- 6 -

or with a rag. Use a brush or vacuum to clear metal chips.

8. Stopping spindle by hand. Stopping the spindle by putting your hand on the work piece or chuck creates an

extreme risk of entanglement, impact, crushing, friction, or cutting hazards. Never attempt to slow or stop the lathe

spindle with your hand. Allow the spindle to come to a stop on its own or use the brake.

9. Crashes. Aggressively driving the cutting tool or other lathe components into the chuck may cause an explosion of

metal fragments, which can result in severe impact injuries and major damage to the lathe. Not leaving lathe

unattended, and checking clearances before starting the lathe. Make sure no part of the tool, tool holder, compound

rest, cross slide, or carriage will contact the chuck during operation.

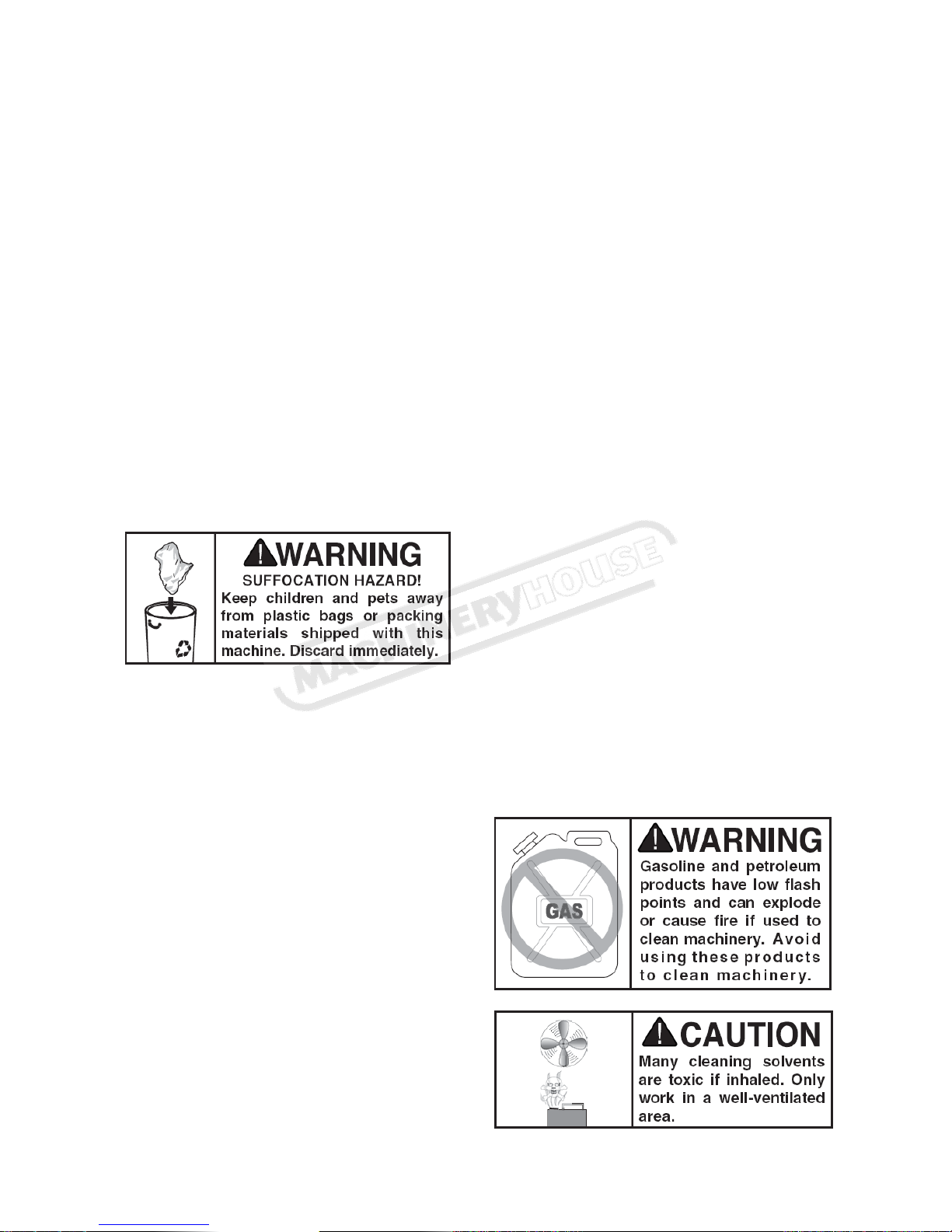

10. Coolant safety. Coolant is a very poisonous biohazard that can cause personal injury from skin contact alone.

Incorrectly positioned coolant nozzles can splash on the operator or the floor, resulting in an exposure or slipping

hazard. To decrease your risk, change coolant regularly and position the nozzle where it will not splash or end up on

the floor.

11. Tool selection. Cutting with an incorrect or dull tool increases the risk of accidental injury due to the extra force

required for the operation, which increases the risk of breaking or dislodging components that can cause small shards

of metal to become dangerous projectiles. Always select the right cutter for the job and make sure it is sharp. A

correct, sharp tool decreases strain and provides a better finish.

Additional chuck safety

WARNING!

1. Entanglement. Entanglement with a rotating chuck can lead to death, amputation, broken bones, or other serious

injury. Never attempt to slow or stop the lathe chuck by hand, and always roll up long sleeves, tie back long hair, and

remove any jewelry or loose apparel before operating.

2. Chuck speed rating. Excessive spindle speeds greatly increase the risk of the work piece or chuck being thrown

from the machine with deadly force. Never use spindle speeds faster than the chuck RPM rating or the safe limits of

your work piece.

3. Using correct equipment. Many work pieces can only be safely turned in a lathe if additional support equipment,

such as a tailstock or steady/follow rest, is used. If the operation is too hazardous to be completed with the lathe or

existing equipment, the operator must have enough experience to know when to use a different machine or find a

safer way.

4. Trained operators only. Using a chuck incorrect can result in work pieces coming loose at high speeds and

striking the operator or bystanders with deadly force. To reduce the risk of this hazard, read and understand this

document and seek additional training from an experienced chuck user before using a chuck.

5. Chuck capacity. Avoid exceeding the capacity of the chuck by clamping an oversized work piece. If the work

piece is too large to safely clamp with the chuck, use a face plate or a large chuck if possible. Otherwise, the work

piece could be thrown from the lathe during operation, resulting in serious impact injury or death.

6. Clamping force. Inadequate clamping force can lead to the work piece being thrown from the chuck and striking

the operator or bystanders. Maximum clamping force is achieved when the chuck is properly maintained and

lubricated, all jaws are fully engaged with the work piece, and the maximum chuck clamping diameter is not

exceeded.

7. Proper maintenance. All chucks must be properly maintained and lubricated to achieve maximum clamping force

and withstand the rigors of centrifugal force. To reduce the risk of a thrown work piece, follow all maintenance

intervals and instructions in this document.

8. Disconnect power. Serious entanglement or impact injuries could occur if the lathe is started while you are

adjusting, servicing, or installing the chuck. Always disconnect the lathe from power before performing these

procedures.