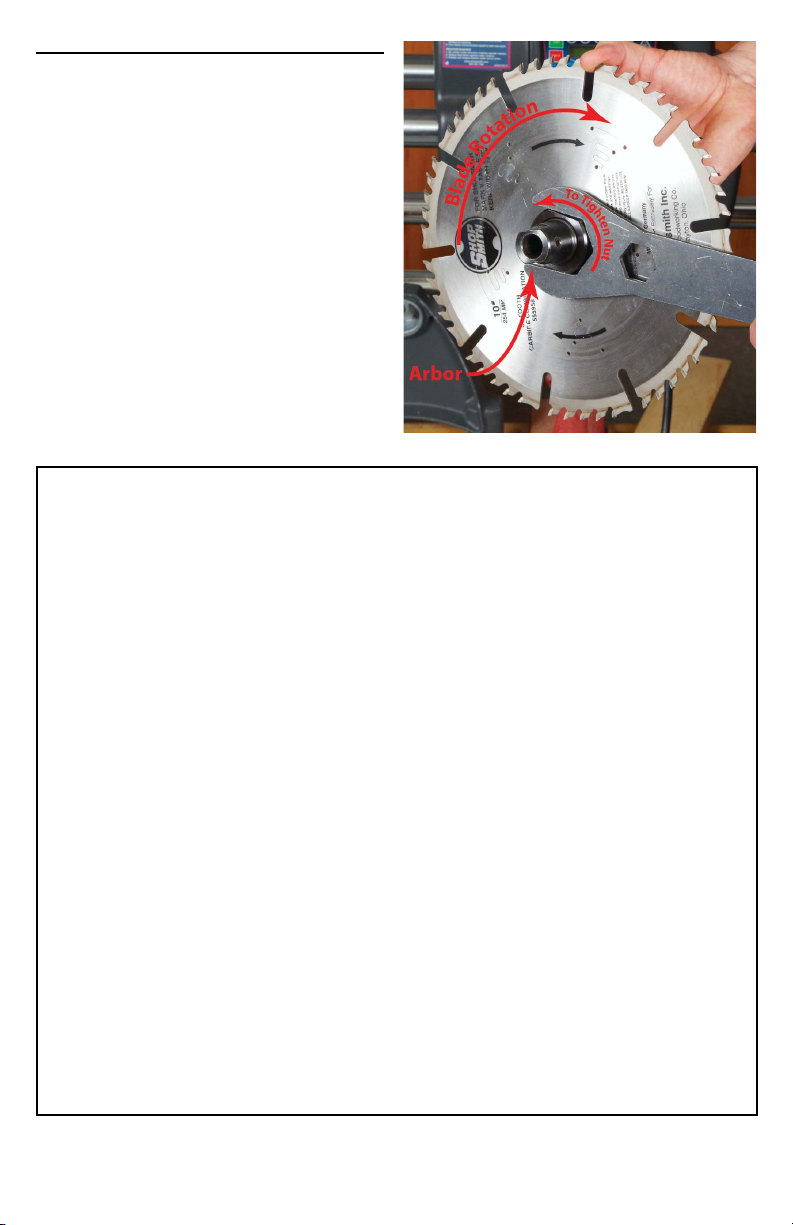

Reverse-Threaded Spindles

Reverse threaded spindles are common on some

types of power tools. “Reverse threaded” just

means that the torque of the motor in normal

operation puts force on the arbor nut to tighten

the “business end” onto the spindle. This is an

inherent safety measure in all power tools and

helps to make sure that cutting blades and

sanding/grinding surfaces don’t loosen during

normal operation.

When a motor brake is used to slow a machine’s

operation, the momentum of the “business end”

puts a loosening force onto the arbor nut. If this

force is sufficiently large, it can loosen or

unscrew the arbor nut. For this reason, you never

want to apply excessive braking torque to a

reverse threaded spindle. To prevent excessive

braking torque on reverse-threaded arbor tools,

adhere to the following operational limitations.

Limitations of Operation

If you have a machine with a reverse threaded spindle, ensure that you follow the rules and

limitations below. Failure to follow the limitations below may increase risk of injury.

1. Check tightness of arbor nut prior to

installation and as a regular

maintenance item.

Regularly check the tightness of your arbor

nut and compare to the listed torque

specifications in your tool manual. To

prevent loosening, use double-nuts or other

positive locking methods.

2. Calibrate braking torque to bring the tool

to stop in no less than two seconds.

When braking a tool with a reverse-threaded

spindle, never calibrate the brake to stop the

tool in less than two seconds. Refer to the

calibration section of this manual for a

discussion of how to calibrate your device.

3. Never use The MAKESafe Power Tool

Brake to brake high inertia

reverse-threaded loads, such as:

○ a lathe with a reverse-threaded

spindle.

○ A saw with a dado or other

non-standard blade installed.

The larger the business end, the more

loosening force will be applied during

braking. For example, a lathe with a

reverse-threaded spindle should never be

used with a motor brake. The chuck has

sufficient mass to unscrew itself from the

spindle during braking and is a severe

safety risk.

4. Always make sure that all power tool

wheel guards, blade guards, shields,

and other manufacturer-provided and

OSHA required guards are properly

installed and adjusted.

Power tools should never be operated

without manufacturer-provided and OSHA

required guards.

MAKESafe Tools, Inc. | Copyright 2021 | Last Updated 12/29/21 Page 7