Makermade Standard Frame User manual

v 1.5 Updated 8.30.21 ©Maker Made, LLC

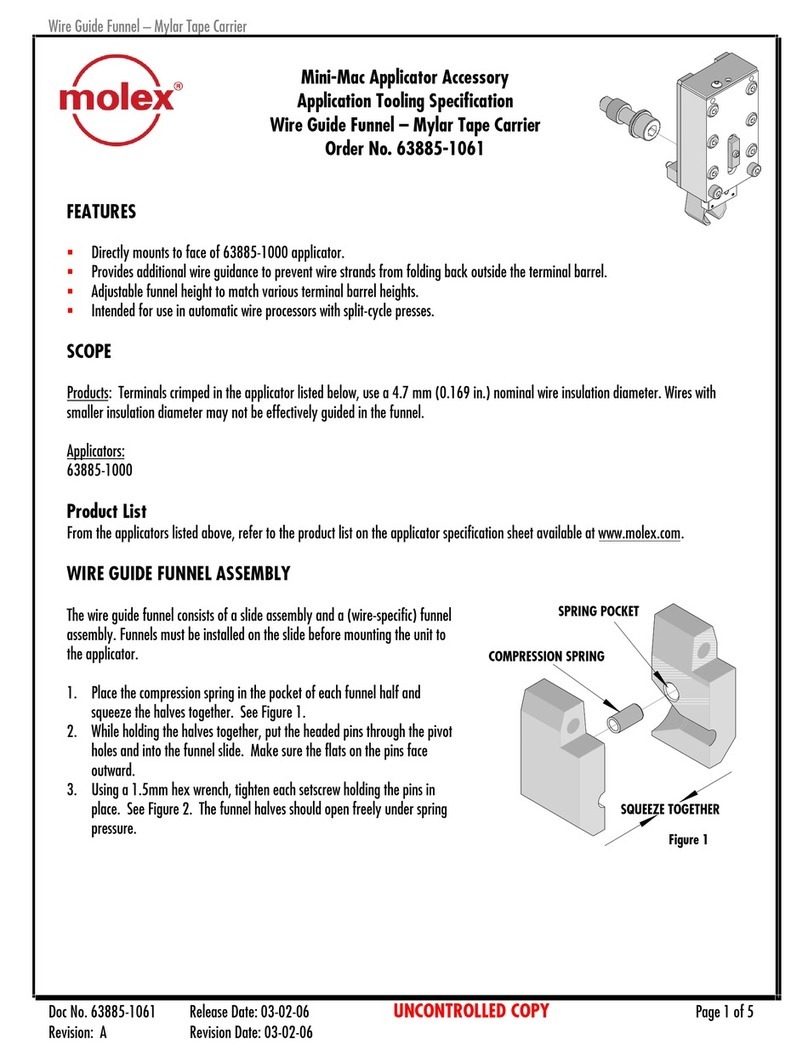

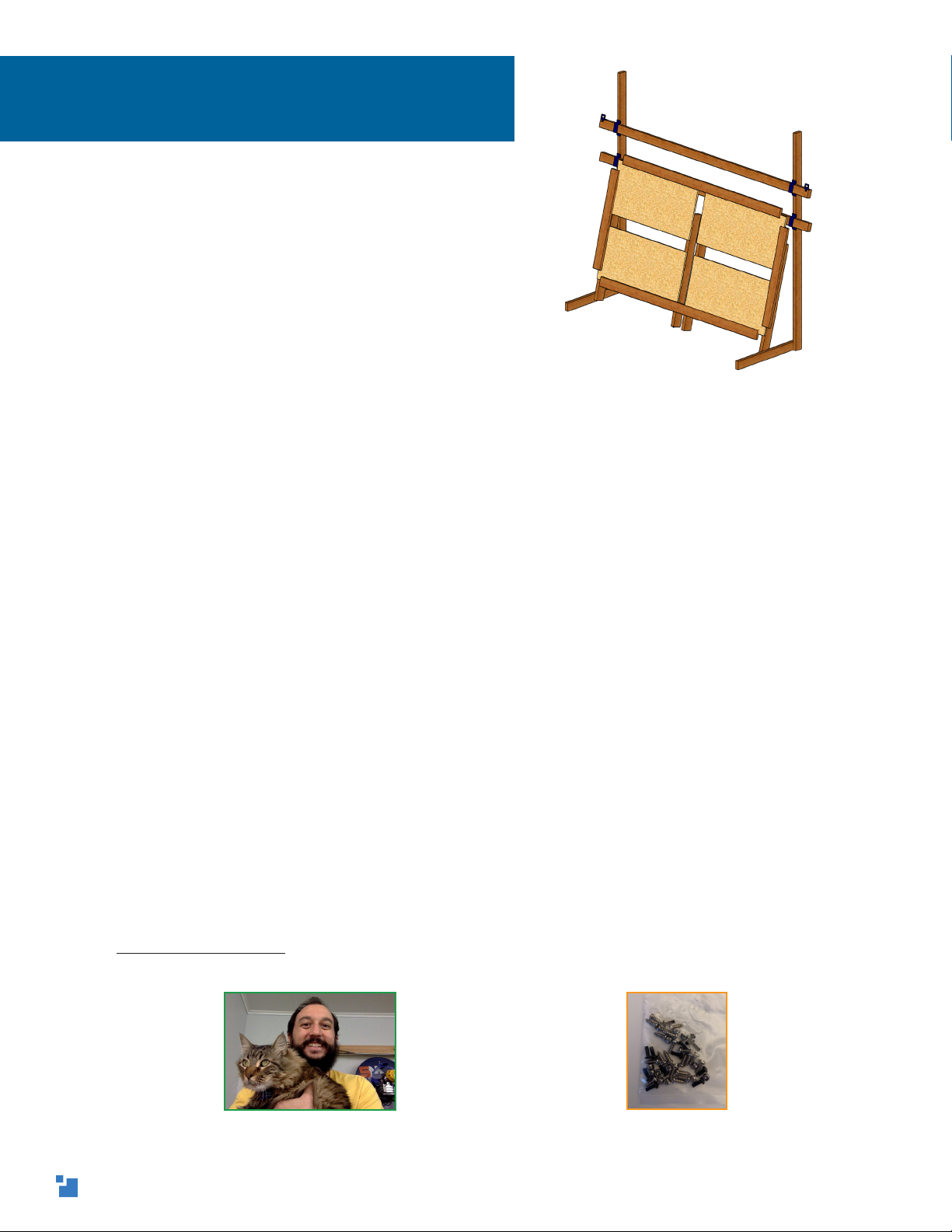

The Standard Frame

A guide to assembling the recommended 10ft top beam

frame for our MakerMade M2 CNC Kit.

Set-Up Guide for

TABLE OF CONTENTS

SECTION 1. Intro - 3

SECTION 2. Materials Needed - 4

SECTION 3. Building the Standard Frame

Building the canvas - 5

Attaching the motors - 6

Attaching the stud mounts - 7

Frame legs - 8

Attaching the canvas frame - 10

Leveling your frame -11

Optional skirts - 12

Attaching the chains - 13

Mounting the M2 to your frame - 14

Arduino DUE and shield - 15

SECTION 4. Appendices

Tips and warnings - 16

What’s in the box? - 17

Standard Frame Dimensions - 19

Custom Frame Tips - 20

2

Thanks for buying the M2 CNC Automated Cutting Machine and

welcome to the MakerMade family! The following instructions are

intended for beginners - with no prior CNC experience.

Here are some notes on the layout...

1. Setting up the M2 can be broken down into three main parts: building

the M2, building the frame (or mounting it on an existing Maslow frame),

and calibration. This guide covers the standard frame.

2. I’m Drew and I made this guide! My notes are tips and tricks to help you

along. They are in a different blue font and look like this:

Drew’s Note: Let us know how this guide can be improved. We love to hear from

you!

Drew’s notes are meant to answer some of the “why” questions you might

have and give you tips to get started. We suggest printing the guide in

color, if you want a paper copy.

3. Each step contains written instructions, a visual rendering of those

instructions, color coded pictures of sub-steps or parts needed for that

step, the hardware bag where you’ll find the parts you’ll need, and

underlined words are something that you should write on your frame in

pencil for reference.

We hope you enjoy setting up your kit, happy making!

INTRODUCTION

Here’s me and Spaghetti,

he’s not impressed with CNC

Like this Bag G in

orange

3

The biggest step to starting your M2 CNC adventure is to build the frame that will

hold your material and the M2 while it cuts. The M2 mounts for your frame are

included, but you will need to purchase the following from a local hardware store

to build the standard frame to cut 4ft x 8ft.

Drew’s Note: We recommend reading this entire section before beginning.

ASSEMBLING THE STANDARD FRAME

10ft Standard Frame - Materials Needed

Amount Needed Type Purpose

22in x 4in x 10ft Top and Bottom Beams

22in x 4in x 8ft Vertical Frame Legs

42in x 4in x 4ft Canvas Legs

22in x 4in x 3ft Horizontal Frame Legs

424in x 48in x 5/8in

Particle Board (1/2in thick

particle board, MDF, or

plywood will also work)

Canvas Wasteboards

1 (a second one is

optional)

1in x 6in x 8ft Bottom Skirt and

optional top skirt (see

Part 6)

2 (optional) 1in x 6in x 4ft Side Skirts (Cut a 1in x

6in x 8ft in two, if not

available in your area,

see Part 6)

Tools for

Building

the frame

Tools for M2

operation

Wrench Router

Hammer Dust Collection

System

Phillips

Screwdriver

2 Standard (4-

5lb) Sized Bricks

Drill / Impact

Driver

2+ Clamps

Tape Measure Material to Cut

Speed Square

Level

Pencil

Extra 1.5in and

2in screws

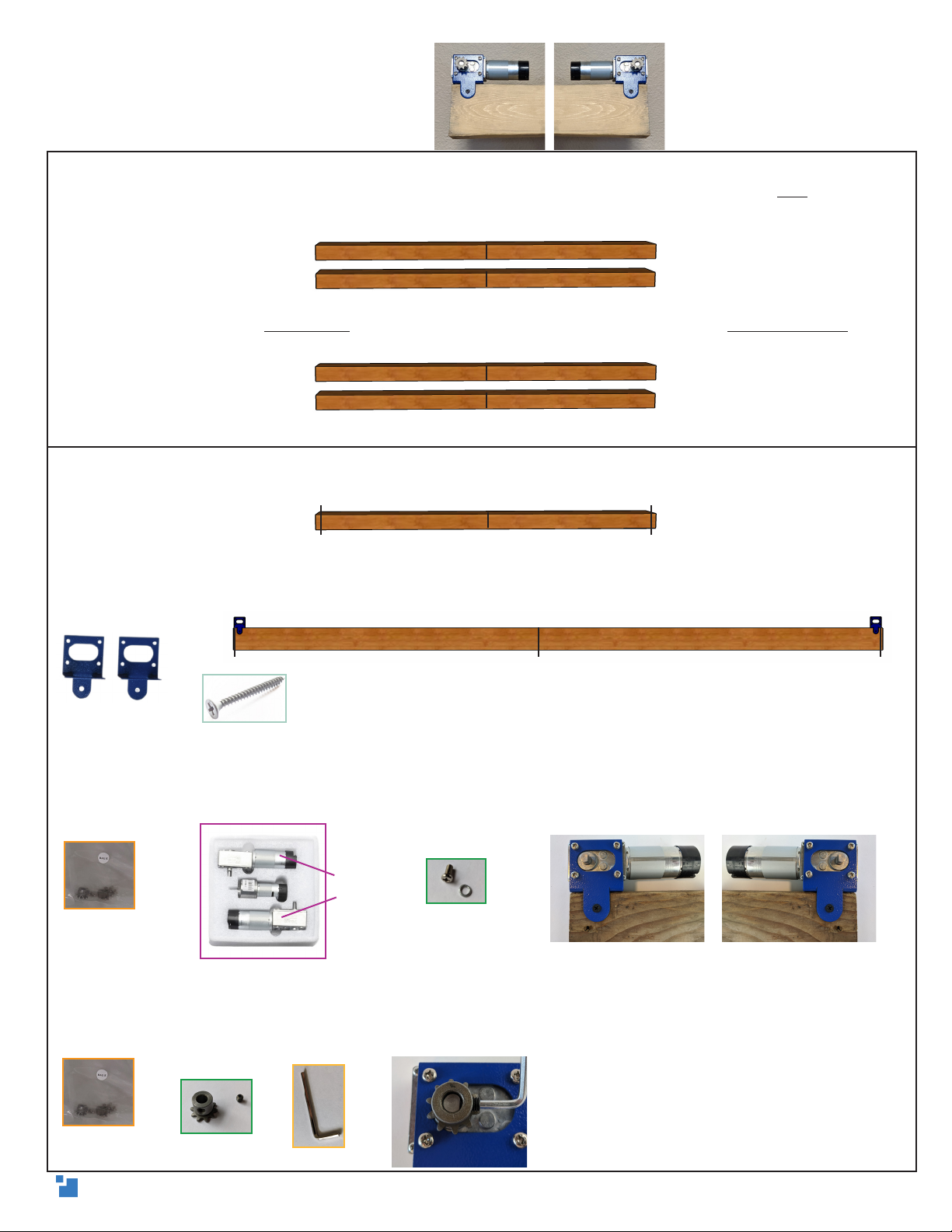

Short/Long frame mounting screws

Bag C and Bag D

Drew’s Note: Nearly every step uses short (1.5in) or long (2in)

wood screws. So, I’m going to leave the bag picture out of the

steps for redundancy’s sake. Just know that you’ll need a lot

of short and long wood screws are from Bags C and D (and

some extras). If you’re experienced with woodworking, feel

free to use any wood screw of your choice to build the frame.

4

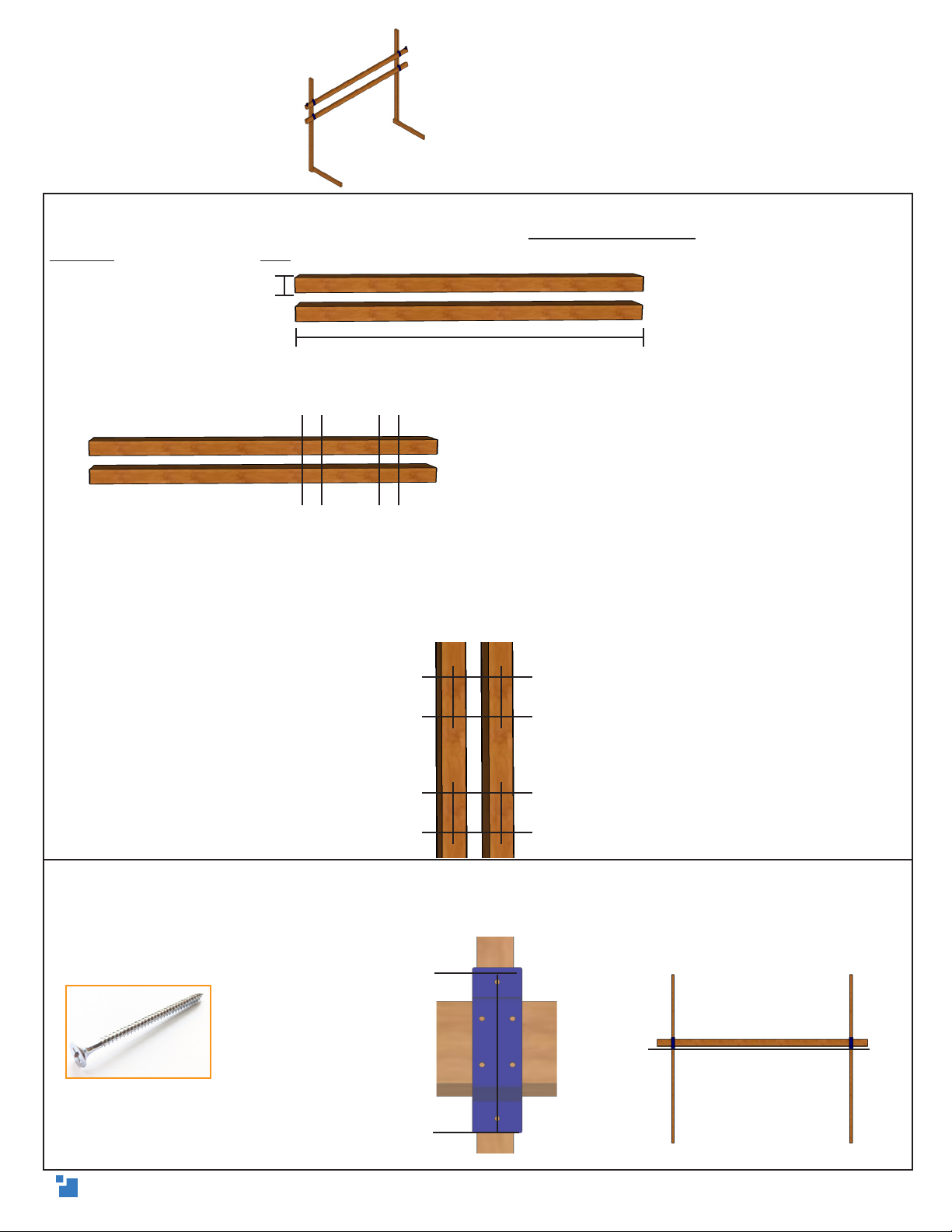

1. (A) To build the canvas, lay the four 2in x 4in x 4ft canvas legs on their 2in edges and mark

with the with the word giraffe (or bottom) on one end of each.

(B) Measuring from the giraffe/bottom end on each, draw a line using a speed square at 9in

and 37in.

(C) Position two canvas legs about 4ft apart. Lay one of the 24in x 48in x 5/8in canvas

wasteboard on them with the legs flush with the 48in ends. Use the speed square to make

the wasteboard flush on the 9in line and screw it into the canvas supports with three long

wood screws, evenly spaced on the leg. Repeat with the other two legs with another canvas

wasteboard.

(D) On the 37in line, position another canvas wasteboard with the speed square and use a 2in x

4in board to support the top edge of the waste-

board while aligning and attaching. Using two

long wood screws per side. Repeat with the

other canvas wasteboards and legs to build the

second canvas.

Building the canvas

2in long wood screw

giraffe

giraffe

4ft

2in

Drew’s Note: Labeling the ends of the board ensures that

we are measuring from the same end of each board. This

mitigates small height differences in the 2in x 4in boards,

so the canvas wasteboards are the same height from the

floor on each canvas. I labeled my ends on the canvas

legs, ‘giraffes’ because giraffes are awesome!

giraffe

giraffe

37in (94cm)

9in (23cm)

2in

37in

(94cm)

9in

(23cm)

giraffe giraffe

5

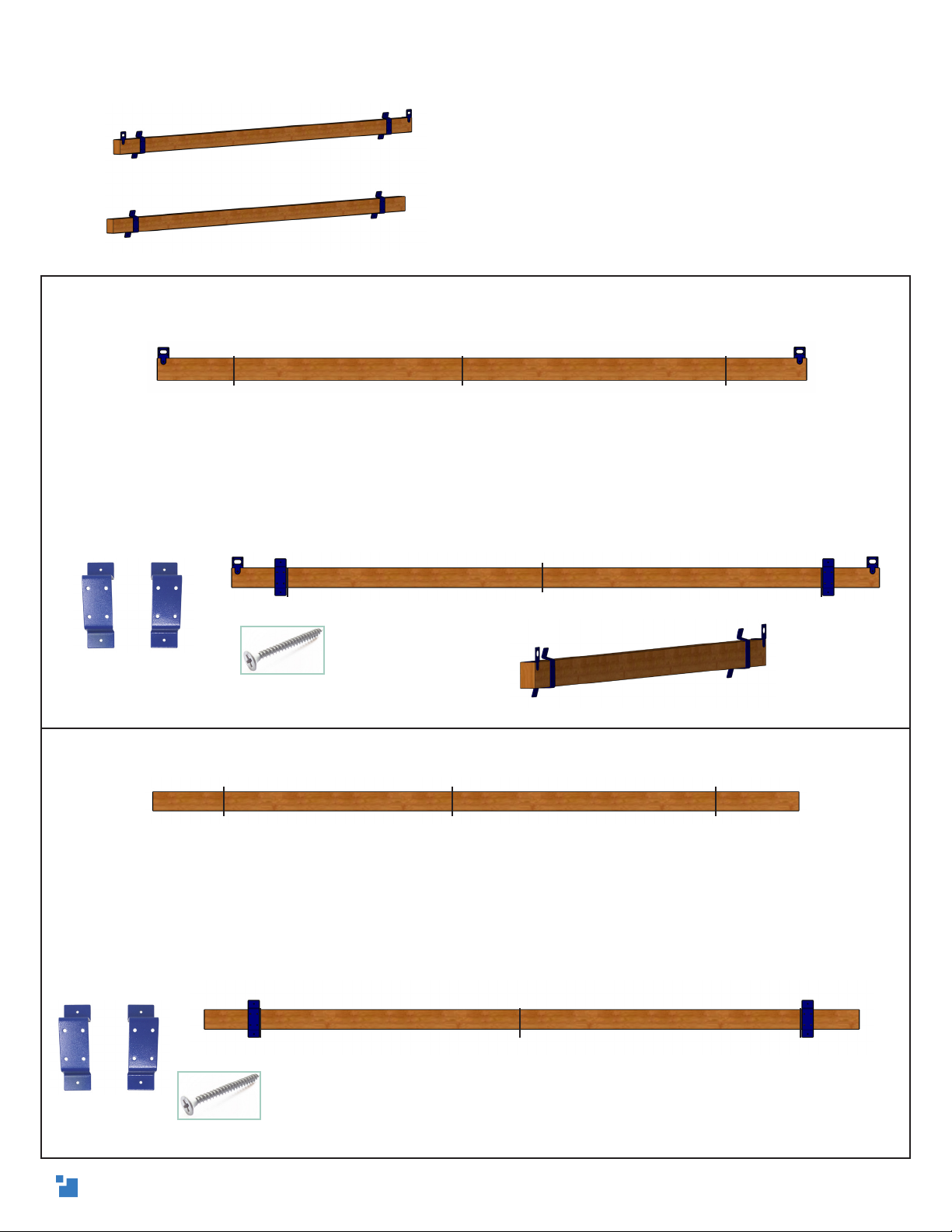

2. (A) Measure the actual length of the 2in x 4in x 10ft beams and mark the exact center of each

on a 4in face. Draw a straight line across the center with the speed square. Write top on a 2in

edge of each and extend the center line around the beam and across the top with the speed

square.

(B) On one beam, write top beam next to the center line. On the other, write bottom beam next

to the center.

3. (A) On the top beam, measure 5ft out from center on each side and draw a straight line with

the speed square on the top edge.

(B) Align the outside edge of the motor mounting brackets flush with the 5ft lines (as shown),

and attach them to the top beam. Use one short wood screw in the front and two in diagonal

holes in the top.

(C) Place one X/Y motor in each bracket, with the black, cylindrical ends toward the center. Use

the motor washers between the bracket and the screw head and fasten the motor screws to the

brackets.

(D) On each motor, attach the motor sprocket by inserting the set screw partially into the gear

hole. Align the set screw with the flat side of the motor shaft, push it all the way down, and

tighten it with 3mm hex wrench to prevent it from slipping.

Attaching the motors

1.5in short wood screw

top

top

center

top beam

bottom beam

motor mounting

brackets

X/Y motors

X/Y Motor

Hardware Bag E

X/Y Motor

Hardware Bag E

top

top

center

5ft 5ftcenter

5ft5ft

top top beam

center

Drew’s Note: If you have Loctite,

placing a bit on this set screw is a great

way to prevent it from loosening over

time.

6

4. (A) On the front face of the top beam, measure and mark 51.5in (130.8cm) from the center on

each side. Draw a straight line with the speed square.

(B) Position a stud mount on the outside of each 51.5in line, with the shorter angle of the stud

mounts toward the top. On one side, push the bottom of the mount against the bottom of the top

beam, use a speed square as a guide to keep it on the 51.5in line, and screw it into the top beam

with four short wood screws. The bottom of the mount should be as flush as possible with the

bottom of the top beam and exactly perpendicular to the beam. Repeat on the other side. Use

the above Drew’s Note for mounting tips!

5. (A) On the front 4in face of the bottom beam, measure and mark 51.5in (130.8cm) from the

center on each side. Draw a straight line with the speed square.

(B) Exactly like attaching to the top beam, position a stud mount on the outside of each 51.5in

line, with the shorter angle of the stud mounts toward the top. On one side, push the bottom of

the mount against the bottom of the top beam, use a speed square as a guide to keep it on the

51.5in line, and screw it into the top beam with four short wood screws. The bottom of the mount

should be as flush as possible with the bottom of the top beam and exactly perpendicular to the

beam. Repeat on the other side.

Attaching the stud mounts

Drew’s Note: For the M2’s alignment calibration

calculation (that’s fun to say), we have to

make sure that the stud mounts are exactly

perpendicular to the beams. To ensure this,

attach each screw part-way before moving

to the next. Repeat on the other two holes and

screw in each from opposite sides by small

increments until they are all tight - just like

changing a tire.

1.5in short wood screw

center51.5in 51.5in

center

51.5in 51.5in

center51.5in 51.5in

center51.5in 51.5in

1.5in short wood screw

stud mount

Side view

stud mount

7

6. (A) Lay the 2in x 4in x 8ft vertical frame legs on the floor, on their 2in edges. Label them

something fun, so you remember that they are, or just vertical frame legs. On each board, write

bottom on one end and top on the other.

(B) Measuring from the bottom end, measure and mark at 55in (139.7cm) , 61.75in (156.8cm), 70in

(177.8cm), and 76.75in (194.9cm) up. Use the speed square to draw a straight line at each mark.

(C) Measure the actual center of each line across the side. Use the speed square to draw a

perpendicular line through the center of the 55in and 61.75in lines. Use the speed square to draw

another perpendicular line intersecting the 70in and 76.75in lines. Repeat on the other leg.

7. Arrange the vertical frame legs parallel on the floor, resting on their 2in edges. Position the

bottom beam on the legs, with the taller ends of the stud mounts flush with the 55in line. Center

the top and bottom holes of the stud mount on the perpendicular center line and attach with the

long wood screws.

Frame legs

Drew’s Note: The actual thickness of your

2in x 4in is around 1.5in. We want to find

the center to ensure that the stud mounts

are mounted perpendicular with the floor

and in the center of your 2in x 4in.

2in long wood screw

bottom

bottom

top

top

8ft

2in

61.75in

70in

55in 55in

61.75in

70in

76.75in 76.75in

bottom

bottom

top

top

55in 76.75in70in61.758in

55in

55in

61.75in

8

8. Position the top beam on the legs, with the taller side of the stud mounts flush with the 70in

line.

Repeat the process of step 7, by centering the top and bottom holes of the stud mount on the

perpendicular line and attaching with the long wood screws.

9. To attach the horizontal frame legs, write back on the ends of the 2in x 4in x 3ft boards. Align

the back end on the inside of the vertical frame legs at a 90 degree angle to make an L shape.

Use the speed square to ensure the 90 angle is square and flush with the back of the vertical

frame legs. Use three long wood screws in a triangle to attach each leg together.

Frame legs (continued)

2in long wood screw

2in long wood screw

70in

76.75in

70in

3ft

Isometric

view

Side view

3ft

Front view

9

~4in

~4in

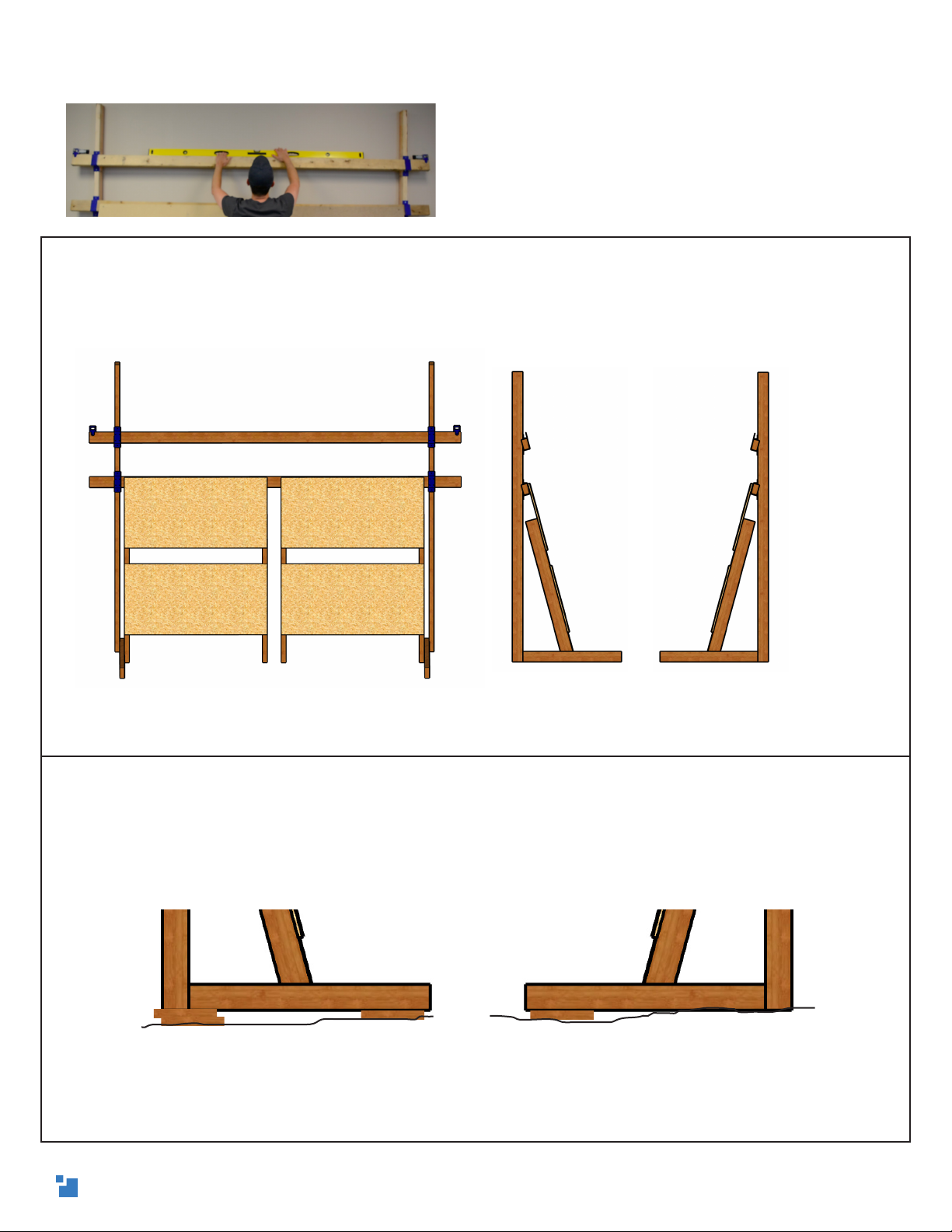

10. (A) Stand up your frame and push it against a wall. Lean your particle board

canvas from Part One inside of the frame legs. They should be pressed against the

support legs on each side, with about a 4in gap between them.

(B) From the back end of the horizontal frame legs, measure and mark 17.25in (43.8cm) out on

each. Angle the canvases, so that the inside of the angle is on the 17.25in line and the top of the

canvas is flat against the bottom beam. Attach to the canvases to the horizontal frame legs with

two long wood screws on each side.

(C) Attach the top of the canvases to the bottom beam using three evenly spaced short wood

screws on each.

Attaching the canvas Drew’s Note: WARNING: This frame is

designed to lean against a wall for

safety. If it is not against a wall, it could

tip over. For added safety, you can

toenail one of the vertical frame legs

into a stud or use an L-bracket (not-

included), similar to what you would

for an oven safety bracket. Look for a

stand-alone update coming soon.

1.5in short wood

screw

2in long wood

screw

17.25in

Side view

17.25in 17.25in

Left view Right view

10

11. (A) Check that your top and bottom beams are level. If they are not, they should be off by the

same amount, since your frame is square. Verify that the frame is level in the following places:

If your frame is level, you’re good to go!

(B) OPTIONAL If it isn’t level, first check your measurements from the previous steps to ensure

that your frame is square. Once your measurements are confirmed for squareness, use a few

shims (small pieces of wood or scrap material) under the back and front of the frame legs, on

one or both sides, until your frame is level. This is especially useful in locations that don’t have

level floors.

Front

Leveling your frame Drew’s Note: It’s very important that your frame

is square and level! All of the M2 calibrations are

based on a well built frame. If the frame isn’t level

and square, the M2 will slant when it cuts and

have all kinds of other small problems.

It will be very difficult, if not impossible to

calibrate properly.

Check here

Here Here

Here

Left Side Right Side

Here

Here Here

Here

Here Here

Drew’s Note: Once you’ve verified your frame is level in the locations in step A, you can

toenail the top and bottom of the vertical frame legs to the wall to keep the frame from

shifting over time.

ex. Left Side ex. Right Side

Unlevel floor

Unlevel floor

11

12. (A) Measure and mark the actual center of the 1in x 6in x 8ft bottom skirt.

(B) On the left canvas, measure and mark 1.5in (3.8cm) up from the bottom. Align one of the 8ft

skirts with the center line and attach it to the particle board, on that line, with one short wood

screw. Place the level on the skirt and rotate it up or down on the screw until it is level. When

level, attach it to the other canvas with another short wood screw. Add three more screws per

canvas to fully attach the bottom skirt.

(C) OPTIONAL: Similar to the bottom skirt, measure the actual length of the top skirt and mark

the center. Then, measure and mark 1.5in (3.8cm) down from the top of the left canvas. Align the

8ft skirt with the center line and attach it to the particle board on that line with one short wood

screw. Place the level on the skirt and rotate it on the screw until it is level. When level, attach

it to the other canvas with another short wood screw. Add two more screws per canvas to fully

attach the top skirt.

(D) OPTIONAL: For the side skirts, measure and mark 1.5in (3.8cm) in on each side of the

canvases, closest to the stud mounts. Attach a 4ft side skirt to each side using 4 short wood

screws.

Attaching the skirts

Drew’s Note: A skirt’s purpose is to act as a stabilizer for your

M2 when it gets near the edge while cutting and the sled

edge extends beyond your canvas. The bottom skirt makes

it easier to mount your material to cut, because it acts as a

support. As long as you’re within 1/4in (6mm) on your skirt

measure measurements and they are level, you’re fine. It’s

optional, so don’t sweat getting the skirt perfect.

1.5in short

wood screw

Drew’s Note: Just like your

frame, it’s very important

that the bottom skirt is level

and parallel with the top

beam! Your material will rest

on it and if your frame isn’t

square and level then your

cuts will be off!

Drew’s Note: Your skirts can be under 1in thick,

so you can use scrap material for them! It’s just

important that they are all the same thickness.

This is because if the material you’re cutting is less

than their thickness, you will need to elevate your

material. Otherwise, your sled will bump into the

skirt when it gets close to the edge.

1.5in short

wood screw

1.5in short

wood screw

12

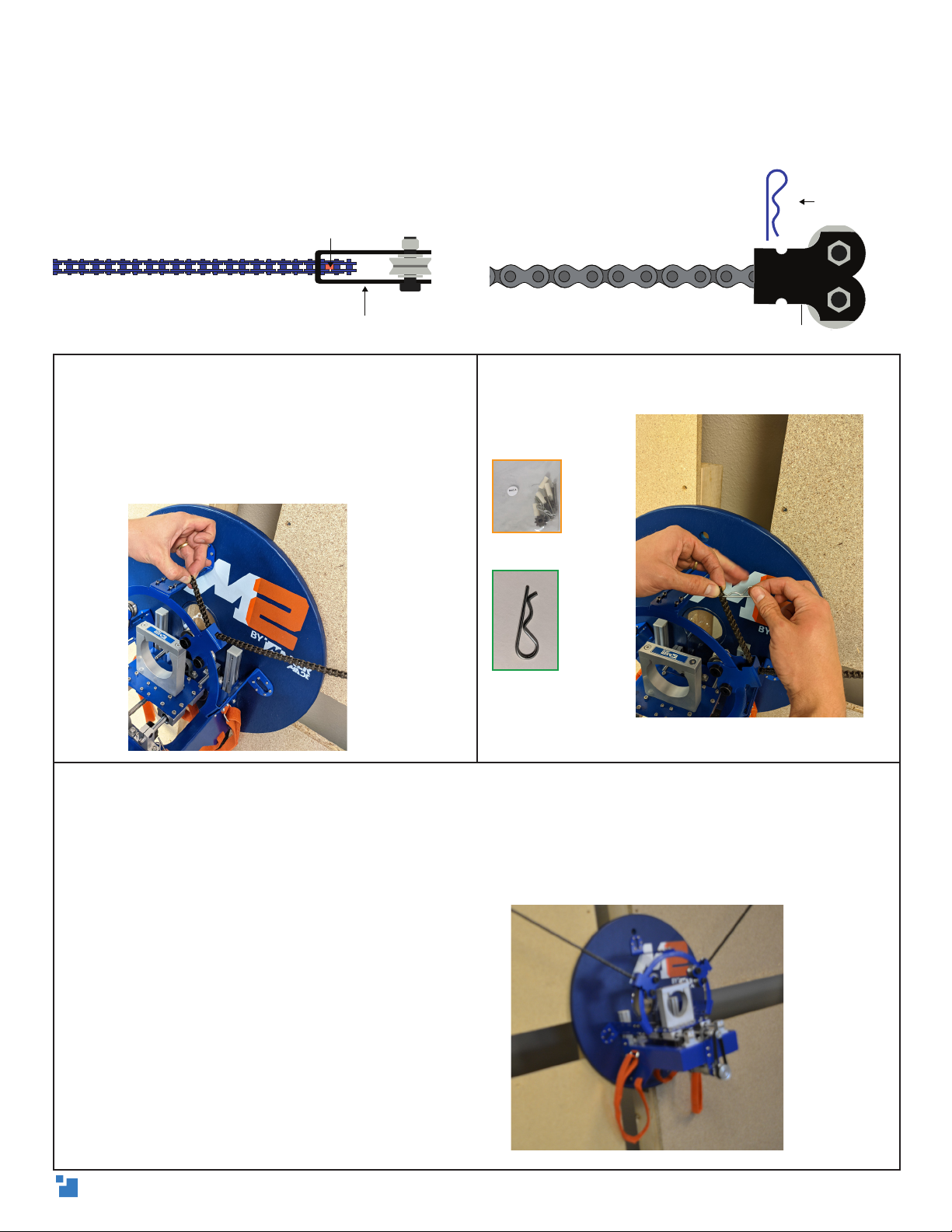

12. (A) To attach the chains on the front of the top beam, measure and mark 1.5in (4cm) from

the bottom and 15in (38cm) toward the center, from the end of the top beam. Insert the small

nail through loop in the last chain link on one chain, and hammer it into that spot. Repeat on the

other side of the motor mounting brackets.

(B) From the nail, measure about 25.5in (65cm) toward the

center of the top beam and loop the chain around your

thumb,back toward the motor and above the nail. Drape

the top of the chain over the motor sprocket so it locks in

place. Repeat on the other side.

(C) On the right side, place the sprocket in the chain loop and attach the quick link through the

hole in the sprocket, with its opening facing away from beam. Don’t tighten the link. On the left

side, attach the spring and tighten the quick link, ensuring the link nut is facing away from the

beam.

(D) Carefully stretch out the spring from the left side to attach it to the other end to the open

quick link on the right side. Tighten the right quick link to lock the chains together.

Attaching the chains Drew’s Note: We recommend a friend help you connect

the spring and each person wear safety goggles

during stretching. The chain can snap back, causing

damage to people, pets, and surroundings!

Chain Mounting

Hardware Bag A

Spring Hardware Bag B

1.5in

15in

Drew’s Note: You can adjust the spring tension on your frame by moving the nails toward or away

from center. The most important part is that the spring keeps the tension on the chains. We use nails

to connect the chain to the frame, so if something goes awry, only the nails will be removed without

damaging your frame.

Chain Mounting

Hardware Bag A

25.5in

13

1. Hold the M2 sled against the wasteboard

near the right chain. Hold it against the frame

with your body weight or have a friend help

by holding it for you. Take the loose end of

one chain and thread up through the hole in

the roller bearing carriage.

2. Insert the cotter pin, with the flat side on

the right, into the second to last chain link to

attach.

3. Manually move the M2 to the center of the Wasteboard and have a friend pull the tension

on the opposite chain to around 20in from the nail to the spring. You can pull the chain

away from the motor sprocket, pull for more length, and set it back for the tension to hold,

and beware of it snapping. When you have enough slack in the chain, thread through the

opposite roller bearing carriage and attach with the other cotter pin into the second to last

chain link. Let go of the sled and it will rest against the canvas.

Drew’s Note: We recommend wearing safety goggles and having a friend help mount the sled to

the frame. The chain can slip off the sprockets, causing the spring to snap and hurt people, pets,

and surroundings. It’s also important to insert the cotter pin into the second to last link, for extra

safety of the chain attachment, as shown below.

Drew’s Note: Your M2 is ready to

calibrate! (Also, don’t forget to

securely attach your bricks with the

Velcro straps, if you waited until it was

mounted).

Mounting the M2 to the frame

Chain Mounting

Hardware Bag A

CARRIAGE MOUNT

CHAIN

INSERT COTTER PIN HERE

Roller bearing carriage

Cotter pin goes here

CARRIAGE MOUNT

COTTER

PIN

CHAIN

Roller bearing carriage

Cotter pin

14

1. Mount the control board in its case to the wall above

your frame or behind the canvas. It helps to mount it in

the middle for the motor wires to reach everything.

2. (A) Plug in the USB, and power.

(B) The longer six-pin motor cables go to the X/Y motors, using the diagrams on the case. The

connections will only fit in one direction.

(C) The shorter blue cable is for the Z motor, and works best

to feed under the frame to the M2 on the front.

Drew’s Note: The M2’s brain is an Arduino DUE

microcontroller. We recommend mounting the DUE to

the wall behind your frame, but it can be mounted in

any safe location where it won’t be stepped on or in

conflict with the M2 during operation.

ARDUINO DUE board and shield

Drew’s Note: You can use the zip ties for cord maintenance! I also suggest putting a

drop of hot glue on the connections to ensure that they don’t wiggle loose over time.

If one of your motors of your M2 doesn’t move during operation, or the M2 generally

moves in a strange direction, the first thing to check are the motor connections. If the

wires connecting the X, Y, and Z motors are loose, even a tiny bit, it will cause your M2 to

malfunction.

Right/Left (X/Y) Motors

15

APPENDIX 1 - TIPS

The MakerMade M2 CNC kit is used to assemble a large format CNC machine. It is

designed to use a router (or another tool) to cut 4ft by 8ft sheet materials. When

used correctly, this machine is very safe. However, some safety precautions must

be taken to prevent injury. These include but are not limited to:

• Always follow the safety guidelines and instructions included with the router

or other tool you attach to the kit.

• Always wear ear and eye protection when running your machine.

• Use adequate dust collection or wear a respirator. Breathing material dust can

be harmful.

• Use proper lifting techniques when loading/unloading materials.

• Always use caution when connecting/removing the sled. This assembly weighs

around 20 lbs.

• NEVER leave your machine running unattended!

• Optionally, you can cut off the ends of the beams and the top of the vertical

frame legs outside of the stud mounts, so your frame isn’t as tall or long.

We’re excited to have you in our community of makers and can’t wait to see what

you create.

Find us on Facebook, Instagram and YouTube @makermadecnc and tag your

projects!

#MakerMadeMaker

Click here to check out updates on our FAQ section!

16

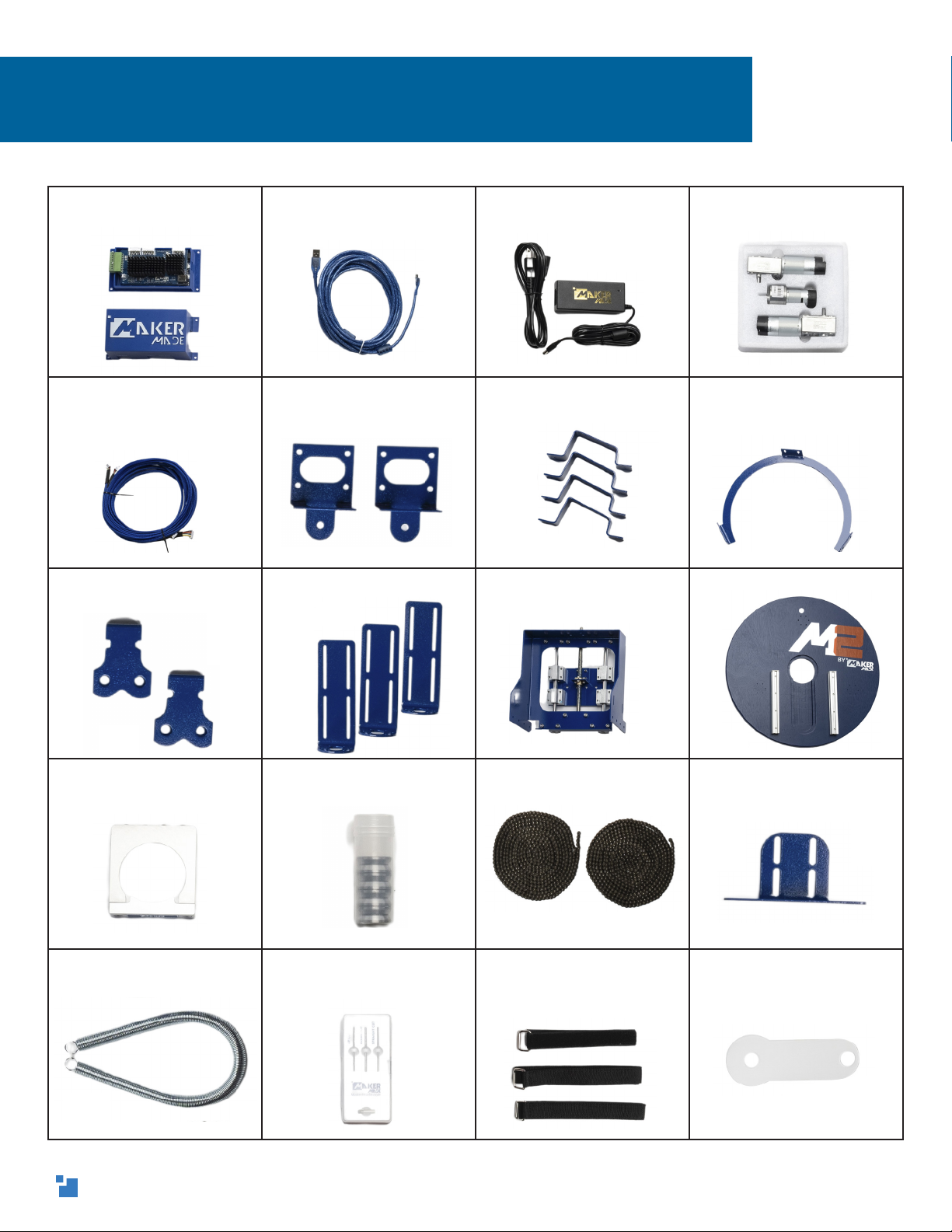

DUE v1.2 Control Board,

Shield, and case

10ft MicroUSB to USB cord AC/DC Power Adapter and

cord

X, Y, and Z Axis Motors (3)

X, Y, and Z Motor Power

Cables

Motor Mounting Brackets

(2)

Stud Mounts (4) Ring Carriage

Roller Bearing Carriages

(2)

Z-Axis Mount L-Brackets

(3)

Z-Axis Assembly Sled

Router Clamp Roller Bearings (4) Chains 335cm/11ft (2) Dust Collection Bracket

Spring Maker Made Router Bit

Starter Set

Velcro Dust Collection and

Brick Mounting Straps (3)

Acrylic Dust Cover

APPENDIX 2 - WHAT’S IN THE BOX?

17

Maker Made USB Marker Stickers, Quick Start

Guide, and Welcome

Letters

Chain Mounting Hardware

Bag A

Cotter pins (2)

Chain sprocket (2)

Small nails (2)

Large nails (2)

White spacers (2)

Spring Hardware Bag B

Quick links (2)

Small screws (4)

Zip ties

Short/Long Frame

Mounting Screws Bag C

Shorter black wood screws

Longer silver

Wood screws

Short/Long Frame

Mounting Screws Bag D

Shorter black wood

screws

Longer silver wood

screws

X/Y Motor Hardware Bag E

Motor sprocket (2)

Grub Screws (2)

Motor screws (8)

Motor washers (8)

Bearing Carriage

Hardware Bag F

Shoulder bolt (4)

Large washer (8)

Large locking nut (4)

Ring and L-Bracket

Hardware Bag G

Tiny wood screws (20)

Small black M3 bolts (12)

Locking nuts (12)

Assembly Tools Bag I

5mm hex wrench

4mm hex wrench

3mm hex wrench

Z Axis Hardware Bag C

Z Motor bracket

2.5mm and 2mm hex wrenches

Flat combo wrench

Belt Black M3 x 8mm bolts (6)

Large gear Small gear

Large set screws (2)

Small set screws (2)

M4 x 8mm bolts (4)

M4 Locking nuts (4)

M5 x 8mm bolts (8)

M5 T-nuts (8)

18

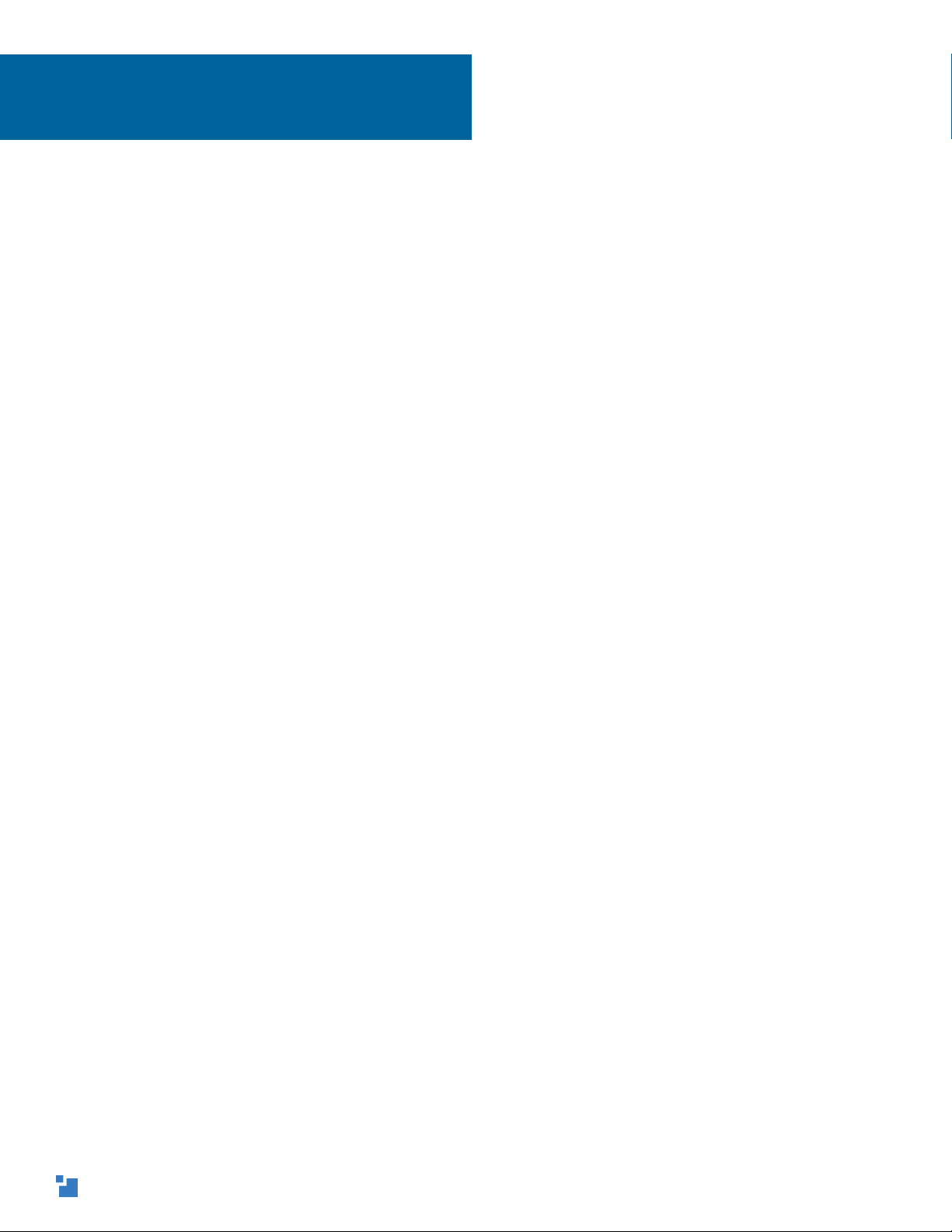

3ft (91cm)

wide

8ft

(2.4m)

tall

8.5ft (2.6m) long

APPENDIX 3 - OVERALL DIMENSIONS

It’s 6.5ft (1.98m) from the floor to the

top of the x/y motors, If the 8ft vertical

frame legs are cut down (optional).

10ft (3.05m)

long at the top

19

Visit our M2 Resources page for instructions over how to build the mini, standard, or XL

frames by MakerMade.

One of the amazing things about the M2 is the wide variety of frames that will work.

From all metal frames to using a weights in place of the spring- the options are almost

limitless!

However, there are four things to keep in mind when going rogue and building a unique

frame:

1. The bottom of your wasteboard should be at least 10” from the floor, so

the M2 has room to go across the bottom of your material.

2. For the trigonometry behind the M2’s movement, the wasteboard should

be clamped or screwed onto the stud mounts, to maintain a 15 degree

angle.

3. The target distance of the motor offset (from where the chain leaves the

motor sprockets to the top of the wasteboard) should be at least 18” for a

10ft top beam, 24” for 12ft top beam, and even higher to cut a larger area.

4. Your top beam and wasteboard must be level and equal distance from

each other.

5. Makerverse Calibration may be more difficult with frames not tested by

MakerMade.

Drew’s Note: Interested in coming up with your own frame design? Hop on our Facebook

Owner’s Group or Forum and discuss with other makers about your idea if someone has

made something similar!

APPENDIX 4 - CUSTOM FRAMES

Mini Frame:

6ft Top Beam

Smaller Chain

Cuts up to 4ft x 4ft

Standard Frame:

6ft Top Beam

11ft chains (included with M2)

Cuts up to 4ft x 8ft

XL Frame:

12ft Top Beam

15ft chains (purchased separately)

Cuts just over 4ft x 8ft

20

This manual suits for next models

1

Table of contents