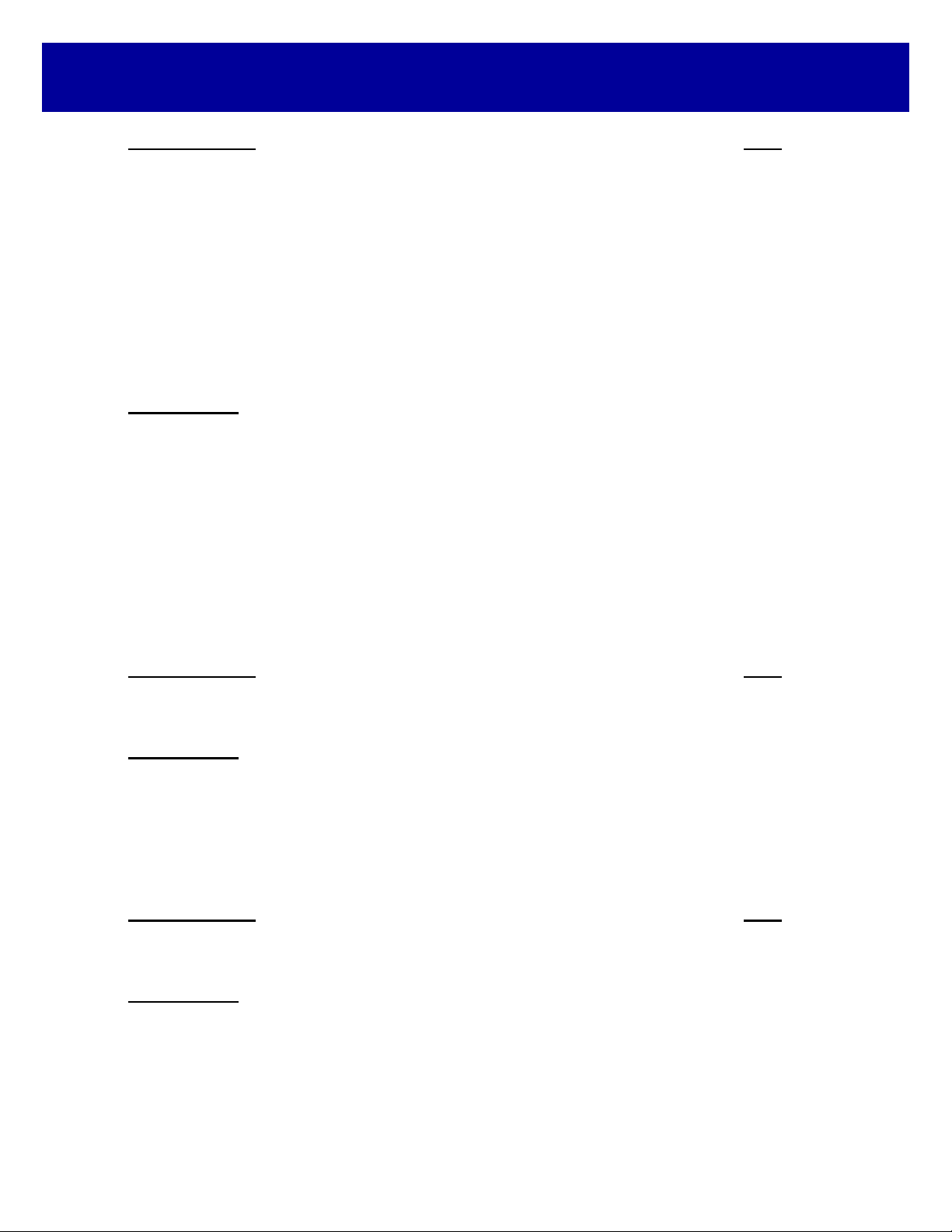

DESCRIPTION QTY

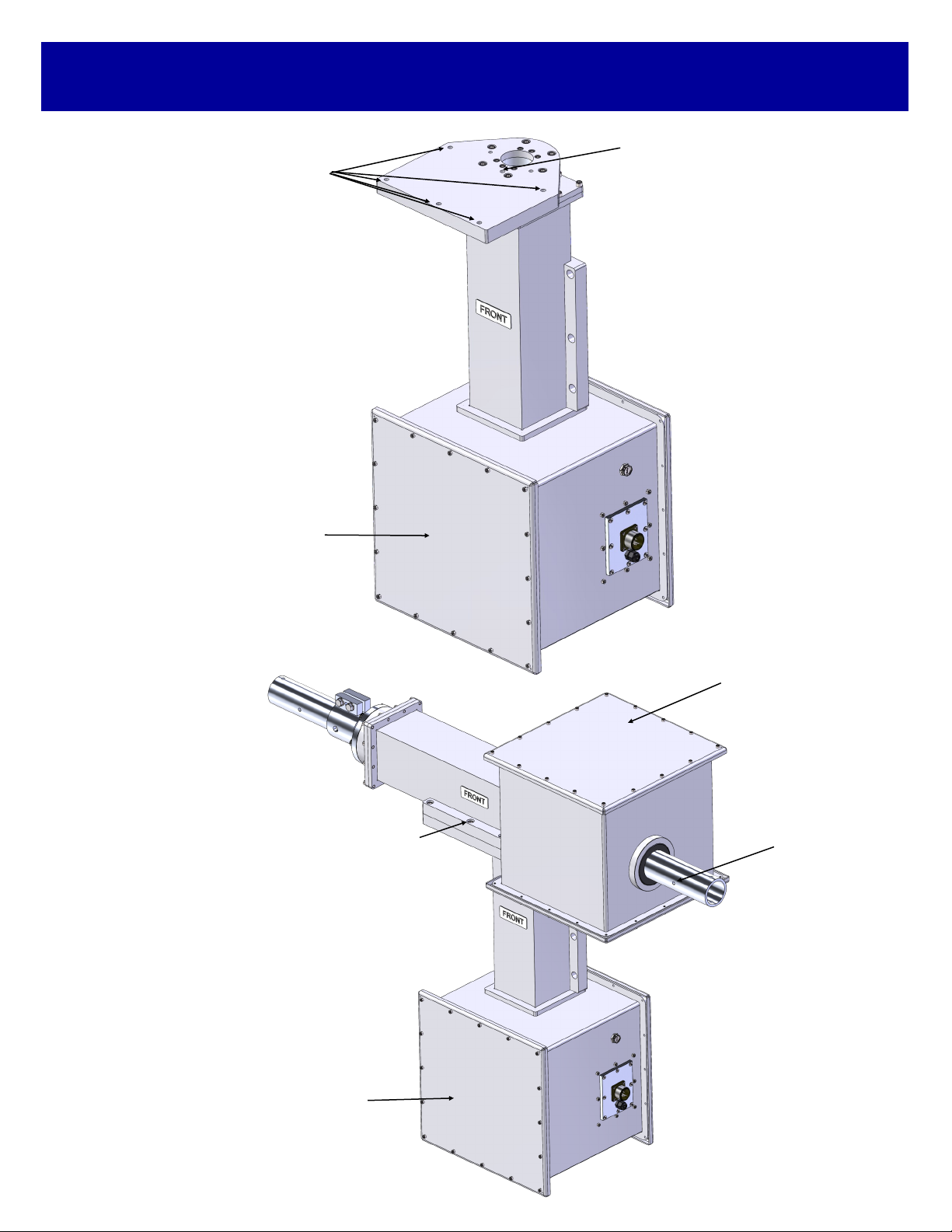

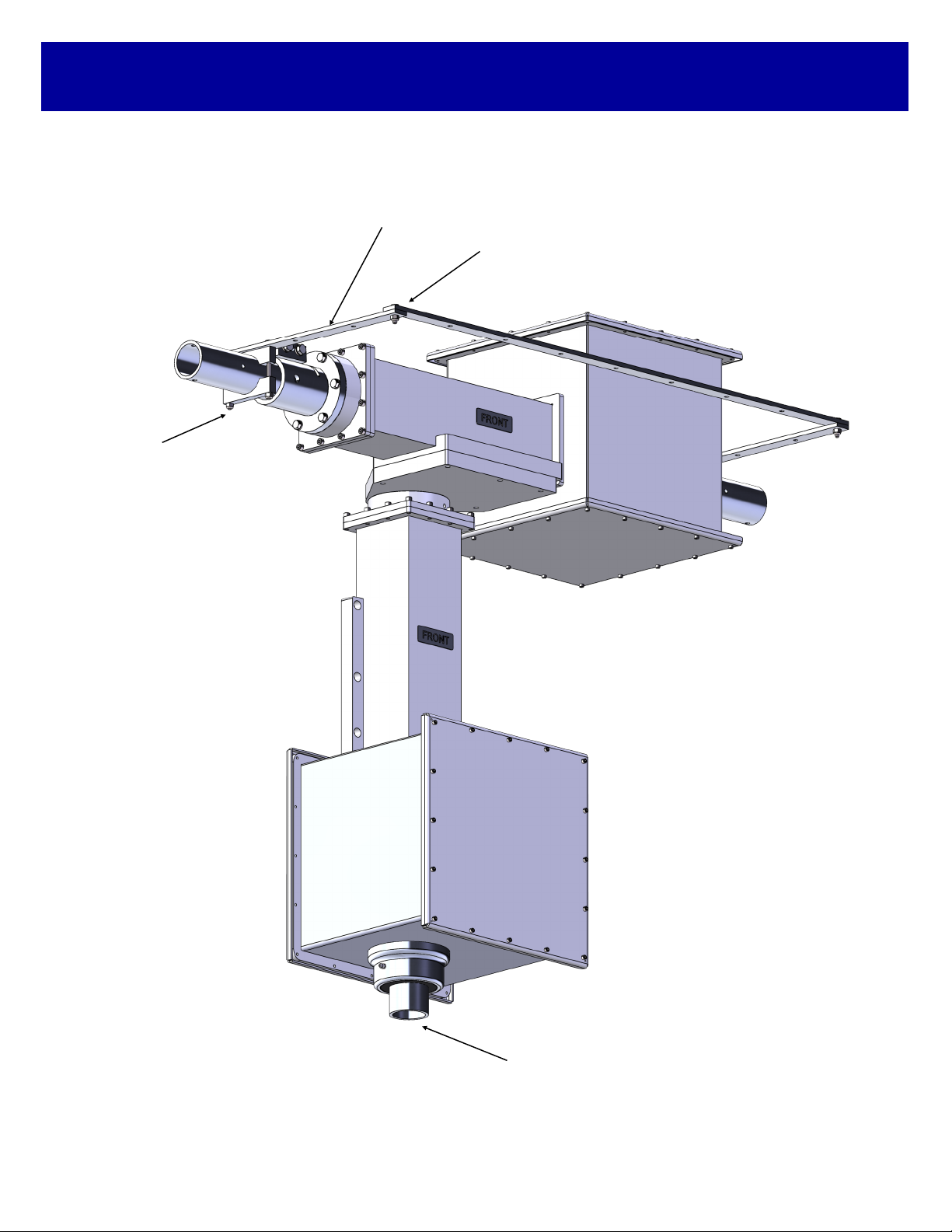

AE1000 ELEVATION ASSEMBLY (SAAE1948) .......................................... 1

AE1000 AZIMUTH ASSEMBLY (SAAE1926) .............................................. 1

7 PIN FEMALE RIGHT ANGLE CONNECTOR ASSEMBLY ....................... 2

CABLE BRACE (M2AAE1928) .................................................................... 1

CABLE BRIDGE ARM (M2AAE1617) .......................................................... 2

CABLE BRIDGE (M2AAE1618) ................................................................... 1

2.4” CRADLE (M2AMC0128) ....................................................................... 4

PENETROX OR ZINC PASTE (1 OZ. CUP). ............................................... 1

NYLON TIE, 12”........................................................................................... 10

NYLON TIE, 7”............................................................................................. 10

DESICCANT BAG........................................................................................ 2

HARDWARE

BOLT, 3/8-16 X 1.0”, SOCKET HEAD, S.S.................................................. 11

BOLT, 3/8-16 X 3/4”, SOCKET HEAD, S.S.................................................. 1

BOLT, 5/6-18 X 1/2” ,SOCKET HEAD, SS................................................... 2

BOLT, 1/4-20 X 3.5” HEX HEAD S.S. ......................................................... 4

BOLT, 1/4-20 X 1.0” HEX HEAD S.S ........................................................... 2

LOCK NUT, 1/4-20, S.S. .............................................................................. 6

SCREW, 8-32 X 1/2”, SET, S.S. .................................................................. 4

ALLEN KEY, 5/64” ....................................................................................... 1

OPTIONAL KITS

□ PIPE MOUNT KIT, 3” (FGAEPMK3)

DESCRIPTION QTY

3” PIPE CLAMP (M2AMC0144) ................................................................... 3

3” PIPE CLAMP CAP (M2AMC0149)........................................................... 3

3” PIPE STOP (M2AAE1608) ...................................................................... 1

HARDWARE

BOLT, 3/8-16 X 3”, HEX HEAD, S.S............................................................ 6

LOCK WASHER, 3/8”, S.S........................................................................... 6

BOLT, 5/16-18 X 2”, HEX HEAD, S.S. ......................................................... 2

FLAT WASHER, 5/16”, S.S.......................................................................... 2

LOCK NUT, 5/16-18, S.S. ............................................................................ 2

□ PIPE MOUNT KIT, 6” (FGAEPMK6)

DESCRIPTION QTY

6” Pipe Clamp #1 (M2AMC0143) ................................................................. 3

6” Pipe Clamp #2 (M2AMC0142) ................................................................. 3

6” Pipe Stop (M2AAE1606).......................................................................... 1

HARDWARE

Bolt, 3/8-16 x 4”, Hex Head S.S. .................................................................. 6

Lock Washer, 3/8” S.S. ................................................................................ 6

Bolt, 5/16-18 x 2”, Hex Head S.S. ................................................................ 2

Flat Washer, 5/16”, S.S................................................................................ 2

Lock Nut, 5/16-18, S.S. ................................................................................ 2

FGAE1000-D1-W-C-A-H PARTS & HARDWARE