4) Make wiring as shown below. Turn power supply on, and

warm up for about 10 minutes.

VOLTAGE

GENERATOR

6TS1

POWER

24V DC

+15

234

6

–

+–RL

RL: STANDARD LOAD (250Ω ±0.1%)

DIGITAL VOLTMETER: 4 DIGITS

CJMTEMP. SENSOR

• Requirements for Calibration Equipment

Voltage Generator: Must be able to generate mV with

temperature sensor calibration func-

tion.

Accuracy ±0.02% or better required.

Temperature sensor: Semiconductor sensor for cold junc-

tion compensation. Accuracy ±0.3°C

or better required in combination

with the Voltage Generator.

Digital Voltmeter: 4-digit meter.

Accuracy ±0.01% or better required.

All calibration instruments must meet or exceed the above

mentioned specifications. M-System does not guarantee

this product’s stated accuracies and specifications if these

calibration requirements are not met.

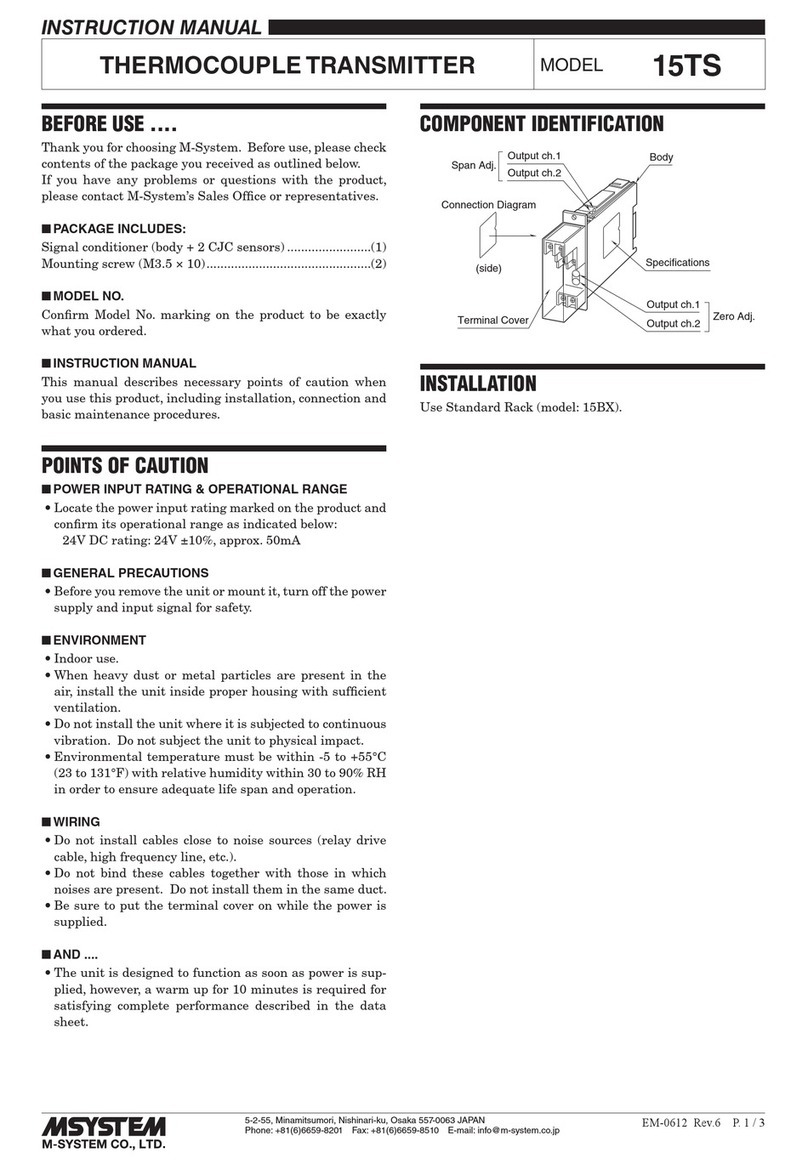

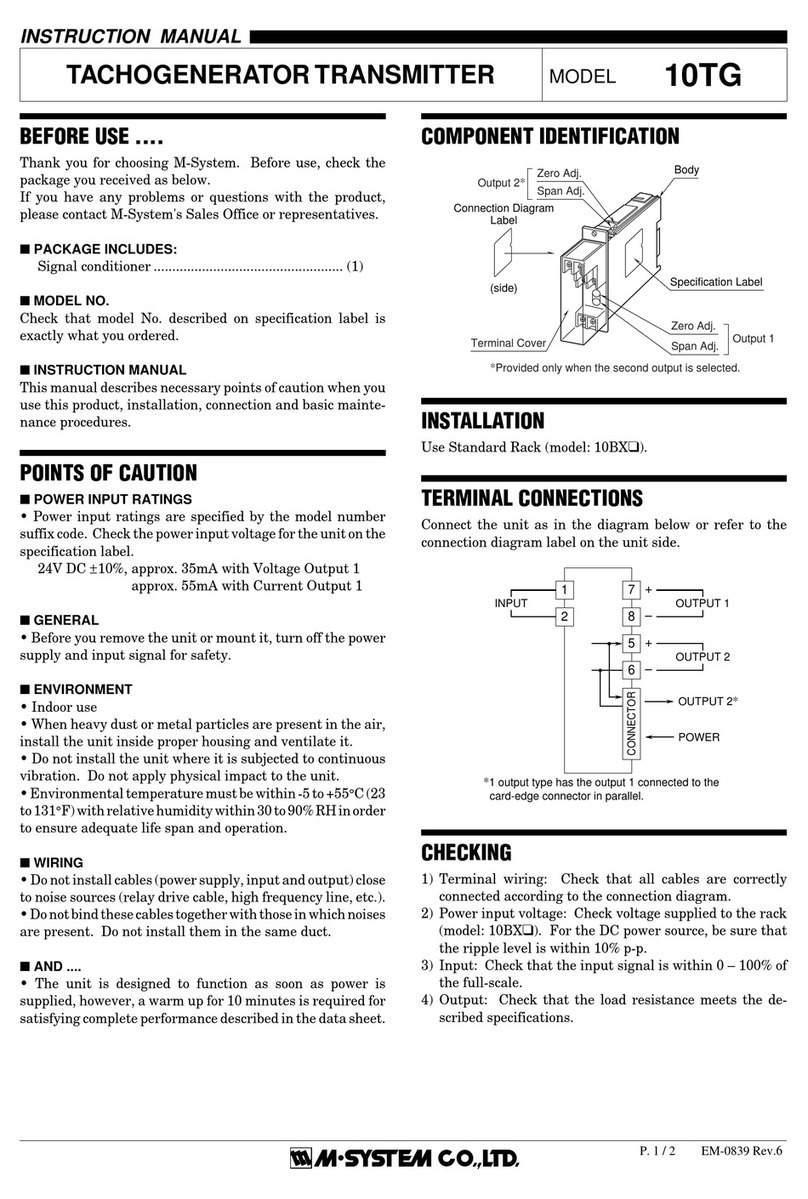

■THERMOCOUPLE TYPE SELECTION

1) Adjust SW1 (rotary code switch) to an appropriate po-

sition for customer’s thermocouple type. Positions are

shown in the illustration below.

3

SS-10

•6

51 42

1 : PR, R, S thermocouples

2 : K (CA) thermocouple

3 : E (CRC) thermocouple

4 : J (IC) thermocouple

5 : T (CC) thermocouple

6 : B thermocouple

■INPUT BIAS ADJUSTMENT (0% temperature)

Check first electromotive force (mV) for 0% (and 100%) tem-

perature in Thermocouple Reference Table.

1) Close across the front terminal 2 – 3 and remove tem-

perature sensor connected to voltage generator as in the

above illustration. (Canceling cold junction compensa-

tion)

2) Connect a digital voltmeter across the front terminal 2

(–) and TP1 (+).

3) With minimum (0%) input, adjust SW2 to appropriate po-

sitions – nearest to desired value – according to Table 1

[INPUT BIAS SELECTION TABLE], and adjust output

reading to 0 ±0.002V with VR5 (zero-coarse adjustment).

4) With minimum (0%) input, adjust output to 0 ±0.05%

with VR1 (zero-fine adjustment).

■INPUT RANGE ADJUSTMENT (100% temperature)

5) With maximum (100%) input, adjust SW3 to appropriate

positions according to Table 4 to Table 6 [INPUT RANGE

SELECTION TABLE], and adjust output to 100 ±0.05%

with VR4 (span-coarse adjustment) and VR2 (span-fine

adjustment).

6) With minimum (0%) input, check that input is 0 ±0.05%.

When the ZERO point is changed, repeat the procedure

2) to 5).

■COLD JUNCTION COMPENSATION ADJUSTMENT

7) Connect temperature sensor to the voltage generator

again and remove shortcircuit across the terminal 2 – 3.

8) With minimum (0%) input, adjust output reading to 0%

with VR3.

■OUTPUT ZERO & SPAN ADJUSTMENT

1) ZERO: Apply 0% input and adjust output to 0% with the

VR1.

2) SPAN: Apply 100% input and adjust output to 100% with

the VR2.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

MAINTENANCE

Regular calibration procedure is explained below:

■CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the “ADJUST-

MENT PROCEDURE” explained earlier.

LIGHTNING SURGE PROTECTION

M-System offers a series of lightning surge protector for

protection against induced lightning surges. Please contact

M-System to choose appropriate models.

6TS1

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4211 Rev.7 P. 3 / 4