Page | 3

TABLE OF CONTENTS

A Thank You From The President...................................................................................2

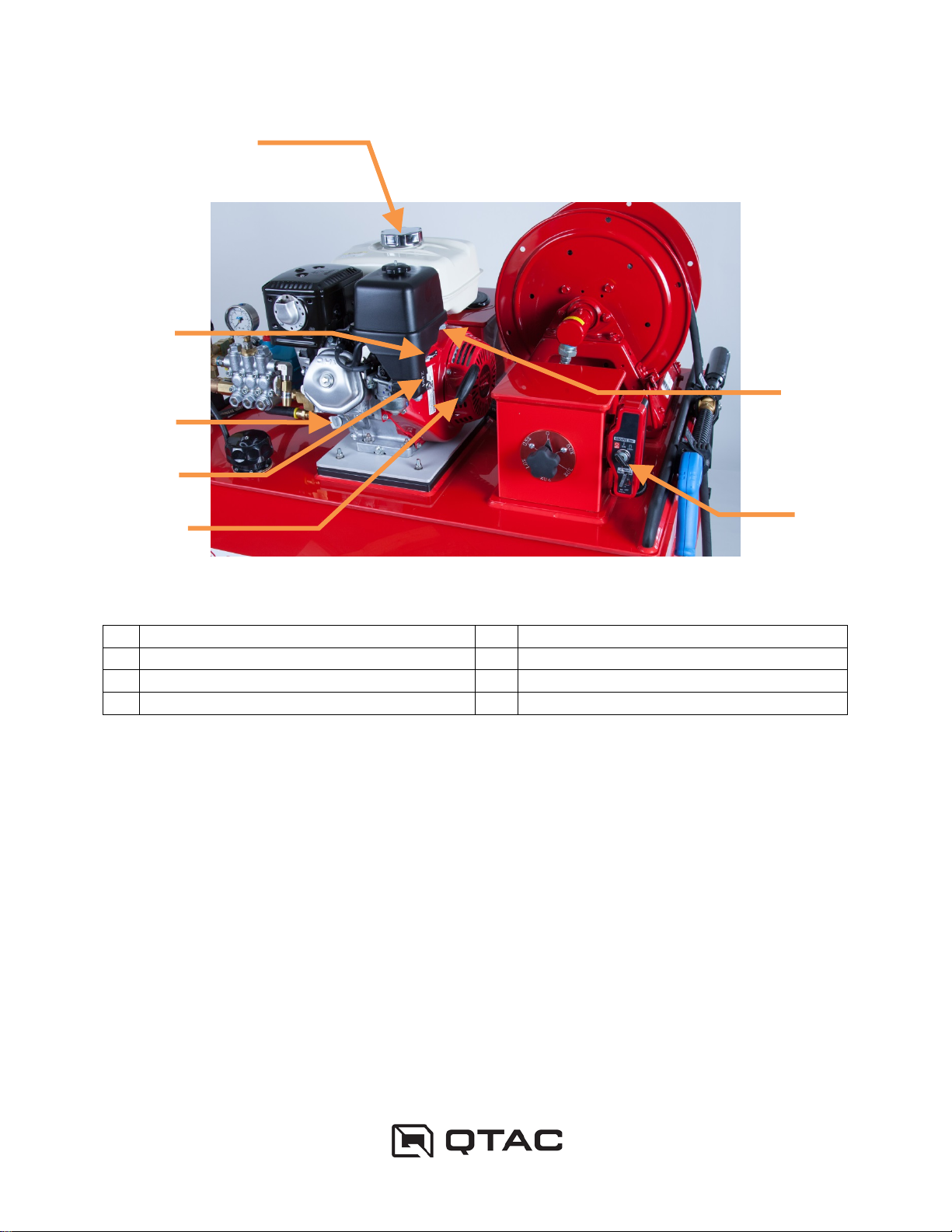

Getting To Know Your QTAC..........................................................................................5

Transporting Your QTAC.................................................................................................9

Gross Vehicle Weight Rating.......................................................................................9

General QTAC Mounting and Fastening......................................................................9

Special Precautions For Carrying a QTAC On Ride-On ATVs Or Side-By-Side UTVs

...................................................................................................................................10

Operating Your QTAC...................................................................................................12

Before Starting Up Your QTAC..................................................................................12

Starting Up Your QTAC.............................................................................................12

Breaking Your QTAC In.............................................................................................13

Running Your QTAC..................................................................................................13

Stopping Your QTAC.................................................................................................14

Storing Your QTAC .......................................................................................................15

General Storage........................................................................................................15

Special QTAC Operation...............................................................................................16

Applying Foam With Your QTAC...............................................................................16

Servicing Your QTAC....................................................................................................17

Cleaning Your QTAC.................................................................................................17

Routine QTAC Maintenance......................................................................................17