HG616 Issue 10 © 2017 1

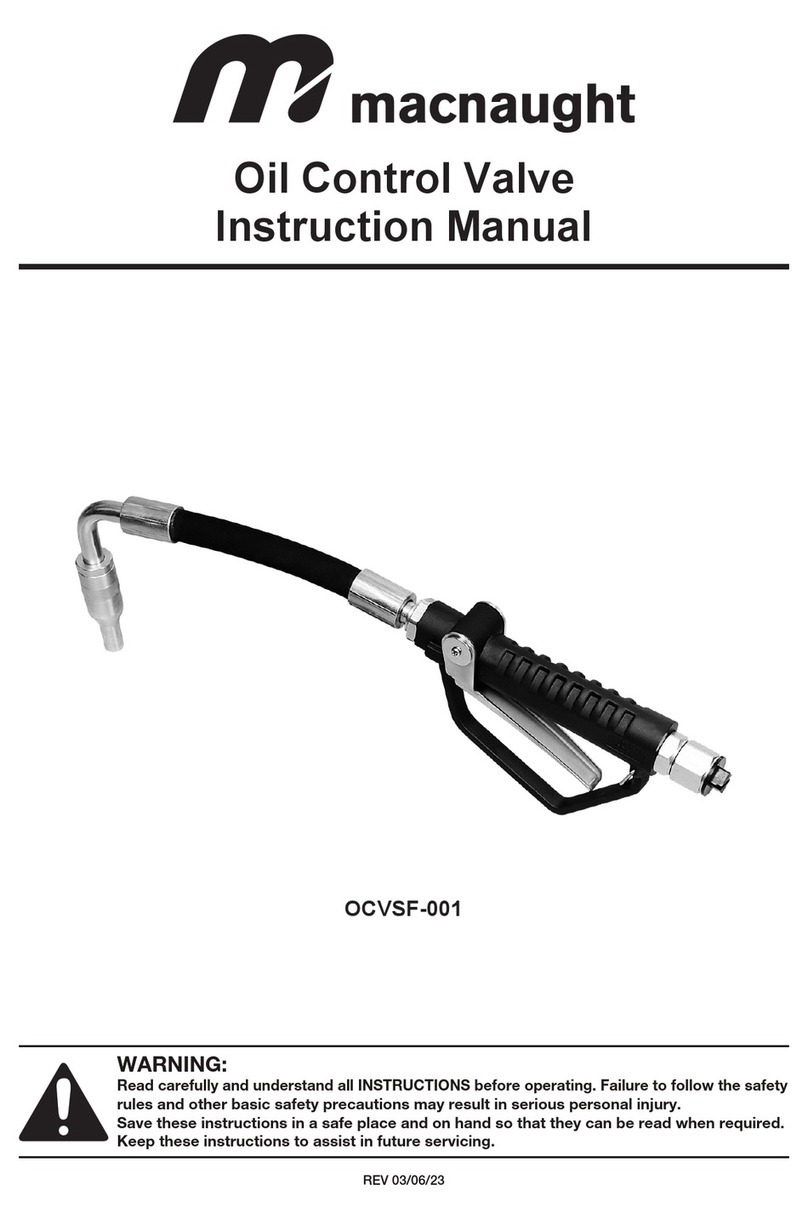

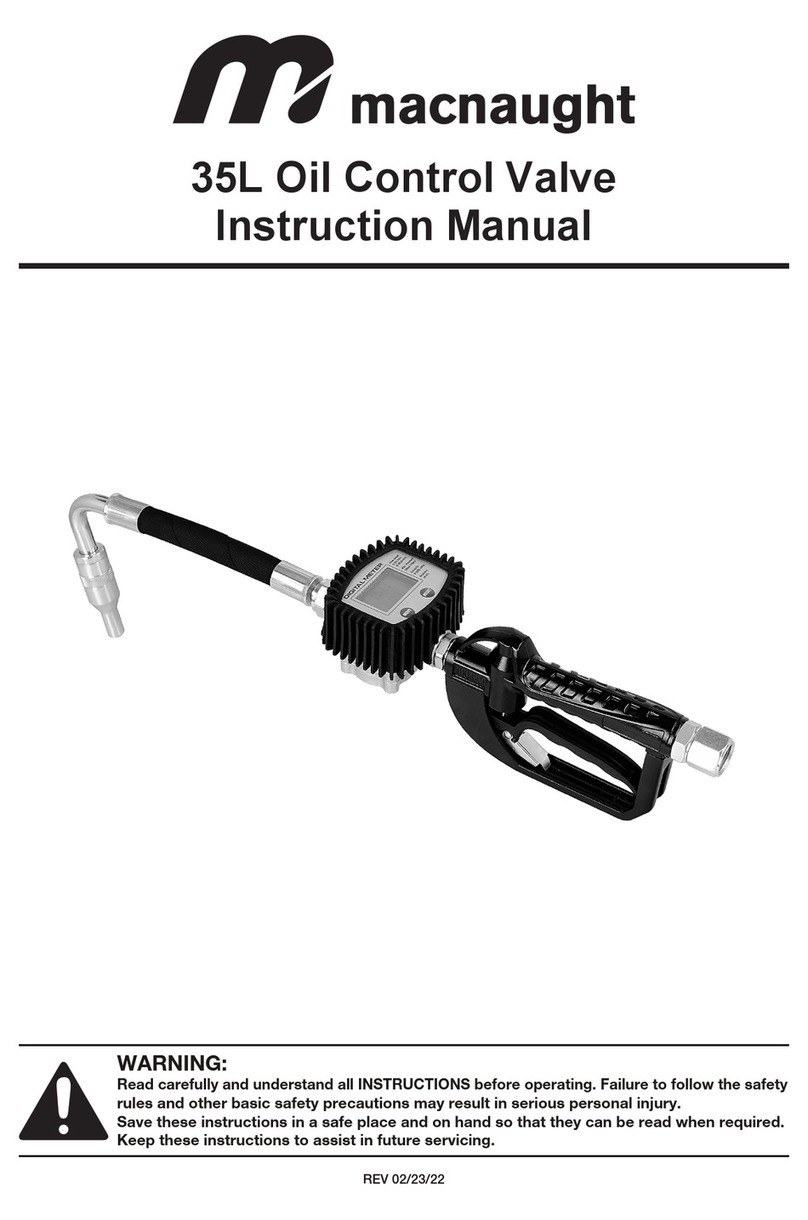

HG 20R(Rigid) & HG20F (Flexible)

OIL CONTROL GUNS

INSTRUCTION MANUAL

INTRODUCTION

Thank ou for purchasing a Macnaught oil dispensing

gun complete with either a flexible or rigid extension.

The Macnaught oil dispensing guns have been

designed for use with engine oil, gear oil, automatic

transmission fluid, anti-freeze/anti-boil and compatible

fluids.

Macnaught also manufacture a complete range of ratio

oil pumps and retractable oil hose reels, greasing

equipment and accessories to fulfil all our fluid

handling and greasing needs requirements.

Please read and retain this instruction manual to

assist ou in the operation and maintenance of this

qualit product.

GENERAL INFORMATION

This manual assists you in operating and maintaining your

new oil control gun. The information contained will help

you ensure many years of dependa le performance and

trou le free operation.

Please take a few moments to read through this manual

efore installing and operating your new oil control gun. If

you experience pro lems with this product, refer to the

trou le shooting sections of this manual. If you require

further assistance please contact your local Macnaught

distri utor or authorised Macnaught service centre.

IMPORTANT INFORMATION

Your safet is important to us. Please read and follow

all safet instructions listed inside.

Some of these instructions alert ou to the potential

for personal injur . “Cautions” listed throughout this

manual advise of potential practices or procedures

which ma cause damage to our equipment.

Ensure all operators have access to adequate

instructions about safe operating and maintenance

procedures.

Do not exceed the maximum working pressure of 6900

kPa / 1000 psi / 69 bar.

Do not hit the oil control gun if it fails to operate. Refer

to “trouble shooting guide” or return the unit to our

nearest authorised service centre.

Never point the nozzle at ourself or an one else.

Never exceed the pressure rating of an component

installed in the S stem.

Before ever use check all hoses for signs of wear,

leaks or loose fittings. Tighten all fluid connections

regularl and replace weak or damaged hoses.

Before attempting an repairs or maintenance of this

product firstl disconnect the air suppl from the oil

pump, then release the oil line pressure b squeezing

the lever on our oil control gun.

ASSEMBLY

Use Teflon tape (or suita le thread sealant ) when

connecting the oil control gun to an oil hose.

OUTLET NOZZLE OPERATION

When fluid flows through the gun the outlet nozzle will

automatically open. When the fluid flow stops the outlet

nozzle will automatically shut.

HANDLE OPERATION

To latch the handle, squeeze the lever, push the utton

and then release lever.

To release the latch in manual mode simply squeeze and

release lever.

READ THIS INFORMATION

CAREFULLY BEFORE USE.

CAUTION

Before carr ing out an maintenance disconnect the

air suppl to the pump and release the fluid pressure

in the s stem b pressing the lever on the control gun.

Inspect your oil control gun daily for any signs of damage.

Replace any damaged parts or components as required.

CAUTION

Includes models

HG20F-01

HG20R-01

HG20R-02