Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output(W)

110

120

220

230

240

Models No.

Description

PRODUCT

Current (A)

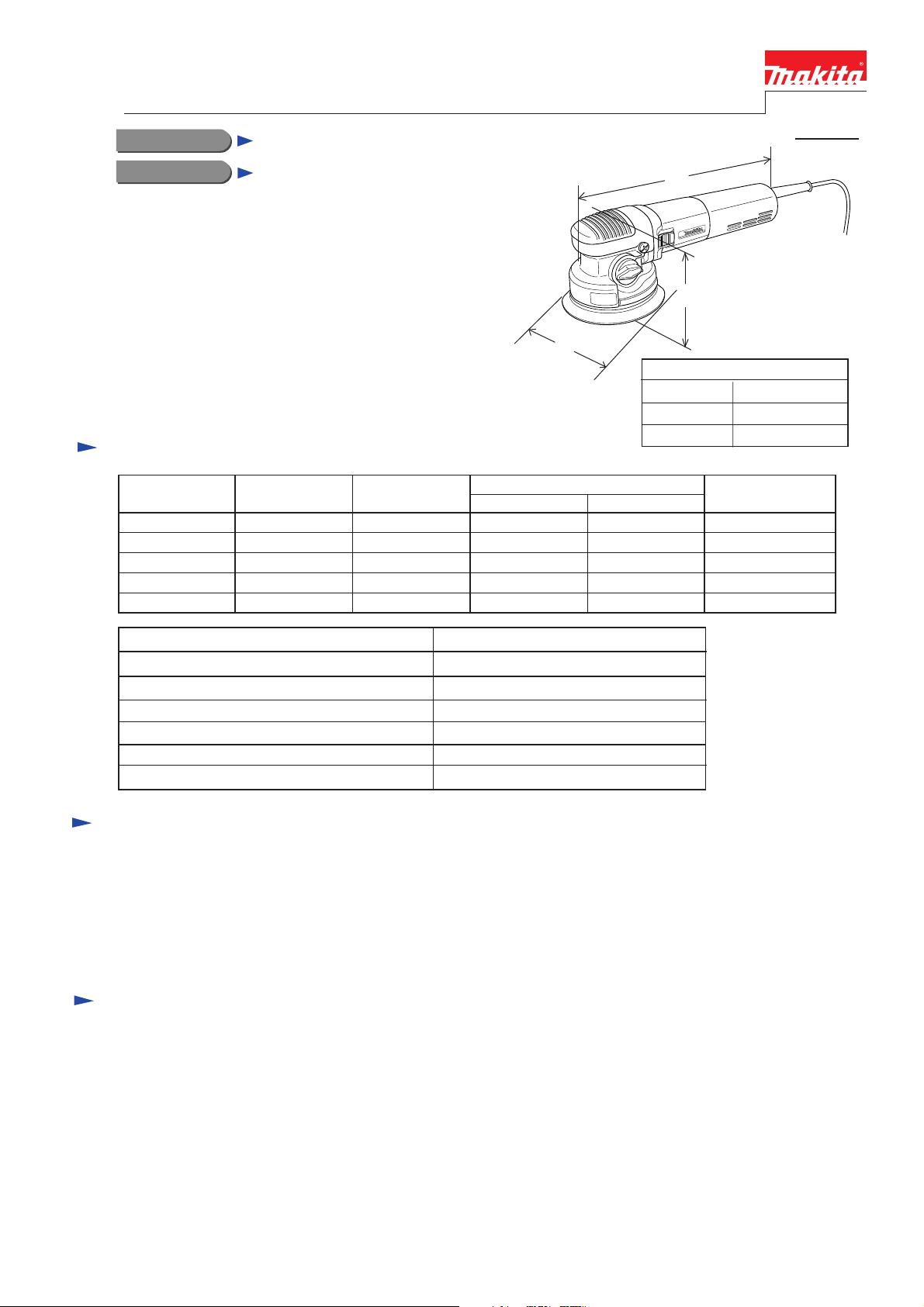

TECHNICAL INFORMATION

CONCEPTION AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 10

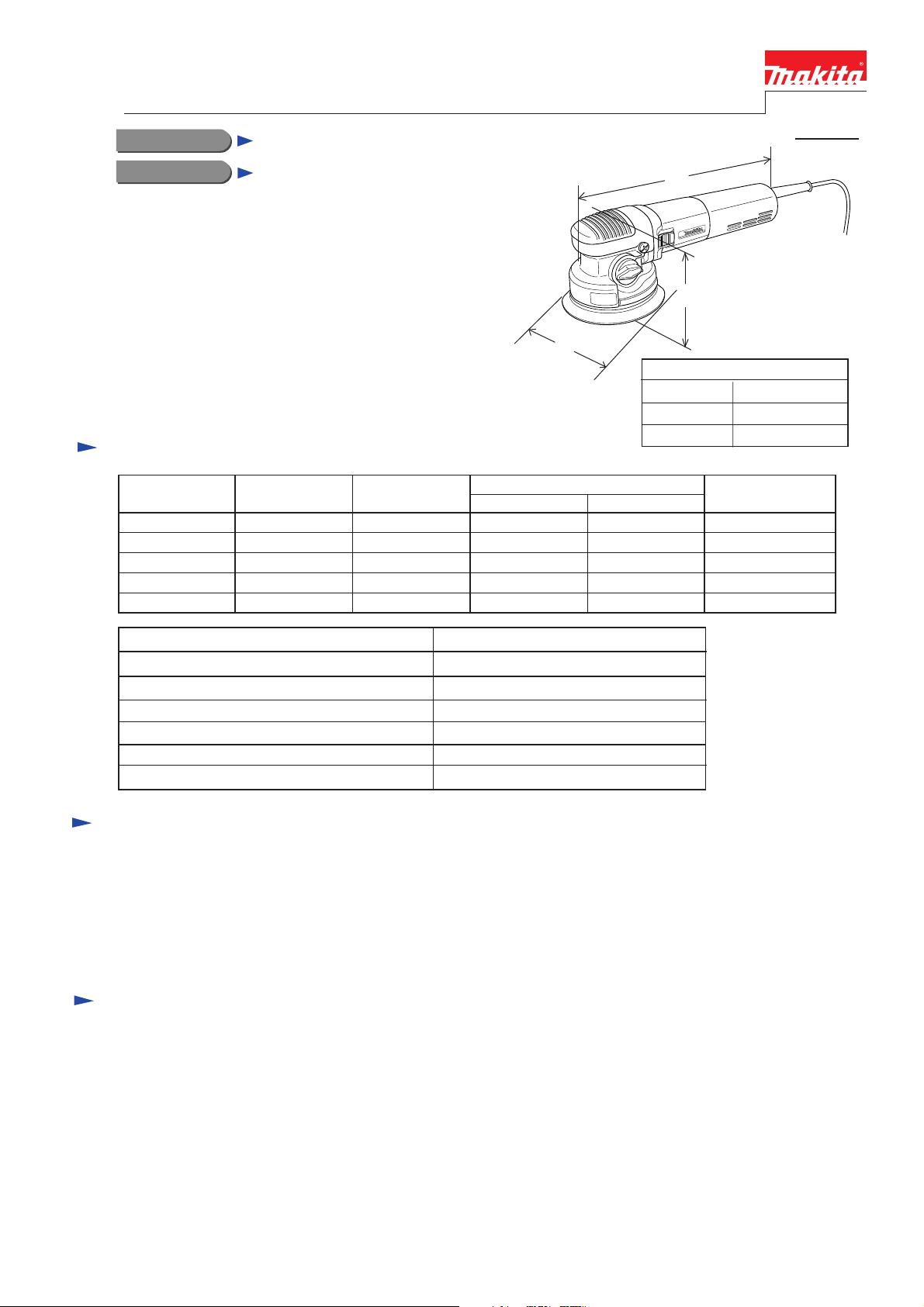

BO6040

150 mm Random Orbit Sander

W

L

H

Dimensions : mm ( " )

Width ( W )

Height ( H )

Length ( L )

150 (5-7/8)

132 (5-3/16)

316 (12-1/2)

Orbits per min. : (min -1= spm)

Orbit diameter : mm (")

Pad diameter : mm (")

Net weight :Kg (lbs )

Cord length : m ( ft )

1,600 - 5,800

3,200 - 11,600

180 - 670

5.5 ( 7/32)

150 ( 6 )

2.5 ( 8.2 )

2.7 ( 5.9 )

7.2

6.6

3.6

3.4

3.3

50 / 60

50 / 60

50 / 60

50 / 60

50 / 60

750 390 850

750 390 850

750 390 850

750 390 850

750 390 850

* Pad 150 (soft ) ........................................................... 1pc. (factory-attached to the machine)

* Abrasive disc 150-120 (Hook and loop type) ........... 1 pc.

* Hex wrench 6 ........................................................... 1 pc.

* Joint ........................................................................... 1 pc. ( only for European market)

* Pad 150 ( hard)

* - ditto - ( soft)

* - ditto - ( super soft)

* Abrasive disc 150 - 40, 60, 80, 120, 180, 240, 400

* Sanding cloth 150 - 100, 200, 800

* Sponge pad 150 ( hook and loop type)

* Felt pad 150 ( hook and loop type )

* Wool pad 150 ( hook and loop type )

* Side grip

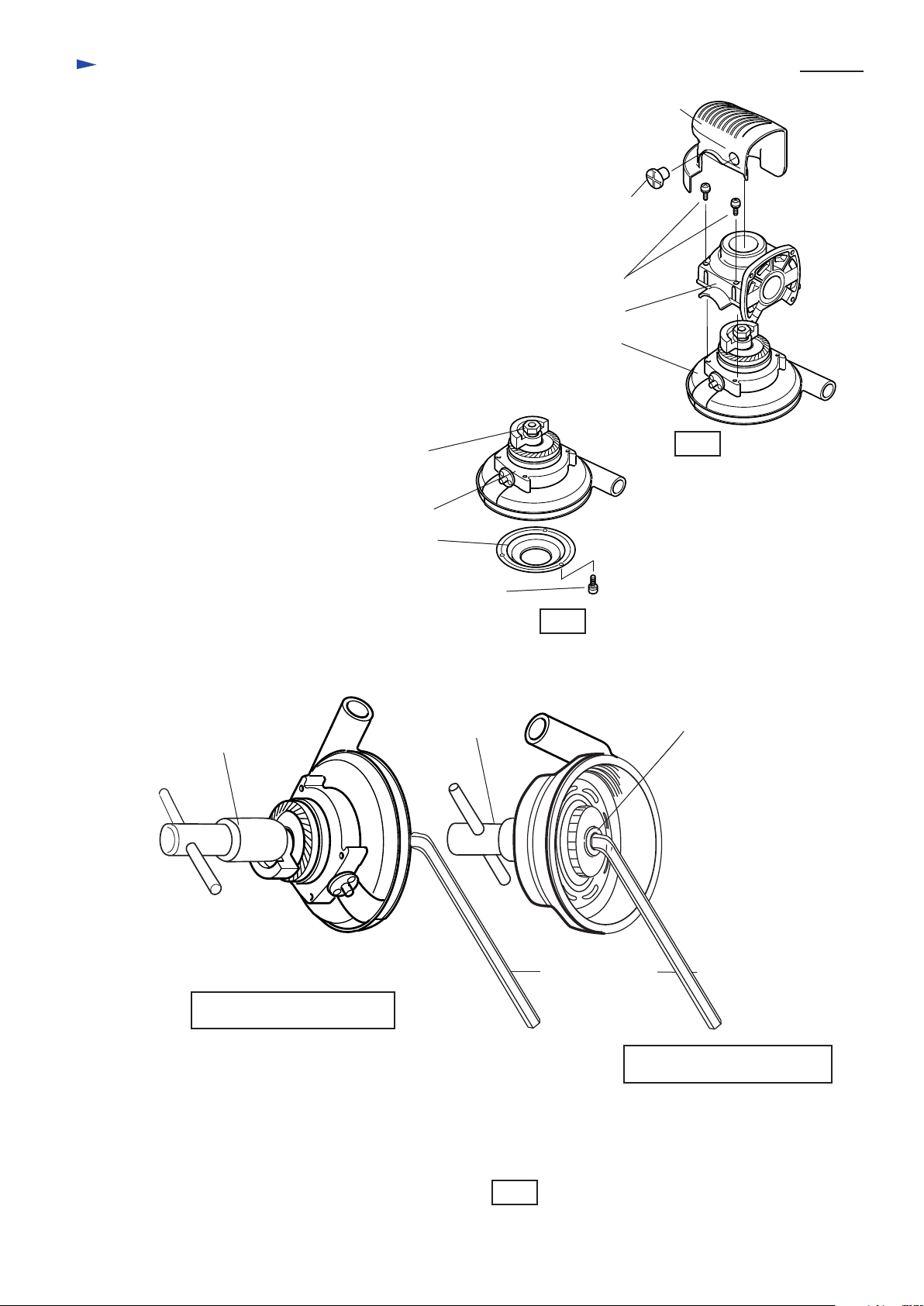

This models is versatile random orbit sander for

professional use.

Due to the two mode selection,

"Forcible rotation mode" / "Free-rotation mode",

rough sanding, fine finishing and polishing can be done

only with this machine.

Oscillation rate per min.: spm = min-1

Rpm.of pad with Forcible-Rotation : rpm = min-1