Universal WE

© 2018 Magnaflux

Page 2 Magnaflux-SRVC-IG037

Issued: May 2018

Rev. 0

1. A minimum of two feet is required at both ends and the rear of the inspection unit to ensure

adequate space for servicing and accessing the circulating pump.

2. A firm, reasonably level floor capable of supporting the inspection unit and the materials

awaiting inspection.

3. Adequate space to accommodate a black light inspection canopy (Optional), material stor-

age, material movement and access to the materials.

4. A power source of the proper voltage, frequency and phase (as designated on the Mag-

naflux Data Plate located on headstock end of inspection unit) capable of providing current

per the nameplate.

5. A compressed air supply capable of providing a minimum of 90-120 psig at 5 cubic feet per

minute. Connect the incoming air supply to the Incoming Air Connection. Follow all local

codes for plumbing pneumatics.

6. Fill the tank (10 Gal (40 L) and add appropriate amount of particles to achieve desired con-

centration level.

Getting Started

continued on Page 3...

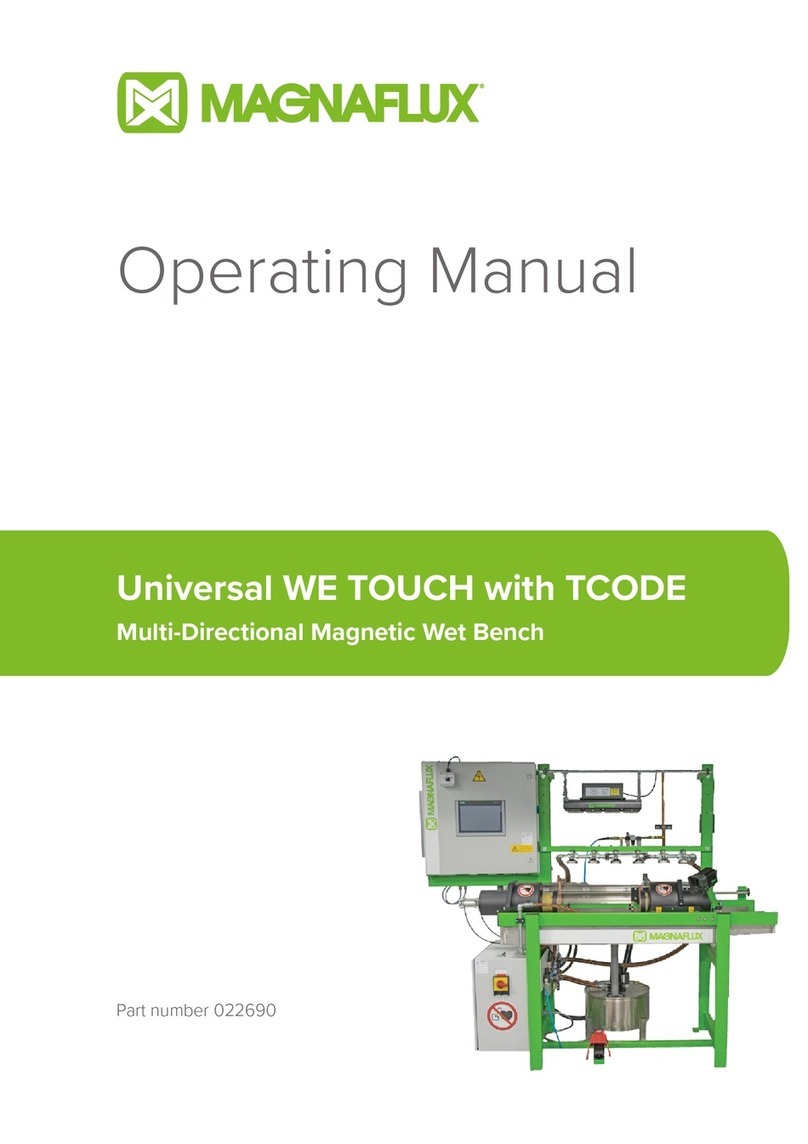

Controls Cabinet

(PLC, Relays,

Control Board…)

Electrical Pow-

er Hookup

(Inside Cabinet)

Compressed Air

Hookup (Front

side of machine)

Circulating tank

with pump for

fluid and parti-

cles.