Product User Guide | 2

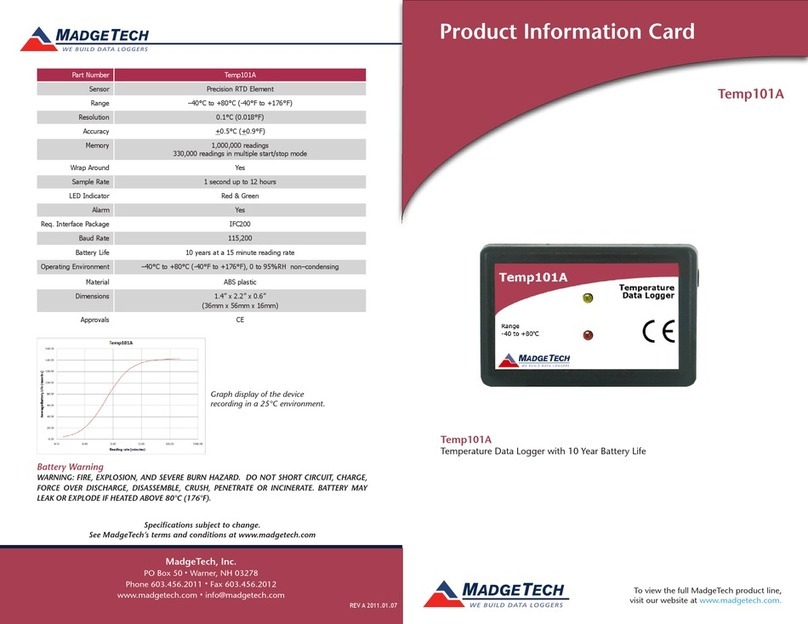

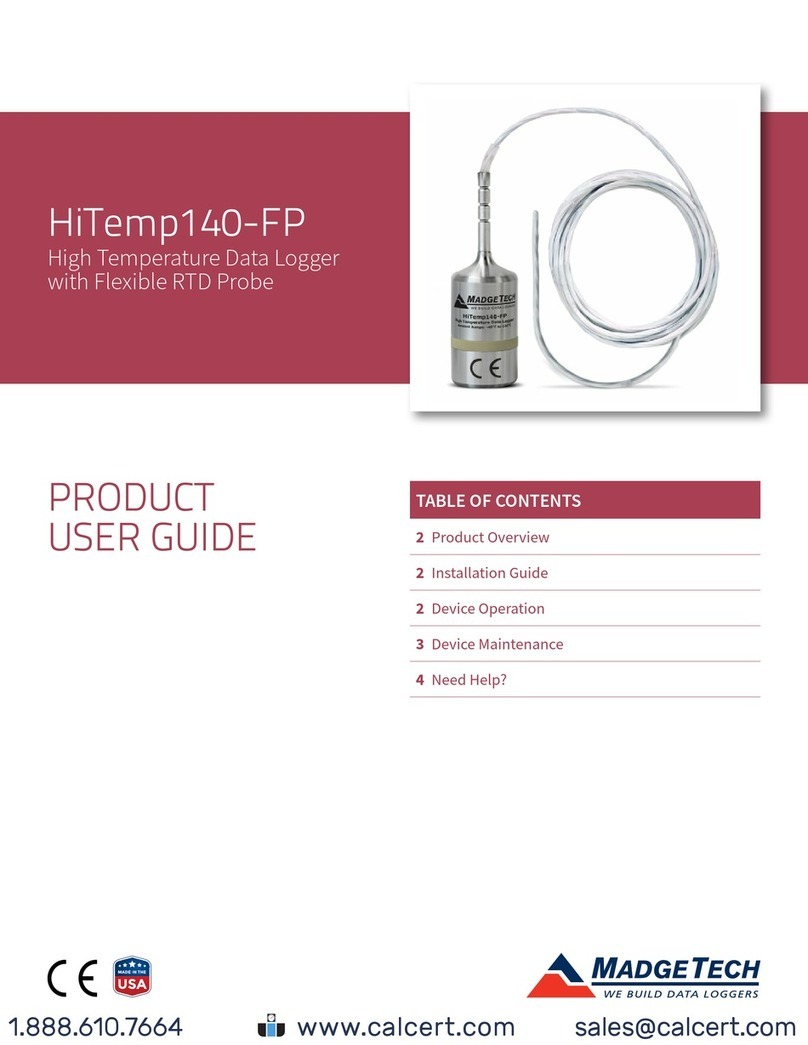

HiTemp140-FP

PRODUCT USER GUIDE

Product Overview

The HiTemp140-FP is a durable, user-friendly high

temperature data logger featuring a long, flexible RTD

probe with a narrow diameter, making it ideal for use in

steam sterilization and lyophilization processes.

Commonly used for mapping, validation and monitoring of

high temperature surfaces, this stainless steel data logger

is available in several models. The flexible probe is coated

with PFA insulation and can withstand temperatures up to

260 °C (500 °F ) with an accuracy of ±0.1.

The HiTemp140-FP probe design is narrow and lightweight

making it ideal for placement within small vials, tubing,

test tube and other small diameter or delicate applications.

Because of the flexible probe, the risks of breakage (both

vial and probe) generally associated with stainless steel

probe loggers are diminished and the location and

placement of the probe is easy to manipulate.

The Trigger Settings feature of the HiTemp140-FP allows

users to configure high and low temperature thresholds

that when met or exceeded, will automatically start or stop

recording data to memory. This data logger is capable of

storing up to 65,536 date and time stamped readings and

features a non-volatile solid state memory which retains

data even if the battery becomes discharged.

Water Resistance

The HiTemp140-FP is rated IP68 and is fully submersible.

Installation Guide

Installing the Software

The Software can be downloaded from the MadgeTech

website at madgetech.com. Follow the instructions

provided in the Installation Wizard.

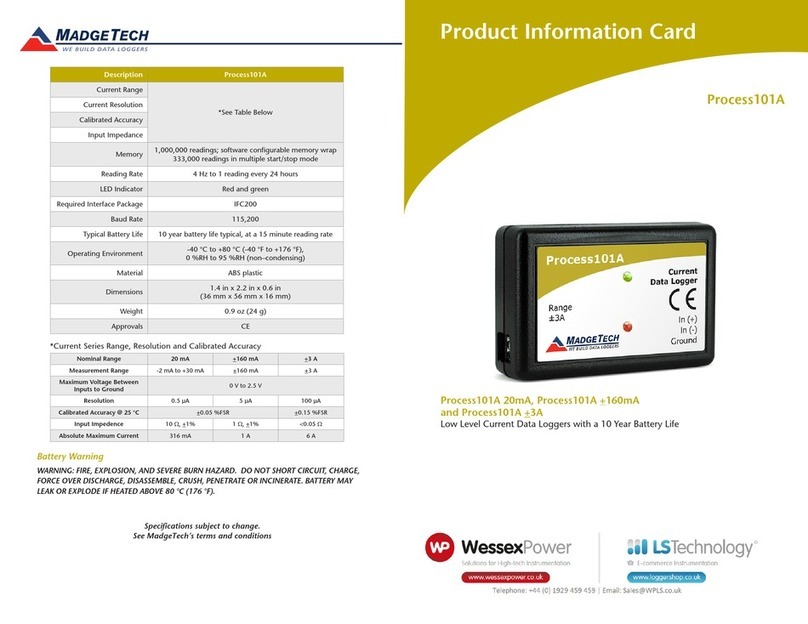

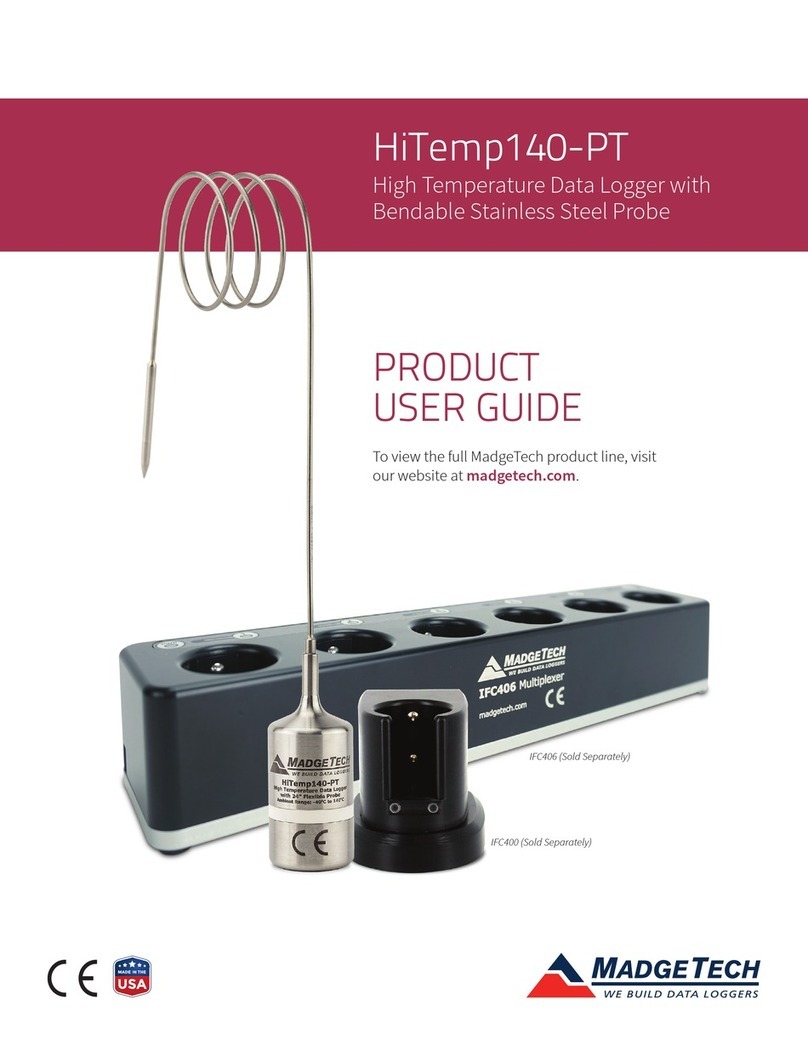

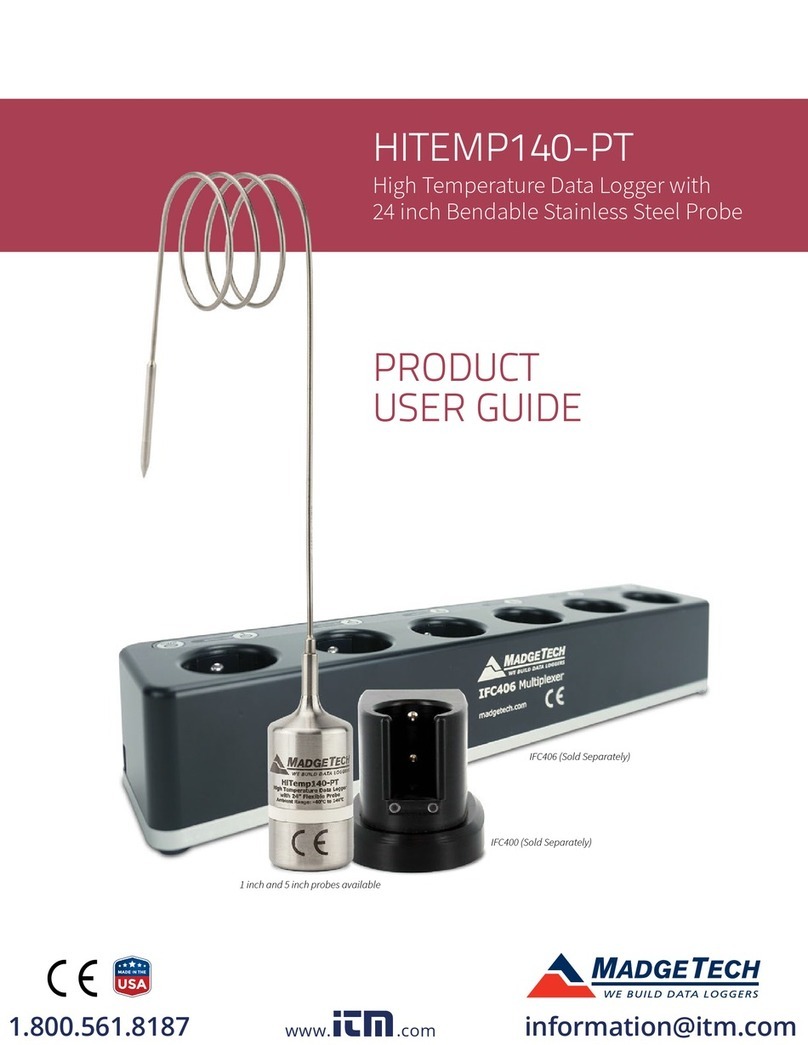

Installing the Docking Station

IFC400 or IFC406 (sold separately) — Connect the device

into a USB port with the interface cable. The drivers will

install automatically.

Device Operation

Connecting and Starting the Data Logger

1. Once the software is installed and running, plug the

interface cable into the docking station.

2. Connect the USB end of the interface cable into an

open USB port on the computer.

3. Place the data logger into the docking station.

4. The data logger will automatically appear under

Connected Devices within the software.

5. For most applications, select Custom Start from

the menu bar and choose the desired start method,

reading rate and other parameters appropriate for the

data logging application and click Start. (Quick Start

applies the most recent custom start options, Batch

Start is used for managing multiple loggers at once,

Real Time Start stores the dataset as it records while

connected to the logger.)

6. The status of the device will change to Running,

Waiting to Start or Waiting to Manual Start,

depending upon your start method.

7. Disconnect the data logger from the interface cable

and place it in the environment to measure.

Note: The device will stop recording data when the end of memory

is reached or the device is stopped. At this point the device cannot be

restarted until it has been re-armed by the computer.

Downloading Data from a Data Logger

1. Place the logger into the docking station.

2. Highlight the data logger in the Connected Devices

list. Click Stop on the menu bar.

3. Once the data logger is stopped, with the logger

highlighted, click Download. You will be prompted to

name your report.

4. Downloading will offload and save all the recorded

data to the PC.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com