TABLE OF CONTENTS

Introduction...................................................................................................................................... i

1 Safety.................................................................................................................................................... 1

1.1 Signal Words................................................................................................................................... 1

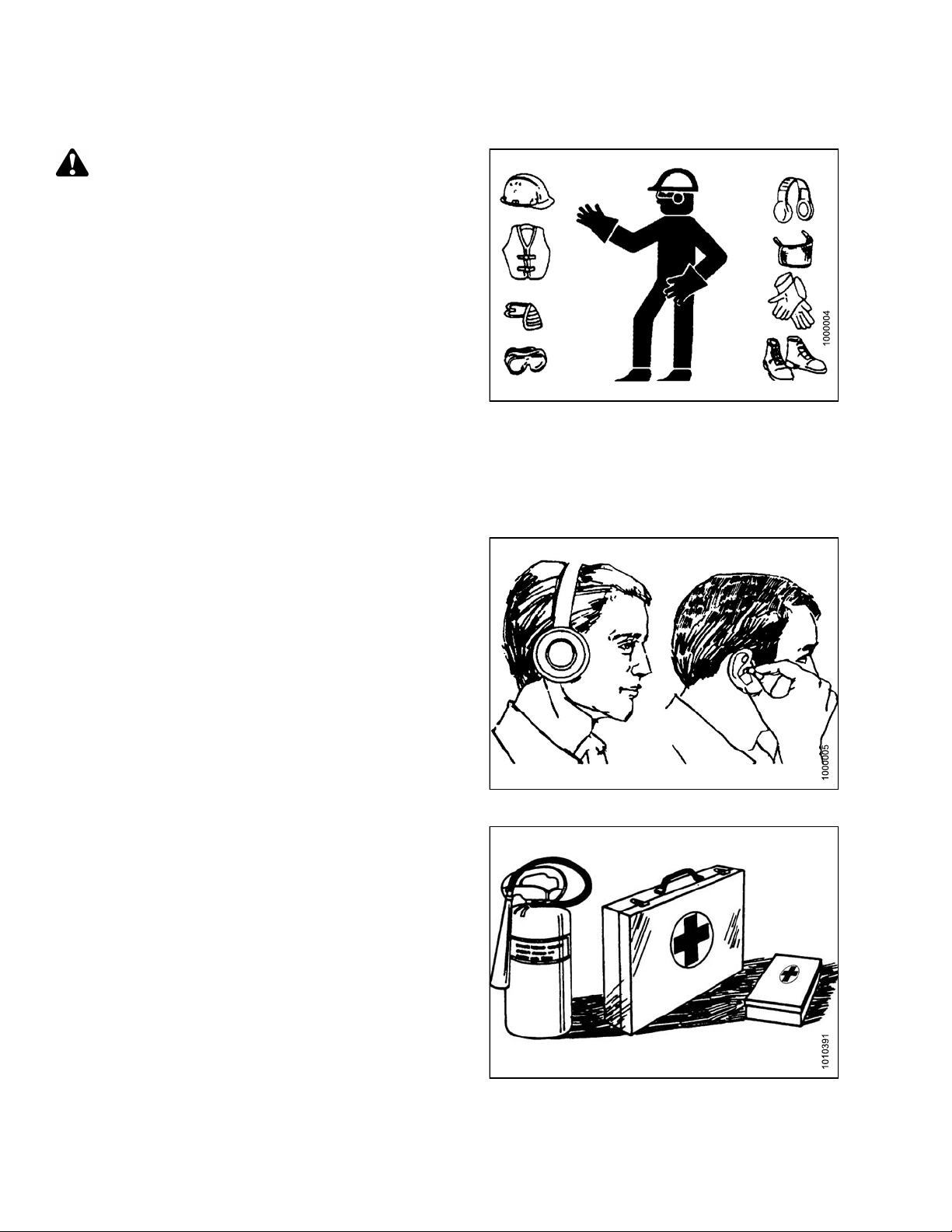

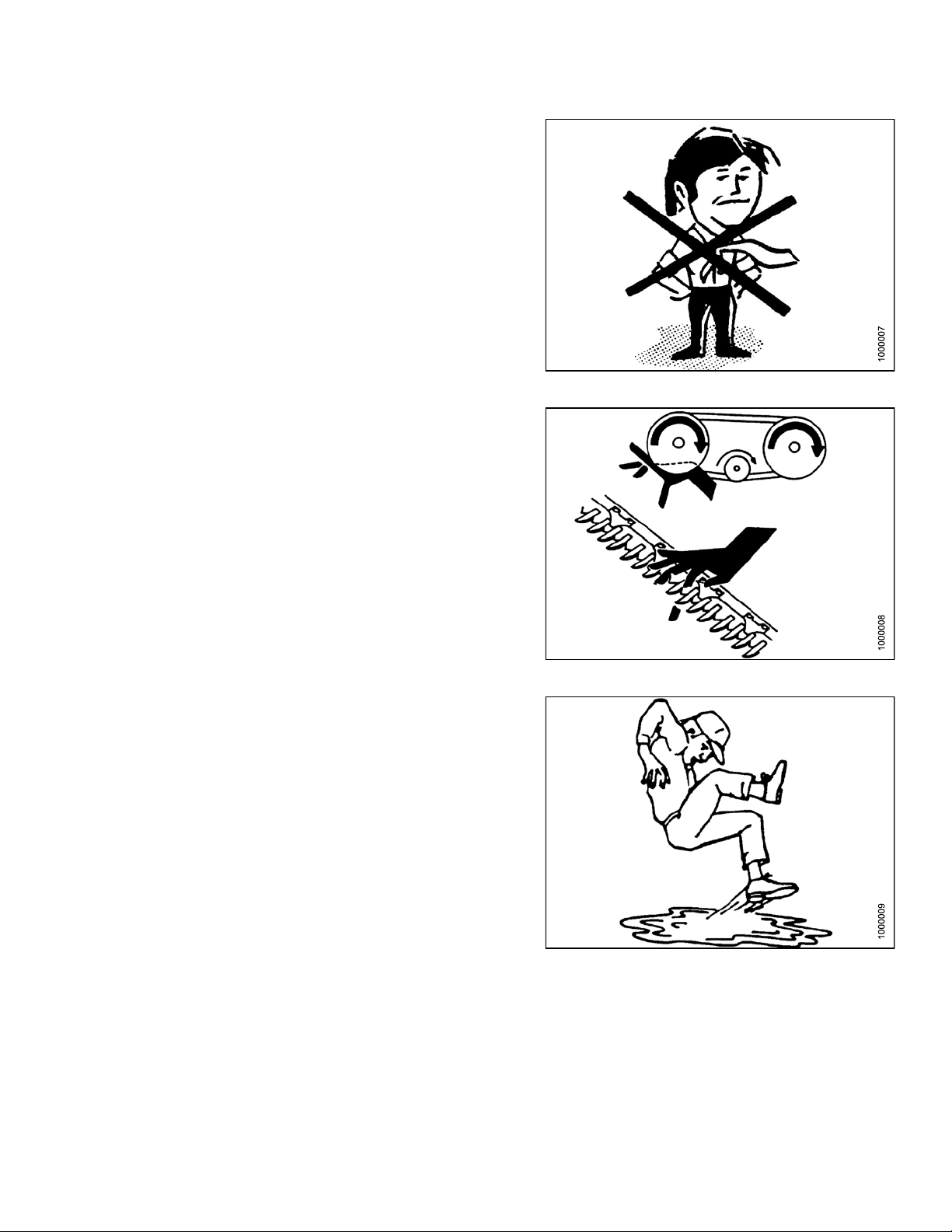

1.2 General Safety ................................................................................................................................ 2

1.3 Battery Safety.................................................................................................................................. 4

1.4 Safety Signs.................................................................................................................................... 5

2 Unloading the Windrower...................................................................................................................... 7

2.1 Using One Forklift to Unload Windrower............................................................................................7

3 Assembling the Windrower................................................................................................................... 9

3.1 Repositioning Right Leg................................................................................................................... 9

3.2 Installing Drive Wheels....................................................................................................................11

3.3 Installing Caster Wheels................................................................................................................. 12

3.4 Repositioning Walking Beam and Installing Caster Wheel Shocks..................................................... 13

3.5 Lowering Steps.............................................................................................................................. 16

3.6 Installing Windshield Access Step................................................................................................... 17

3.7 Positioning Mirror Arms.................................................................................................................. 18

3.8 Installing Slow Moving Vehicle (SMV) Signs .................................................................................... 19

3.9 Replacing Speed Identification Symbol (SIS) Decal (US Only).......................................................... 20

3.10 Installing Rear Ballast Package ...................................................................................................... 21

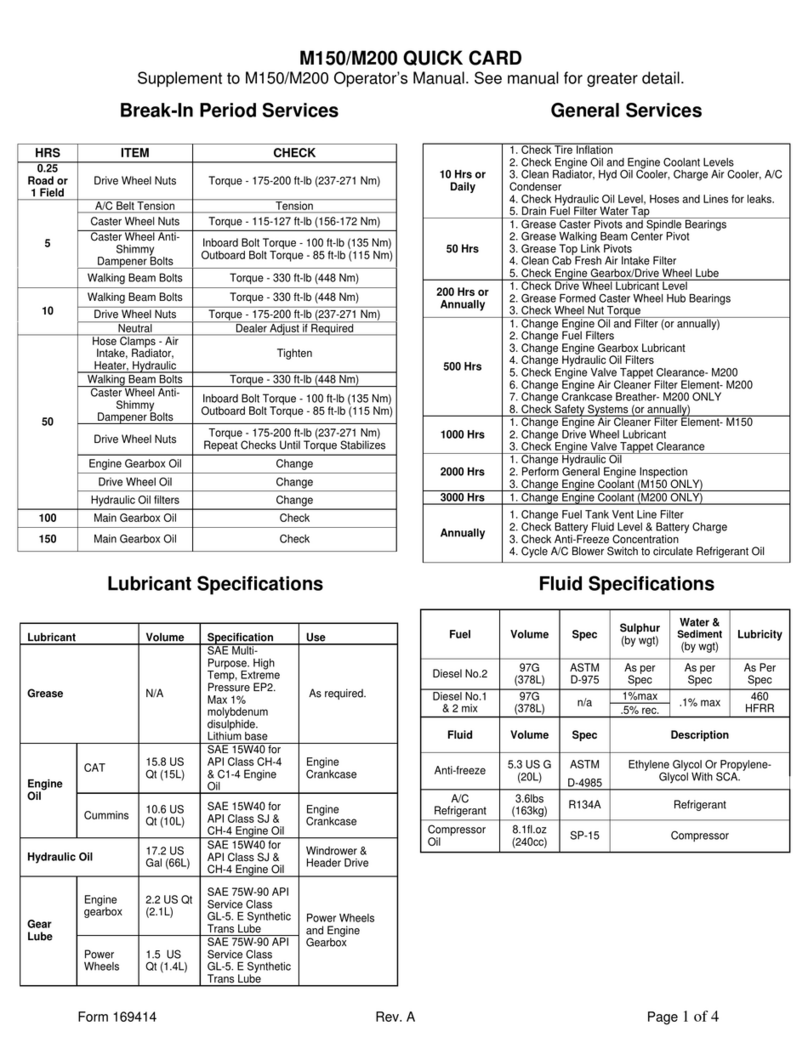

3.11 Lubricating the Windrower.............................................................................................................. 25

3.11.1 Lubrication Procedure ............................................................................................................ 25

3.11.2 Lubrication Points................................................................................................................... 25

3.12 Connecting Batteries...................................................................................................................... 26

3.13 Starting the Engine........................................................................................................................ 28

4 Attaching Headers to M1 Series Windrower........................................................................................ 31

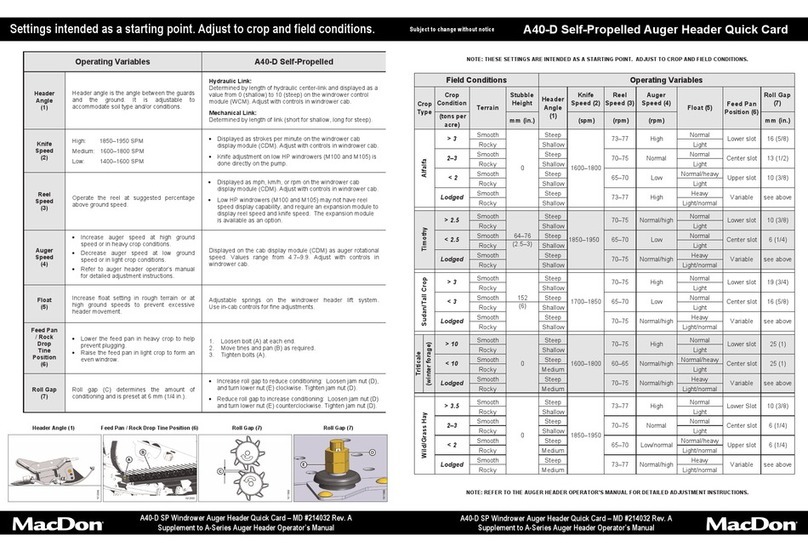

4.1 A40 D Auger Header...................................................................................................................... 31

4.1.1 Attaching an A40 D Auger Header........................................................................................... 31

4.1.2 Connecting A40 D Hydraulics.................................................................................................. 36

4.1.3 Detaching an A40 D Auger Header.......................................................................................... 38

4.2 D1X or D1XL Series Header........................................................................................................... 43

4.2.1 Attaching Draper Header Supports.......................................................................................... 43

4.2.2 Attaching a D1X or D1XL Series Header.................................................................................. 43

4.2.3 Connecting D1X or D1XL Series Hydraulics............................................................................. 49

4.2.4 Detaching a D1X or D1XL Series Header................................................................................. 52

4.3 R85 16-Foot Header...................................................................................................................... 57

4.3.1 Attaching an R85 16-Foot Header........................................................................................... 57

4.3.2 Connecting R85 16-Foot Header Hydraulics ............................................................................ 63

4.3.3 Detaching R85 16-Foot Header............................................................................................... 65

5 Performing Predelivery Checks........................................................................................................... 69

5.1 Completing Predelivery Checklist.................................................................................................... 69

5.1.1 Recording Serial Numbers...................................................................................................... 69

5.1.2 Checking and Adding Wheel Drive Lubricant Level................................................................... 70

5.1.3 Checking Tire Pressures......................................................................................................... 70

5.1.4 Checking Engine Air Intake..................................................................................................... 72

5.1.5 Checking Engine Oil Level...................................................................................................... 72

5.1.6 Checking and Adding Hydraulic Oil.......................................................................................... 73

5.1.7 Checking Fuel Separator........................................................................................................ 74

5.1.8 Checking Engine Coolant Level............................................................................................... 74

5.1.9 Checking Engine Gearbox Lubricant Level and Adding Lubricant.............................................. 76

5.1.10 Checking Air Conditioning (A/C) Compressor Belts................................................................... 76

5.1.11 Checking Operating Safety System......................................................................................... 76

5.2 Performing Operational Checks...................................................................................................... 78

5.2.1 Checking Harvest Performance Display (HPT)......................................................................... 78

214056 iii Revision A