BK104B and BK110B 2 06/01/2021

WARNING INFORMATION

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

IMPORTANT: READ THESE INSTRUCTIONS BEFORE OPERATING

BEFORE USING THIS DEVICE, READ THIS MANUAL COMPLETELY AND THOROUGHLY, UNDERSTAND ITS OPERATING PROCEDURES, SAFETY WARNINGS

AND MAINTENANCE REQUIREMENTS. SAVE THESE INSTRUCTIONS.

It is the responsibility of the owner to make sure all personnel read this manual prior to using this Portable Hydraulic Power Kit. It is also the responsibility of the

kit owner to keep this manual intact and in a convenient location for all to see and read. If the manual or product labels are lost or not legible, contact Mac Tools

for replacements. If the operator is not fluent in English, the product and safety instructions shall be read to and discussed with the operator in the operator's

native language by the purchaser/owner or his designee, making sure that the operator comprehends its contents.

This product is intended only for use in the repair of vehicle bodies and frames. Do not use or modify this product for any other purpose than that for which it

was designed without consulting the manufacturer's authorized representative. The use of portable automotive lifting devices are subject to certain hazards

that cannot be prevented by mechanical means, but only by the exercise of intelligence, care, and common sense. It is therefore essential to have owners and

personnel involved in the use and operation of the equipment who are careful, competent, trained, and qualified in the safe operation of the equipment and its

proper use. Examples of hazards are dropping, tipping or slipping of loads caused primarily by improperly securing loads, overloading, off-centered loads, use

on other than hard level surfaces, and using equipment for a purpose for which it was not designed.

METHODS TO AVOID HAZARDOUS SITUATIONS

• Read, study, understand, and follow all instructions before operating this device.

• The kit owner is responsible for the kit being used in accordance with OSHA, state, and local safety standards.

• User and bystanders must wear eye protection that meets ANSI Z87.1 and OSHA standards.

• Do not use beyond rated capacity.

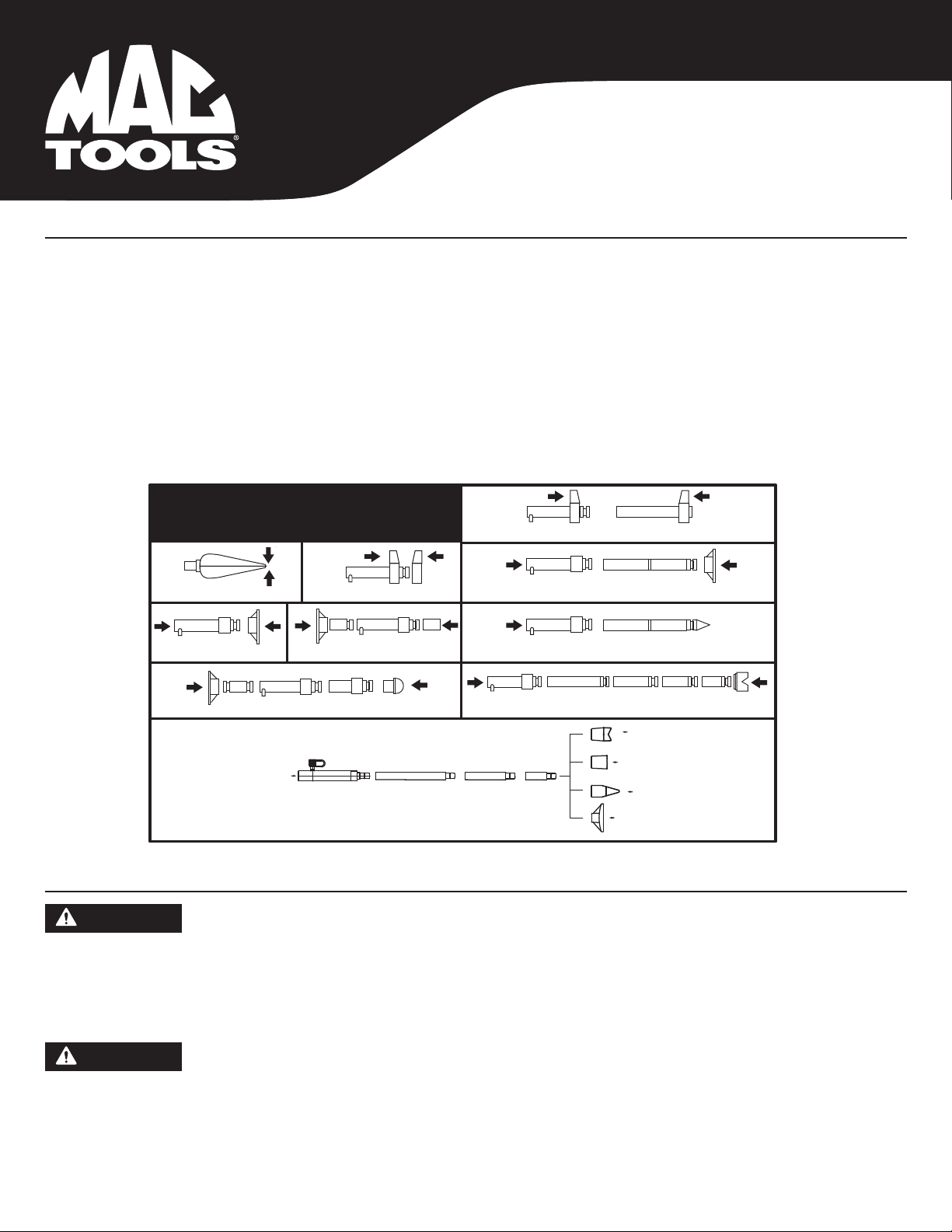

• When attachments and adapters are used with the kit, the rated capacity of the kit shall be no greater than the rated capacity of the lowest rated

component or combination of components that makes up the kit. Refer to the Owner’s Manual section titled “APPLYING FORCE” for typical

applications and corresponding load capacities.

• Use a pressure gauge that indicates force applied.

• Spreader Ram is rated at 1/2 ton capacity.

• Rubber Heads are rated at 1/2 ton capacity in the 4 ton kit and 1 ton capacity in the 10 ton kit.

• Do not overextend the rams.

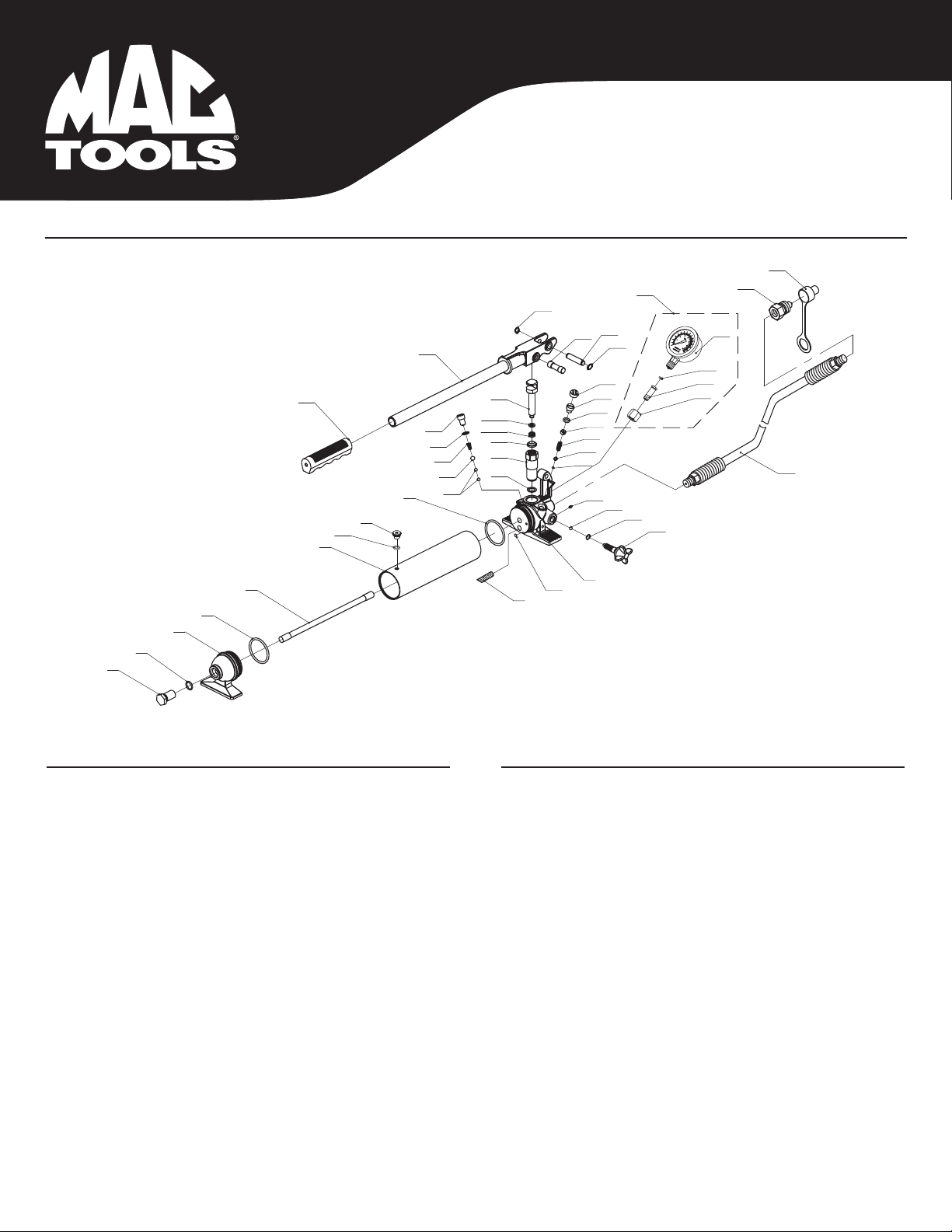

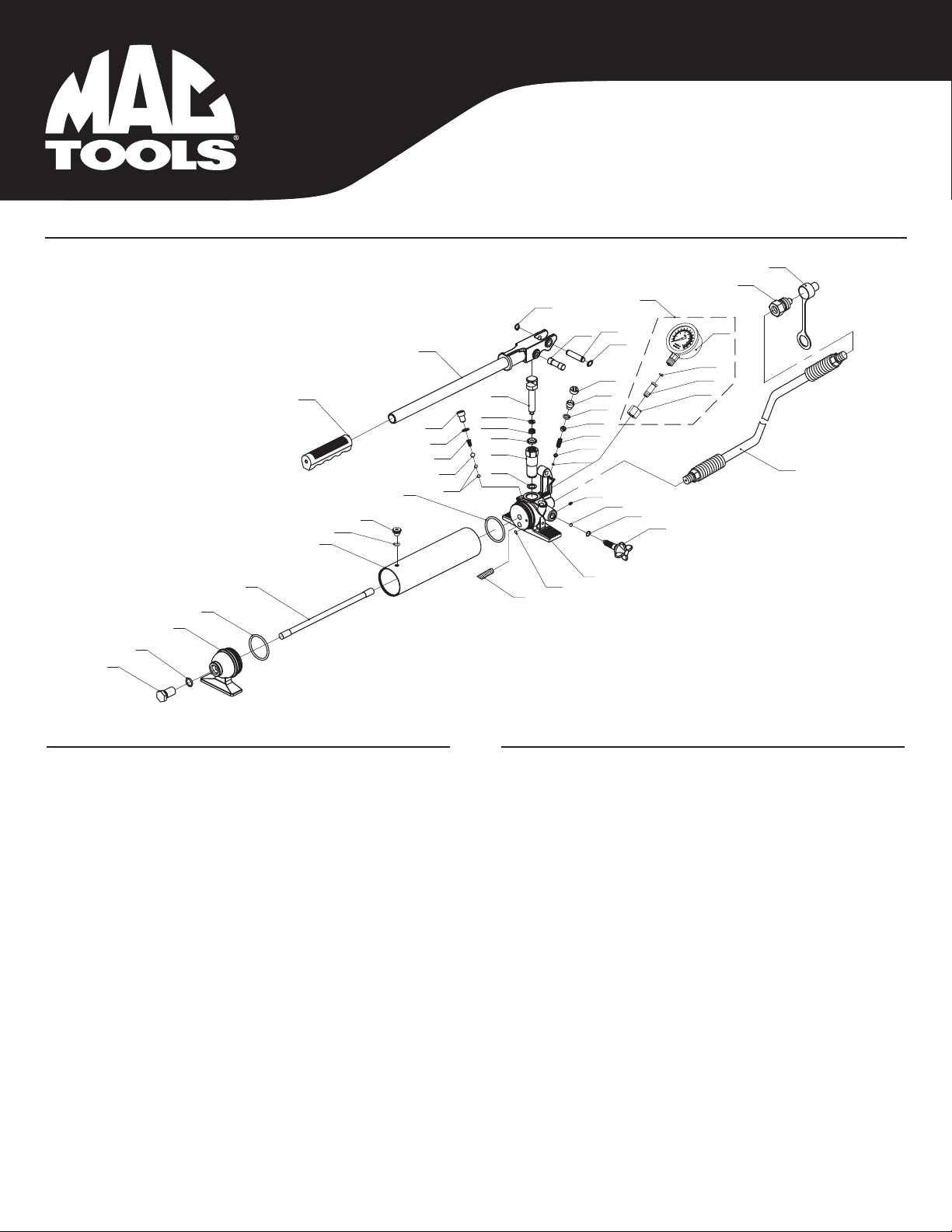

• When using extension tubes, position the shortest tube farthest away from the cylinder.

• Attachments and extension tubes must be aligned and fully engaged so the ram force is straight and avoids off-center conditions.

• Before operating, tighten all hose, gauge and manifold connections so they are secure and leak free. Do not over tighten or it may cause premature

thread failure or split pressure fittings. Tighten all hose quick disconnect fittings by hand only.

• Do not subject the hose to extreme heat or cold, sharp surfaces, abrasion, impact, kinking, twisting, curling, bending or any condition that restricts

or affects fluid flow.

• Make sure setup is stable and secure before performing any work.

• Use this kit for the intended purpose of vehicle body/frame repair only.

• Only components supplied with this kit shall be used with this kit.

• No alterations or modifications shall be made to any of the kit components.

• Failure to follow these warnings could result in death or serious injury and/or property damage.

WARNING: This product can expose you to chemicals including nickel, which is known to the State of California to cause cancer and birth defects

or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

WARNING: Indicates a hazardous situation

which, if not avoided, could result in death

or serious injury.

WARNING

WARNING

WARNING

THIS INSTRUCTION MANUAL USES THE FOLLOWING SYMBOLS AND DEFINITIONS TO ALERT YOU TO HAZARDOUS CONDITIONS WHICH MAY CREATE A RISK

OF PERSONAL INJURY AND/OR PROPERTY DAMAGE.