215028 iii Revision A

Introduction ................................................................................................................................................i

Summary of Changes....................................................................................................................................ii

Chapter 1: Safety ........................................................................................................................................ 1

1.1 Signal Words .........................................................................................................................................1

1.2 General Safety .......................................................................................................................................2

1.3 Welding Precaution ................................................................................................................................4

1.4 Safety Signs ...........................................................................................................................................5

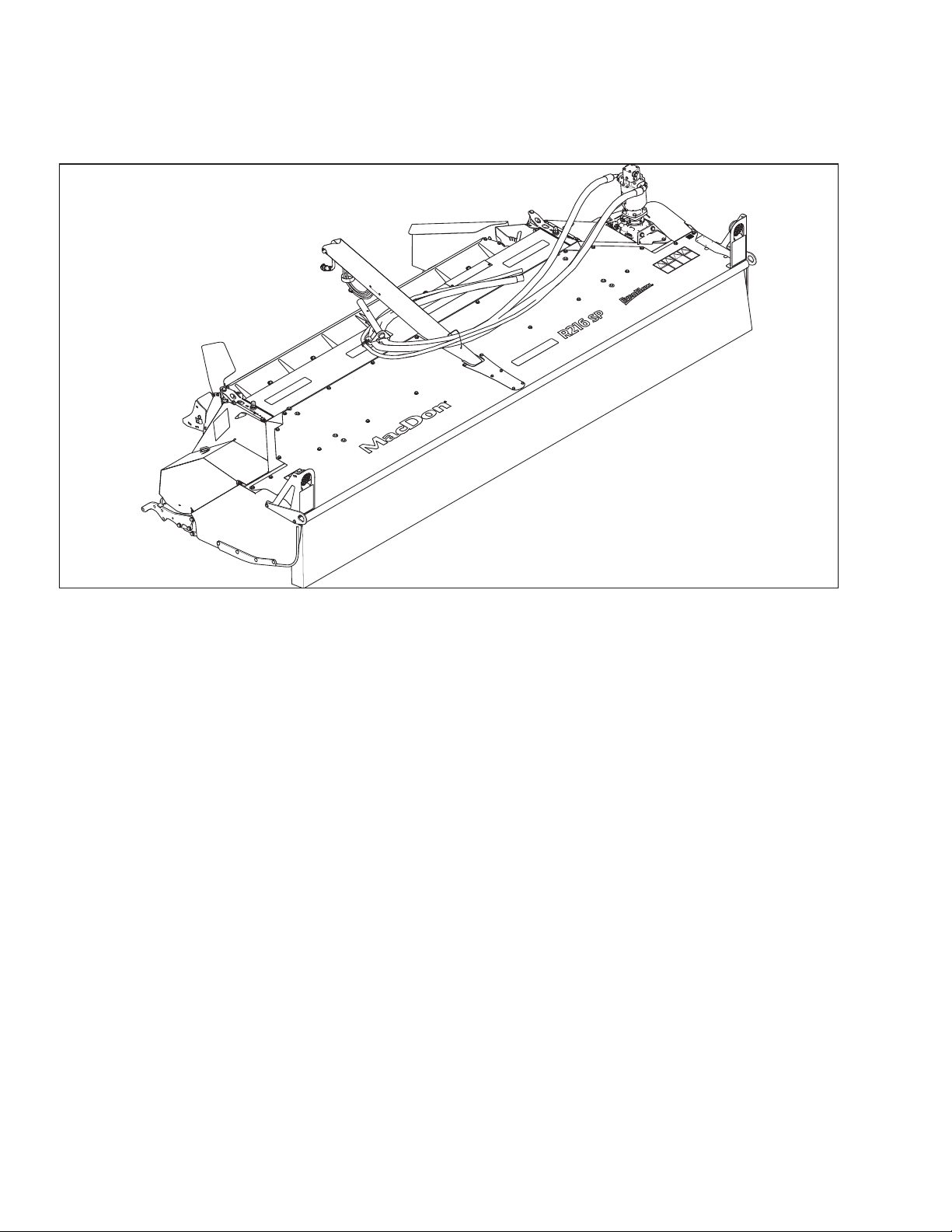

Chapter 2: Unloading the Header from a Trailer ...................................................................................... 7

Chapter 3: Assembling the Header ............................................................................................................ 9

3.1 Removing Shipping Supports ....................................................................................................................9

3.2 Lowering the Header............................................................................................................................. 11

3.3 Unpacking Hydraulic Hoses and Electrical Harness –M1240......................................................................... 13

3.4 Removing Shipping Stands ..................................................................................................................... 14

3.5 Installing Manual Rear Deflectors ............................................................................................................ 17

Chapter 4: Attaching Rotary Disc Header to M1240 Windrower........................................................... 19

4.1 Attaching Header to M1240 ................................................................................................................... 19

4.1.1 Assembling and Installing Forming Shield ......................................................................................... 19

4.1.2 Routing Electrical Harness ............................................................................................................. 26

4.1.3 Attaching Rotary Disc Header......................................................................................................... 29

4.1.4 Connecting Rotary Disc Header Hydraulics Using Quick Couplers –M1240 Windrowers............................ 34

4.1.5 Connecting Rotary Disc Header Hydraulics Using Hard Plumbing .......................................................... 36

4.1.6 Restoring Float for Rotary Disc Header............................................................................................. 38

4.1.7 Calibrating Windrower Knife Drive on the Harvest Performance Tracker Display ..................................... 40

4.1.8 Unpacking the Curtain .................................................................................................................. 41

Chapter 5: Installing Options.................................................................................................................... 43

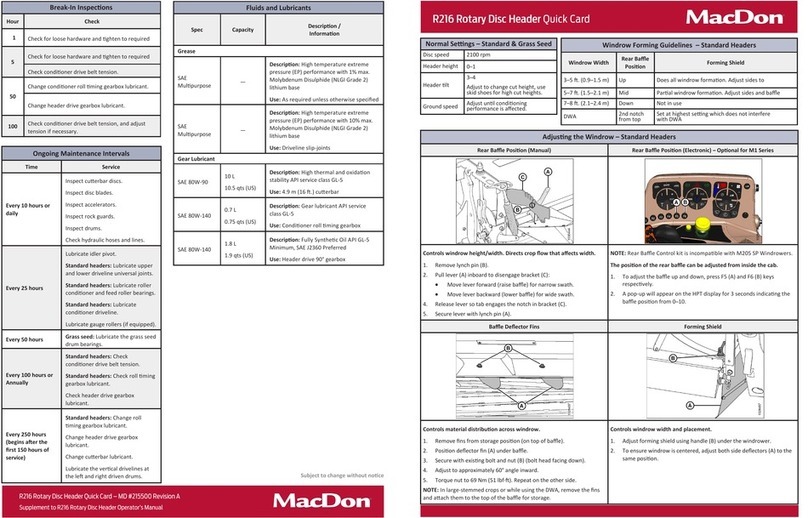

Chapter 6: Lubricating the Rotary Disc Header....................................................................................... 45

6.1 Lubrication Locations ............................................................................................................................ 46

Chapter 7: Performing Predelivery Checks.............................................................................................. 49

7.1 Conditioner Drive Belt ........................................................................................................................... 49

7.1.1 Inspecting Conditioner Drive Belt.................................................................................................... 49

7.1.2 Adjusting Conditioner Drive Belt ..................................................................................................... 50

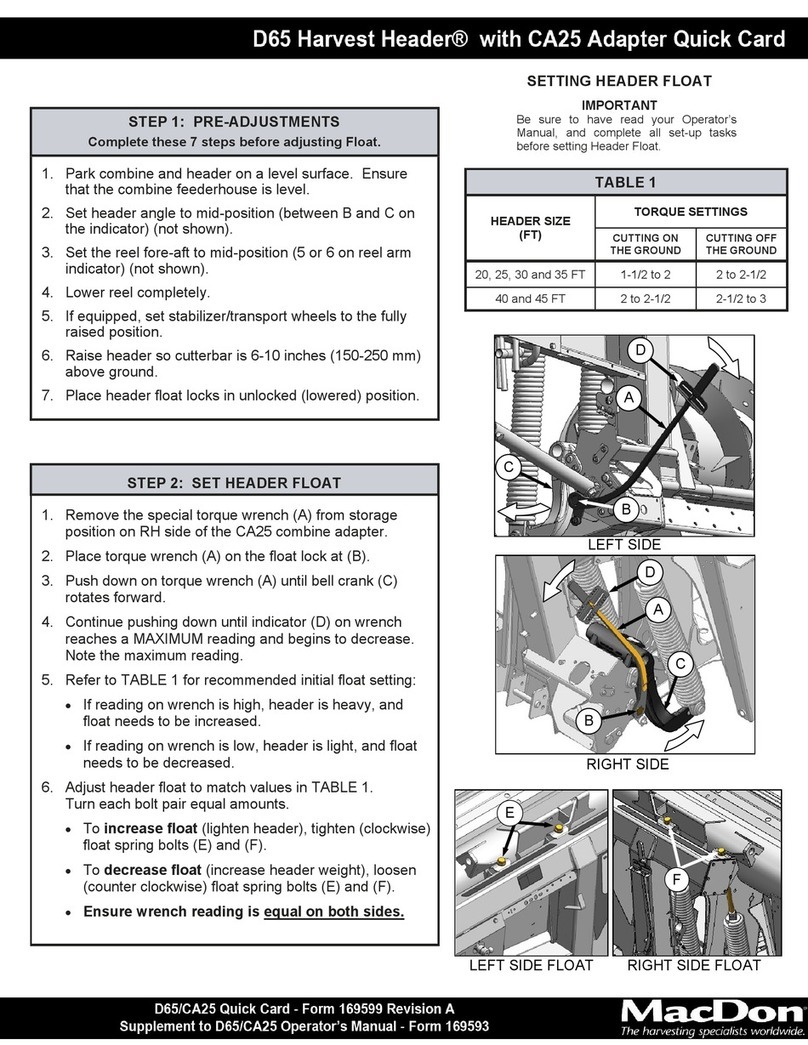

7.2 Header Float........................................................................................................................................ 52

7.2.1 Checking Float............................................................................................................................. 52

7.2.2 Setting the Float .......................................................................................................................... 52

7.3 Suspended Drum Drive.......................................................................................................................... 54

7.3.1 Checking Suspended Drum Drive .................................................................................................... 54

7.4 Feed Roll Drive..................................................................................................................................... 55

TABLE OF CONTENTS