TABLE OF CONTENTS

Form 169304 3Model Year - 2009

6.2.2 Windrower Tractor Operating Symbols ...................................................................................................45

6.2.3 Header Functions....................................................................................................................................46

6.3 WINDROWER TRACTOR OPERATION.....................................................................................47

6.3.1 Operational Safety ..................................................................................................................................47

6.3.2 Break-In Period .......................................................................................................................................47

6.3.3 Pre-Season Check..................................................................................................................................48

6.3.4 Daily Check.............................................................................................................................................48

6.3.5 Engine Operation ....................................................................................................................................49

6.3.6 Driving the Windrower.............................................................................................................................53

6.3.7 Adjustable Caster Tread Width (Optional) ..............................................................................................57

6.3.8 Transporting............................................................................................................................................58

6.3.9 Storage ...................................................................................................................................................61

6.4 HEADER OPERATION................................................................................................................62

6.4.1 Header Lift Cylinder Stops ......................................................................................................................62

6.4.2 Header Flotation .....................................................................................................................................63

6.4.3 Header Drive...........................................................................................................................................66

6.4.4 Header Angle..........................................................................................................................................66

6.4.5 Cutting Height .........................................................................................................................................68

6.5 D SERIES HEADER OPERATION..............................................................................................70

6.5.1 Header Attachment - D Series ................................................................................................................70

6.5.2 Header Detachment - D Series ...............................................................................................................73

6.5.3 Reel Speed .............................................................................................................................................75

6.5.4 Draper Speed .........................................................................................................................................77

6.5.5 Knife Speed ............................................................................................................................................79

6.5.6 Deck Shift (Optional)...............................................................................................................................81

6.6 A SERIES HEADER OPERATION ..............................................................................................82

6.6.1 Header Attachment – A Series ...............................................................................................................82

6.6.2 Header Detachment – A Series ..............................................................................................................84

6.6.3 Auger Speed...........................................................................................................................................86

6.6.4 Knife Speed ............................................................................................................................................87

7MAINTENANCE/SERVICE ..................................................................................................................89

7.1 PREPARATION FOR SERVICING .............................................................................................89

7.1.1 Welding Precautions ...............................................................................................................................89

7.2 RECOMMENDED SAFETY PROCEDURES ..............................................................................89

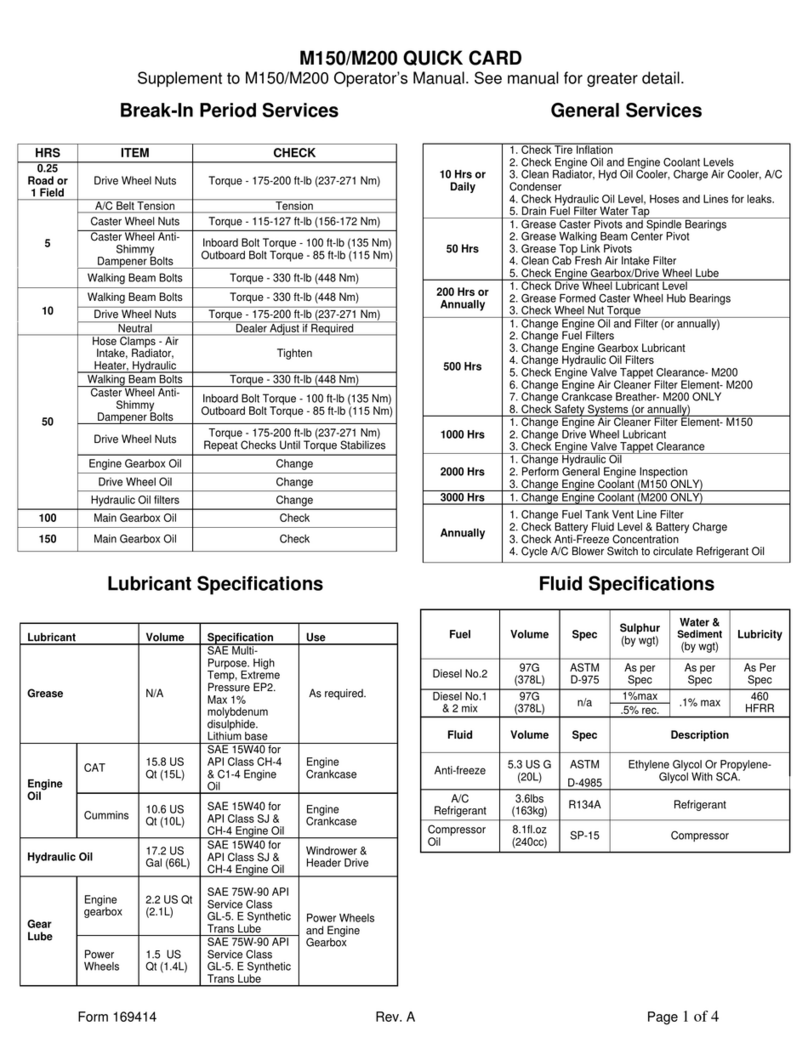

7.3 MAINTENANCE SPECIFICATIONS ...........................................................................................90

7.3.1 Recommended Fluids, Fuel, and Lubricants...........................................................................................90

7.3.2 Recommended Torques .........................................................................................................................91

7.3.3 Conversion Chart ....................................................................................................................................93

7.4 ENGINE COMPARTMENT HOOD ..............................................................................................94

7.5 MAINTENANCE PLATFORM ......................................................................................................95

7.5.1 Opening/Closing Platform .......................................................................................................................95

7.5.2 Opening/Closing Platform for Major Servicing ........................................................................................95

7.6 LUBRICATING THE WINDROWER............................................................................................96

7.6.1 Procedure ...............................................................................................................................................96

7.6.2 Lubrication Points ...................................................................................................................................97

7.7 OPERATOR’S STATION.............................................................................................................98

7.7.1 Seat Belts ...............................................................................................................................................98

7.7.2 Safety Systems .......................................................................................................................................98

7.7.3 Traction Drive Adjustments.....................................................................................................................99

7.7.4 Neutral Set-Up Procedure.....................................................................................................................104

7.7.5 HVAC System .......................................................................................................................................106

7.8 ENGINE .....................................................................................................................................109

7.8.1 General Engine Inspection....................................................................................................................109

7.8.2 Oil Level ................................................................................................................................................109

7.8.3 Changing Oil and Oil Filter....................................................................................................................110

7.8.4 Air Intake System..................................................................................................................................111

7.8.5 Fuel System..........................................................................................................................................114

7.8.6 Engine Cooling System.........................................................................................................................119

7.8.7 Exhaust System ....................................................................................................................................122

7.8.8 Belts......................................................................................................................................................123

7.8.9 Engine Speed .......................................................................................................................................124

7.9 COOLING BOX..........................................................................................................................125

7.9.1 Cooling Box Screen Cleaners ...............................................................................................................125