P 2/ 9

Repair

CAUTION: Unplug the tool and remove the wheel cover and grinding wheel from the machine

for safety before repair/ maintenance in accordance with the instruction manual!

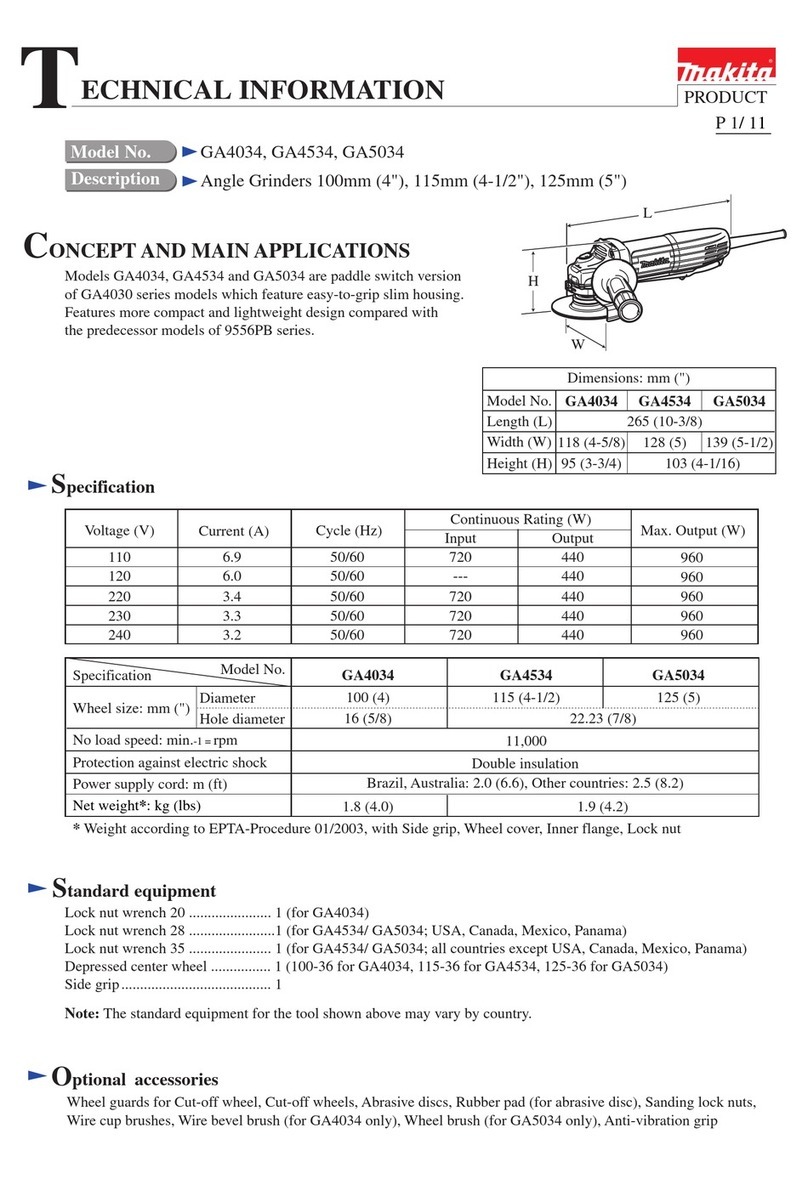

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Armature, Small Spiral Bevel Gear on Armature shaft

Fig. 1

Code No. Description Use for

1R217 Ring 22 Supporting Bearing box when Removing spindle from Large spiral bevel gear

1R041 Vise plate Use with Vise to protect the clamped part

1R004 Retaining ring pliers ST-2 Removing Retaining ring S-6 from Armature shaft of model 9566CR and 9566CVR

1R268 Spring pin extractor 3 Removing Pin for Shaft lock

1R269 Bearing extractor Removing Ball bearing 627DDW from commutator end of Armature

1R291 Retaining ring S & R pliers Removing / mounting Retaining ring S-12 from / to the drive end of Armature shaft

1R340 Bearing retainer wrench Removing / mounting Bearing retainer

1R350 Ring 60 Supporting Gear housing when removing Pin for Shaft lock

Item No.

Apply Makita grease SG No.0 and Disulfied molybdenum to the following portions designated with triangles to protect

parts and product from unusual abrasion.

Description Portion to lubricate Lubricant Amount

DISASSEMBLING

3

6

7

6

7 Lock ring 12

Armature

3 Gear housing complete Gear room

Cylindrical portion where armature shaft is inserted

Cylindrical portion which accepts 6 ‘s drum portion

Makita grease SG No.0.

Small spiral bevel gear

15g

a little

Disulfied molybdenum

(1) In order to protect Armature’s commutator, disconnect carbon brushes from the Commutator as illustrated in Fig. 2.

4x18 Tapping screw

First, remove Rear cover by unscrewing

4x18 Tapping screw.

Shift Spiral spring from

Carbon brush top.

Disconnect Carbon brush from

commutator by pulling up.

No need to remove.

Rear cover

Brush holder

Fig. 2

Model No.

Spiral bevel gear 11 (teeth: 11)

Spiral bevel gear 9 (teeth: 12)

Spiral bevel gear 38 (teeth: 38)

Spiral bevel gear 35 (teeth: 35)

9564CR, 9564CVR, 9565CR,9565CVR

9566CR, 9566CVR

Small spiral bevel gear on Armature shaft Large spiral bevel gear on Spindle

Note: Spiral bevel gears vary in type from model to model. See list shown below.