262300 vi Revision A

6.3 Connecting Header Hydraulic and Electrical Systems –M1240 Windrower...................................................... 83

6.4 Connecting Header Hydraulic and Electrical Systems –M1170 Windrower...................................................... 89

6.4.1 Calibrating M1 Series Windrower Knife Drive and Header on Harvest Performance Tracker Display............ 92

6.5 Connecting Header Hydraulic and Electrical Systems –M155 or M155E4 Windrowers ...................................... 94

6.6 Connecting Header Hydraulic and Electrical Systems –M205 Windrower ..................................................... 101

Chapter 7: Unpacking Curtains .............................................................................................................. 103

Chapter 8: Installing Options.................................................................................................................. 105

8.1 Installing Tall Crop Dividers .................................................................................................................. 105

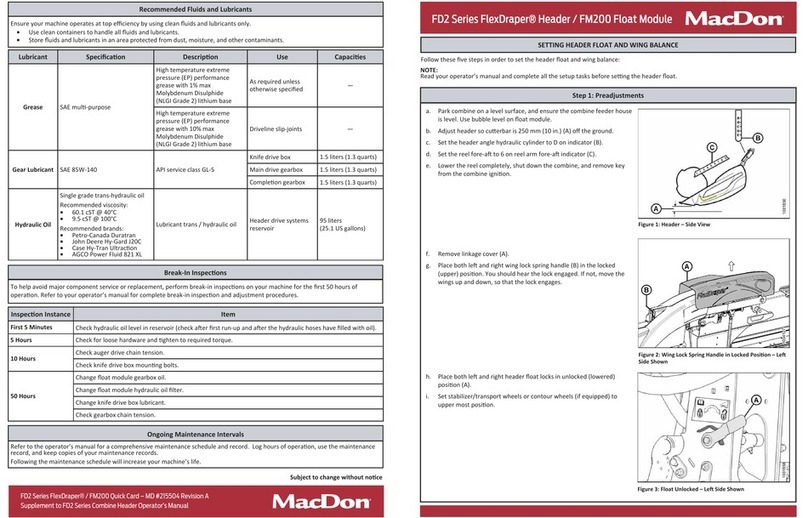

Chapter 9: Lubricating Rotary Disc Header ........................................................................................... 107

9.1 Lubrication Locations .......................................................................................................................... 108

Chapter 10: Performing Predelivery Checks.......................................................................................... 109

10.1 Checking Conditioner Drive Belt .......................................................................................................... 109

10.1.1 Adjusting Conditioner Drive Belt ................................................................................................. 110

10.2 Checking Skid Shoes .......................................................................................................................... 111

10.3 Checking Float –M1 and M2 Series Windrowers .................................................................................... 112

10.3.1 Setting Float –M1 Series Windrowers.......................................................................................... 113

10.3.2 Setting Float –M2 Series Windrowers.......................................................................................... 114

10.4 Checking Float –M Series Windrower .................................................................................................. 116

10.4.1 Adjusting Float Using Drawbolts –M Series Windrowers ................................................................. 117

10.5 Checking Roll Timing ......................................................................................................................... 118

10.5.1 Adjusting Roll Timing ................................................................................................................ 118

10.6 Checking and Adding Lubricant –Conditioner Roll Timing Gearbox ............................................................ 121

10.7 Checking Header Drive Gearbox Lubricant............................................................................................. 123

10.8 Checking and Adding Lubricant –Cutterbar ........................................................................................... 124

10.9 Checking Roll Gap ............................................................................................................................. 126

10.9.1 Adjusting Roll Gap –Steel Rolls................................................................................................... 126

10.9.2 Adjusting Roll Gap –Polyurethane Rolls ....................................................................................... 127

10.10 Checking Roll Tension ...................................................................................................................... 128

10.10.1 Adjusting Roll Tension ............................................................................................................. 128

10.11 Adjusting Conditioner Baffle Position.................................................................................................. 129

10.12 Checking and Adjusting Forming Shield Deflector Position...................................................................... 130

10.13 Checking Lights............................................................................................................................... 131

10.14 Checking Manuals ........................................................................................................................... 132

10.15 Checking Disc Timing Tool and Spindle Nut Wrench .............................................................................. 133

10.16 Running up Header.......................................................................................................................... 134

Chapter 11: Reference............................................................................................................................ 135

11.1 Opening Driveshields......................................................................................................................... 135

11.2 Closing Driveshields........................................................................................................................... 137

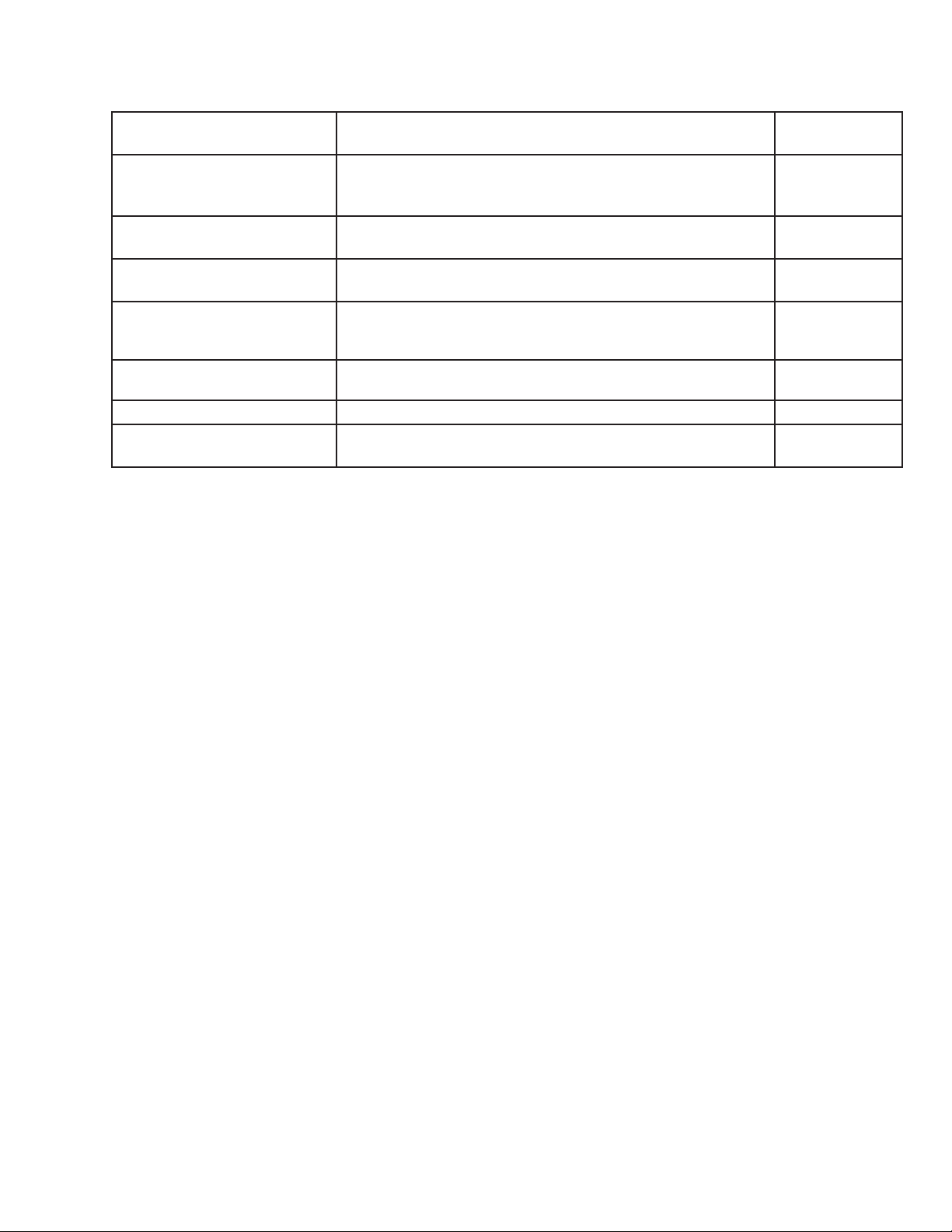

TABLE OF CONTENTS