©2011 Tyco Electronics Corporation, a TE Connectivity Ltd. Company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1of 5

Instruction Sheet

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com LOC B

408-6789

Pistol Grip Pneumatic

Handle Assembly 58075-1 25 JUL 11 Rev E

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use

and low volume applications. A wide selection of powered application equipment for extended-use, production operations is available.

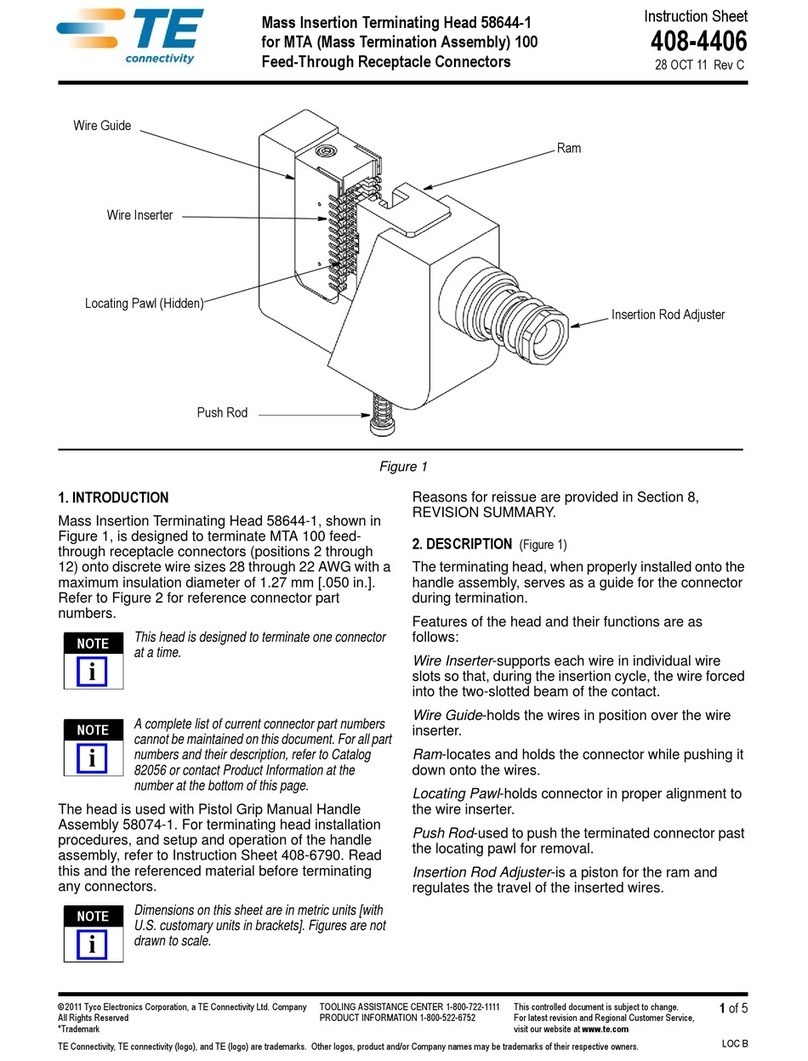

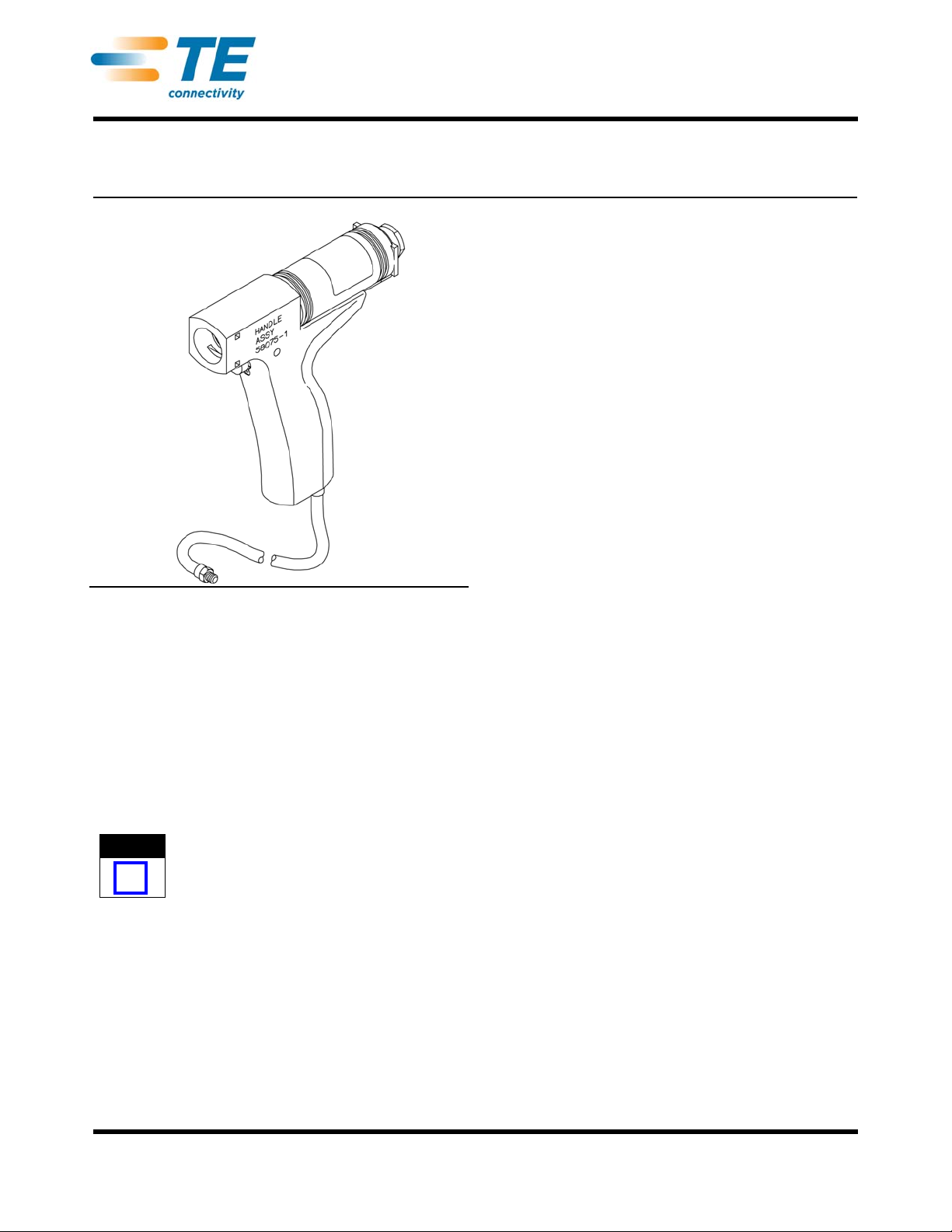

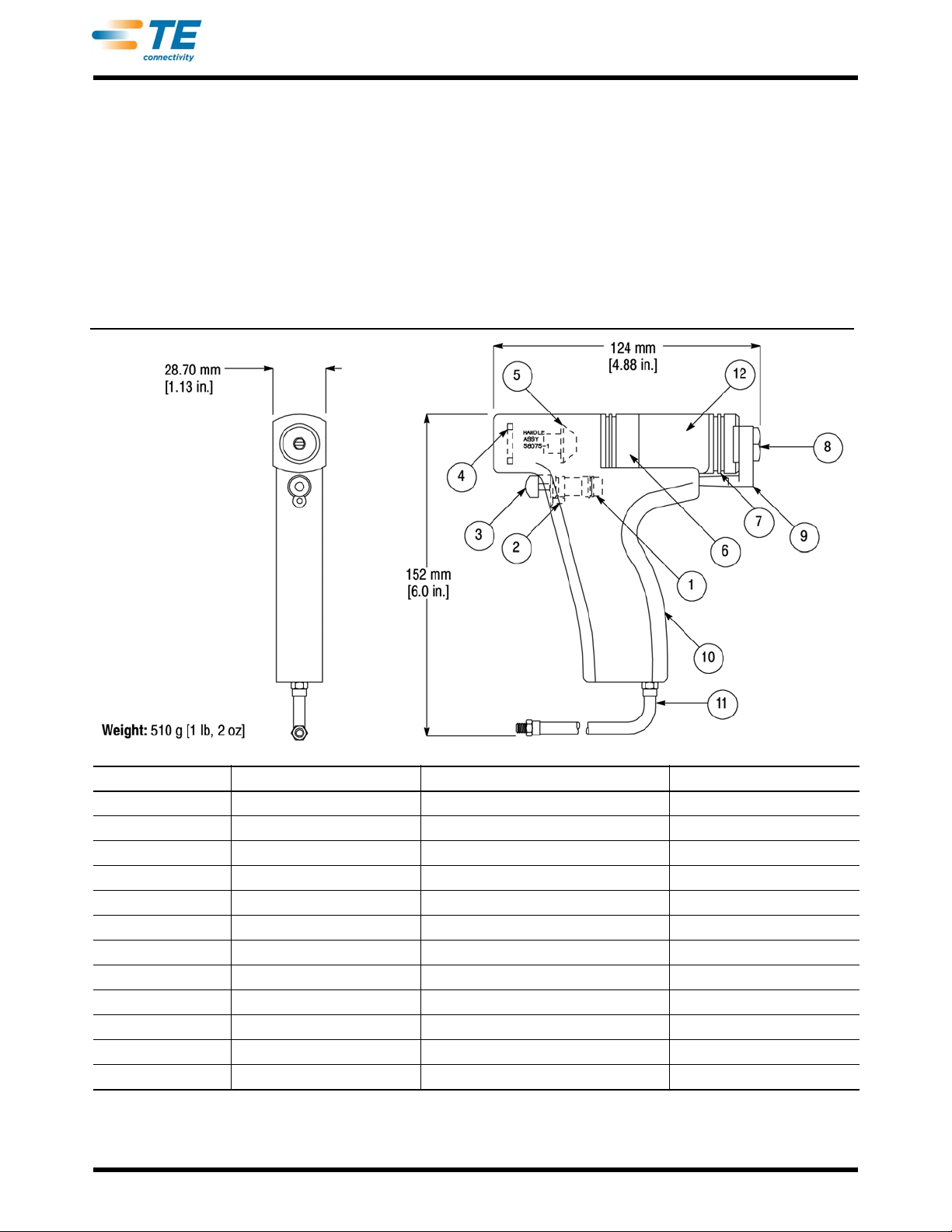

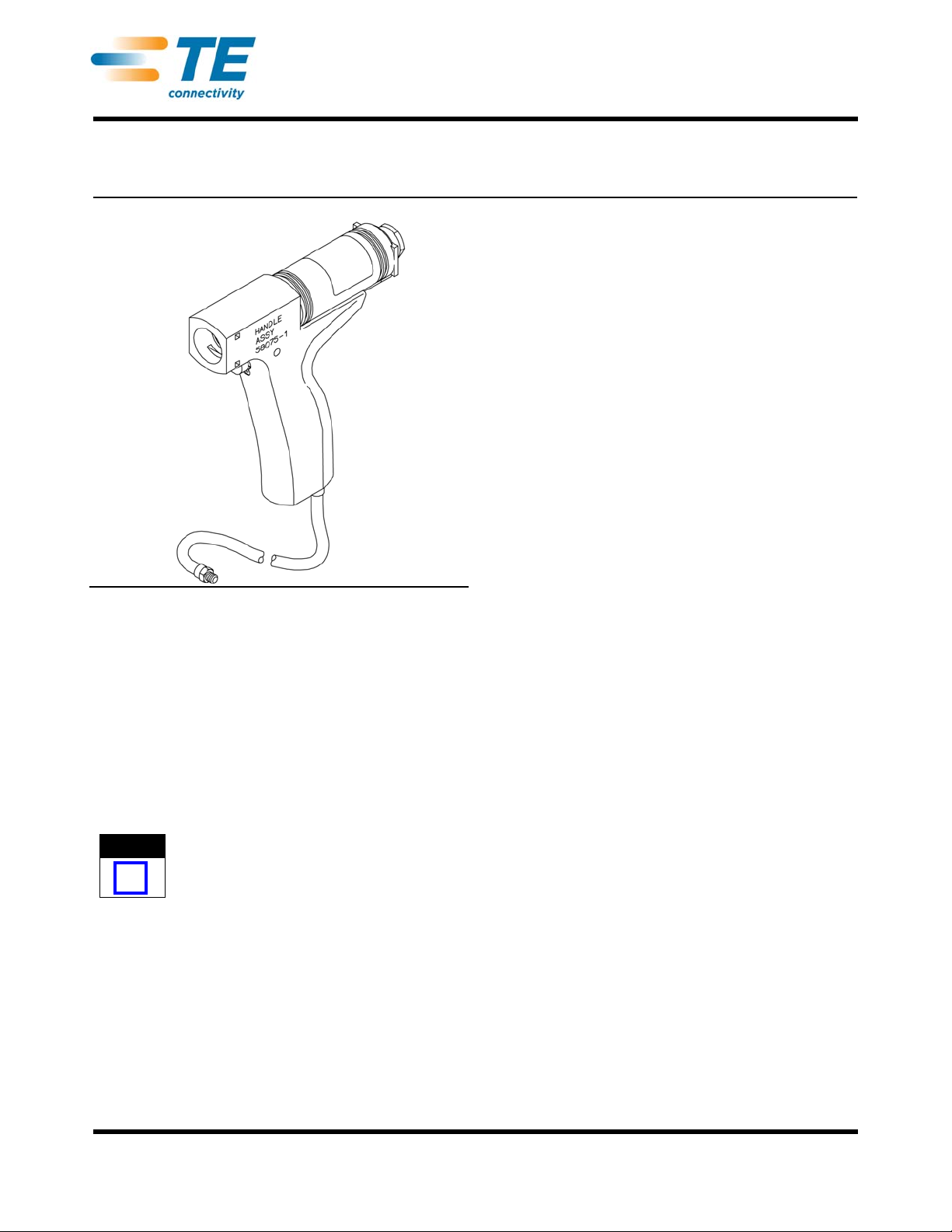

Figure 1

1. INTRODUCTION

These instructions deal with the safety, installation,

operation and maintenance of the Pistol Grip

Pneumatic Handle Assembly 58075-1. See Figure 1.

Pistol Grip Pneumatic Handle Assembly 58075-1

accepts interchangeable terminating heads that

terminate wires in connectors. To ensure accurate

termination of wires, setup adjustments, and head

maintenance, refer to the instructions packaged with

the terminating head.

Dimensions in this instruction sheet are in metric

units [with U.S. customary units in brackets].

Figures are for reference onlyand are not drawn to

scale.

Reasons for reissue of this instruction sheet are

provided in Section 9, REVISION SUMMARY.

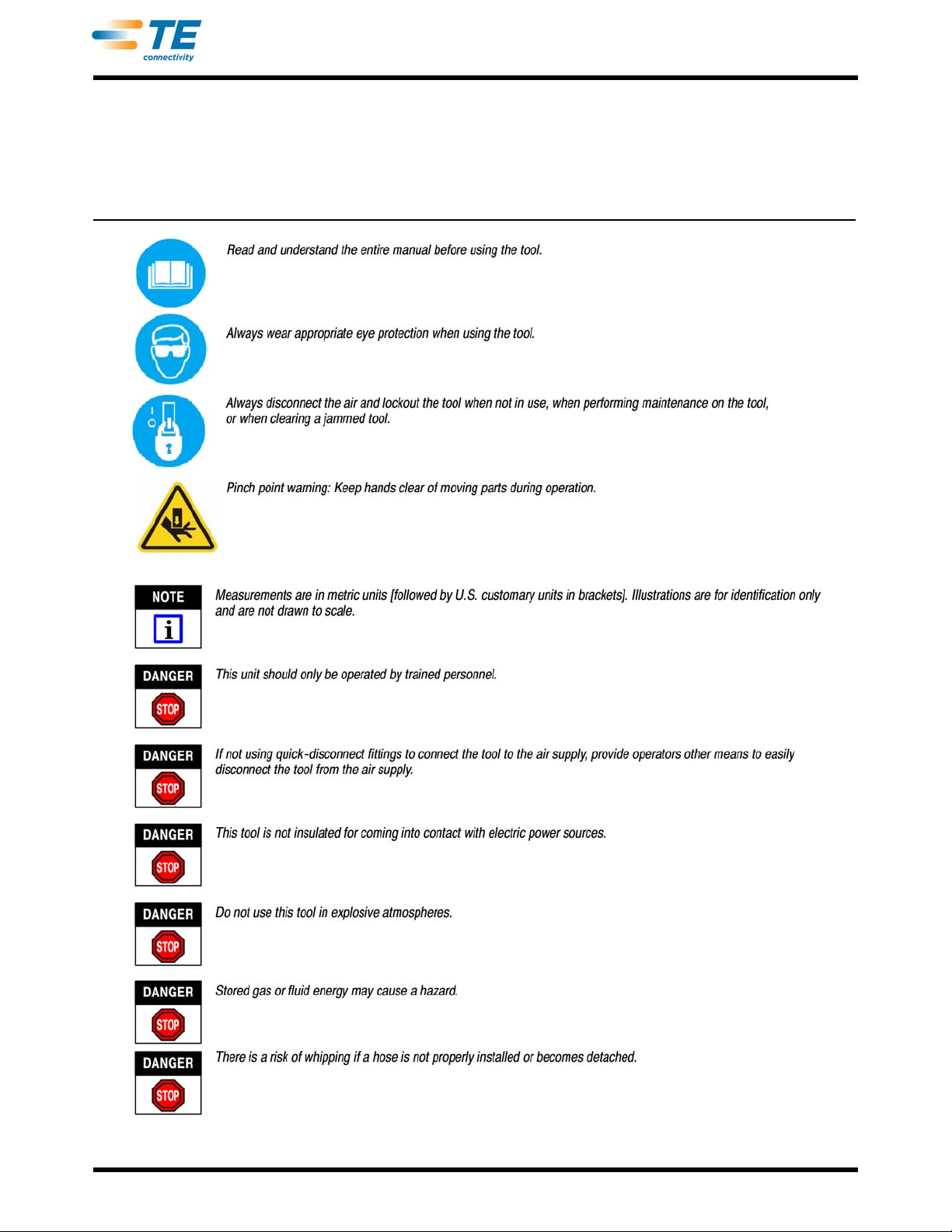

2. SAFETY PRECAUTIONS AND COMPANY CONTACT

2.1. Safety

Safeguards are designed into this application

equipment to protect operators and maintenance

personnel from most hazards during equipment

operation. However, certain safety precautions must

be taken by the operator and repair personnel to avoid

personal injury, as well as damage to the equipment.

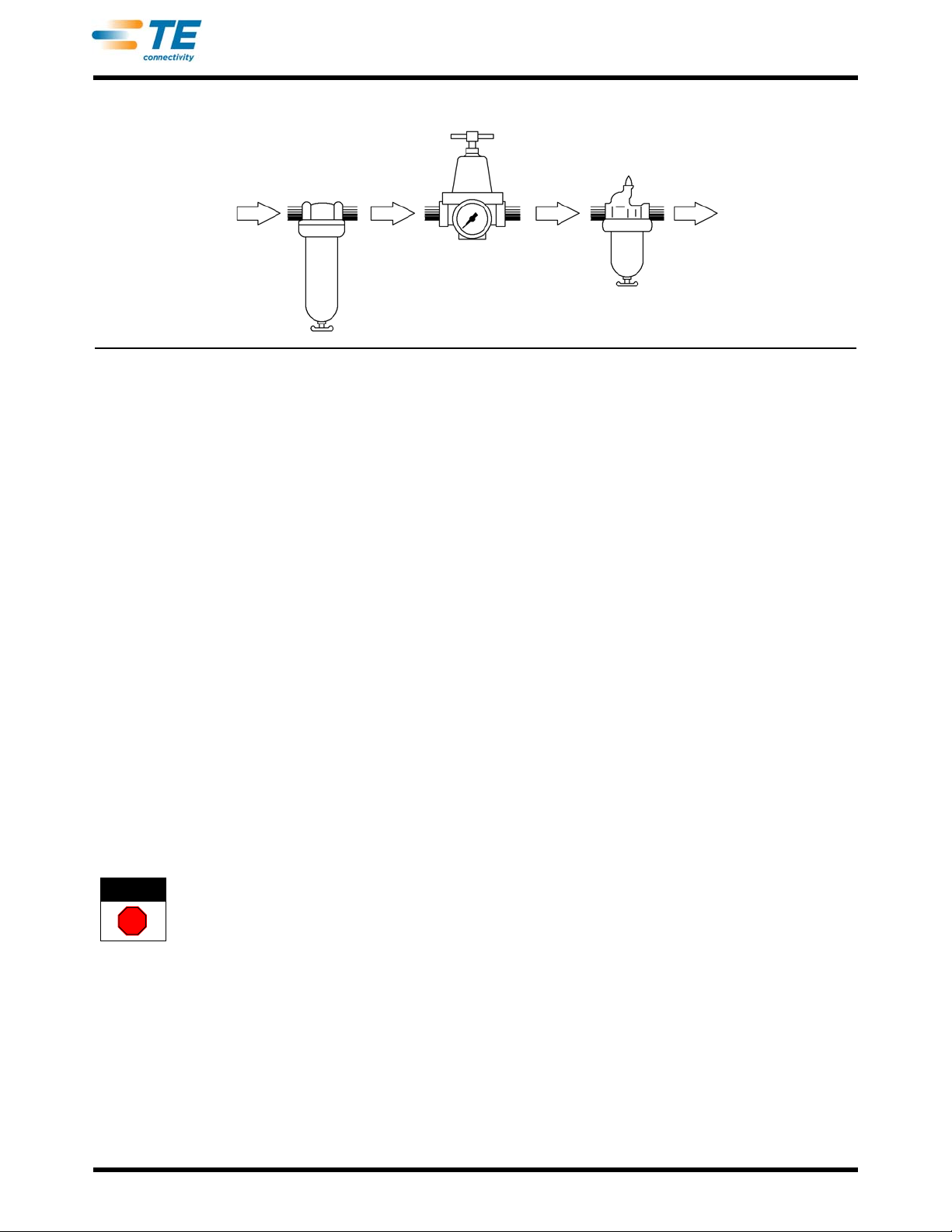

For best results, application equipment must be

operated in a dry, dust-free environment. Do not

operate equipment in a gaseous or hazardous

environment.

Carefully observe the following safety precautions

before and during operation of the equipment:

•ALWAYS wear appropriate ear protection.

•ALWAYS wear approved eye protection when

operating powered equipment.

•ALWAYS keep guard(s) in place during normal

operation.

•ALWAYS disconnect the tool from its power

source when performing maintenance on the

equipment.

•NEVER wear loose clothing or jewelry that may

catch in moving parts of the application equipment.

•NEVER insert hands into installed application

equipment.

•NEVER alter, modify, or misuse the application

equipment.

2.2. Contact

CALL TOLL FREE 1-800-722-1111 (CONTINENTAL

UNITED STATES AND PUERTO RICO ONLY)

The Tooling Assistance Center offers a means of

providing technical assistance when required.

In addition, Field Service Specialists are available to

provide assistance in the adjustment or repair of the

application equipment when problems arise which

your maintenance personnel are unable to correct.

When calling the Tooling Assistance Center regarding

service to equipment, it is suggested that a person

familiar with the device be present with a copy of the

manual (and drawings) to receive instructions. Many

difficulties can be avoided in this manner.

When calling the Tooling Assistance Center, be ready

with the following information:

1. Customer name

2. Customer address

3. Person to contact (name, title, telephone number,

and extension)

4. Person calling

ORIGINAL INSTRUCTIONS