1-800-MAGLINE (624-5463) Page 2 www.magliner.com

CooLift®

Table of Contents

CooLift Toolkit ........................................................................................................................................3

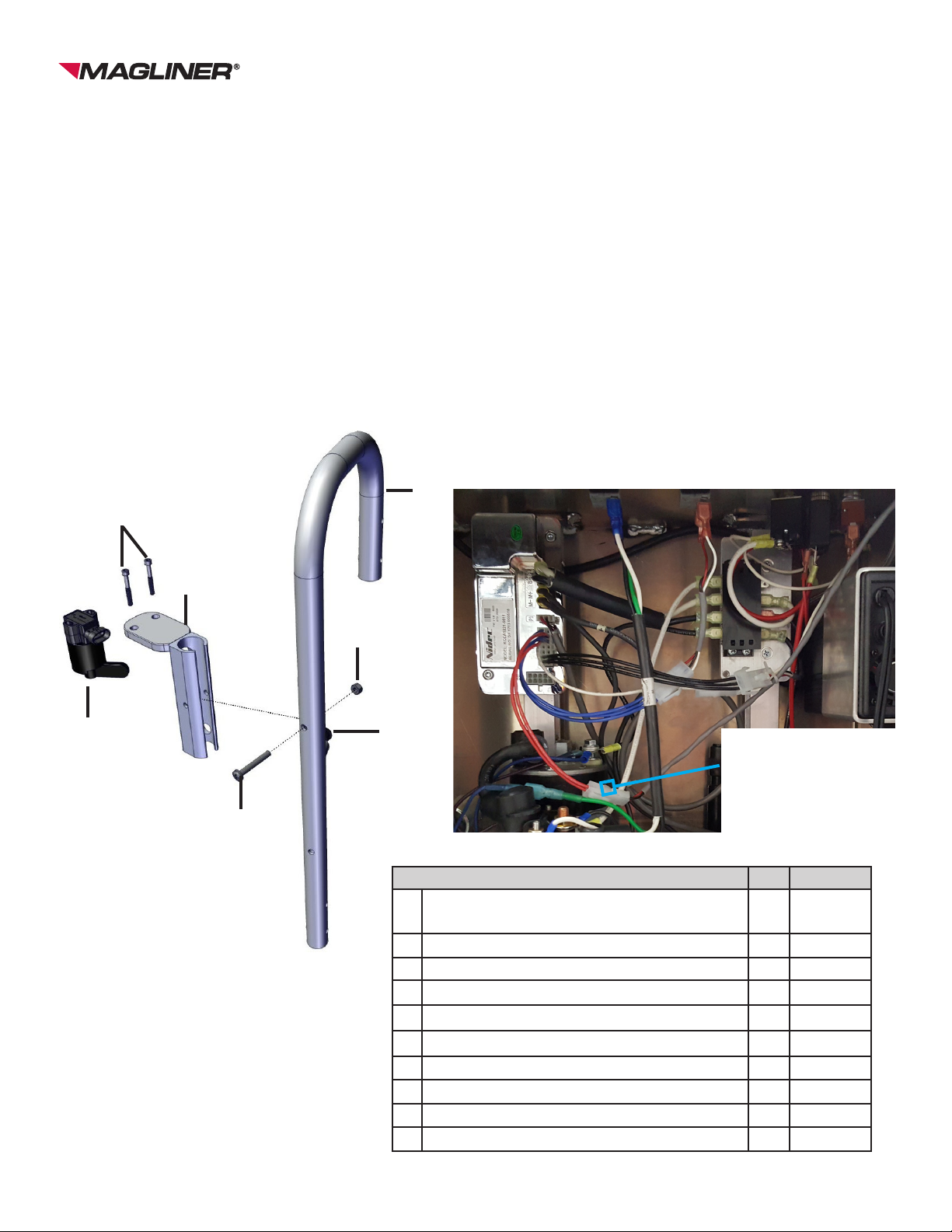

Vertical Loop Throttle Handle Removal ................................................................................................4

Vertical Loop Throttle Handle Replacement...................................................................................... 4-5

Replacing Throttle .................................................................................................................................6

Replacing Throttle Interlock Button .......................................................................................................7

Bulk Head Removal and Installation.................................................................................................8-11

Replacing Corner Post ........................................................................................................................12

Replacing Pallet Stops ........................................................................................................................12

Replacing Front Wheel........................................................................................................................13

Replacing Rear Swivel Caster.............................................................................................................13

Replacing Brushes ..............................................................................................................................14

Replacing Back Panel Latch................................................................................................................15

Removing Deck ...................................................................................................................................15

Removing Bottom Pans/Brace ............................................................................................................16

Replacing Containment Strap and Tongue..........................................................................................17

Replacing Battery Charger ..................................................................................................................18

Replacing Charger Cord................................................................................................................ 19-20

Replacing Power Switches..................................................................................................................21

Replacing Directional Switch...............................................................................................................21

Replacing Battery Meter......................................................................................................................22

Replacing Circuit Breaker....................................................................................................................23

Replacing Propulsion Controller..........................................................................................................24

Electrical Schematic ............................................................................................................................25

Replacing Motor Assembly ............................................................................................................ 26-27

Replacing Clutch Assembly ........................................................................................................... 28-29

Replacing Dierential Assembly .................................................................................................... 30-31

Changing Brake Caliper ................................................................................................................ 32-33

Changing Brake Pad ..................................................................................................................... 34-35

Changing Upper Brake Line .......................................................................................................... 36-37

Changing Lower Brake Line .......................................................................................................... 38-39

Replacing Brake Master Cylinder.................................................................................................. 40-41

Bleeding Brakes ............................................................................................................................ 42-43

Changing Hydraulic Pump............................................................................................................. 44-45

Changing Hydraulic Cylinder......................................................................................................... 46-47

Bleeding Hydraulic System............................................................................................................ 48-49

Replacing Brake Pawl ................................................................................................................... 50-51

Relocating Master Cylinder .................................................................................................................51

Replacing Center Wheel and Brake Disc ............................................................................................52

Troubleshooting............................................................................................................................. 53-54

Inspection / Maintenance Checklist................................................................................................ 55-62