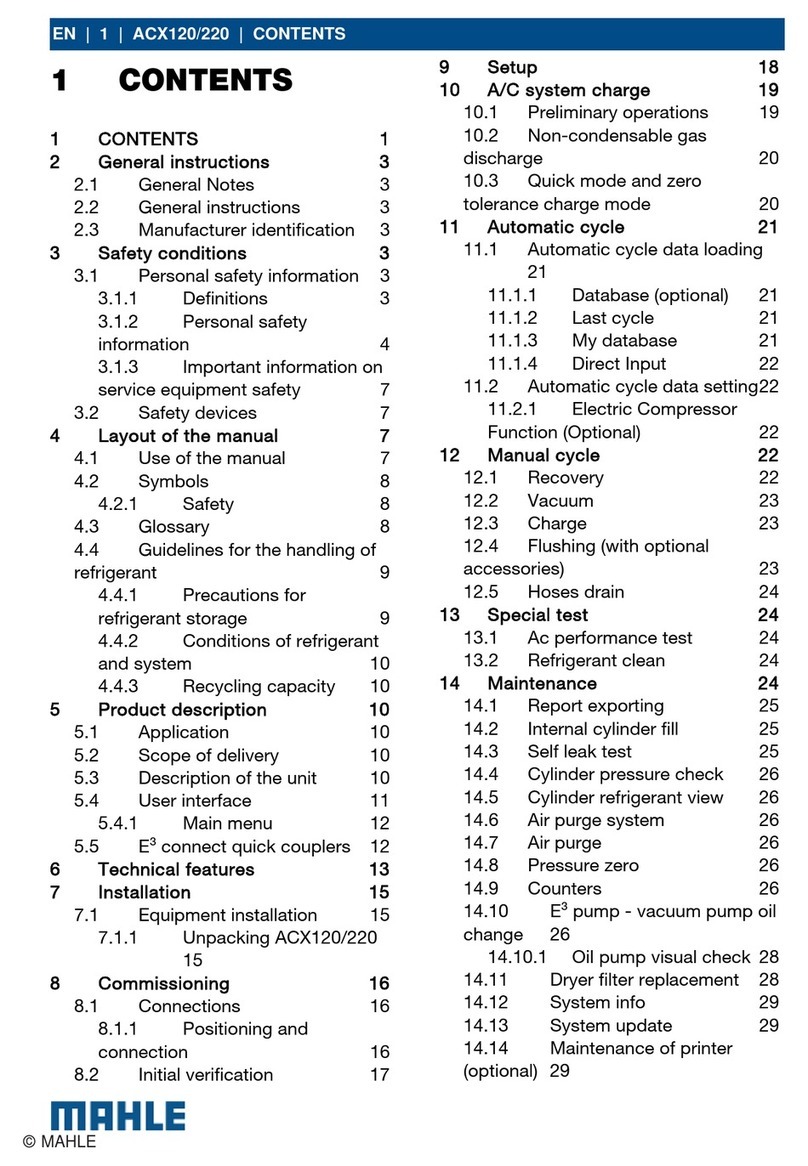

en

|ACX380/480

Contents

1

General instructions ....................................... 3

1.1

General notes .......................................... 3

1.2

General instructions ................................ 3

1.3

Manufacturer identification...................... 3

1.4

Environmental precautions ...................... 3

2

Safety conditions ........................................... 3

2.1

ersonal safety information ..................... 3

2.1.1

Definitions ......................................................... 3

2.1.2

ersonal safety information .............................. 3

2.2

Important information on service

equipment safety .................................................... 5

2.3

Safety devices ......................................... 5

3

Layout of the manual ...................................... 5

3.1

Use of the manual ................................... 5

3.2

Symbols................................................... 6

3.2.1

Safety ............................................................... 6

3.3

Glossary .................................................. 6

3.4

Guidelines for the handling of refrigerant 6

3.4.1

recautions for refrigerant storage ................... 6

3.4.2

Conditions of refrigerant and system ............... 7

3.4.3

Recycling capacity ........................................... 7

4

roduct description ........................................ 7

4.1

Application .............................................. 7

4.2

Scope of delivery ..................................... 7

4.3

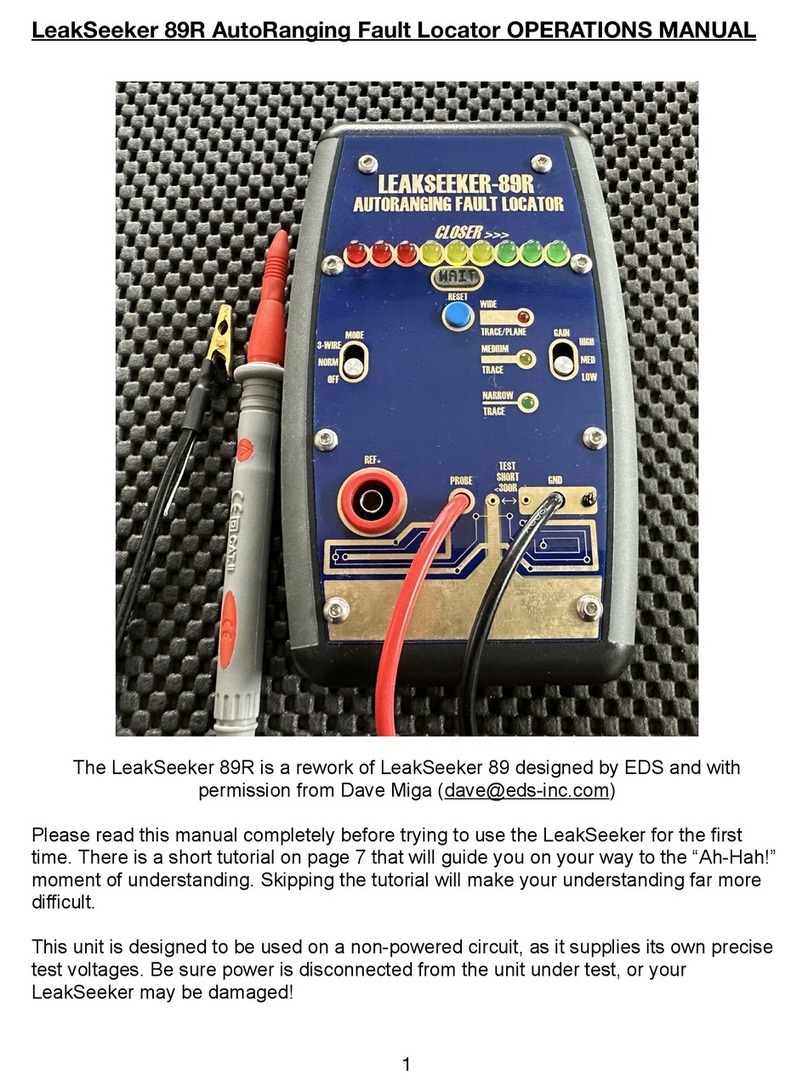

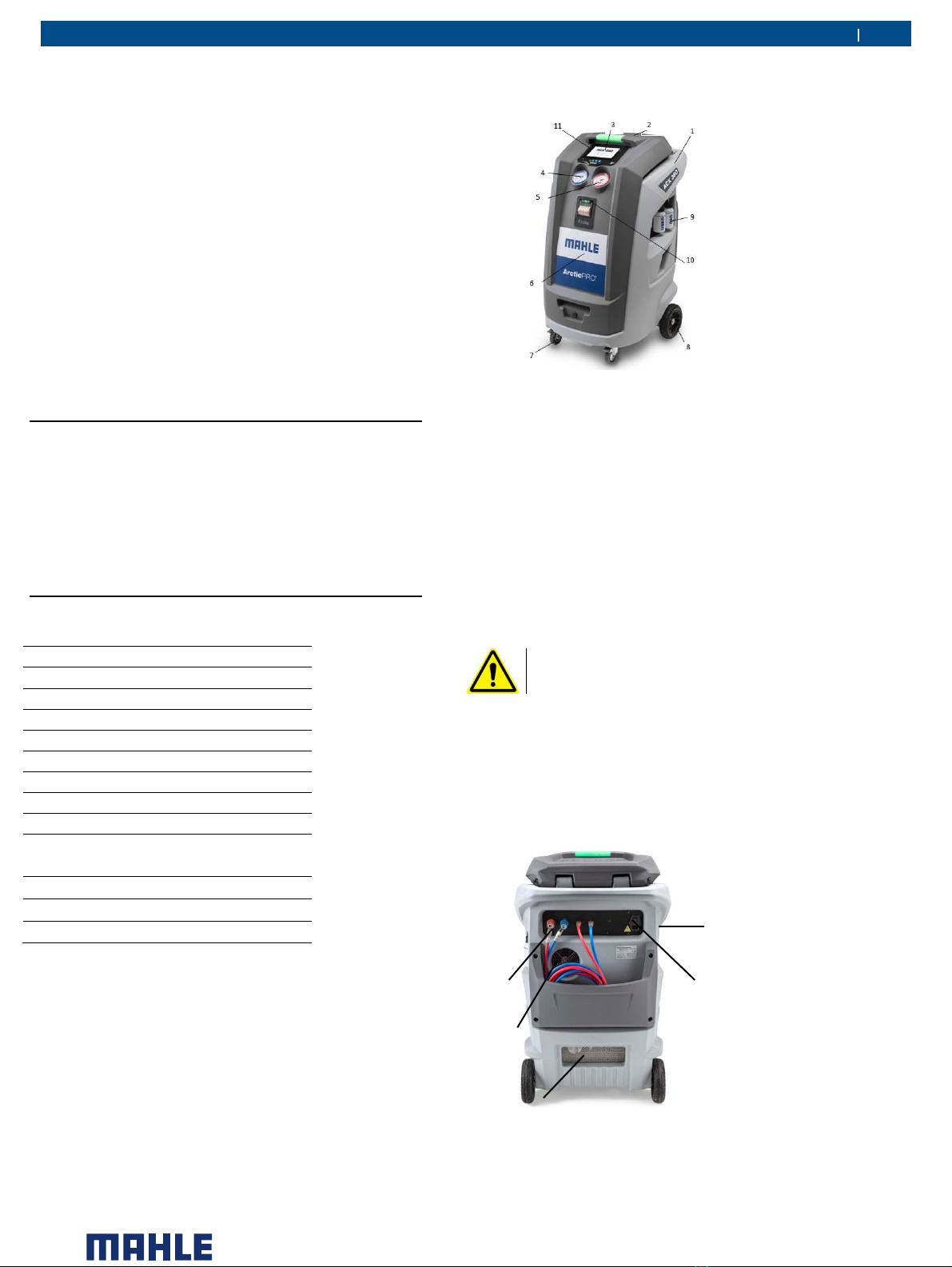

Description of the unit ............................. 7

4.4

User interface .......................................... 8

4.4.1

Main menu ........................................................ 9

4.5

E³ CONNECT quick couplers .................. 9

5

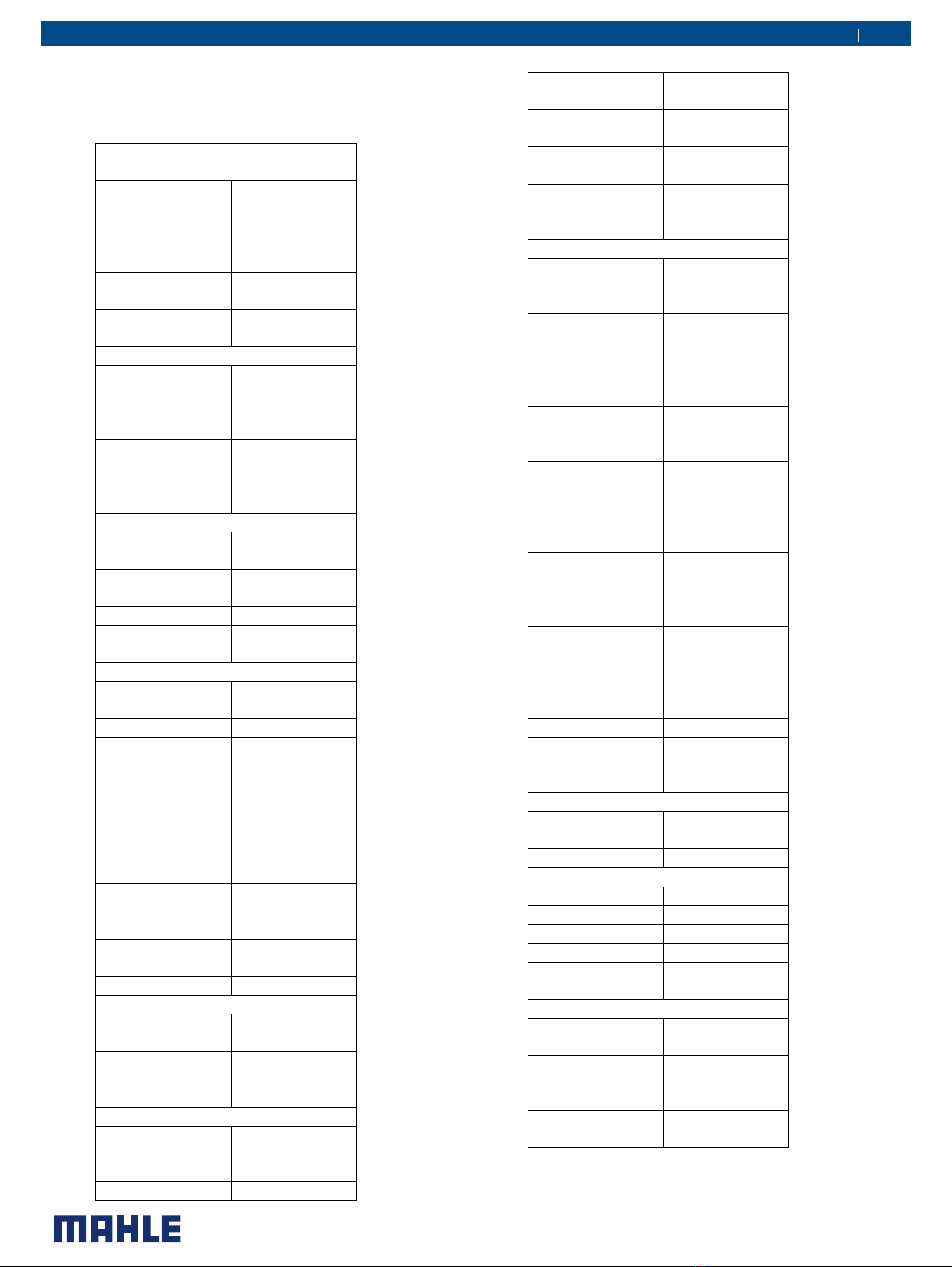

Technical features ........................................ 10

6

Installation.................................................... 11

6.1

Equipment installation ........................... 11

6.1.1

Unpacking ...................................................... 11

7

Commissioning............................................. 11

7.1

Connections .......................................... 11

7.1.1

ositioning and connection ............................ 11

7.2

Software update .................................... 12

7.3

Initial verification .................................... 12

7.4

New AG and OE oil bottles filling ...... 12

7.5

UV dye bottle filling ............................... 13

8

Setup ........................................................... 14

9

Service Menu

............................................ 15

9.1

Manual activations and analogue channel

view

............................................................... 15

9.2

ressures calibration (service kit)

.............. 15

9.3

OOB ressures calibration (service kit)

...... 16

9.4

Gas weight calibration

.............................. 16

9.5

Calibration check

..................................... 17

9.6

Oil weight calibration

................................ 17

9.7

Compressor and vacuum pump test

......... 17

9.8

Spare parts & consumables

...................... 17

10

Equipment

and simulator ........................... 17

11

Refrigerant fluid circuit

............................ 17

11.1

Refrigerant fluid circuit

............................. 17

11.2

Operational cycles

................................... 18

11.3

Receiving tank (refrigerant cylinder)

.......... 18

11.4

Manifold charts

....................................... 18

11.5

NITROGEN

TEST and FORMING GAS

LEAK TEST - MANIFOLD ..................................... 20

11.6

Suction circuit components

...................... 21

12

Non

-permanent junction .............................. 21

13

Electrical connections

............................. 21

14

Maintenance

............................................. 22

14.1

Maintenance interval

............................... 22

14.2

Hoses

emptying ..................................... 23

14.3

Air

purge ................................................ 23

14.4

Vessel

filling ........................................... 23

14.5

ressures

zero ....................................... 23

14.6

Self

leak test .......................................... 23

14.7

E³

UM

................................................ 23

14.8

ump

oil change .................................... 24

14.9

Dryer

filter change ................................. 24

14.10

Replacement

of Active Oil rotection

Cartridge .............................................................. 25

14.11

Calibration

check ................................... 25

14.12

Maintenance

of printer ........................... 25

14.13

eriodic

checks ..................................... 26

14.14

Refrigerant

type change (only for ACX 380)

.............................................................. 27

14.15

Air purge

................................................. 27

14.16

Counters

................................................ 27

14.17

Replacing white sample filter (Refrigerant

identification unit

).................................................... 27

15

Replacement interventions ........................... 28

15.1

Extraordinary maintenance list

................. 28

15.2

Extraordinary maintenance

...................... 28

15.2.1

Replacement of component connected

to refrigerant circuit

....................................................... 28

15.2.2

Replacement

of logic electronic board with

display .................................................................... 29

15.2.3

Replacement

of electronic power board .. 29

16

Spare and wearing parts

.............................. 30

16.1

Refrigerant identification unit

.................... 30

A ENDIX 1 – REFRIGERANT FLUID CIRCUIT

ACX380/480 ....................................................... 31

A ENDIX 2 – REFRIGERANT FLUID CIRCUIT

ACX380/480 O ERATIONAL CYCLES

............ 32

A ENDIX 3 – ACX380/480 - ELECTRICAL

CONNECTION – LOGIC ELECTRONIC BOARD

........................................................................... 36

A ENDIX 4 – ACX380/480 - ELECTRICAL

CONNECTION – OWER ELECTRONIC

BOARD AND OWER SU LY

....................... 37

A ENDIX 5 – ACX380/480 - ELECTRICAL

CONNECTION – STATUS AND WARNING

INDICATOR LIGHT ELECTRONIC BOARD ........ 39

A ENDIX 6 – TROUBLE SHOOTING .......................... 40

A ENDIX 7 – FAILURE LIST ACX380/480 .................. 41