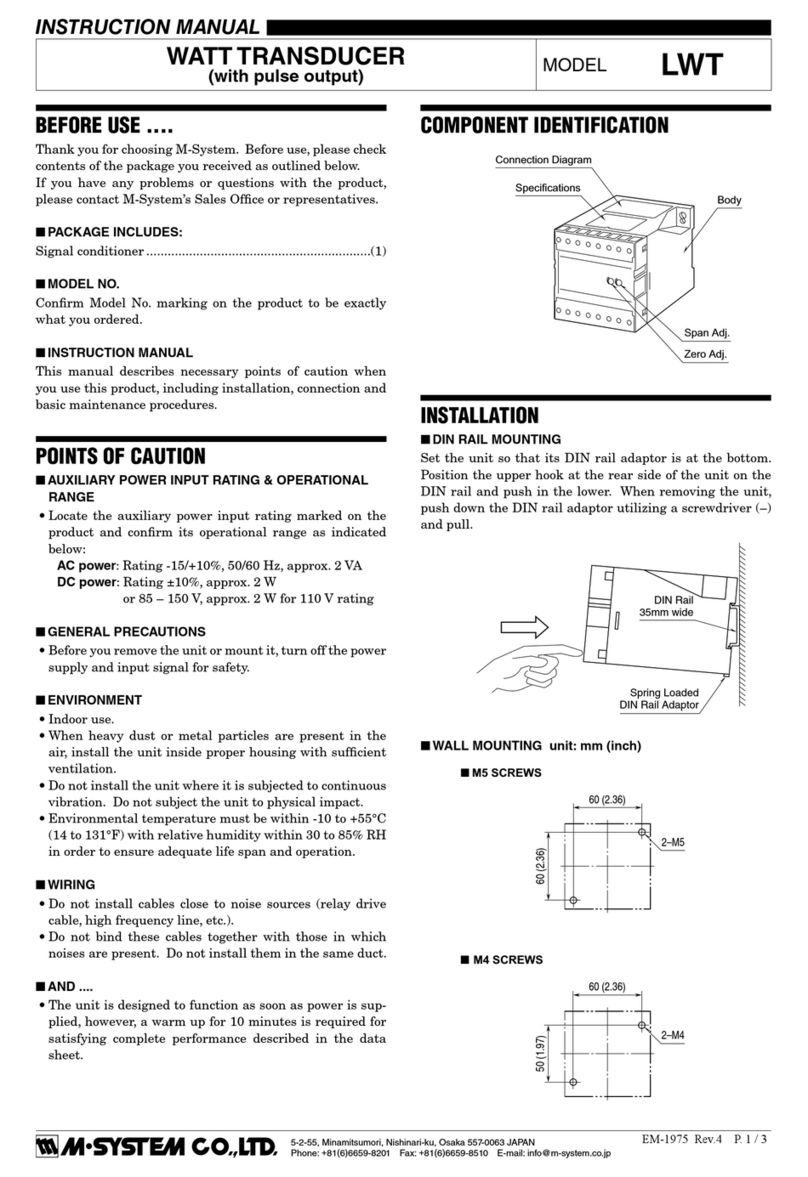

M-system LWT User manual

M-system

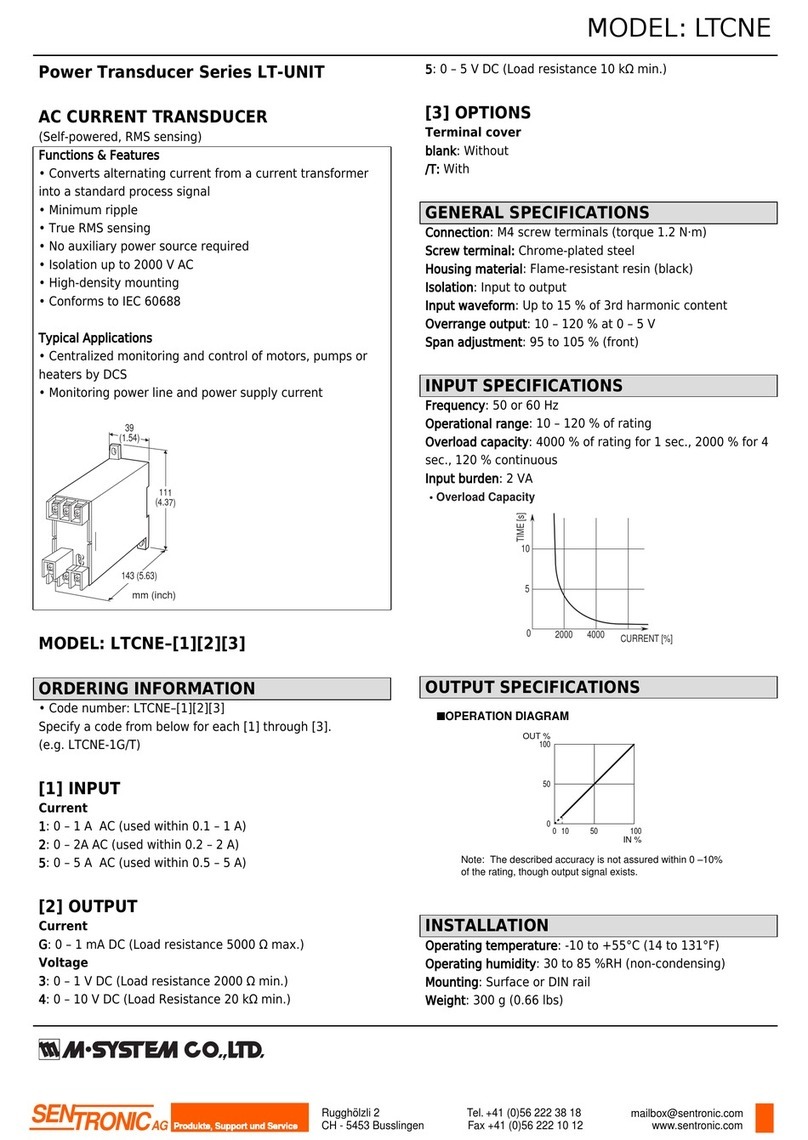

M-system LTCNE User manual

M-system

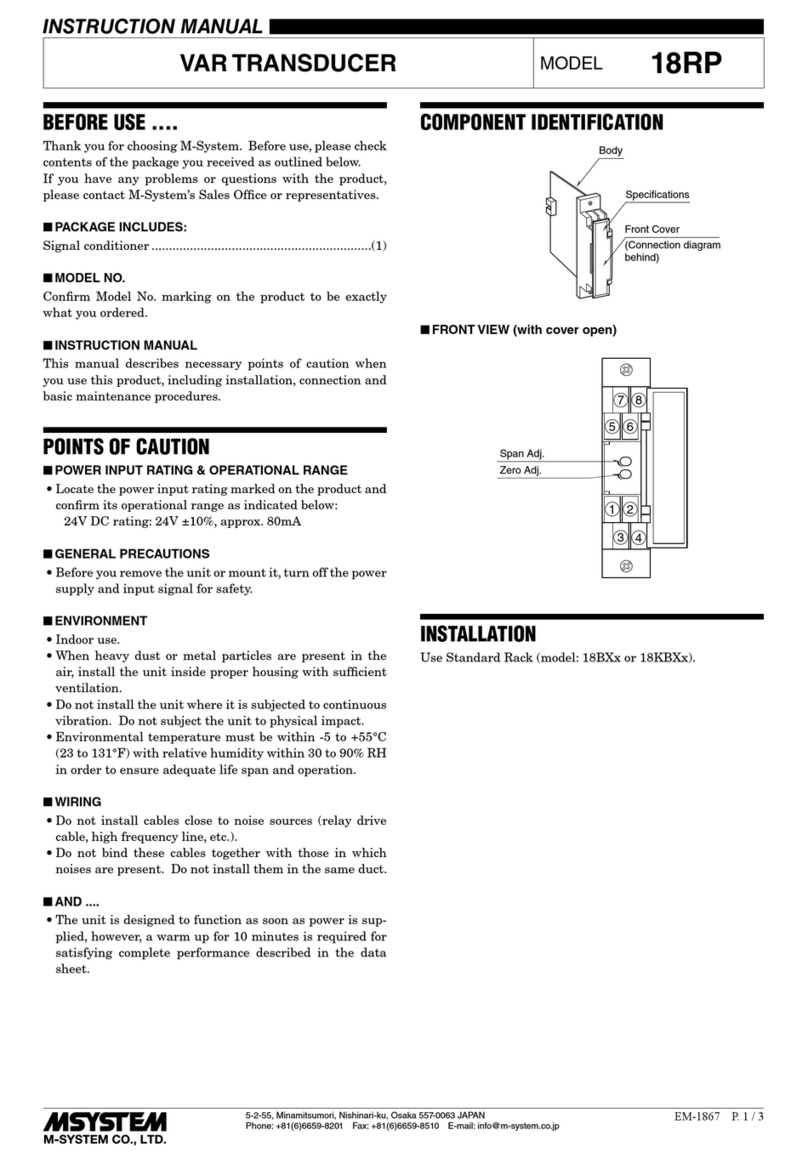

M-system 18RP User manual

Popular Transducer manuals by other brands

Mianyang Weibo Electronic

Mianyang Weibo Electronic WB Series user manual

ProMinent

ProMinent Dulcometer DMT operating instructions

Camille Bauer

Camille Bauer SIRAX CH-5610 operating instructions

Veris Industries

Veris Industries PW Series installation guide

HBM

HBM TJ1-S6 installation manual

Simrad

Simrad ES120-7C - REV D Dimensions