4

modify the power plug or use an ungrounded power socket. If an extension cord is necessary,

use only a 3-wire extension cord that provides grounding.

To prevent accidents and failures, be sure to observe the following precautions:

1. The air outlet and surrounding maybe very hot. Please take great care

against being hurt.

2.The hot air gun must be put on the holder. Never place it on table or other

places.

3.Make sure air outlet is clear without any objection.

4.The unit can be turned off only when it cools below 100℃.

5.Keep the nozzle at least 2mm from the part being heated.

6.Disconnect power when not in use for a long time.

7.Keep the unit out of reach of children.

8.Never use and keep away the unit with flammable gases or near other flammable

materials.

9.Handle with care, do not to shack the unit.

10.Don’t operate the unit with wet hand to avoid short-circuited or electric

shock.

11.Differences in temperature may exist when different nozzles are used.

12.Hidden areas such as behind walls, ceilings, floors and other panels may

contain flammable materials that could be ignited by the unit when working

in these locations. The ignition of these materials may not be readily

apparent and could result in property damage and injury to persons. When

working in these locations, keep the unit moving in a back-and forth motion.

Lingering or pausing in one spot could ignite the panel or the material

behind it.

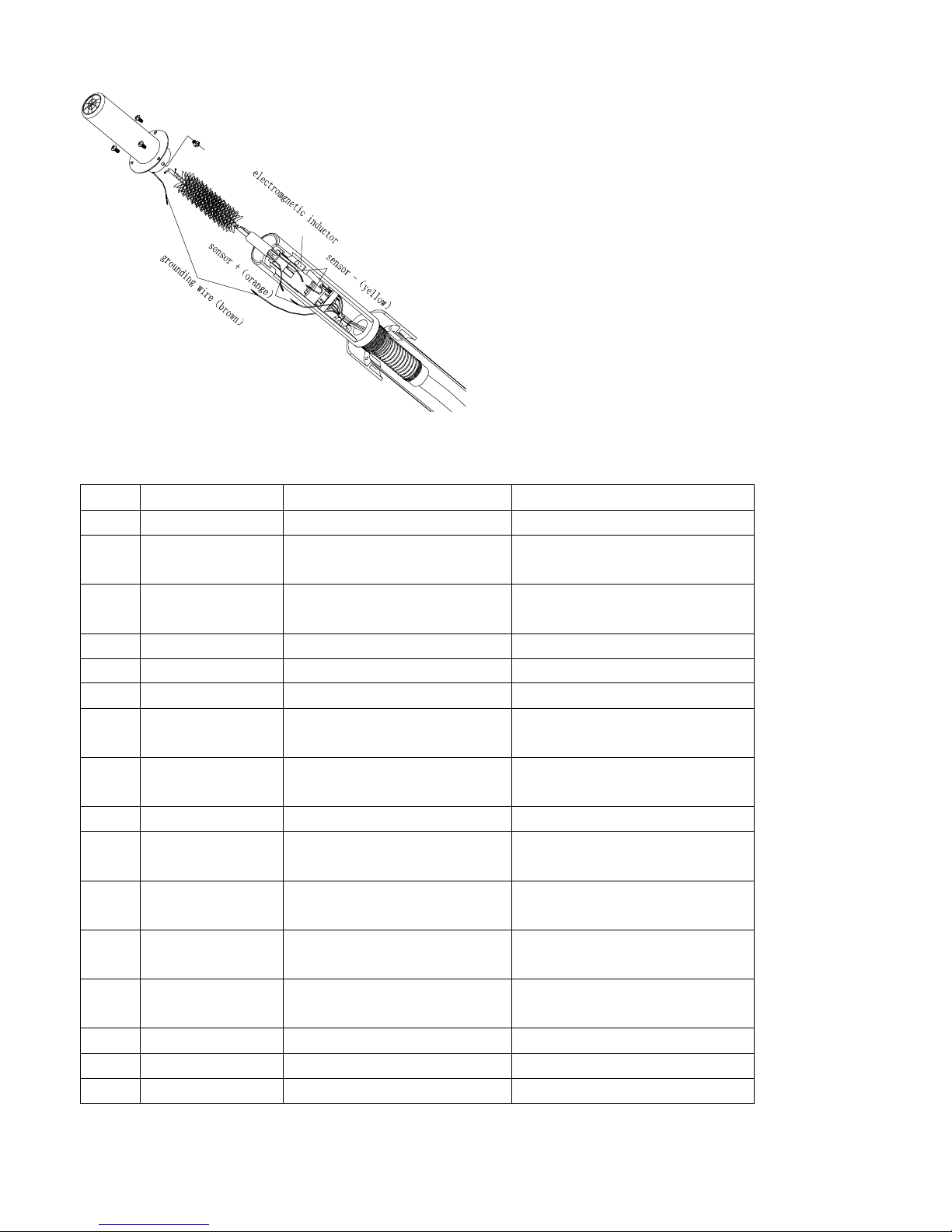

5.Replacement of Heating Element

1. Remove the anti-folding spring on the handle assembly.

2. As shown in the diagram, remove the three screws used to secure the steel

tube. Pull the steel tube out from the handle housing.

3. Loosen screws on the steel tube and also inside the frame of the handle,

get out the tube assembly. Make sure not to drop or lose the quarts-glass

and heat-insulator.

4. Disconnect the grounding wire, sensor connector and heater connector, get

out the heater assembly (including heating element and sensor)

5.Insert a new heater, then connect the heater connector. As sensor wires have

slopes, it is necessary to connect wires with the same colors.

6.Reassemble the handle.