................................................................................................................................. 19

.......................................................................................................................... 18

....................................................................................................................... 18

.......... 18

.......... 18

........... 18

......... 17

............. 17

..................... 16

.................. 16

.................................................................................................................... 16

........................ 15

..................................................................................................... 14

........................................................................................................ 14

................. 13

............. 12

...................... 12

................................................................................................................10

................10

...........................................................................8

.....................9

...........................3

.......20

.......21

.......22

.......23

Stand Diagram and Part List.........................................................................................................

Fence Diagram and Part List.......................................................................................................

Jointer Body Diagram and Part List.............................................................................................

Cutterhead Diagram and Part List.................................................................................................

..............................................................................................................................

Troubleshooting

................................................................................................................ 10Setting Outfeed Table Hight

.................7

..........................................................................................................................7

.......................................................................................................................6

..........................................................................................................................6

.........................5

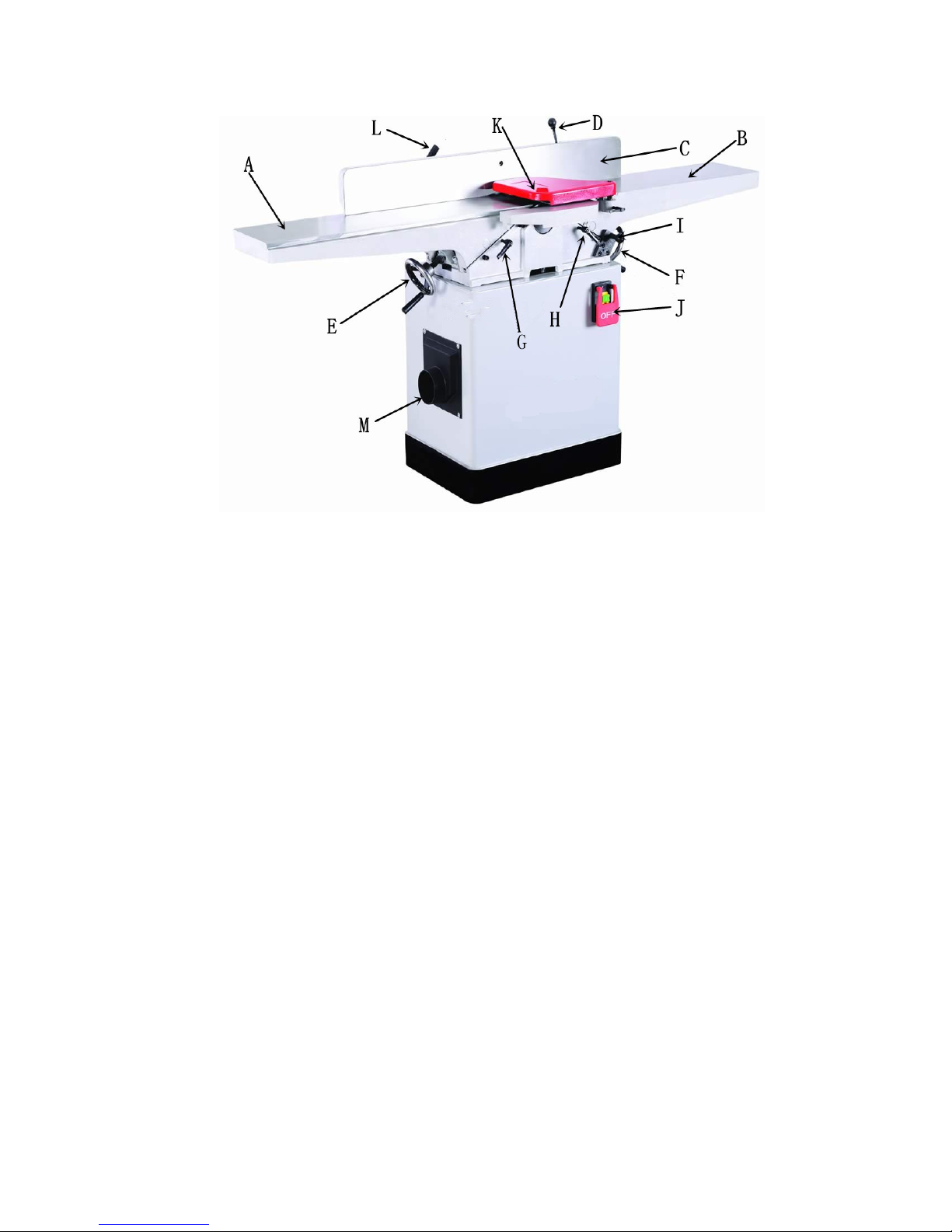

Identification

......................2

2

Table of Contents ..............................................................................................................

Table of Contents

Warning........................................................................................................................

.............. 5

Specifications .................................................................................................................

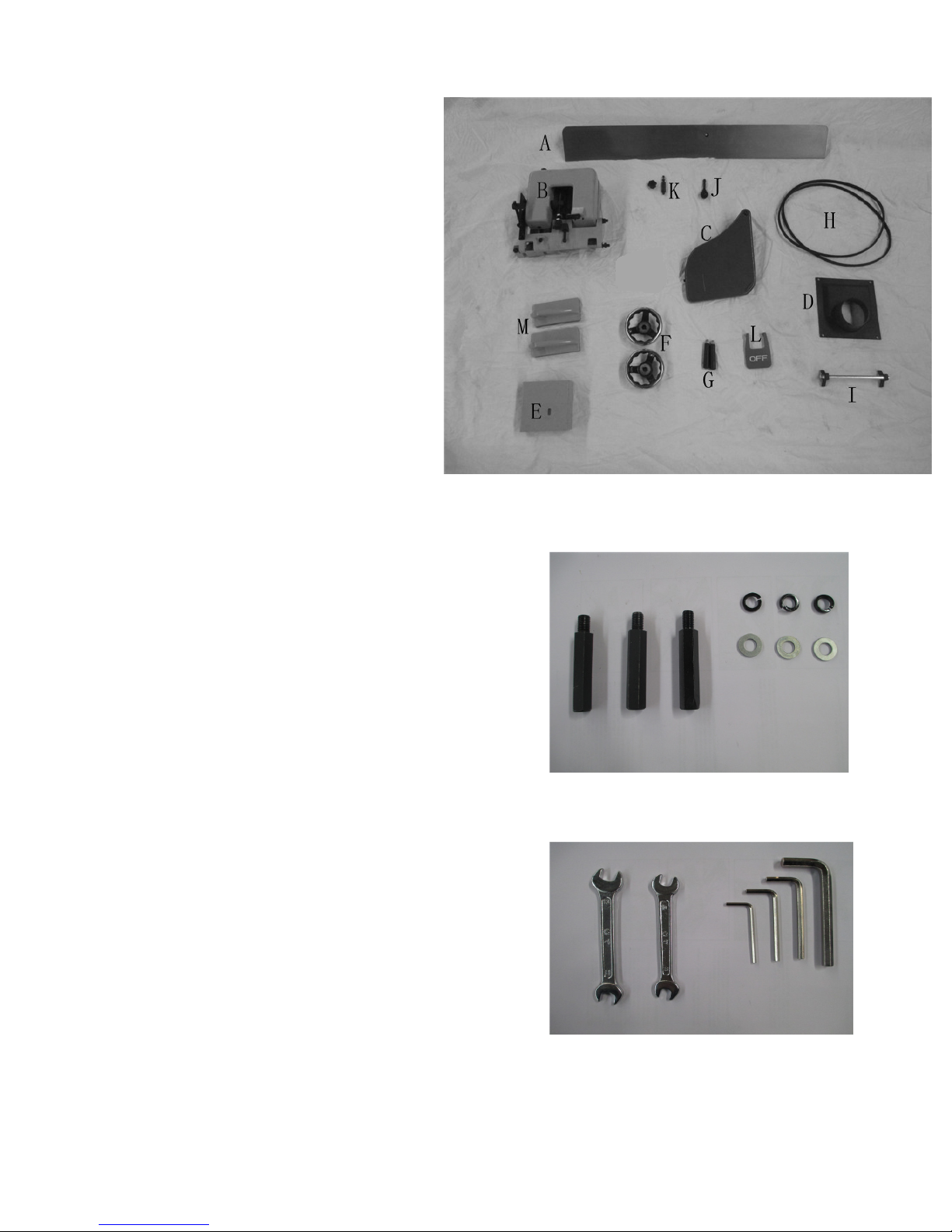

Unpacking and Cleanup

Unpacking and Cleanup

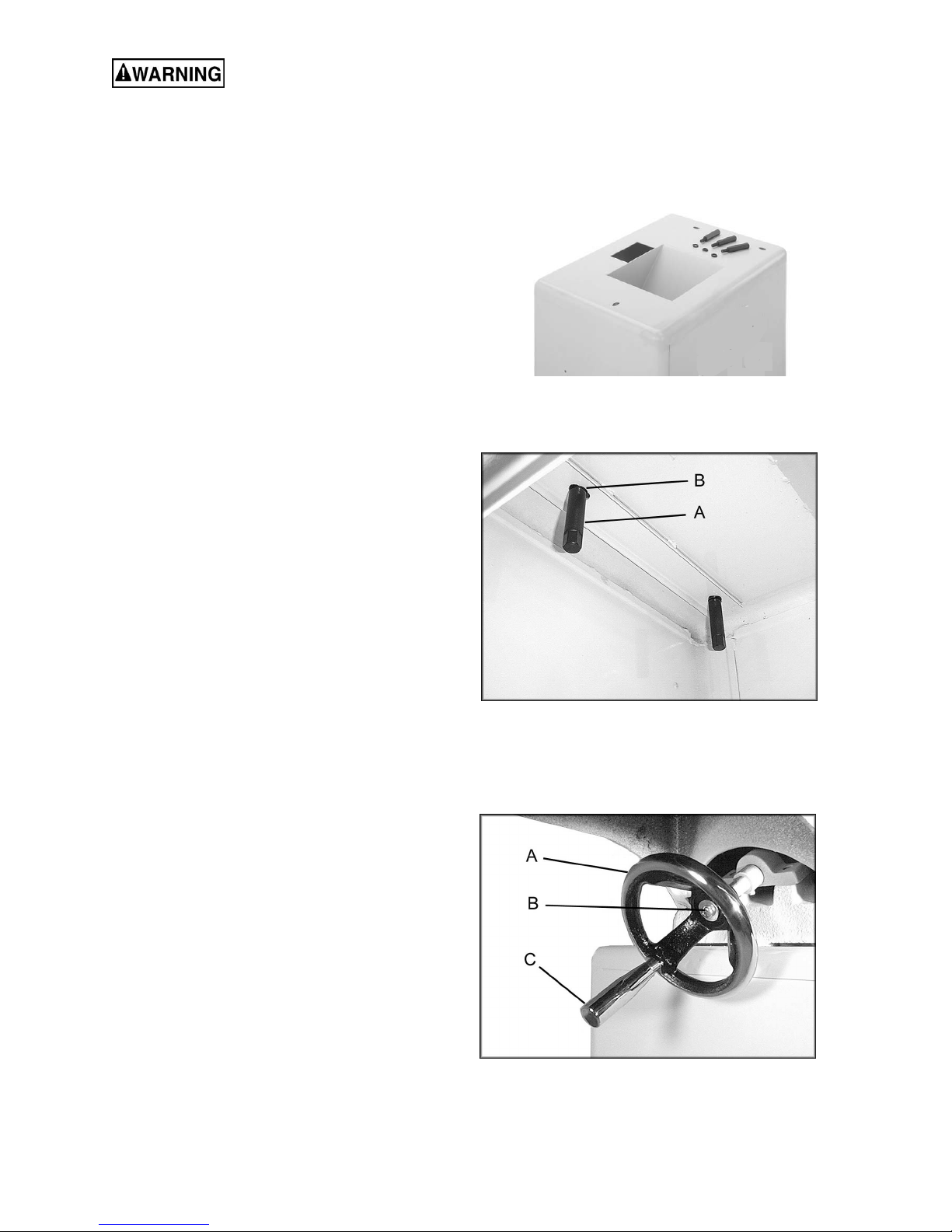

Installing Bed to Stand ........................................................................................................

Installing Handwheels

Installing V-Belts .............................................................................................................

Installing Cutterhead Guard

Installing Dust Chute..........................................................................................................

Adjustments ....................................................................................................................

90° Fence Adjustment...........................................................................................................

45° Fence Adjustment........................................................................................................................ 12

Removing and Replacing Knives

Replacing or Rotating Knife Inserts

Gib Adjustment .................................................................................................................

Operation ......................................................................................................................

Jointing Warped Material

Direction of Grain.............................................................................................................

Bevel Cut......................................................................................................................

Taper Cut..............................................................................................................................

Rabbet Cut ...............................................................................................................................

Maintenance...............................................................................................................................

Lubrication ...............................................................................................................................

Blade Care...............................................................................................................................

Sharpening the Knives

Cutterhead Removal

Instakking Fende To Fence Carriage.............................