© 2016 Magnaflux Page 2 Magnaflux-SRVC-TS032

Issued: Mar 2016

Rev. 1

Repairs that are possible on the EV-6000 (Refer to Page 5 in the EV-6000

Manual for exact part location and part numbers)

A. Replacement of Rear Cover Gasket (Index #10)

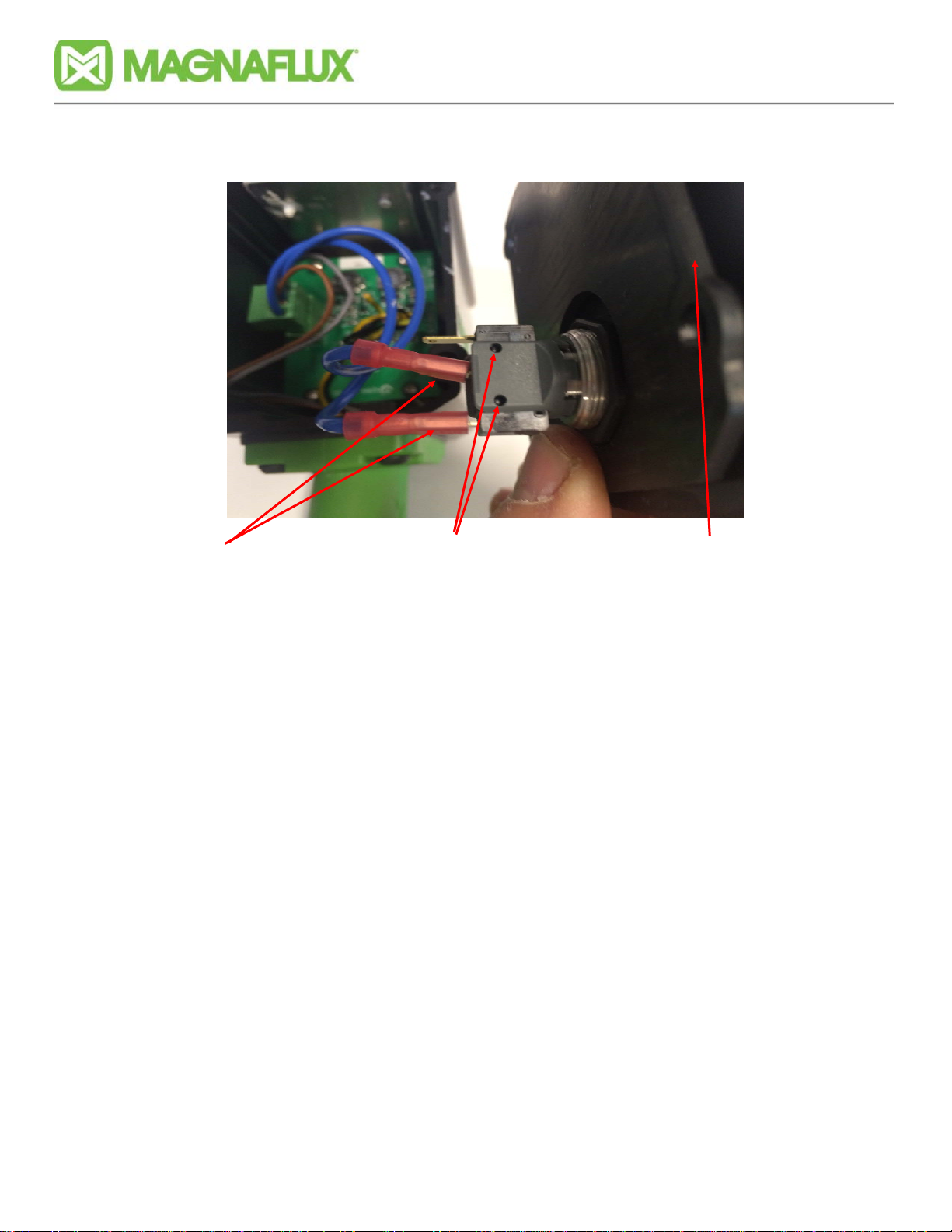

B. Replacement of “On/Off” Power Switch (Index #12)

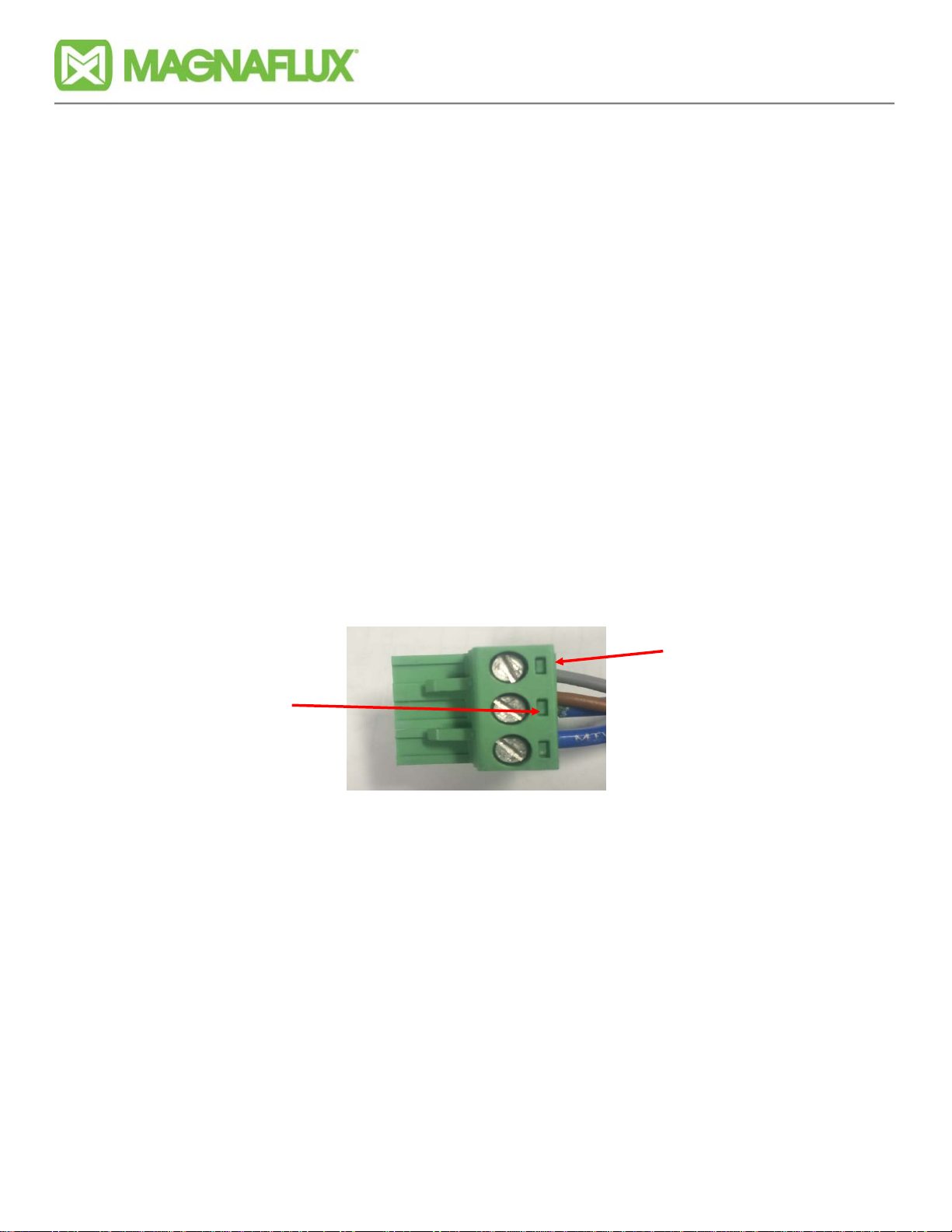

C. Testing and Replacing EV6000 Power Cable (Index #17)

D. Testing and Replacing EV6000 Power Supply (Not shown in manual)

E. Replacement of EV6000 LED Assembly (Index #7) — Note: Only complete replacement

of the EV6000 LED Assembly is authorized. No repairs are possible and the optic lens

are not field replaceable.

NOTE #1: Replacement of the UV filter, filter gasket and front cover gasket (Index #’s 3, 4

and 6)— Instructions are located on page 4 of the EV6000 manual.

NOTE #2: Anytime the rear cover is removed, the rear cover gasket should be inspected for

any signs of degradation, deformation, or tears. If anything unusual is observed, replace

the gasket.

Tools needed to perform work:

1. 2.5 mm Hex Key Wrench (Used for LED Array Assembly)

2. 3 mm Hex Key Wrench (Used for removal of front and rear covers

3. 22 mm wrench or crescent wrench (only needed if replacing “On/Off” Power Switch)

4. Needle nose pliers (only needed if replacing “On/Off” Power Switch)

5. AC/DC voltmeter — Capable of reading 115/230 volts AC and 24 volts DC

Additional items needed if replacing the EV6000 LED Assembly:

1. Static control mat with grounding protection

2. Techspray Silicone Free Heat Sink Compound 1978-DP (4 oz. tube). Please note that

other silicone free heat sink compounds have not been tested for compatibility with the

EV6000 LED Array Assembly and therefore are not authorized to be used.