P 2/ 14

Repair

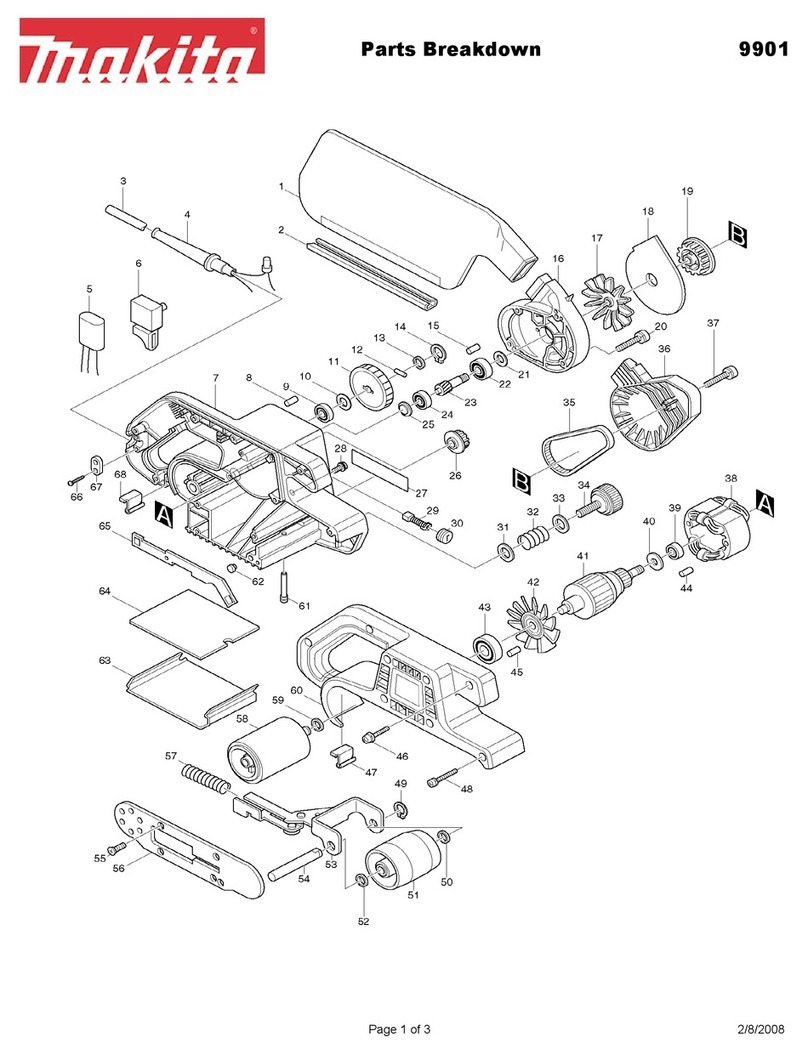

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No. Description Use for

1R014 1/4" Hex. shank bit M4 removing / tightening M4x16 Hex socket head bolt

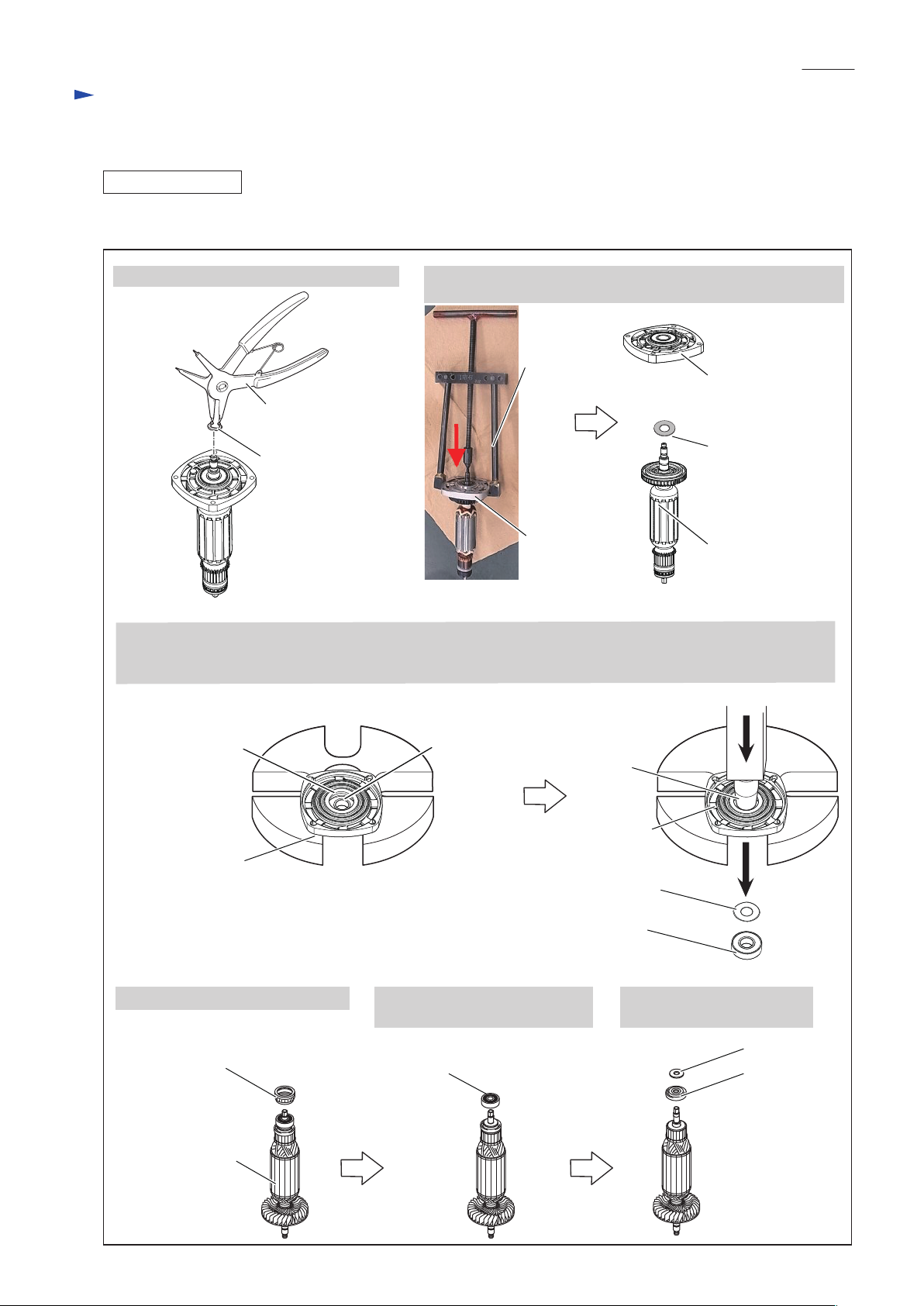

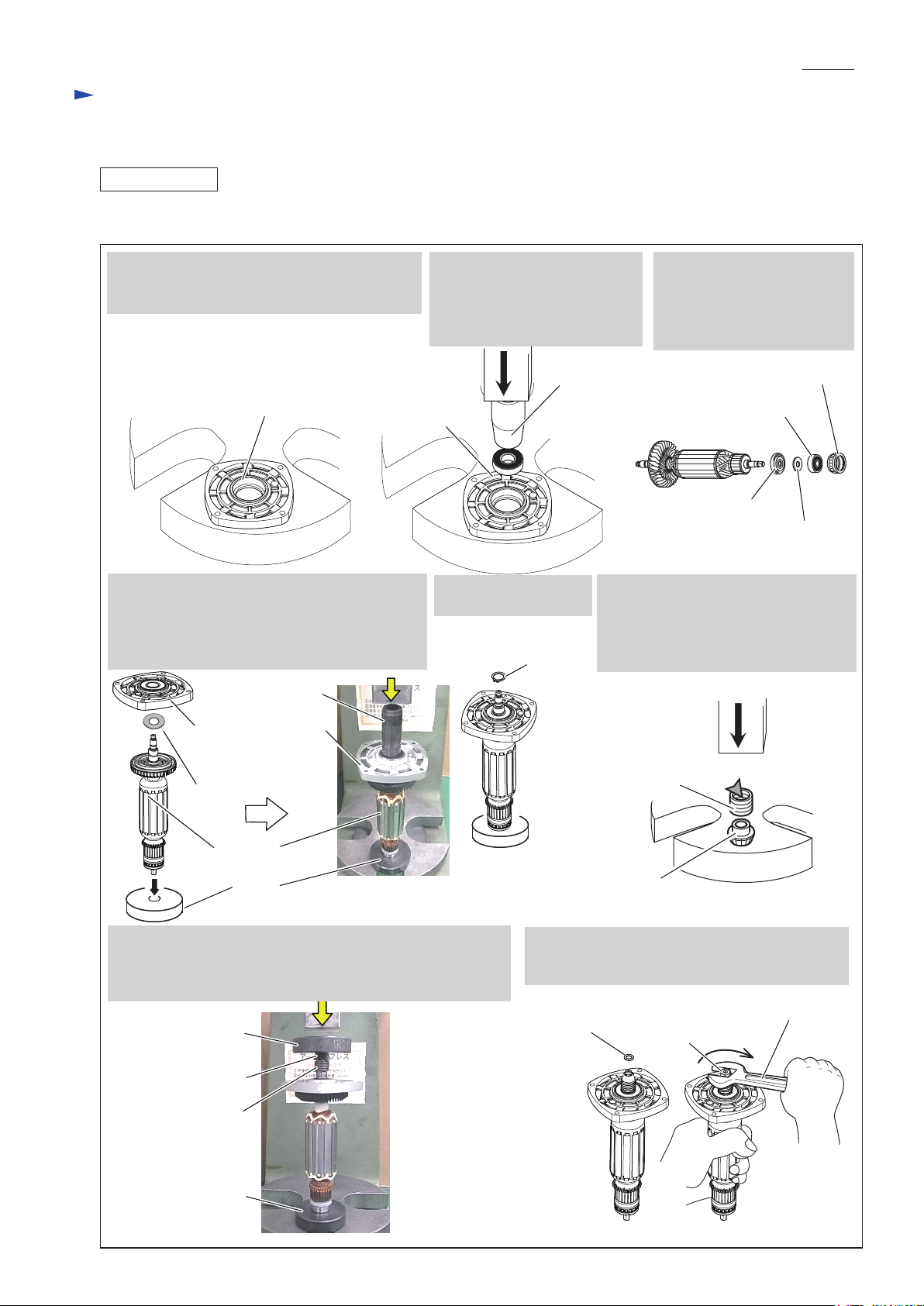

1R027 Bearing setting pipe 18-10.2 removing Ball bearings 6001LLB and 6201DDW

1R028

1R030

1R031

1R032

1R033

1R035

1R045

1R258 V block

1R268 Spring pin extractor M3

1R269 Bearing extractor

1R281 Round bar for arbor 7-50

Round bar for arbor 9-501R283

1R291 Retaining ring S and R pliers

1R340 Bearing retainer wrench

1R350 Ring 60

Bearing setting pipe 20-12.2

Bearing setting pipe 25-17.2

Bearing setting pipe 28-20.2

Bearing setting plate 8.2

Bearing setting plate 10.2

Bearing setting plate 15.2

Gear extractor

supporting Bearing box when removing Spiral bevel gear 38

removing Shoulder pin 7 from Pin cap

removing Spiral bevel gear 11 from Armature

removing Spindle from Spiral bevel gear 38

Locking Switch knob when removing Switch lever

removing / assembling Retaining ring S-12 from / to Armature

removing / assembling Bearing retainer 19-33

supporting Gear housing when removing Shoulder pin 7

assembling Spiral bevel gear 38 to Spindle

assembling Ball bearing 6001LLB to Gear housing cover

supporting Armature when assembling Ball bearing 6001LLB

assembling Spiral bevel gear 11 to Armature

supporting Bearing box when assembling Spiral bevel gear 38

removing Armature from Gear housing cover

assembling Gear housing cover with Ball bearing 6001LLB to Armature

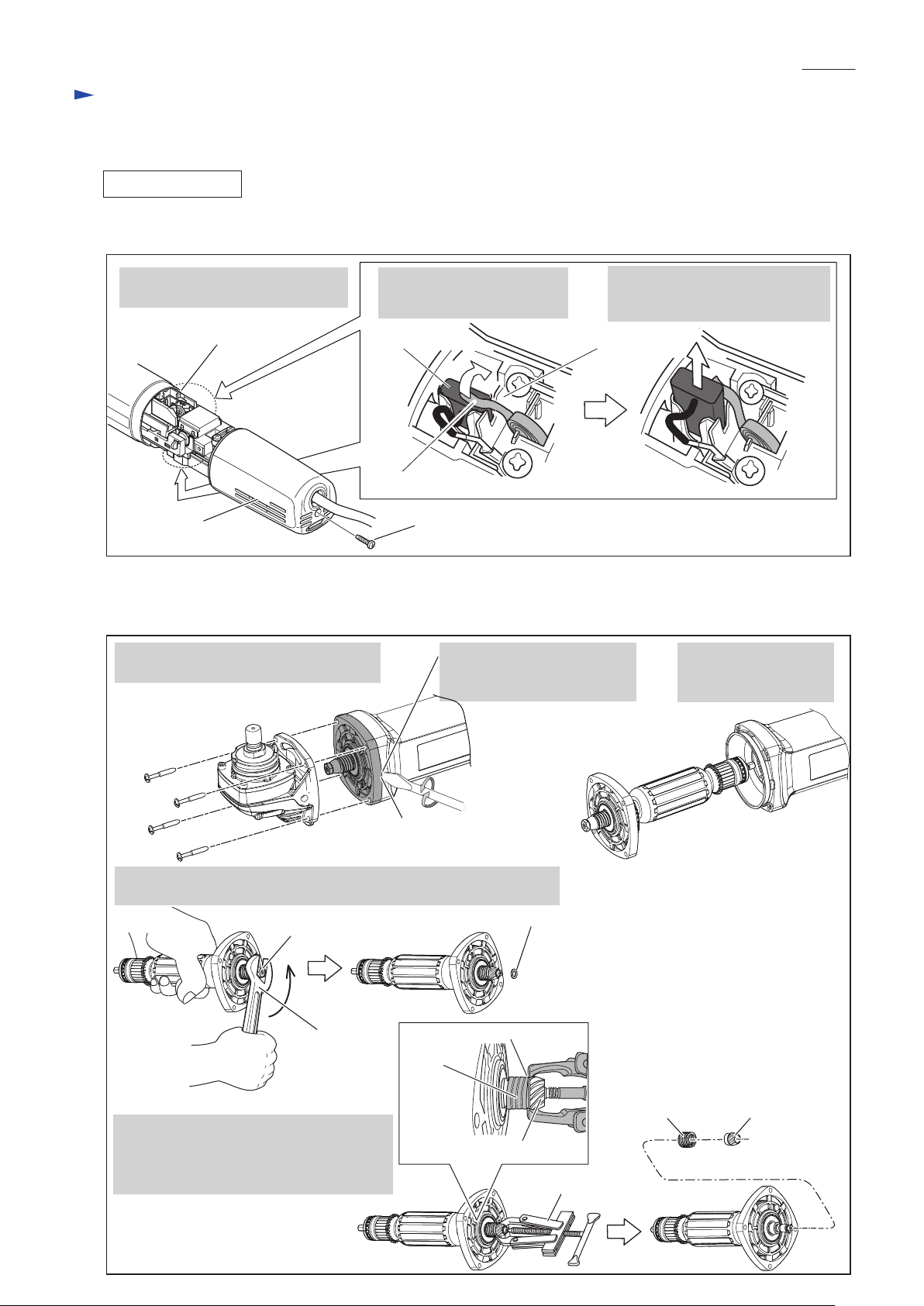

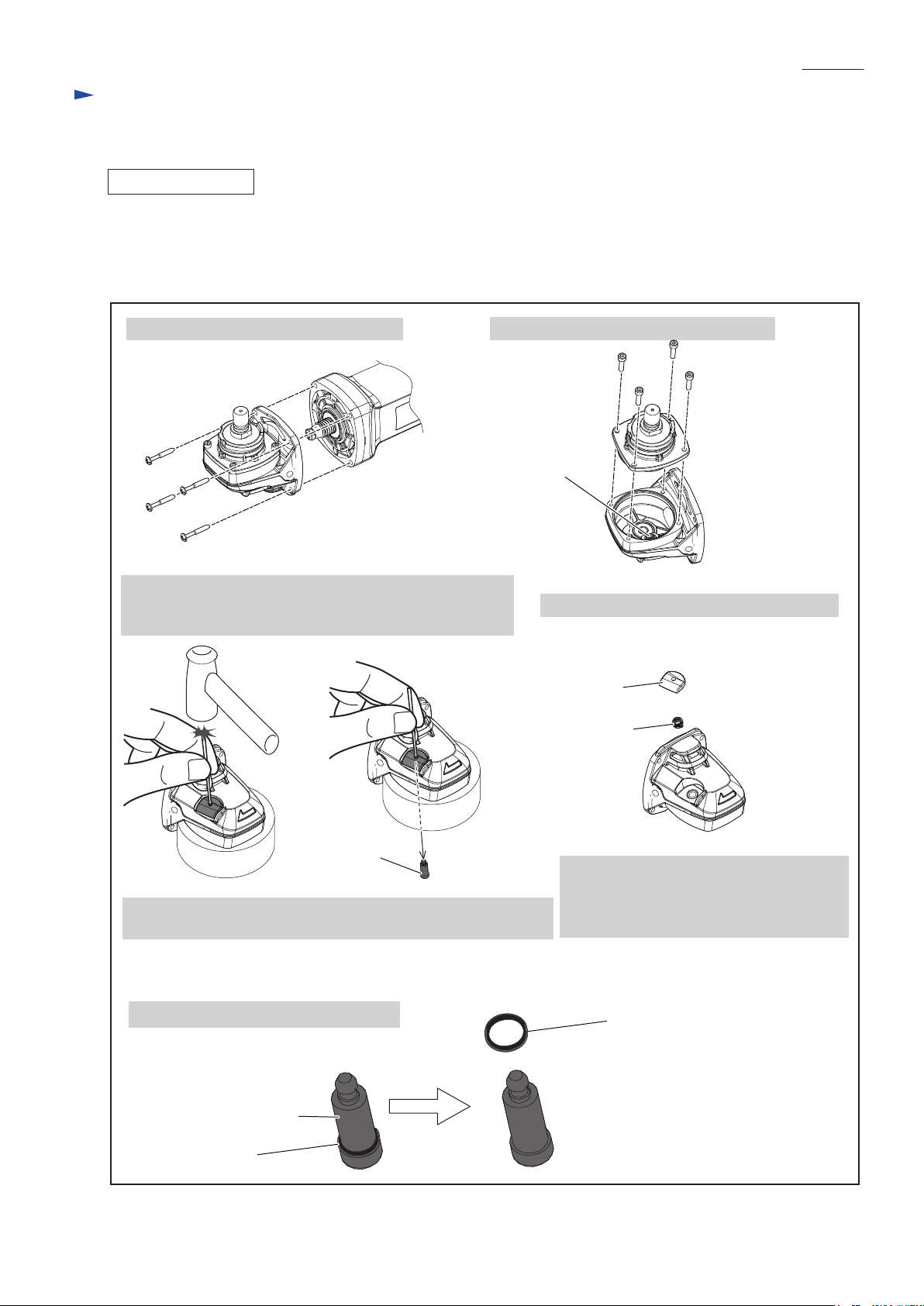

[2] LUBRICATION

Apply Makita grease R. No.00 to the portions designated with the black triangle, and Disulfide molybdenum

to the portions designated with the gray triangle, protect parts and product from unusual abrasion.

Fig. 1

Item No. Description AmountPortion to lubricate Lubricant

3

6

7

6

7 Lock spring 12

Armature

3 Gear housing complete Gear room

Cylindrical portion where armature shaft is inserted

Cylindrical portion which accepts 6 ‘s drum portion

Spiral bevel gear 11

15g

a little

a little

Makita grease R No.00

Disulfide molybdenum