EVOC MEC--5004 User manual

MEC5004

Fanless Embedded PC with Low Power

Consumption

Version:A1

Announcement

TheinformationinthismanualrepresentsnopromiseorguaranteebyEVOC.EVOC

reserves the right to make changes to the manual, without prior notice to customer.

EVOC will notbe held liable for any direct,indirect, intended or unintended losses

and/orhiddendangersduetoinstallationorimproperoperation.

EVOC is a registered trademark of EVOC Intelligent Technology Co., Ltd. All

trademarks,registeredtrademarks,andtradenamesusedinthisUser’sGuidearethe

propertyoftheirrespectiveowners.

EVOCIntelligentTechnologyCo.,Ltd.©2008,CopyrightReserved.Nopartofthis

manual may be reproduced in any form or by any means, electronic or mechanical,

withoutpermissioninwritingfromEVOC.

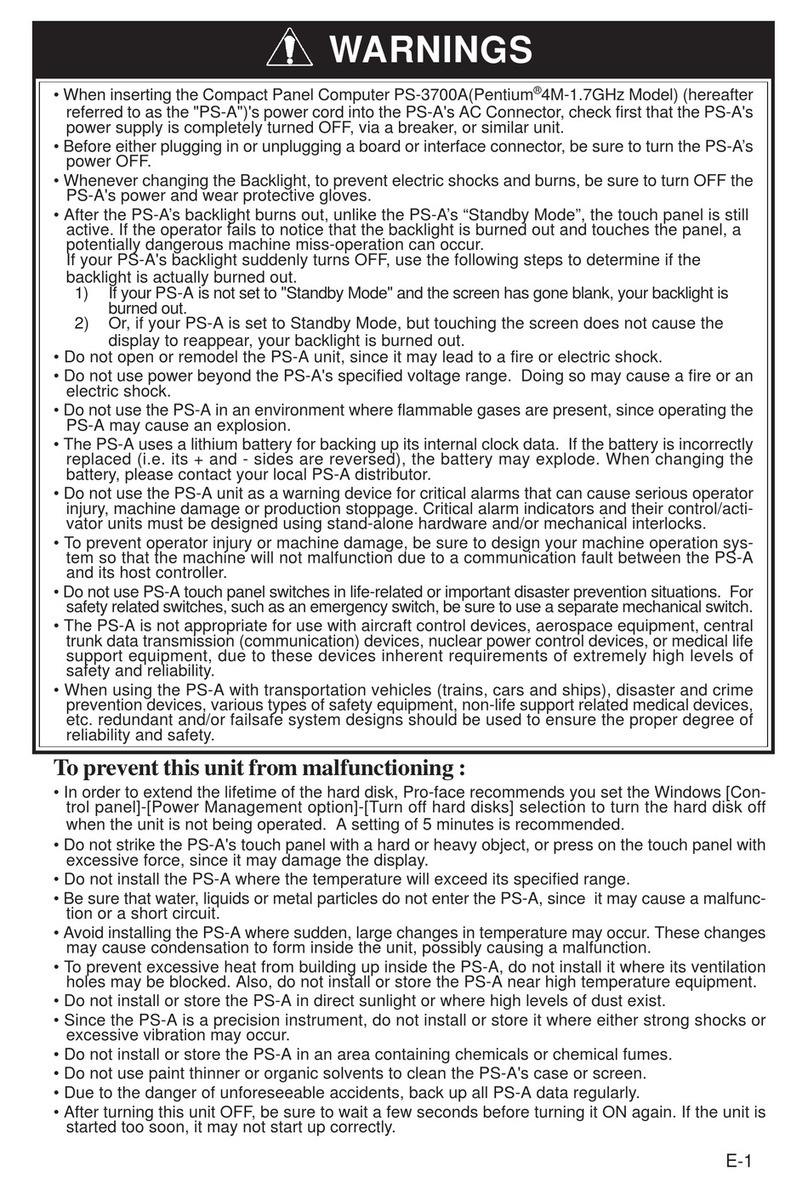

SafetyInstructions

1. Pleasereadtheuser'smanualcarefullybeforeusingtheproduct.

2. Before inserting, removing or reconfiguring motherboard or expansion card,

firstdisconnectthecomputerandperipheralsfrom theirpowersources;

3. Before removing boards or computer, first turn off all power resources and

disconnectthepowercordfrompowersource;

4. Forwholeset,wheninsertingorremovingboards,firstdisconnectthecomputer

andperipheralsfromtheirpowersources;

5. Before you connect or unplug any signal cable, make sure all power cords are

unpluggedinadvance;

6. Toavoidpoweron/offcomputerfrequently,waitatleast30secondsafterturning

offthecomputerbeforereturningonthecomputer.

7. Staticelectricitycanharmsystemboards.PerformserviceatanESDworkstation

andfollowproperESDproceduretoreducetheriskofdamagetocomponents;

8. If there's no ESD workstation, You can take the following steps to prevent

damagefromelectrostaticdischarge(ESD):

a) Weara groundedwriststrapagainstyour skinto eliminate staticon your

body;

b) Always touch the metal chassis or frame before you touch any

componentsinthechassis;

c) Keep partof yourbodyincontact withthemetalchassisto dissipatethe

staticchargewhilehandlingcomponents;

d) Avoidallunnecessarymovement;

e) Handlecomponentsandboardswithcare.Don’ttouchthecomponentsor

contacts on a board. Hold a boardby its edges or by its metal mounting

bracket;

f) Placethecomponentsonagrounded,staticfreesurface.Useaconductive

foampadifavailablebutnotthecomponentwrapper.

g) Donotletthecomponentsslideontheoperatingplatform.

9. Usecrossheadscrewdrivertooperate.Amagneticscrewdriverisrecommended

(magnettocollectscrews).Donot leaveanytoolsorscrewsinsidethechassis;

10. Assureabundantcoolingandstreamlineventilation.

Contents

Chapter1ProductIntroduction ................................................................................ 1

Overview ....................................................................................................... 1

FeaturesandSpecification .............................................................................. 1

MainPerformances......................................................................................... 2

RequirementsofTransportationandStorage.................................................... 4

Troubleshooting ............................................................................................. 4

Chapter2Installation .............................................................................................. 5

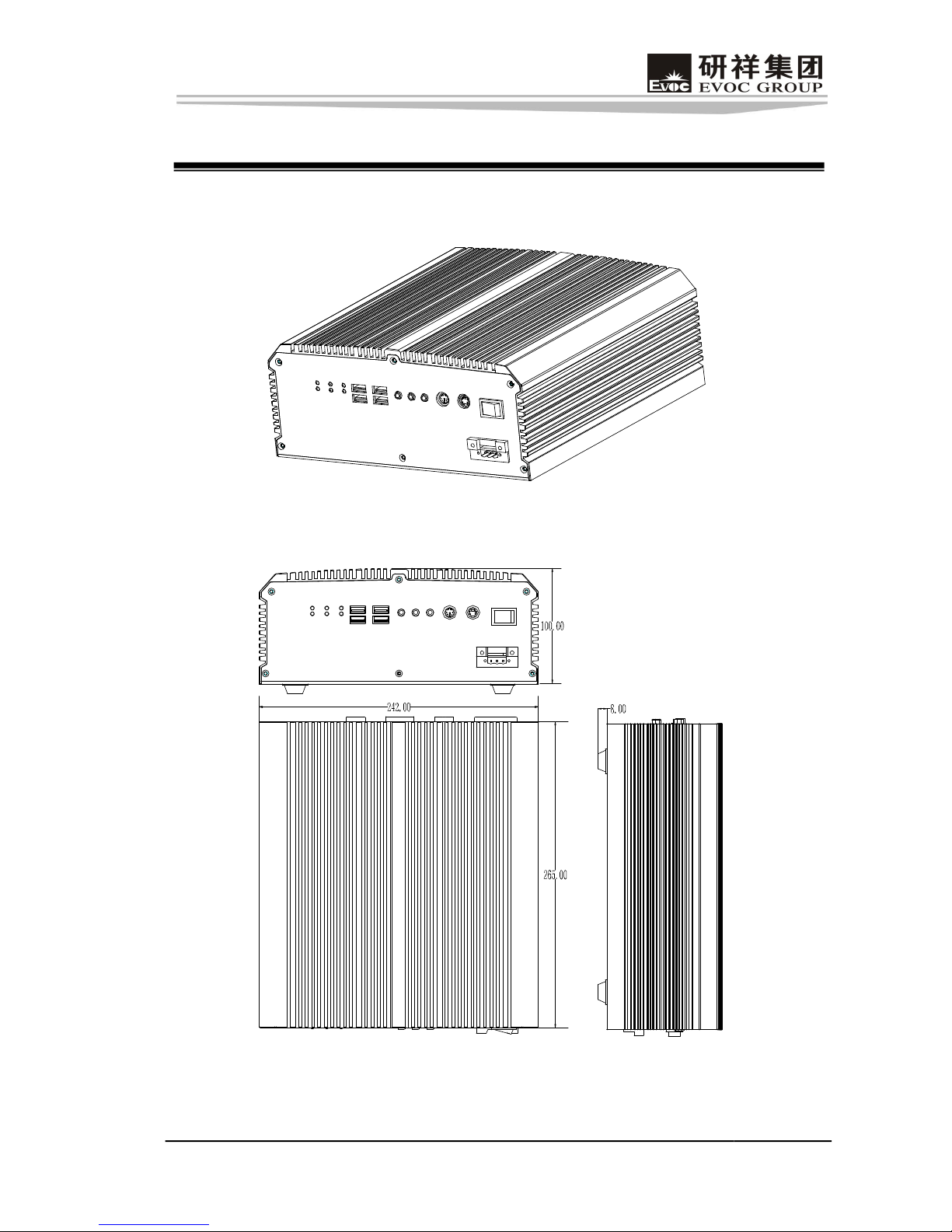

ProductOutline .............................................................................................. 5

ProductDimension......................................................................................... 5

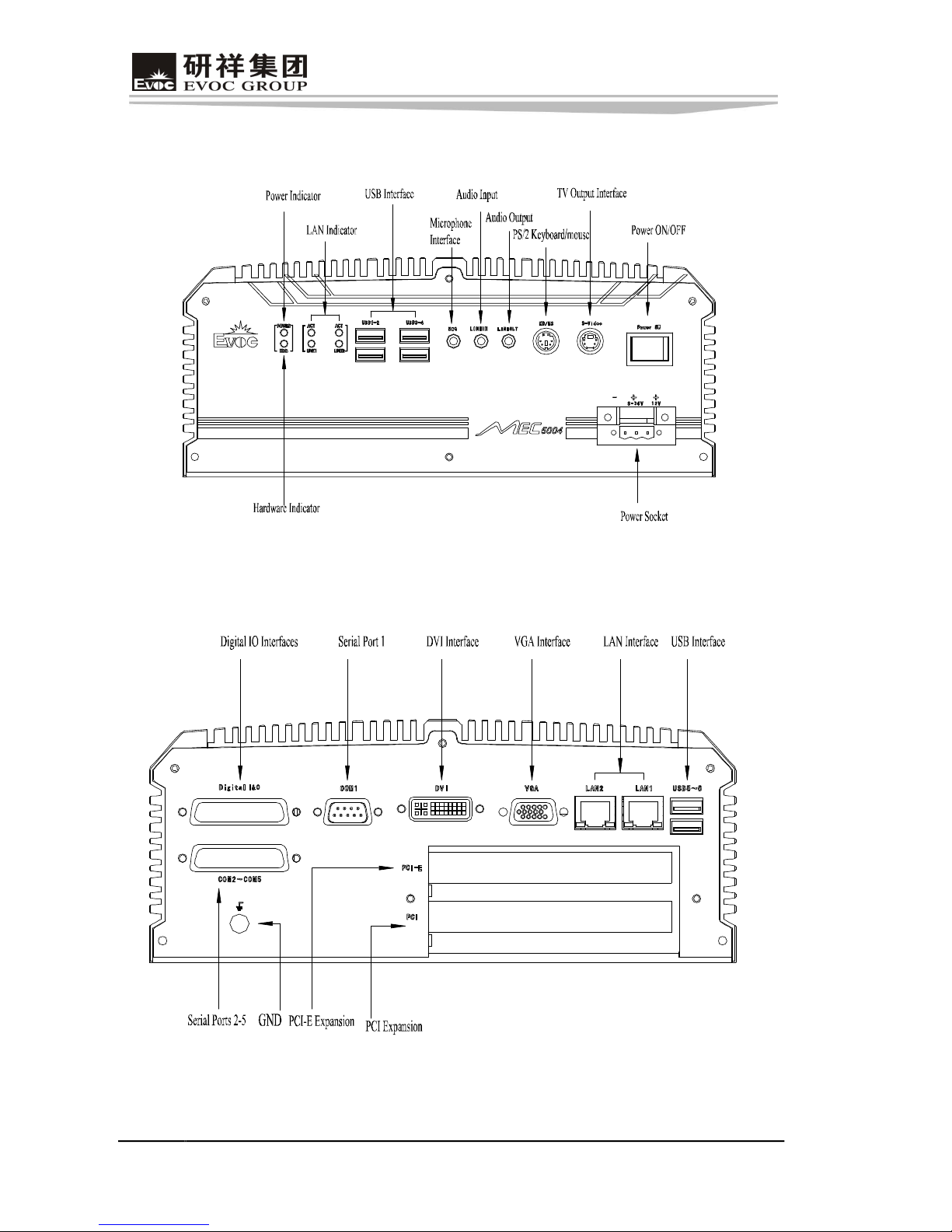

ExternalI/OInterfacesOutline........................................................................ 6

AssemblyExplanation.................................................................................... 7

CriticalPieceInstallation................................................................................ 7

IntroductiononSpecialInterfaces ................................................................... 8

SerialPortsandDigitalIOInterface................................................................ 9

Chapter3BIOSIntroduction ................................................................................. 12

Chapter4InstallationofDrivers ............................................................................ 13

Appendix.............................................................................................................. 14

DigitalIOProgrammingGuide..................................................................... 14

Chapter 1ProductIntroduction

MEC5004 1

Chapter1ProductIntroduction

Overview

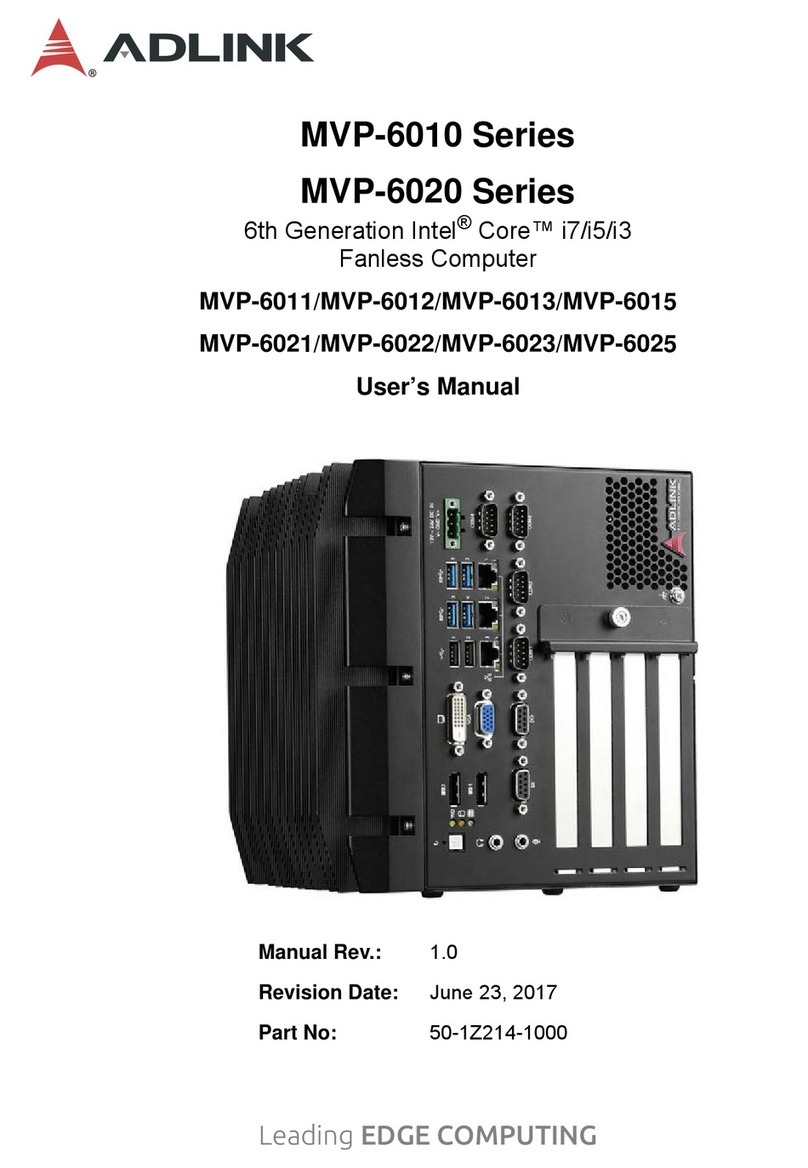

MEC5004 is a sort of fanless Core 2 Duo embedded PC with low power

consumption; the alalloy chassis has goodperformance on airproof, dustproof,

heatdispersionandantivibration;themotherboardadoptsIntelCore2DuoU7500or

L7500 processor with low power consumption; Intel GM965+ICH8ME chipsets

integratingGMAX3100graphicprocessingcouldsharedisplaymemory invastrange;

italsosupportsVGAandDVIindependentdualdisplay,whichcouldbewidelyused

inGPS,intelligenttransportation,digitalvideocontrollingsystemandsoon.

FeaturesandSpecification

CPU

IntelCoreDuoU7500/L7500.

Chipset

IntelGM965+ICH8ME.

SystemMemory

OneSODIMM slot,support 2GBDDR2533/667MHz memory.

NetworkFunction

One PCIE x1 RTL8111C Gigabit Ethernet chipset; one Intel 82566MC Gigabit

Ethernet chipset.

Chapter1ProductIntroduction

2 MEC5004

VideoFunction

Builtin Mobile Intel® Graphics Media Accelerator X3100; support LVDS output,

LVDSandCRTcoulddisplaysimultaneously;alsosupportTVoutput.

AudioFunction

OnboardastandardAC’97audioeffectchipset,provideexcellent soundeffect.

ExpansionBus

OnePCIEexpansionslot; onePCI expansionslot.

I/OFunction

Ø Four USB interfaces on the front, one PS/2 keyboard/mouse interface, one

Svideointerfaceanda setofaudiointerfaces;

Ø TherearIOboardprovidestwoGigabitEthernetports,oneVGAinterface,one

DVIinterface,oneGPIOinterface,fiveCOMportsandtwoUSBinterfaces.

PowerSupplySelection

WidevoltageDC9V~36V/DC12V dualinput,redundancypowersupply.

MainPerformances

Environment/ WeightandDimensions

l Dimensions: 242.00mm(W) x 265.00 mm(D)x 100.00 mm(H)

l Weight: 4.5 Kg

l OperatingTemperature: 10°C~+55°C

l Relative Humidity: RH=93%(noncondensing);

l NonOperatingTemperature: 40°C~ +60°C

Chapter1ProductIntroduction

MEC5004 3

EMCCompliance

1. Limitof InterferenceofElectromagnetic Product

l LimitsofradiodisturbanceiscompliantwithGB 92541998, classA.

l Harmoniccurrent iscompliantwiththelimitsofGB/T17625.11998,classD.

2. AntiinterferenceCapacityofElectromagneticProduct

l ElectrostaticdischargeimmunitytestiscompliantwithGB/T17626.298,class3.

l Immunity test of radiation from radio frequency electromagnetic field is

compliantwithGB/T17626.398, class2.

l Immunity to conducted disturbances induced by radiofrequency fields is

compliantwithGB/T17626.698, class2.

l ElectricalFastTransientBurstImmunitytestiscompliantwithGB/T17626.498,

class2.

l Voltage dips, short interruption and voltage variations immunity tests are

compliantwithGB/T17626.1198.

l SurgetestiscompliantwithGB/T17626.599, class2.

Reliability

l MTBF 5000h≧ ;

l MTTR 0.5h≦ ;

Safety

Meet the requirements in 1.7 “marking and instruction” and 2.3, 2.9 “electric

structure” ofGB4943.

Chapter1ProductIntroduction

4 MEC5004

Mechanical Adaptability

l Antivibration:amplitude519Hz/1.2mm;acceleration19200Hz/1.2g;

l Antishock:acceleration15g,duration11ms.

RequirementsofTransportationandStorage

l Transportation:

Wellpackaged products suit for transportation by truck, ship, and plane. During

transportation, products should not be put in open cabin or carriage. When

transshipping en route,products should not be stored in the openwithoutprotection

from the atmospheric conditions. Products should not be transported together with

inflammable,explosiveandcorrosivesubstancesandarenotallowedtobeexposedto

rain,snowandliquidsubstancesandmechanicalforce.

l Storage:

Products should be stored in package box when it is not used. And warehouse

temperature should be 0°C~40°C, and relative humidity is 20%~85%. In the

warehouse, there should not be harmful gas, inflammable, explosive products, and

corrosive chemical products, and strong mechanical vibration, shock and strong

magneticfieldaffection.The packageboxshouldbeovergroundatleast10cmheight,

and50cm awayfromwall,thermalsource,andvent.

Troubleshooting

Please refer to Common Trouble Analysis and Treatment of Industrial Control

Computer foradetaileddescriptionofthetroubleshooting.

Chapter2 Installation

MEC5004 5

Chapter2Installation

ProductOutline

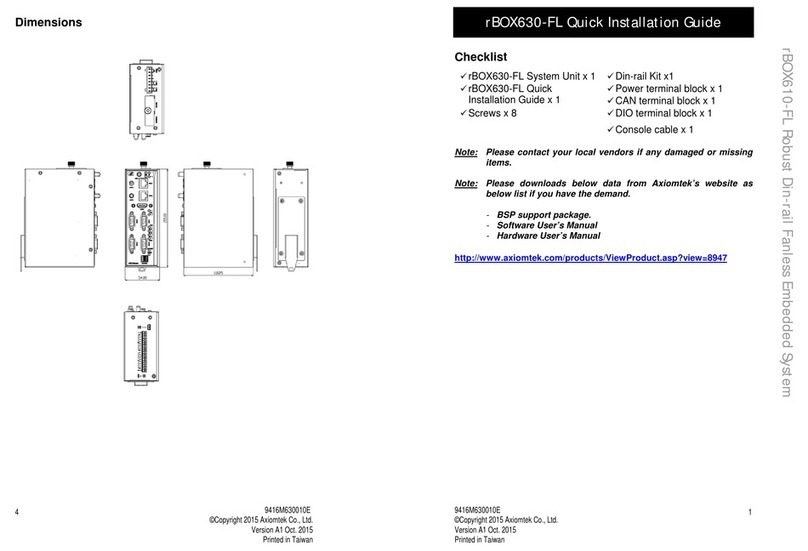

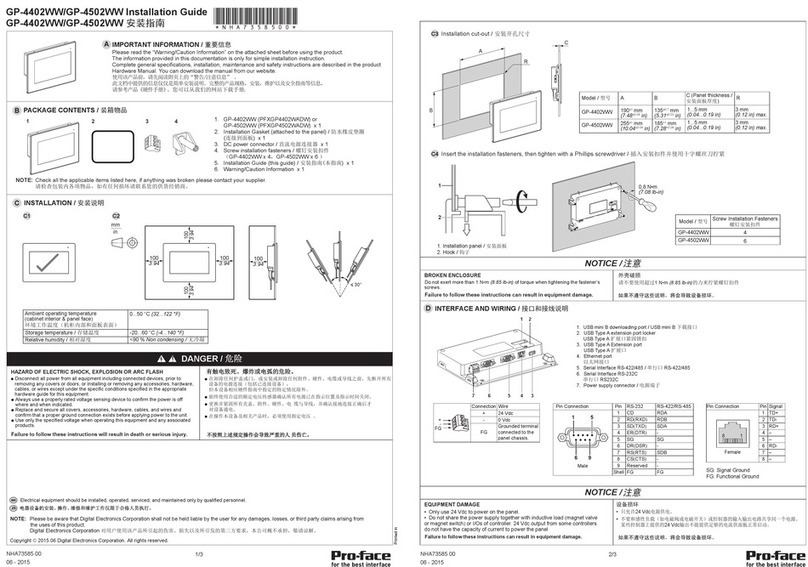

ProductDimension

Unit:mm

Chapter2 Installation

6 MEC5004

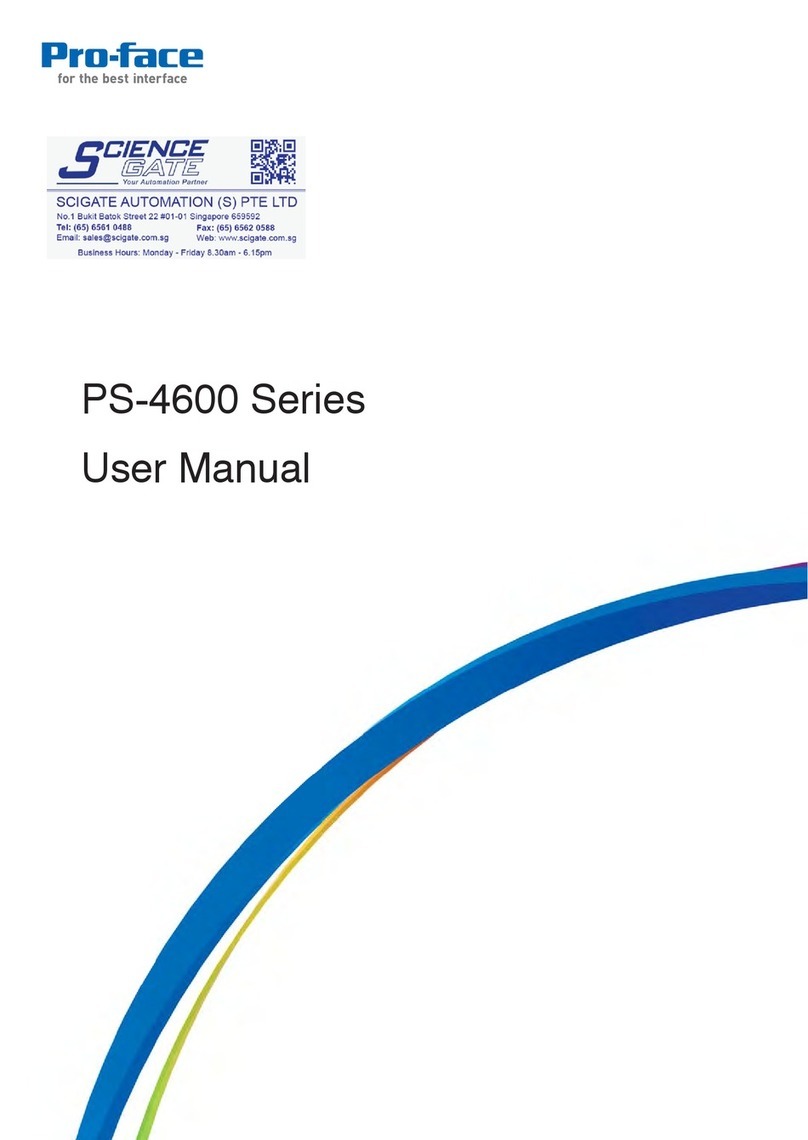

ExternalI/OInterfacesOutline

FrontPanel IOInterfaces

Rear PanelIOInterfaces

Chapter2 Installation

MEC5004 7

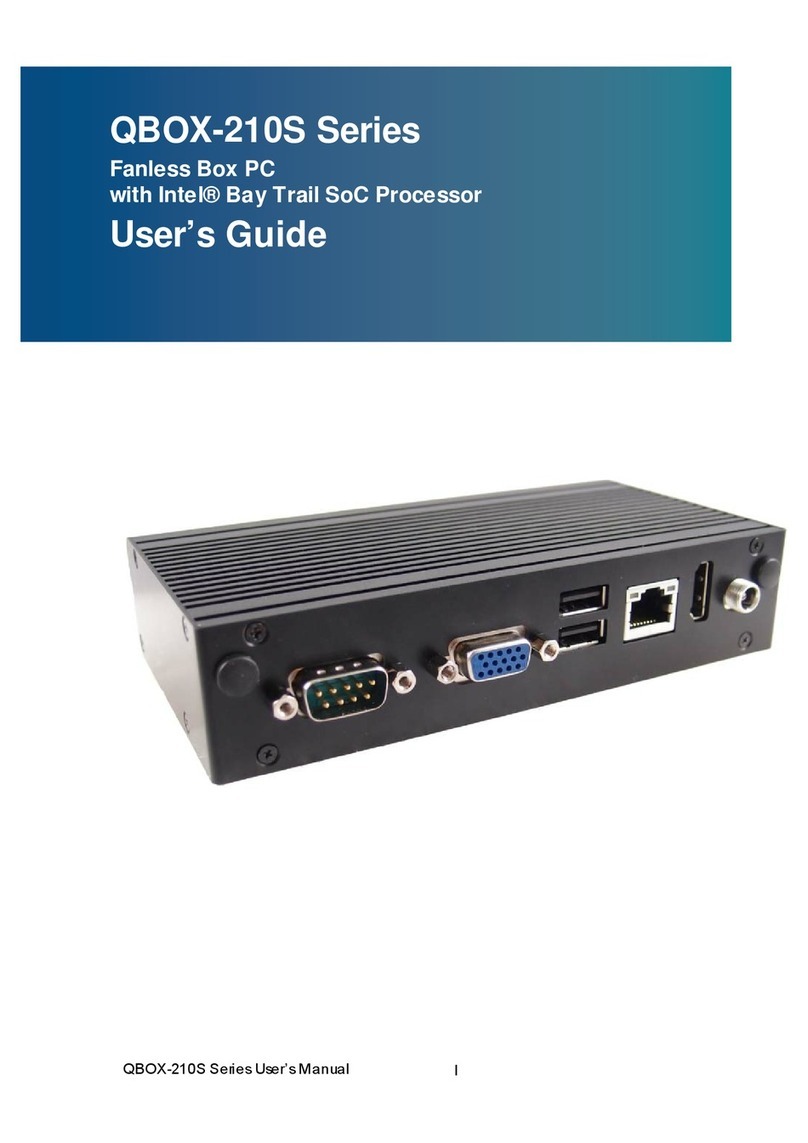

AssemblyExplanation

1. LeftPanel 2. I/OFrame 3. Rear Panel

4.Cover 5. Right Panel 6.FrontPanel

7.HardDisk 8. BottomCover 9. PCI TransferBoard

10. Carrier 11.HeatConductive AluminumPlate 12.Power

CriticalPieceInstallation

Whenassemblingthecoreboard,pleaseassembletheheatconductivealuminumplate,

thecoreboardandthecarriertogetherfirstly andtheninstallitintothemachinesoas

to ensure the core board is securely connected with the interfaces on board. PCI

transfer board can be inserted to the slot directly and fixed to the left panel with

screws.

Chapter2 Installation

8 MEC5004

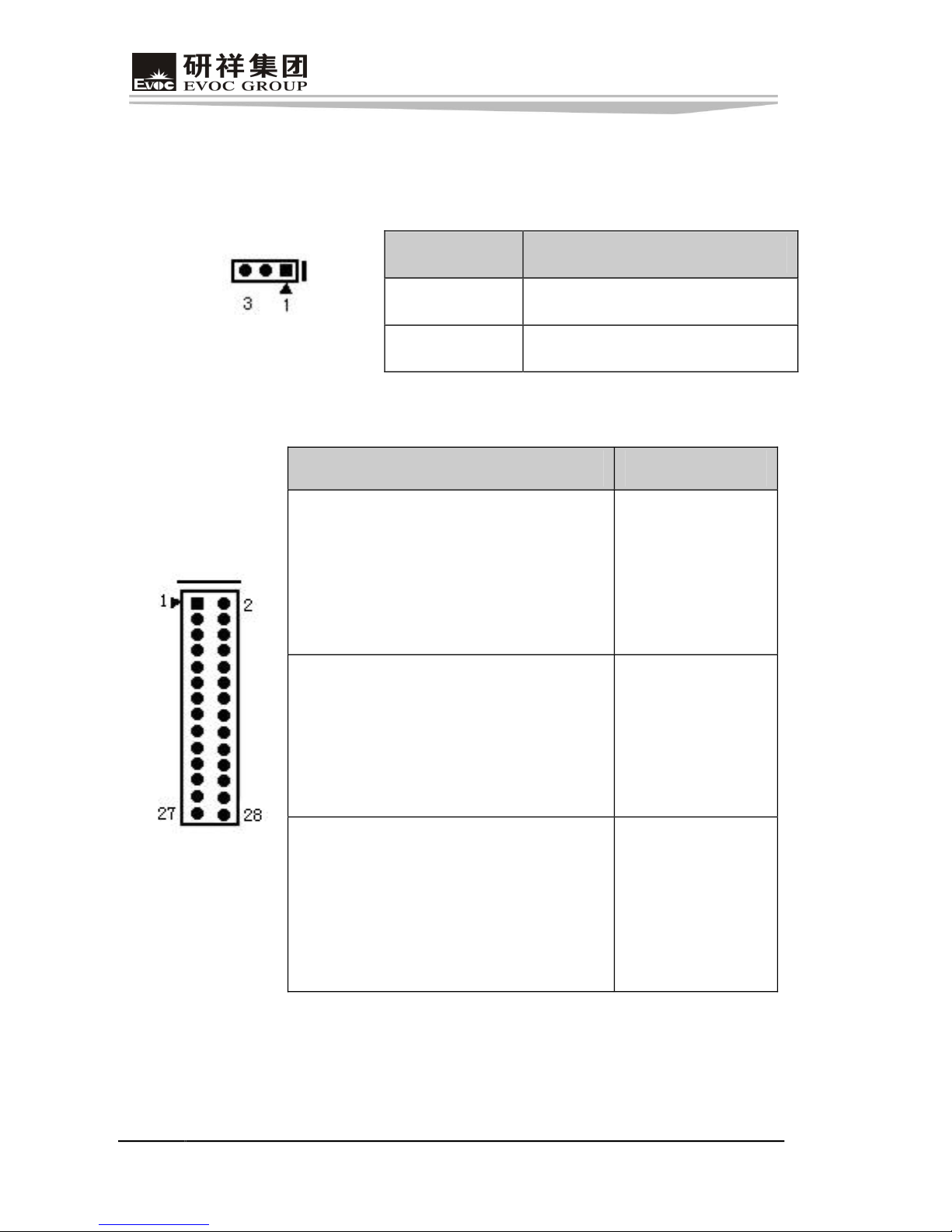

Introduction onSpecialInterfaces

Select differentinterfacemodes throughsetupthejumperontheboard.

1. Selectionforthe Compact Flash CardPower(JCF1)

Setup Function

[12] Short +3.3V

JCF1 [23] Short +5V (Default)

2. Selectionforthe COM1RS232/RS422/RS485 Mode(JPCOM1)

Setup Function

[12] Short [34] Short

[56] Short [78] Short

[910] Short [1112] Short

Otherpinsaredisconnected

RS232 Mode

[1314] Short [1516] Short

[1718] Shorted[1920] Shorted

[2122] Shorted[2324] Shorted

Otherpinsaredisconnected

RS422 Mode

JPCOM1

[1718] Shorted[1920] Shorted

[2122] Shorted[2324] Shorted

[2526]Shorted [2728] Shorted

Otherpinsaredisconnected

RS485 Mode

Chapter2 Installation

MEC5004 9

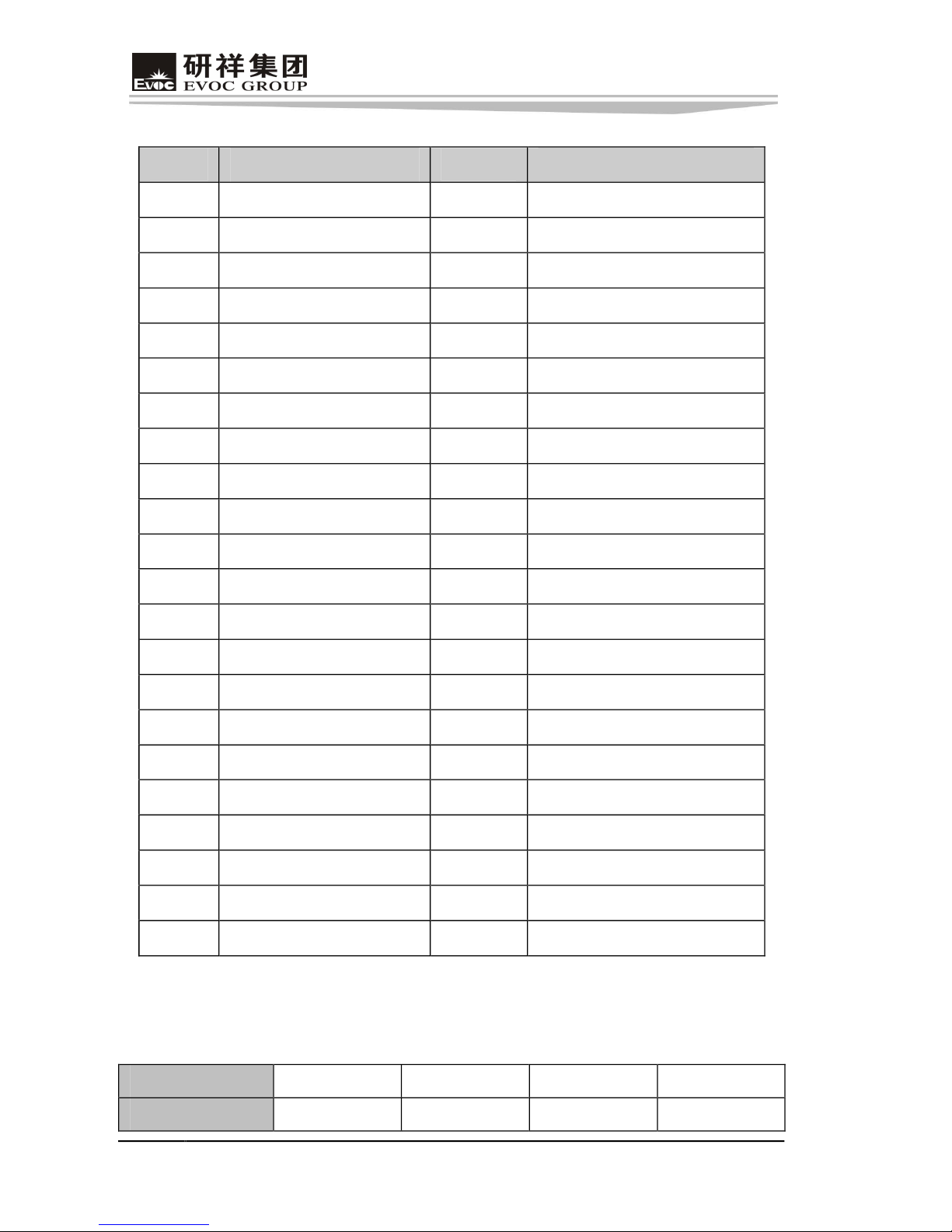

SerialPortsandDigitalIOInterface

Providefiveserialportsandtwosetsof8lanedigitalI/Ointerfaces;oneoftheserial

ports is a standard DB9 interface (COM1). Through jumper setup, users can

implement mode selection among RS232/RS422/RS485. In addition, the four

serial ports COM2, COM3, COM4 and COM5, switched from interface J1, could

connect with devices with standard RS232 interface, like mouse, modem, digital

cameraandsoon.

SignalName

Pin

RS232 RS422 RS485

1 DCD# TXD Data

2 RXD TXD+ Data+

3 TXD RXD+ X

4 DTR# RXD X

5 GND GND GND

6 DSR# X X

7 RTS# X X

8 CTS# X X

COM1

9 RI# X X

InterfaceDefinitionof COM2,COM3,COM4,COM5 and GPIO:

J1

Chapter2 Installation

10 MEC5004

Pin COM2, COM3 Signal Pin COM4, COM5 Signal

1 COM2_DCD 23 GND

2 COM2_RXD 24 COM4_DTR

3 COM2_TXD 25 COM4_DSR

4 GND 26 COM4_RTS

5 COM3_DCD 27 GND

6 COM3_RXD 28 COM5_DTR

7 COM3_TXD 29 COM5_DSR

8 GND 30 COM5_RTS

9 COM4_DCD 31 COM2_CTS

10 COM4_RXD 32 COM2_RI

11 COM4_TXD 33 GND

12 GND 34 GND

13 COM5_DCD 35 COM3_CTS

14 COM5_RXD 36 COM3_RI

15 COM5_TXD 37 GND

16 COM2_DTR 38 GND

17 COM2_DSR 39 COM4_CTS

18 COM2_RTS 40 COM4_RI

19 GND 41 GND

20 COM3_DTR 42 GND

21 COM3_DSR 43 COM5_CTS

22 COM3_RTS 44 COM5_RI

Note:Thecorresponding relationshipbetweenthefourserialports(COM2,

COM3,COM4,COM5)andexternalwiresilkscreenisshowedasfollows:

SerialPort COM2 COM3 COM4 COM5

Silkscreen D C B A

Chapter2 Installation

MEC5004 11

Pin GPIO SignalName Pin GPIO SignalName

1 INPUT0 23 OUTPUT7

2 INPUT1 24 GND

3 INPUT2 25 GND

4 INPUT3 26 GND

5 INPUT4 27 GND

6 INPUT5 28 GND

7 INPUT6 29 GND

8 INPUT7 30 GND

9 GND 31 VCC3.3

10 GND 32 VCC3.3

11 GND 33 GND

12 GND 34 GND

13 GND 35 GND

14 GND 36 GND

15 GND 37 GND

16 OUTPUT0 38 GND

17 OUTPUT1 39 GND

18 OUTPUT2 40 GND

19 OUTPUT3 41 GND

20 OUTPUT4 42 GND

21 OUTPUT5 43 GND

22 OUTPUT6 44 GND

Chapter3 BIOSIntroduction

12 MEC5004

Chapter3 BIOSIntroduction

FormoreinformationaboutBIOSsetup,pleaserefertoour AMIBIOSSetupGuide.

Chapter4InstallationofDrivers

MEC5004 13

Chapter4Installation ofDrivers

Regardingtheinstallationofthedriverprogramoftheproduct,pleaserefertotheCD

ofassociatedPC.

Appendix

14 MEC5004

Appendix

DigitalIOProgrammingGuide

#defineopen{outportb(INDEXP,0x87);outportb(INDEXP,0x87);}

intINDEXP=0x2e;

intDATAP=0x2f;

intHardwareID=0;

shortSetIndexData()

{

outportb(INDEXP,0x87);

outportb(INDEXP,0x87);

outportb(INDEXP,0x20);

HardwareID=inportb(DATAP);

If (HardwareID==0xff)

{

INDEXP=0x4e;

DATAP=0x4f;

}

return 0;

}

voidwrite(intreg,intdata)

{

outportb(INDEXP,reg);

outportb(DATAP,data);

}

intread(intreg)

Appendix

MEC5004 15

{

intvalue;

outportb(INDEXP,reg);

value=inportb(DATAP);

return(value);

}

intval;

int data[2];

SetIndexData();

open

val=read(0x2c);

val&=0xfe;

val|=0x02;

write(0x2c,val); //selectGPIO4asGPIO

write(0x07,0x09);

write(0x30,0x04);

write(0xf4,0x0f); //selectGP40~GP43in;GP44~GP47out;

write(0xf6,0x00);

write(0xf5,0x00);

sleep(1);

write(0xf5,0xf0);

Please visithttp://www.evoc.com formoreinformation.

声明

本手册包含的内容并不代表本公司的承诺,本公司保留对此手册更改的权

利,且不另行通知。对于任何因安装、使用不当而导致的直接、间接、有意或无

意的损坏及隐患概不负责。

EVOC 是研祥智能科技股份有限公司的注册商标。本手册所涉及到的其他商

标,其所有权为相应的产品厂家所拥有。

研祥智能科技股份有限公司©2008,版权所有,违者必究。未经许可,不得

以机械、电子或其它任何方式进行复制。

安全使用小常识

1. 产品使用前,务必仔细阅读产品说明书;

2. 为避免人体被电击或产品被损坏,在每次对板卡进行拔插、重新装配或配

置前,须先关闭交流电源或将交流电源线从电源插座中拔掉;

3. 在需对产品进行搬动时,务必先将交流电源线从电源插座中拔掉;

4. 当产品需增加/减少板卡时,务必先拔掉交流电源;

5. 当需连接或拔除任何信号线前,须确定所有的电源线事先已被拔掉;

6. 为避免频繁开关机对产品造成不必要的损伤,关机后,应至少等待 30 秒后

再开机;

7. 如果要进行升级或拆装等动作,须在静电放电工作台上完成所有操作,因

为有些精密器件对静电放电(ESD)很敏感;

8. 如果没有静电放电工作台,可通过以下方法降低 ESD 可能造成的危害:

a) 戴上一条防静电腕带并与相应产品的金属部分相连;

b) 在触摸产品部件前,先触摸相应产品机箱上的金属壳;

c) 当插拔部件时,身体最好与产品的金属机箱保持接触,以释放静电;

d) 避免不必要的走动;

e) 拿产品部件(尤其是板卡)时仅拿住边缘;

f) 将产品部件置于一个接地的无静电的操作平台上。如果可能的话,使

用一块导电泡沫垫(非部件的包装材料);

g) 不要让部件在操作平台上滑动。

9. 用十字螺丝刀进行操作,最好是强力螺丝刀(带磁性,避免螺丝遗留在机

箱内)。要注意的是,一定不要将工具或零件遗漏在机箱内;

10. 保证系统良好的散热与通风。

目 录

第一章 产品介绍..................................................................................................1

简介...............................................................................................................1

主要功能介绍................................................................................................1

主要性能指标................................................................................................2

运输与贮存要求 ............................................................................................3

常见故障处理................................................................................................4

第二章 安装说明..................................................................................................5

产品外观图....................................................................................................5

产品安装尺寸图 ............................................................................................5

外部 IO 接口图..............................................................................................6

装配说明........................................................................................................7

主要载板安装说明.........................................................................................7

特殊接口介绍................................................................................................8

串口与数字 IO 接口 ......................................................................................9

第三章 BIOS 功能简介.......................................................................................12

第四章 驱动程序安装说明 .................................................................................13

附录......................................................................................................................14

数字 IO 编程指引 ........................................................................................14

Table of contents

Other EVOC Industrial PC manuals

EVOC

EVOC LNB-1406 User manual

EVOC

EVOC NPC-8130 User manual

EVOC

EVOC PPC-1006 User manual

EVOC

EVOC IPC-8462 User manual

EVOC

EVOC ERC-1004A User manual

EVOC

EVOC P15 Series User manual

EVOC

EVOC MEC-4032 User manual

EVOC

EVOC EIS-2205 User manual

EVOC

EVOC P12 Series User manual

EVOC

EVOC MEC-5031-M Series User manual