|

LADENMÜHLEN SHOP GRINDER

2.3 Electrical power

Never touch parts that are exposed to electrical volt-

age. These can cause an electric shock that can lead to

severe injury or death!

Never operate the machine with a defective mains cable. Defective

mains cables or plugs must be replaced immediately by authorized spe-

cialist personnel or by our Customer Services department.

NOTICE

Before connecting the machine to the mains, check whether the local

operating voltage, frequency and circuit breakers/fuses match the data

shown on the nameplate and with the technical data in these Operating

Instructions. If the data does not match, do not connect the machine to

the mains!

2.4 Use in accordance with the intended purpose

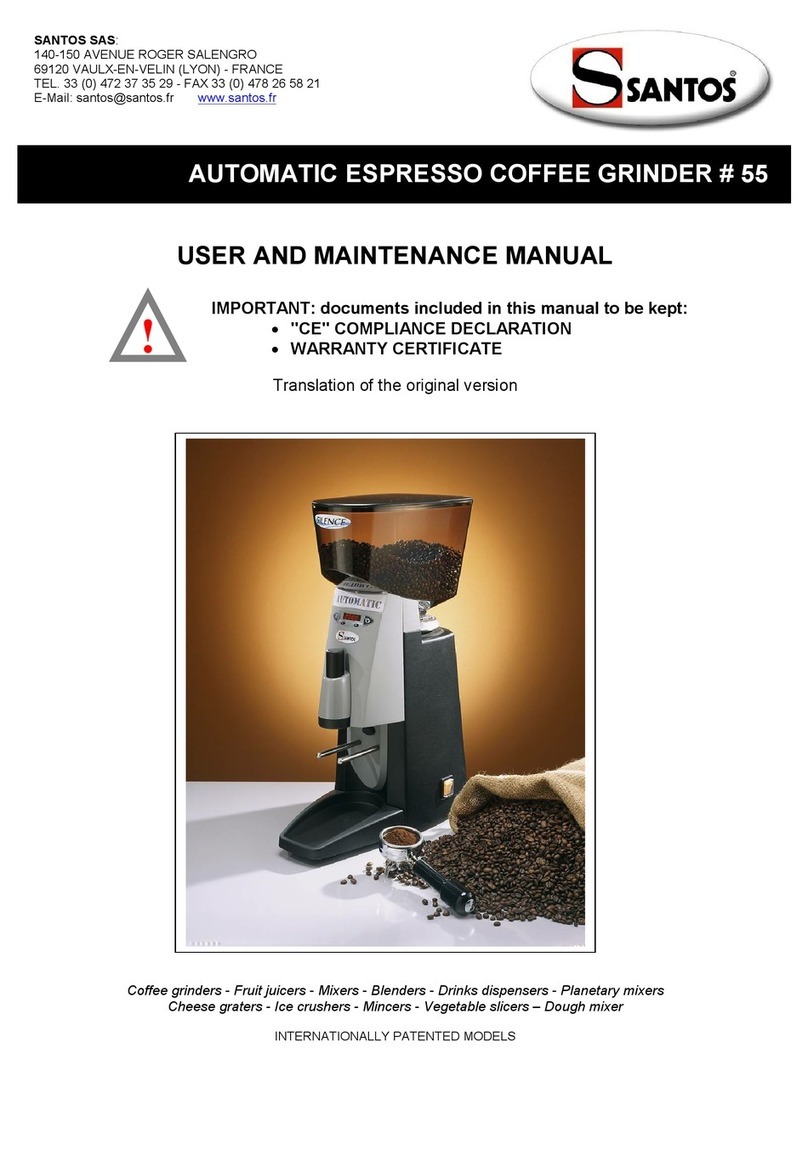

The sole function of the Coffee Grinder is to grind whole roasted cof-

fee beans. Any other use is deemed to be not in accordance with the

intended purpose.

NOTICE

Only whole coffee beans may be loaded into the bean hopper. Do not

put ground coffee into the bean hopper. Coffee that has already been

ground once must not be loaded into the bean hopper and reground.

NOTICE

Only coffee beans may be loaded into the bean hopper. Do not put oth-

er objects or liquids into the bean hopper, since this will damage the

grinder.

HINT

The machine can be dangerous if it is used improperly or not in accor-

dance with the intended purpose. Use in accordance with the intended

purpose also includes observation of operating and maintenance condi-

tions as prescribed by the manufacturer.

2.5 Service staff requirements

The machine may only be serviced and maintained by personnel who

have been trained and assigned to the equipment. The operator must

warn service staff of any hazards that may be present.

The operator must clearly assign responsibilities as to servicing and

maintenance, so that, as far as safety is concerned, no one is unclear as

to who is responsible for what. The operator must take care that no un-

authorized persons perform such tasks on the equipment.

2.6 Warranty and liability

The warranty is limited to the replacement of defective parts. The manu-

facturer shall not be liable in respect of claims in excess of this. Spare

parts must conform to the technical specifications of the manufacturer.

Use only MAHLKÖNIG – original spare parts.

The machine must be operated in the prescribed manner as described in

these Operating Instructions. No other use of the equipment is permit-

ted. The operator must not convert or modify the machine.