Limits of increasing the performance of Industrial Ethernet protocols - Scientific Figure on ResearchGate. Available

from: https://www.researchgate.net/figure/EtherCAT-with-100-Mbps_fig4_4304922 [accessed 21 Jan, 2022]

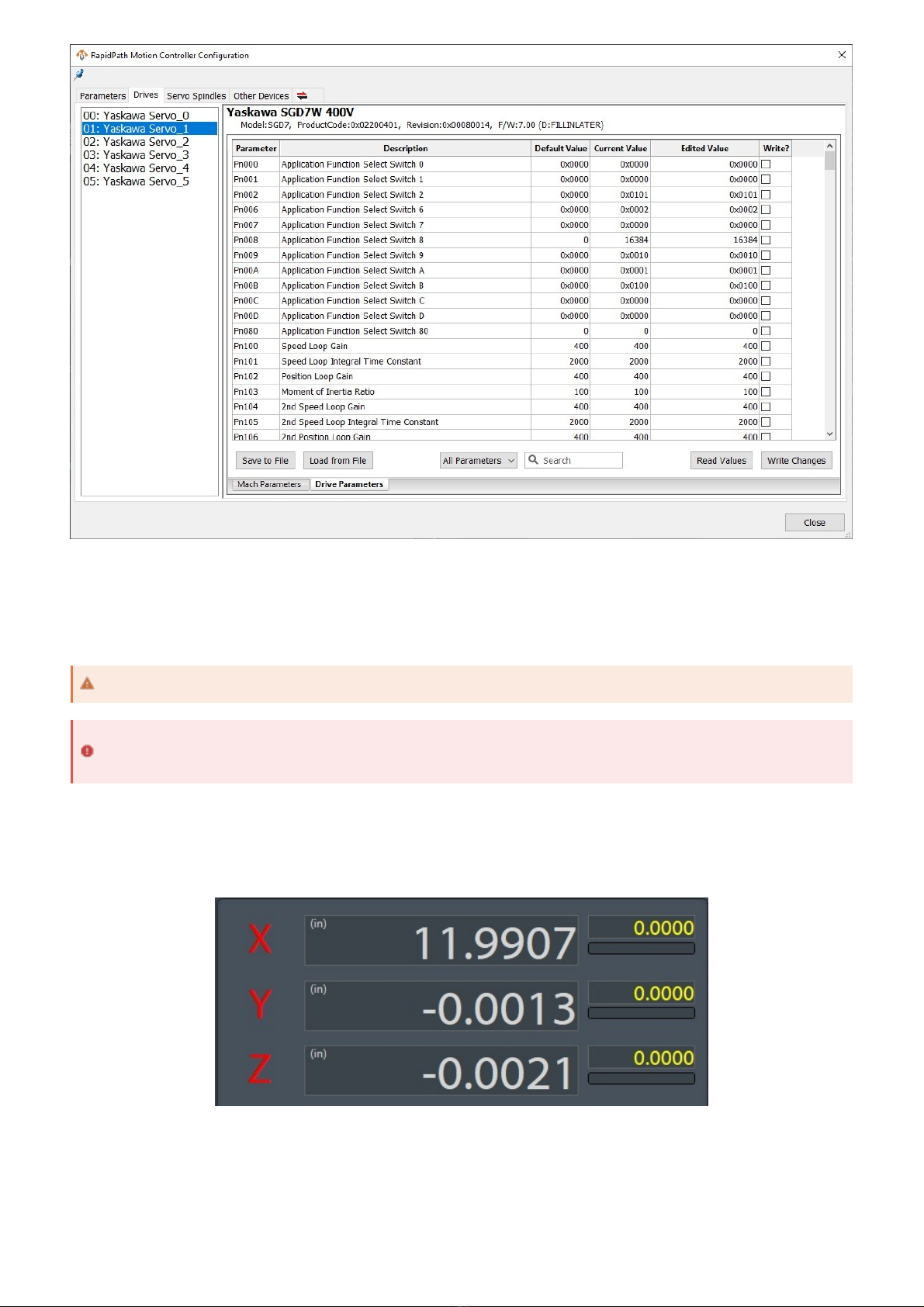

RapidPath is MachMotion's EtherCAT motion controller solution. It has integrations for a range of Yaskawa EtherCAT

servo drives, VFDs, the Titanio EverCNC stepper drive, and a subset of the Beckhoff I/O devices. It can be licensed for

up to 64 motors. The control uses a Windows interface to a real time operating system where the EtherCAT master

resides. The operating system is called Intime and the interface is called RapidSetup.

An EtherCAT network is comprised of a communication master and a series of network nodes. Each millisecond, a

packet of information (known as a frame) is sent from the master to the network and a responding frame is received

back. The frame from the master includes information for each node, such as commanded axis position and outputs.

The frame the master receives back includes feedback position and input status, among many other things.

An EtherCAT network is a sequence of devices called nodes. A node is added to the network by plugging an EtherCAT

cable from the out port of one node to the in port of the next node. The in port of the first node is attached to the

EtherCAT port on the back of the control. The out port of the last node will be empty and unconnected. This will create

a chain of devices in order.

I/O couplers will have multiple node items on the network for each coupler. Only the couplers have in and out ports,

but each I/O slice is a distinct node on the network. Some I/O slices that are all 0V connections are not part of the

network. Other example of potential network nodes include servo drives and VFDs.

When there are changes to the network topology due to nodes being added or removed, the communication on the

network will be shut down and the system will have to regenerate. If the machine is running during this time, all

systems will disable. The machine is unable to be enabled while the network is not operational.

If the network has had nodes added to it, the regeneration process will need no interaction from the operator. If the

network has had nodes removed from it, the control will ask if the user wants to override the saved topology and use

the new network. This may result in settings or I/O mappings being lost, as some devices are no longer on the network.

Note that the network does not distinguish unique order of nodes on the network; if you swap the order of two servo

2000 Series RapidPath Operating

Manual

Introduction

EtherCAT Network Basics

Communication

Building a Network

Regenerating a Network