9PM-1440-2SM 8-2023 Copyright © 2023 Quality Machine Tools, LLC

Section 3 USING THE LATHE

What is not in this section ...

This is a conventional engine lathe that requires little expla-

nation other than specic numbers — speed selection, thread

cutting, and the saddle/cross-slide power feed system. Be-

cause the user is assumed to be familiar with general purpose

metal lathes, this section contains no tutorial.

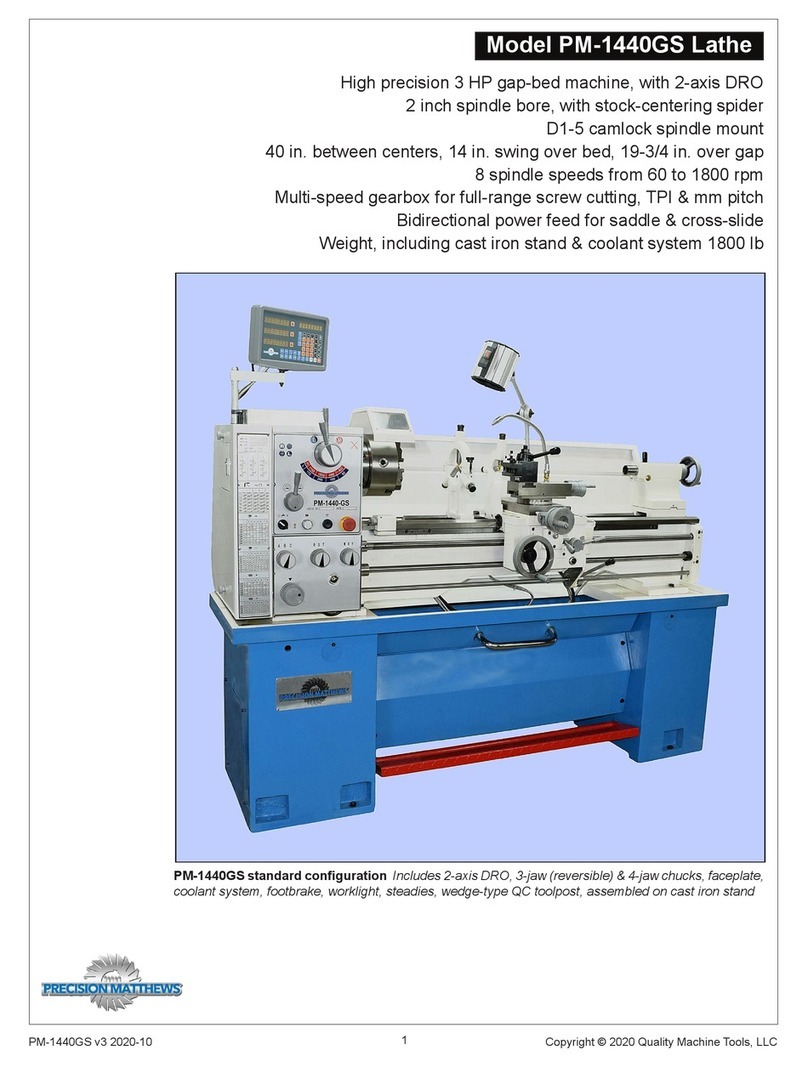

Figure 3-1A 2SM Front panel and power-feed gearbox controls

(1) Power lamp

(2) Intermediate power switch

(3) Coolant ON/OFF

(4) E-Stop button. Disables the machine when pressed; twist it (pops

out) to restore power

(5) Jog push button — runs the spindle forward a few degrees when

pressed (only if the motor control lever is mid-travel, Figure 3-2)

(6) Direction lever (power feed), shown here set to the usual direc-

tion—saddle moves to the left

(7) Speed range selectors — Hi/Lo, plus 8 gearbox speeds

(8) This knob selects either feed shaft or leadscrew, Figure 3-2.

Precision Matthews recommends draining and relling all

three gearboxes (Headstock, Power Feed and Apron) after

approximately 20 hours of initial run time. Lubricants are

specied in Section 4.

8

Feed rate

1-2-3-4-5-6-7-8

Oil

level

2 3 45

1

7

PM-1440-2SM INITIAL CHECKS

Do not shift gears while the spindle is running

Before connecting power, do the following:

1. Visually check the entire machine for possible distur-

bance in shipping, including the motor, belt and external

gears under the belt cover left of the headstock. Replace

the belt cover.

2. Check oil level (sight glasses) in the headstock, the

power-feed gearbox, and the apron. See Section 4.

3. If a chuck or faceplate is installed, check tightness of the

six Camlocks on the spindle nose, explained later.

4. Set the larger gear lever to L(low), and the smaller lever

to 76-60 (these numbers apply if the motor-to-headstock

belt I-II is set for low speed); if I-II is set for high speed,

the numbers will be 430-340. Make sure the gears are

properly meshed by “jiggling while shifting” — rotate the

chuck back and forth by hand while moving the levers

into position. Make certain that the motor control lever is

set to OFF, mid-travel, Figure 3-2.

5. Set the power-feed direction lever to its center (neutral)

position, Figure 3-1A (6).

6. Check that there are no clamps or locks on moving parts,

and that movement of the saddle is not impeded by items

fastened to the bed.

7. Check that the footbrake treadle is released (UP).

8. Set the saddle and cross slide to approximate mid-travel.

9. Switch on 220 Vac power (rotary switch located at

back-left of the headstock), then turn on the "intermedi-

ate" power switch, Figure 3-1A (2). The power lamp (1)

should light, unless a circuit breaker in the electrical com-

partment has tripped, or the Emergency Stop (E-Stop)

button is pushed in (it should pop out when twisted

clockwise).

10. Shift the motor control lever DOWN. The spindle should

turn forward, counter clockwise, viewed at the chuck

(nose) end.

11. Check the emergency function by pressing the E-Stop

button. The motor should stop. If this doesn’t happen,

the E-stop function is defective, and needs attention.

12. Reset (twist) the E-Stop button to restore power.

13. Check that the footbrake stops the motor — a

microswitch in the LH stand cabinet disconnects power,

and a drum brake in the drive pulley stops the spindle.

14. Return the motor control lever to OFF, mid-travel.

15. Shift the motor control lever UP. The spindle should

Reverse, clockwise rotation, viewed at the chuck (nose)

end.

6