Existing Installation

1. Relieve the pressure

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always

follow the pressure relief procedure on page E1.

2. Loosen and disconnect the hose from the old dispense valve (the one that you are replacing)

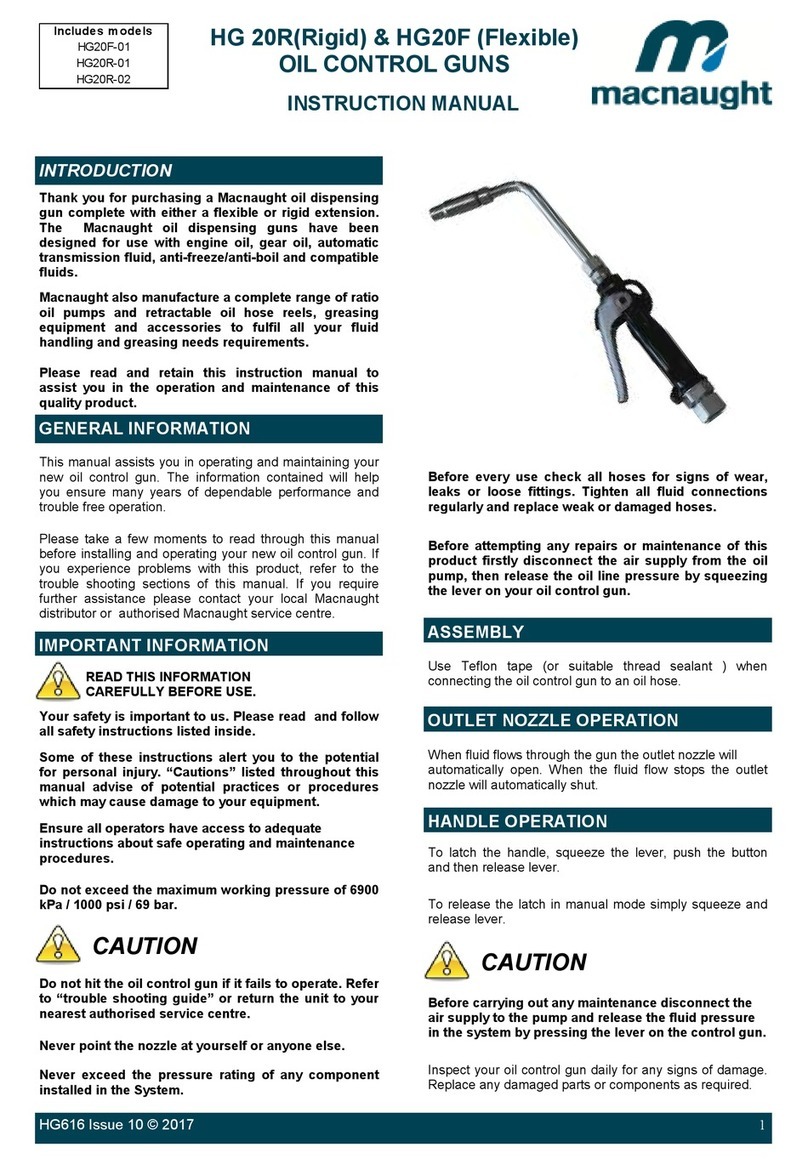

3. Thread the extension into the outlet of the dispense valve, and tighten firmly.

NOTE: Do not over tighten the extension tube assembly by using the nozzle adapter to hand

turn the nozzle. For rigid extensions, thread the extension in at least three full turns, position

the extension for proper alignment, and tighten the sealing nut. The PTFE seal on the

sealing nut must face the valve housing.

4. Apply thread sealant to the male threads of the hose fitting, thread the hose fitting into the

swivel, and tighten firmly.

5. Thread the new nozzle or nozzle adapter onto the extension, and tighten firmly.

6. Open all dispense position shut-off valves, and start the pump to pressurize the system. See

the Operation section for proper operation.

7. For metered dispense valves, to ensure dispensing accuracy, purge all air from the fluid

lines and dispense valves before you use them.

Grounding

Proper grounding is an essential part of maintaining a safe system.

To reduce the risk of static sparking, ground all system components per local and national

electrical codes.

Refer to the user manuals for the pump and other system components to ground the following:

1. Pump: Follow manufacture’s recommendations.

2. Air and Fluid hoses: Use only grounded hoses.

3. Air compressor: Follow manufacture’s recommendations

4. Fluid supply container: Follow your local code.

5. To maintain grounding continuity when flushing or relieving pressure, always hold a metal

part of the valve firmly to the side of a grounded metal pail, then trigger the valve.

OPERATION

CAUTION: To prevent line contamination, which can cause equipment malfunction or

damaged, flush the lines before you install this equipment in the system.

Pressure Relief Procedure

Pressurized Equipment Hazard

The equipment stays pressurized Fluid under high pressure can be injected through the skin

and cause serious injury. To reduce the risk of an injury from injection, splashing fluid, or

moving parts, follow the pressure relief procedure whenever you:

1. Are instructed to relieve pressure,

2. Check, clean or service any of the system equipment.

3. Install or clean the nozzle.

1. Turn off the power supply to the pump.

2. Trigger the valve into a waste container to relieve pressure.

3. Open any bleed-type master air valves and fluid drain valves in the system.

4. Leave the drain valve open until you are ready to pressurize the system.

If you suspect that the dispensing valve, extension, or nozzle is clogged or that

pressure has not been fully relieved after following the steps above, very slowly loosen

a fitting on the fluid line to relieve pressure gradually, then loosen it completely, then

clear the clog.

To reduce the risk of a serious bodily injury, including fluid injection, never exceed the

maximum working pressure of the valve you are using or of the lowest rated component

in your system.

E3

TECHNICAL

DETAILS

INSTALLATIONOPERATION

LIMITED

WARRANTY

EXPLODED AND

PARTS LIST

SAFETY

PRECAUTIONS

TROUBLE

SHOOTING GUIDE