Maguire Products, Inc.

LineMaster

Enhanced Extrusion Control with Loss-in-Weight Hopper

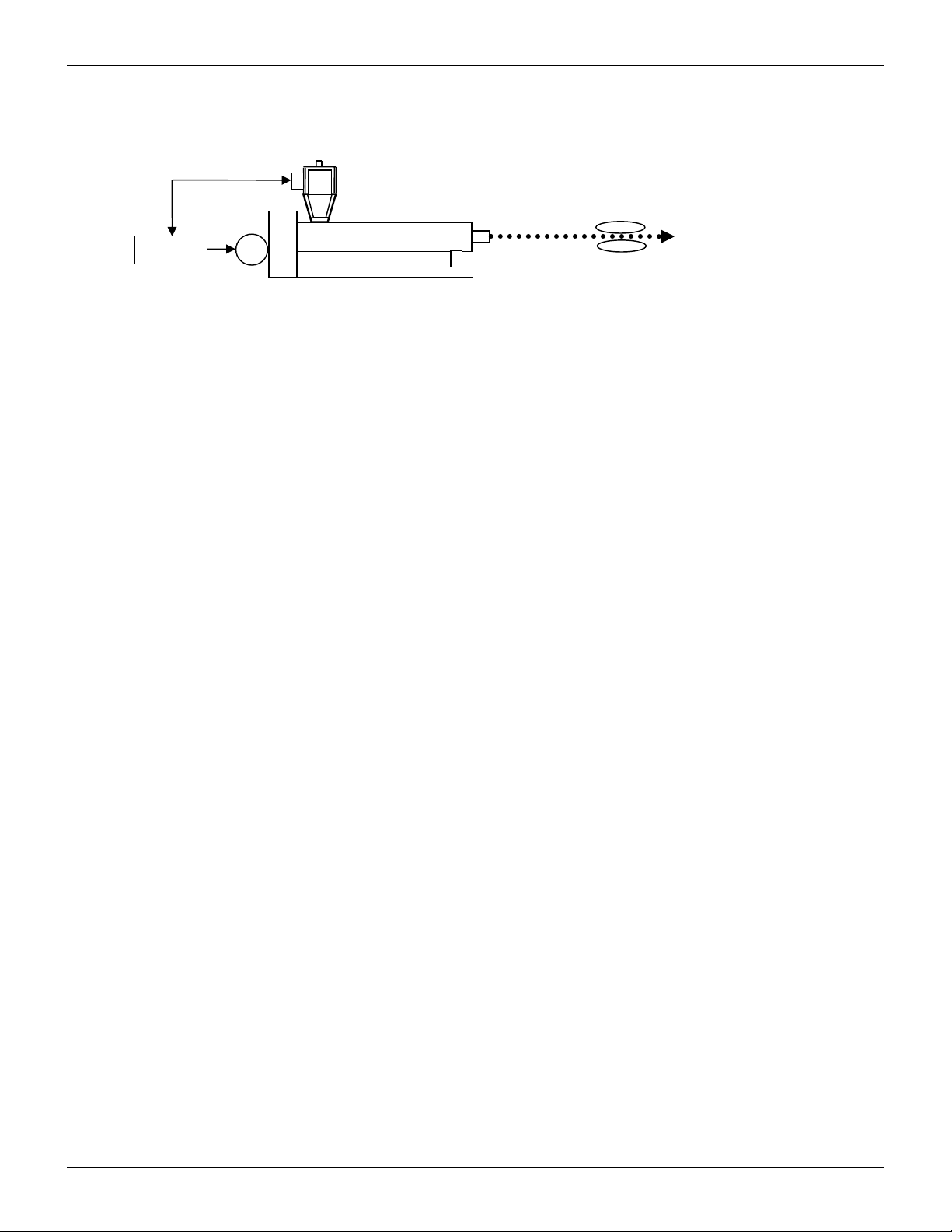

The LineMasterTM product range has the option of monitoring material consumption by a loss-in-

weight hopper mounted on the process throat. The weight consumption data can be reported to

one of two control options: Enhanced Extrusion Control with a Maguire blender integrates the

extrusion control functions into the blender controller for a single point of control. The second

option is Enhanced LIW Extrusion Control, which utilizes LineMaster Control Operator Interface

(XCC) to be used as a stand-alone solution for throughput or yield control. Additionally, it can be

utilized in a multi-layer control application.

The weight consumption data is communicated directly to the respective controller and updates

consumption information frequently. The loss-in-weight hopper determines accurate throughput

within 5 seconds and updates thereafter every 1 second.

XC CONTROL OPTIONS

LineMaster is a comprehensive range of products that is designed to serve the vast majority of

extrusion operations that require solutions based at every level of the cost / performance

spectrum. The available control options provide throughput control for pounds or kilograms per

hour, weight per length control for lb/ft or gm/M and gauge control in microns.

XC-1 Throughput Control

Control is maintained by monitoring the throughput of the process and regulating the extruder

speed. The XCC controller utilizing the consumption data from the LIW hopper communicates with

the XCD-X Extruder Drive Speed Control to adjust the extruder speed via a 0-10 volt signal to

maintain the throughput target.

XC-2 Yield Control

XC-2 offers the ability to maintain a product’s weight per length (lb/ft or gm/M) by monitoring the

process throughput against the line speed. An XCE Digital Encoder mounted on a take-off device

monitors the line speed. Control is accomplished by adjusting either the extruder speed with a

XCD-X Drive Speed Control Module by referencing the manually controlled line speed or

controlling the take-off speed with a XCD-T Line Speed Control Module from a manually controlled

extruder.

XC-3 Multi-Layer Yield Control via Computer and G2 Software

XC-3 provides complete weight per length control (lb/ft or gm/M), via simultaneous control of the

extruder and take-off. Controllers are connected via a high speed serial or Ethernet network using

the XC Software. Gauge or thickness control can be initiated in set-up utilizing data of the

materials or blend specific gravity.

Advanced Weigh Control Benefits:

Lines requiring constant feedback

Frequent job / material / production changes

Blenders not mounted on the extruder throat

Co-extrusion lines

Lines requiring frequent ramp up / ramp down control

Lines using only one material